Abstract

Context

One of the most important wood defects affecting the value yield from European beech (Fagus sylvatica [L.]) logs is knots that are visible on the sawn wood surface. The non-invasive technology of X-ray computed tomography (CT) can be used for the assessment of log internal features, especially the geometry and position of knots before primary breakdown to support the decision of value-optimised log rotation in sawmills.

Aims

The objective of this study was to test whether value-optimised log rotation can be performed successfully by using the CT-derived knowledge of internal knottiness for the hardwood species beech.

Methods

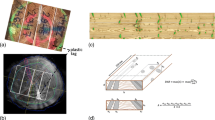

Size parameters of 670 knots were measured and their position was marked in CT images from 33 logs. The 3D-reconstructed logs were virtually sawn in 12 different rotational angles using the software InnoSIM. This allowed visual grading of the simulated sawn wood and the calculation of product volume and value.

Results

The results show that if optimal rotation was applied to each single log, both total volume as well as total product value yield could be improved by up to 24 % compared with the average yield of all simulated rotational angles.

Conclusion

In this small-scale study, it is demonstrated that CT technology could be used to support the decision about optimal rotational angle of beech logs to maximise volume and value yield.

Similar content being viewed by others

References

Berglund A, Broman O, Grönlund A, Fredriksson M (2013) Improved log rotation using information from a computed tomography scanner. Comput Electron Agric 90:152–158. doi:10.1016/j.compag.2012.09.012

Bhandarkar SM, Faust TD, Tang M (2002) Design and prototype development of a computer vision-based lumber production planning system. Image Vision Comput 20:167–189. doi:10.1016/S0262-8856(01)00087-7

Bhandarkar SM, Luo X, Daniels R, Tollner EW (2006) A novel feature-based tracking approach to the detection, localization, and 3-D reconstruction of internal defects in hardwood logs using computer tomography. Pattern Anal Appl 9:155–175. doi:10.1007/s10044-006-0035-9

Boukadida H, Longuetaud F, Colin F, Freyburger C, Constant T, Leban JM, Mothe F (2012) PithExtract: a robust algorithm for pith detection in computer tomography images of wood—application to 125 logs from 17 tree species. Comput Electron Agric 85:90–98. doi:10.1016/j.compag.2012.03.012

Chang SJ, Gazo R (2009) Measuring the effect of internal log defect scanning on the value of lumber produced. For Prod J 59:56–59

Chang SJ, Cooper C, Guddanti S (2005) Effects of the log’s rotational orientation and the depth of the opening cut on the value of lumber produced in sawing hardwood logs. For Prod J 55:49–55

Colin F, Mothe F, Freyburger C, Morisset J, Leban JM, Fontaine F (2010) Tracking rameal traces in sessile oak trunks with X-ray computer tomography: biological bases, preliminary results and perspectives. Trees 24:953–967. doi:10.1007/s00468-010-0466-1

DIN (2011) DIN EN 975–1:2011–08: Sawn timber - Appearance grading of hardwoods - Part 1: Oak and beech; German version EN 975–1:2009 + AC:2010. Deutsches Institut für Normung e. V, Berlin

DIN (2013) DIN EN 1316–1:2013–01: Hardwood round timber—Qualitative classification—Part 1: Oak and beech; German version EN 1316–1:2012. Deutsches Institut für Normung e. V, Berlin

Gazo R, Benes B (2013) Computed tomography log scanning: an industrial application. In: Berti S, Achim A, Fioravanti M, Lihra T, Loewe Muñoz V, Marchal R, Wiedenbeck J, Zanuttini R (eds) ISCHP13 Proceedings, pp 140–147

Hodges DG, Anderson WC, McMillin CW (1990) The economic potential of CT scanners for hardwood sawmills. For Prod J 40:65–69

Laudon N, Baumgartner R, Brüchert F, Sauter UH (2012) Automatic Detection of Fungal Wood Decay in high-speed Computed Tomography Images. In: IUFRO-Division 5-Forest Products (ed) Proceedings of the 2012 IUFRO Conference All-Division 5 Forest Products, p 88

