Abstract

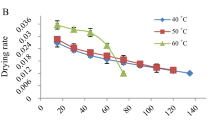

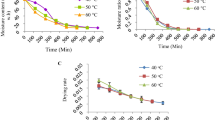

Coriander (Coriandrum sativum L.) is an aromatic and nutritious herb but often wasted due to limited processing. Drying is a common method for extending its shelf life. In the study, coriander was hot water blanched, pureed and dried with varying thicknesses of puree (2, 4 and 6 mm) and water temperatures (70, 80 and 90 °C) to assess drying characteristics, mass transfer and quality of coriander powder. It was noted that the time required for drying decreased as the water temperature was raised from 70 to 90 °C. The mathematical modelling showed that the Exponential two-term model had the highest R2 and lowest RSME and SEE values. Moreover, MR was accurately predicted using MLF-ANN with back-propagation algorithm, outperforming the mathematical model. Mass transfer calculated using Dincer and Dost analytical approach showed Deff and hm in the range of 1.980 × 10−9 to 1.839 × 10−8 m2/s and 1.881 × 10−6 to 5.653 × 10−6 m/s, respectively. Regardless of puree thickness, samples dried at 70 °C exhibited superior quality, followed by those dried at 80 °C and 90 °C. The 2-mm-thick puree, dried at 70 °C, displayed the highest antioxidant activity (82.893%), total phenolic content (20.833 mg GAE/100 g dw), total flavonoid content (11.159 mg QE/100 g dw) and total chlorophyll content (95.306 mg/100 g dw), in spite of a longer drying duration. This method appears favourable for yielding high-quality coriander powders.

Similar content being viewed by others

Data availability

The authors have chosen not to share data.

Abbreviations

- ANN:

-

Artificial neural network

- ANOVA:

-

Analysis of variance

- B i :

-

Biot number

- D eff :

-

Effective moisture diffusivity (m2/s)

- DPFE:

-

Department of Processing and Food Engineering

- DPPH:

-

2,2-Diphenyl-1-picrylhydrazyl

- dx/dt :

-

Drying rate (g H2O/g min)

- E :

-

Evaporative capacity (kg/m2 h)

- F o :

-

Fourier number

- G :

-

Lag factor

- GAE:

-

Gallic acid equivalents

- h m :

-

Mass transfer coefficient (m/s)

- L :

-

Characteristic dimension (half thickness of slab, m)

- L p :

-

Thickness of puree (m)

- M :

-

Moisture content at any instance (%)

- M e :

-

Equilibrium moisture content (%)

- MLF:

-

Multi-layer feed-forward

- M o :

-

Initial moisture content (%)

- MR :

-

Moisture ratio

- MSE:

-

Mean square error

- n :

-

Number of observations

- PAU:

-

Punjab Agricultural University

- QE:

-

Quercetin equivalent

- R value:

-

Correlation coefficient

- R 2 :

-

Coefficient of determination

- RMSE:

-

Root mean square error

- RWD:

-

Refractance window drying

- S :

-

Drying coefficient (s−1)

- SEC:

-

Specific energy consumption (kWh/kg)

- SEE:

-

Standard error of the estimate

- t :

-

Drying time (min)

- V e , i :

-

Experimental MR for the ith observation

- V p , i :

-

Predicted MR for the ith observation

- V p , m :

-

Mean value of predicted MR

- ρ :

-

Density of the puree (kg/m3)

- χ 2 :

-

Reduced chi-square

- µ n :

-

nth root of the transcendental characteristic equation

References

Ahmed J, Shivhare US, Singh G (2001) Drying characteristics and product quality of coriander leaves. Food Bioprod Process 79:103–106. https://doi.org/10.1205/096030801750286258

Rajeshwari U, Andallu B (2011) Medicinal benefits of coriander (Coriandrum sativum L). Spatula DD 1:51–58. https://doi.org/10.5455/spatula.20110106123153

Nadeem M, Muhammad Anjum F, Issa Khan M et al (2013) Nutritional and medicinal aspects of coriander (Coriandrum sativum L.). Br Food J 115:743–755. https://doi.org/10.1108/00070701311331526

Forny L, Marabi A, Palzer S (2011) Wetting, disintegration and dissolution of agglomerated water soluble powders. Powder Technol 206:72–78. https://doi.org/10.1016/J.POWTEC.2010.07.022

