Abstract

In two test series, liquid and solid gold-based neutron flux monitor materials were investigated with respect to the effects of neutron absorbers such as chlorine, scattering effects, and the dependence of the enhanced activation caused by the epithermal resonance integral. The liquid monitors were prepared from aqueous solutions of tetraamminegold(III) nitrate and tetrachloroauric(III) acid. The presence of chlorine-35 partly suppresses the activation of gold-197; this effect depends not only on the concentration of the absorber but also on the state of the neutron flux density monitor. Aqueous samples show greater relative losses than solid monitors. Neutron scattering occurs in hydrogen-rich sample matrices which is shown by the fact that cadmium-shielded aqueous samples show an over proportional activation. Hence, fast neutrons must be moderated to the epithermal energies covered by the resonance integral, which is characterized by much greater cross sections for the capture of neutrons. The insight of this study with respect to neutron scattering in hydrogen-rich matrices must be taken into account also for neutron activation analysis; sample and standard must have a similar matrix with respect to its neutron scattering properties, otherwise the effect of increased activation as well as of enhanced self-shielding are underestimated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One of the most important physical parameters of a nuclear research reactor is its neutron flux density. It is measured by determining the activity of a material—the neutron flux monitor—that is exposed to the neutron beam causing its activation. The activity of the monitor is given by the parameters of the activation equation (Eq. 1).

where A = activity [becquerel], N = number of atoms in the monitor [ ], Φ = neutron flux density [per square centimeter per second], σ = nuclear cross section [square centimeter], λ = decay constant [per second], and t = irradiation duration [seconds].

Gold is among the most commonly used materials for neutron flux monitors. It offers several advantages, e.g., it can be produced in great purity; it yields high activities due to its large thermal cross section (98.65 barn; 1 b = 10−24 cm2) for neutron capture in the nuclear reaction 197Au(n,γ)198Au; 198Au has a very convenient half-life of 2.7 days; the cross section of gold and its other nuclear properties are among the best known of all nuclei [1]. Due to its cross section characteristics, in particular its large resonance integral for the capture of epithermal neutrons, it is possible to apply the cadmium difference method [2] to obtain information on the energy spectrum of the neutron source. Gold in pure metallic form or in the form of alloys (e.g., Al-0.1% Au) is thus usually applied in the form of foils, disks, or wires to monitor the flux in a certain irradiation position.

The application of gold-based flux monitors, however, offers some disadvantages as well. First, it is often activated too strongly if applied in larger amounts than in the milligram range (especially in long-term activation experiments) and hence requires long cooling times before it can be measured properly. As an alternative to reducing the activation duration, the power level of the reactor can be diminished for the flux measurement. However, this not only affects the reactor operation and possibly influences the experiments of other users of the reactor; it often also makes the flux measurement appear as an approximation in case the samples and the monitor are activated at different power levels (mainly due to reactor power nonlinearity). Second, the high cross section of gold can lead to significant neutron self-shielding and thus has to be corrected mathematically (e.g., [3]). Third, gold foils or wires not necessarily simulate the sample geometry accordingly, if the neutron flux is determined in preparation of the irradiation of samples in the reactor. Many samples which are commonly irradiated in research reactors, however, have other geometry than the disk, foil, or wire shape (but rather the shape of a more or less cylindrical vial).

The use of gold alloys (such as the aforementioned Al–Au alloys, e.g., IRMM-530RA or IRMM-530RC) may overcome most of these disadvantages. In particular, such materials avoid neutron self-shielding effects as well as strong activation beyond the levels of safe handling and measurability. However, those materials are relatively pricey; they do not necessarily simulate the sample geometry and, due to the aluminum matrix, they can yield other activation products which may cause interferences and thus require certain periods of cooling (important nuclear reactions of Al are 27Al(n,γ)28Al with a half-life of 2.2 min; 27Al(n,α)24Na with a half-life of 15 h).