Lin W, Wang J (2012) An integrated 3D log processing optimization system for hardwood sawmills in central Appalachia, USA. Comput Electron Agric 82:61–74. doi:10.1016/j.compag.2011.12.014

Lundahl CG, Grönlund A (2010) Increased yield in sawmills by applying alternate rotation and lateral positioning. For Prod J 60:331–338

Malcom F (1964) A simplified procedure for developing grade lumber from hardwood logs; Research Note FPL-098, Madison, Wis

R Development Core Team (2013) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria

Rinnhofer A, Petutschnigg A, Andreu J (2003) Internal log scanning for optimizing breakdown. Comput Electron Agric 41:7–21. doi:10.1016/S0168-1699(03)00039-5

Sarigul E, Abbott A, Schmoldt DL (2003) Rule-driven defect detection in CT images of hardwood logs. Comput Electron Agric 41:101–119. doi:10.1016/S0168-1699(03)00046-2

Song T, Usenius A (2007) INNOSIM—a simulation model of wood conversion chain. In: van Acker J, Usenius A (eds) Modelling the wood chain: forestry–wood industry–wood product markets. Ghent University, Ghent

Stängle SM, Brüchert F, Kretschmer U, Spiecker H, Sauter UH (2014) Clear wood content in standing trees predicted from branch scar measurements with terrestrial LiDAR and verified with X-ray computed tomography. Can J For Res 44:145–153. doi:10.1139/cjfr-2013-0170

Steele P, Wagner F, Kumar L, Araman PA (1993) The value versus volume yield problem for live-sawn hardwood sawlogs. For Prod J 43:35–40

Steele P, Harless T, Wagner F, Kumar L, Taylor F (1994) Increased lumber value from optimum orientation of internal defects with respect to sawing pattern in hardwood sawlogs. For Prod J 44:69–72

Thawornwong S, Occeña LG, Schmoldt DL (2003) Lumber value differences from reduced CT spatial resolution and simulated log sawing. Comput Electron Agric 41:23–43. doi:10.1016/S0168-1699(03)00040-1

Todoroki C (2003) Accuracy considerations when optimally sawing pruned logs: internal defects and sawing precision. Nondestruct Test Eval 19:29–41. doi:10.1080/10589750310001613415

Trendelenburg R, Mayer-Wegelin H (1955) Das Holz als Rohstoff. Carl Hanser, Munich

Wei Q, Leblon B, La Rocque A (2011) On the use of X-ray computed tomography for determining wood properties: a review. Can J For Res 41:2120–2140. doi:10.1139/X11-111

Wessels CB (2009) Cant sawing log positioning optimization: a simulation study. For Prod J 59:17–22

Acknowledgements

The project was supported by the European Commission under the Food, Agriculture and Fisheries, and Biotechnology Theme of the 7th Framework Programme for Research and Technological Development, FP7 Grant Agreement No. 245136. We would like to thank all project partners involved in the FlexWood project. Furthermore, we thank Aikaterini Nakou for statistical advice. The suggestions from two anonymous reviewers and the associate editor were very much appreciated and helped improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Barry Alan Gardiner

Contribution of the co-authors

Stängle: supervising the CT image analysis, running the data analysis and writing the paper;

Brüchert: developing the study design, supervising the work, coordinating the research project and revising the manuscript;

Heikkila: performing the sawing simulations and analysing data;

Usenius, T.: performing the sawing simulations;

Usenius, A.: supervising the sawing simulation, revising the manuscript;

Sauter: coordinating the research project, supervising the work, revising the manuscript;

Rights and permissions

About this article

Cite this article

Stängle, S.M., Brüchert, F., Heikkila, A. et al. Potentially increased sawmill yield from hardwoods using X-ray computed tomography for knot detection. Annals of Forest Science 72, 57–65 (2015). https://doi.org/10.1007/s13595-014-0385-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13595-014-0385-1