In order to overcome these problems, aqueous gold solutions may be regarded as a suitable alternative. Some research reactor operators are reluctant to irradiate liquids because of potential contamination risks. Due to the short half-life of 198Au, however, gold-based neutron flux monitors can be recycled after some weeks of cooling, thus justifying additional efforts to seal the irradiation vials tightly in order to minimize this risk. In any case, the amount of gold can be easily reduced in liquids at the experimenter’s wish, hence reducing the total activity of the monitor and minimizing self-shielding effects. Furthermore, a solution can be filled into almost any sample geometry, thus allowing monitoring the neutron flux, exactly where and how the samples are exposed to it. Unfortunately, almost all common and purchasable gold compounds are based on chlorine, namely the tetrachloroaurate anion [AuCl −4 ]. Chlorine has a nasty activation product stemming from 37Cl(n,γ)38Cl (T 1/2 = 37 min) and is also a strong neutron absorber (35Cl, σ = 44 barn for thermal (n,γ) neutron capture). Hence, Cl compounds are likely to cause self-shielding effects in the sample. Tetrabromoaurates(III) are purchasable as well, but the highly gamma ray emitting activation product 82Br (T 1/2 = 35.3 h) makes them even less suitable.

The aim of this study was to compare the performance of various flux monitor materials, in particular to compare liquid and solid gold monitors. We tried to conduct experiments to gain further insight into important effects such as neutron self-shielding, neutron scattering, and neutron energy aspects, which all need to be considered.

Experimental and methods

The experiments were conducted in two series: first, the comparison of various liquid neutron flux monitors and, second, the comparison of liquid and solid materials under different conditions. For all irradiation experiments in this study, the so-called Weber-tube no. 2 of the institute’s 250 kWth TRIGA Mark II reactor was chosen. Its irradiation position is located outside the graphite reflector of the reactor core and has a 90% thermalized neutron flux of approximately 1⋅1011 cm−2 s−1 at full reactor power. All experiments were conducted within 1 h in order to provide the utmost comparable neutron flux conditions to all samples.

First test series

For the comparison of materials based on dissolved gold compounds, three substances were tested: aqueous solutions of tetrachloroauric(III) acid H[AuCl4]; aqueous solutions of tetraamminegold(III) nitrate, [Au(NH3)4](NO3)3 (TAGN); and, in order to simulate the dissolution of metallic gold in aqua regia, H[AuCl4] in 30% hydrochloric acid (HCl, Merck™, suprapure). TAGN was synthesized according to literature (Eq. 2) [4, 5].

In particular, 250 mg of H[AuCl4]·3 H2O (Sigma Aldrich™, 99.9 + %) were dissolved in 5 ml of a solution that has been saturated with NH4NO3 at room temperature. In the next step, NH3 (g) steam from an ammonia solution bottle was bubbled through the solution with a syringe until white crystals started precipitating or the yellow solution lost its color almost abruptly. Precipitation was completed overnight and yielded a significant amount of crystalline and very pure TAGN (as confirmed by elemental CHN analysis). The purity of the crystals with respect to the residual chlorine was checked with INAA providing a negative result.

Stem solutions of TAGN and H[AuCl4]⋅3 H2O were prepared by dissolving these solids in triply distilled H2O. In both cases, the resulting formal gold concentration was 1.00 mg/ml. The Au3+ concentration in both stem solutions was analyzed by total reflection X-ray fluorescence (TXRF, Atomika 8030 C) [6]. TXRF was chosen as an independent method to confirm the formal concentrations of gold (1,023 ± 35 μg/ml for TAGN, 1,088 ± 71 μg/ml for H[AuCl4]).

Five replicates were prepared from each of the three liquid flux monitor materials. Aliquots corresponding to 50 μg Au were pipetted and weighed into cylindrical polyethylene (PE) irradiation vials (diameter, 12.5 mm; fluid level, 42 mm). In order to provide the utmost accurate sample geometry, each vial was filled with 5 ml of triply distilled H2O (in the case of TAGN and H[AuCl4]) or 5 ml 30% HCl (for the experiment “H[AuCl4] in HCl”, samples S1-S5), respectively.

After a preliminary experiment, we observed signs of radiolysis in some of the solutions. In the course of radiolysis, Au3+-containing solutions generally tend to change their color towards red, pink, or brown. Sometimes even precipitation of brownish flakes occurs. Hence, potassium cyanide (KCN) was added to the TAGN solutions in an ion ratio Au3+/CN– = 1:8 for stabilization [7] (see Fig. 1). Addition of KCN could not be done with the acidic solutions based on tetrachloroauric(III) acid because of the possible formation of very poisonous hydrocyanic acid (HCN) gas. It should be noted at this point that aqueous solutions of H[AuCl4] should not be neutralized with ammonia because of the possible formation of fulminating gold (Knallgold) [4].

A foamed PE plastic lid was placed on the surface of the liquid, which allowed any expansion of the sample (due to temperature and the formation of radiolytic gases). Then the vial was sealed with paraffinic wax. All monitors of the first test series were irradiated sequentially in the mentioned position for 2 min each in order to cancel out flux variations.

The liquid monitors could be measured immediately (TAGN) after irradiation or after 24 h (for the Cl-containing monitors), respectively. The activity was determined by measurement with a 226-cm3 HPGe detector (Canberra™, detector model GC5020; 2.0 keV resolution at 1,332 keV 60Co peak; 52.8% relative efficiency), connected to a PC-based multichannel analyzer with preloaded filter. The detector efficiency for the 411-keV peak of 198Au was calibrated with a QCY48 (Amersham® Ltd.) solution. The necessary measurement times were usually quite short (until the uncertainty due to counting statistics was <1%).

Second test series

For the second test series, the TAGN monitors (Z1-Z4) were recycled after sufficient cooling time. The second test series comprised the experiments shown in Table 1.

The gold wire (Alfa Aesar; 99.998%) had a thickness of 0.1 mm and a length of 42 mm (equal to the filling level); the gold foil had a diameter of 5 mm and a thickness of 0.05 mm. The foil was placed on the half height of the filling level of the liquid samples. In order to grant a stable position of the wires and foils in the water-filled samples, water was supplied in the form of aqueous cornstarch pudding (96% water), which had a sufficient viscosity to prevent any unwanted movement of the monitor. The cadmium shielding (the cartridge as well as the “sandwich”) had a thickness of 1 mm. For the measurement, the gold foils and wires, respectively, were dissolved in the minimum amount of aqua regia and filled to a level of 5 ml, equivalent to the geometry of the liquid monitors.

In order to yield sufficient activity with the cadmium-shielded samples, the irradiation time was increased to 5 min in the second test series. The cadmium-shielded samples as well as the TAGN vials were measured immediately after irradiation. The unshielded metallic flux monitors required a cooling time of 3 weeks.

Results and discussion

The results of both test series are tabulated in Tables 2 and 3. Although the irradiation conditions were comparable in all experiments of the first series, the specific activities obtained show three sharply distinguished groups. Obviously, the chlorine content in the sample affects the performance of the respective neutron flux monitor. Compared to the TAGN-based monitor (Z samples), activation of Au is suppressed in H[AuCl4] in water (W samples) and, to a much greater extent, in H[AuCl4] in concentrated hydrochloric acid (S samples).

The specific activities of the gold foils have been corrected with a factor G according to the self-shielding correction established by de Corte [3] (Eq. 3).

The correction factor G is calculated as shown in Eqs. 4, 5, 6, where t is the foil thickness and N is the number of atoms per unit volume. For a foil thickness of 0.05 mm, Eq. 6 applies. In our case, G is 0.968.

Figure 2 shows the specific activities of the neutron flux monitors made of solid gold foils and wires, once fixed in air in the irradiation vial (F9, D1), once immersed in water (F1, D2). Whereas no significant effect can be observed for the gold foil when irradiated in air or in water; the gold wire shows a significantly higher specific activity when immersed in an aqueous medium (+26%).

This effect must be due to neutron scattering in the water-filled vial, causing an increasing probability for neutron capture. Interestingly, this effect has not been observed with the gold foil and only for the wire. We plan to elucidate these contradictory results with gold foils and wires in future studies.

In Fig. 3, the influence of chlorine onto the activation of the gold monitor is shown, in particular the comparison between solid and liquid materials. The graph on the left-hand side shows the specific activity of the liquid monitors TAGN in water (Z1–Z5), H[AuCl4] in water (W1–W5), and H[AuCl4] in concentrated hydrochloric acid (S1–S5) (calculated for 300 s activation time based on the 120-s experiments). In comparison, the graph on the right-hand side illustrates the specific activity of the gold foil immersed in water and in chloride solution with identical chlorine content like the hydrochloric acid above.

Specific activities of 198Au of neutron flux density monitors irradiated in an aqueous solution with different chlorine content. The bar on the left-hand side shows the dissolved gold samples: TAGN in water (Z1–Z5; light blue) yielding the highest specific activity, followed by H[AuCl4] in water (W1–W5; light green) and finally H[AuCl4] in hydrochloric acid with a chlorine content of 29.2 wt.% (S1–S5; dark green). The bar on the right-hand side shows the specific activities obtained by the gold foil in water (F1; light blue) and the gold foil immersed in aqueous NH4Cl solution (F4; dark green) with a chlorine content of 29.2 wt.% as well

The negative influence of chlorine on the activation of gold is confirmed by this result; this effect is much enhanced for the liquid samples containing dissolved gold ions compared with the sample containing a solid gold foil. Even the small chlorine content in the samples containing H[AuCl4] dissolved in water (W1–W5) causes a significant decrease of the activation of gold by approximately 12.3%. The experiment shows that the neutron scattering in the dissolved (aqueous) monitor materials causes not only an overall higher specific activity of 198Au but also a reinforced relative attenuation of its activity in the presence of neutron absorbing impurities or matrix elements (compared with solid gold monitors surrounded by neutron absorbers).

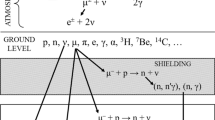

The cross section for neutron capture is strongly neutron energy dependent, hence some insight can be gathered from shielding the thermal neutron fraction with cadmium. Taking into consideration that the fast neutron flux in the used irradiation position is 10% of the total flux, as a first approach, one would expect a resulting 198Au activity of significantly less than 10% for cadmium shielded monitors because the cross section for 197Au(n,γ)198Au is roughly two orders of magnitude lower for fast neutrons. Since the energy spectrum of neutrons passing the cadmium shielding are already in the epithermal energy range, the resonance integral for the epithermal neutron capture by 197Au, however, is in a position to cause an activation of the monitor of more than only 10% of the unshielded monitors.

We observed that scattering effects and the previously mentioned resonance integral yield higher activities in the aqueous samples (Fig. 4). Again, this effect is the greatest for the TAGN-based neutron flux monitors. From this result, the scattering inside the sample appears as approved; fast neutrons passing the cadmium shield are moderated inside the monitor to epithermal energies, thus coinciding with the relatively narrow resonance integral. Also, the scattering of neutrons in general inside the vial causes neutrons to stay longer inside the vial. This causes an over proportional activation of 197Au. The same behavior is observed in the comparison of the Cd-shielded and unshielded gold foils immersed in water. In this context, the gold wire immersed in water and shielded with cadmium shows an unexpected low activation of approximately 7%, which will require more in-depth investigation, also with respect to the sample geometry, which may have an influence.

Specific activities of 198Au of Cd shielded (gray) and unshielded (yellow) neutron flux monitors. Shielding was performed in a Cd cartridge. TAGN in water (mean values of Z1 + Z2 vs. Z3 + Z4) is shown on the left-hand side; gold wire in water (D2 vs. D3) in the center; gold foil in water (F1 vs. F3) on the right-hand side

In another experiment, scattering effects and thus the influence of the resonance integral were minimized, by immersing a cadmium–gold–cadmium “sandwich” (F5) into a water-filled vial. In that case, any moderation towards the resonance integral in the space between the cadmium shielding and the gold foil was de facto excluded since practically no water could enter the space in-between. Hence, the activity of the “sandwich” was only 76% of the gold foil immersed in water and shielded with cadmium cartridge on the outside of the vial.

Conclusions

Neutron absorbers such as 35Cl partly suppress the activation of 197Au; this effect, however, depends not only on the concentration of the absorber, but also on the state of the neutron flux density monitor. In solid samples (such as gold foils), the effect shows to be humble; in liquid samples of dissolved gold compounds, the effect is significantly amplified.

The results evidence that scattering occurs in hydrogen-rich sample matrices which is shown by the fact that cadmium-shielded aqueous samples show an over proportional activation. Hence, fast neutrons must be moderated to the epithermal energies covered by the resonance integral.

The TAGN-based neutron flux monitor appears as a very promising material for the manufacturing of neutron flux density monitors in liquid form, in case the neutron flux in an aqueous sample (or any other hydrogen-rich matrix) needs to be determined [8]. It is produced in a straightforward synthesis and from relatively cheap raw materials and can be recycled after a couple of weeks cooling.

The insight of this study with respect to neutron scattering in hydrogen-rich matrices must be taken into account also for neutron activation analysis (NAA); sample and standard must have a similar matrix with respect to its neutron scattering properties, otherwise the effect of increased activation as well as of enhanced self-shielding are underestimated. Also, for absolute NAA methods using single comparators, the assumption that a metal foil can supply sufficient information for a highly scattering matrix, is perhaps a simplification which may lead to relevant deviations in the subsequent calculations. For example, the determination of trace elements in crude oil, as recently shown in [9] may be affected by the effects discussed above. Perhaps a TAGN-based neutron flux monitor would be helpful in such analytical protocols. Under this point of view, the use of artificial synthetic standard materials in NAA should only be regarded as an approximation because they do not necessarily reflect the influence on the neutron flux caused by the various possible matrices in samples of various types.

References

Myerscough L (1973) The nuclear properties of gold. Gold Bull 6:62–68

Vermaercke P, Sneyers L, Bruggeman M, Wispelaere A, De Corte F (2008) Neutron spectrum calibration using the Cd-ratio for multi-monitor method with a synthetic multi-element standard. J Radioanal Nucl Chem 278:631–636

De Corte F (1969) Activeringsanalyse van sporenelementen in silicium. Dissertation, Ghent University

Steinhauser G, Evers J, Jakob S, Klapötke TM, Oehlinger G (2008) A review on fulminating gold (Knallgold). Gold Bull 41:305–317

Weishaupt M, Straehle J (1976) Crystal structure and vibrational spectrum of tetraamminegold(III) nitrate. Z Naturforsch B: Anorg Chem, Org Chem 31B:554–557

Wobrauschek P (2007) Total reflection x-ray fluorescence analysis—a review. X-Ray Spectrom 36:289–300

Steinhauser G (2008) Quantification of the abrasive wear of a gold wedding ring. Gold Bull 41:51–57

Steinhauser G, Merz S, Villa M (2010) Neutronenflussmonitor. VUT, Austrian patent 509490; application no. 706/2010

El-Khayatt AM (2010) Elemental analysis of Egyptian crude oils by INAA using rabbit irradiation system at ETRR-2 reactor. Appl Radiat Isot 68:2438–2442

Acknowledgments

We gratefully acknowledge the financial support by the Vienna University of Technology in the course of patenting and the help by Angelika Valenta in the patenting process. Further, we thank both anonymous reviewers who helped us find the right track for this study.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Steinhauser, G., Merz, S., Stadlbauer, F. et al. Performance and comparison of gold-based neutron flux monitors. Gold Bull 45, 17–22 (2012). https://doi.org/10.1007/s13404-011-0039-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-011-0039-0