Zotarelli MF, Carciofi BAM, Laurindo JB (2015) Effect of process variables on the drying rate of mango pulp by refractance window. Food Res Int 69:410–417. https://doi.org/10.1016/j.foodres.2015.01.013

Raghavi LM, Moses JA, Anandharamakrishnan C (2018) Refractance window drying of foods: a review. J Food Eng 222:267–275. https://doi.org/10.1016/j.jfoodeng.2017.11.032

Shende D, Datta AK (2019) Refractance window drying of fruits and vegetables: a review. J Sci Food Agric 99:1449–1456. https://doi.org/10.1002/jsfa.9356

Magoon RE (1986) US4631837A-Method and apparatus for drying fruit pulp and the like. (Patent) Online available at https://patents.google.com/patent/US4631837A/en. Accessed 26 Apr 2022

Rajoriya D, Bhavya ML, Hebbar HU (2021) Impact of process parameters on drying behaviour, mass transfer and quality profile of refractance window dried banana puree. LWT Food Sci Technol 145:111330. https://doi.org/10.1016/j.lwt.2021.111330

Santos VCS, de Souza RL, Figueiredo RT, de Alsina OLS (2022) A review on refractance window drying process of fruits and vegetables: its integration with renewable energies. Braz J Food Technol 25:e2021153. https://doi.org/10.1590/1981-6723.15321

Waghmare R (2021) Refractance window drying: a cohort review on quality characteristics. Trends Food Sci Technol 110:652–662. https://doi.org/10.1016/j.tifs.2021.02.030

Kumar M, Madhumita M, Prabhakar PK, Basu S (2022) Refractance window drying of food and biological materials: status on mechanisms, diffusion modelling and hybrid drying approach. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2022.2132210

Durigon A, Parisotto EIB, Carciofi BAM, Laurindo JB (2018) Heat transfer and drying kinetics of tomato pulp processed by cast-tape drying. Drying Technol 36:160–168. https://doi.org/10.1080/07373937.2017.1304411

Singh SN, Suthar SH, Jena S et al (2022) Comparative studies on chromatic properties for refractance window, hot air tray and solar tunnel drying of carrot (Daucus carota subsp. sativus) puree. Pharma Innov J 11:17–25

Duarte-Correa Y, Vargas-Carmona MI, Vásquez-Restrepo A et al (2021) Native potato (Solanum phureja) powder by refractance window drying: a promising way for potato processing. J Food Process Eng e13819. https://doi.org/10.1111/jfpe.13819

Shrivastav S, Ganorkar PM, Prajapati KM, Patel DB (2021) Drying kinetics, heat quantities, and physiochemical characteristics of strawberry puree by refractance window drying system. J Food Process Eng 44. https://doi.org/10.1111/jfpe.13776

Nemzer B, Vargas L, Xia X et al (2018) Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem 262:242–250. https://doi.org/10.1016/j.foodchem.2018.04.047

Padhi S, Dwivedi M (2022) Physico-chemical, structural, functional and powder flow properties of unripe green banana flour after the application of refractance window drying. Future Foods 5:100101. https://doi.org/10.1016/J.FUFO.2021.100101

Seyfi A, Rezaei Asl A, Motevali A (2021) Comparison of the energy and pollution parameters in solar refractance window (photovoltaic-thermal), conventional refractance window, and hot air dryer. Sol Energy 229:162–173. https://doi.org/10.1016/j.solener.2021.05.094

Zalpouri R, Singh M, Kaur P et al (2023) Drying kinetics, physicochemical and thermal analysis of onion puree dried using a refractance window dryer. Processes 11:700. https://doi.org/10.3390/PR11030700

Omari A, Behroozi-Khazaei N, Sharifian F (2018) Drying kinetic and artificial neural network modeling of mushroom drying process in microwave-hot air dryer. J Food Process Eng 41. https://doi.org/10.1111/jfpe.12849

Delfiya DSA, Prashob K, Murali S et al (2022) Drying kinetics of food materials in infrared radiation drying: a review. J Food Process Eng 45:e13810. https://doi.org/10.1111/jfpe.13810

Farkas I (2013) Use of artificial intelligence for the modelling of drying processes. Drying Technol 31:848–855. https://doi.org/10.1080/07373937.2013.769002

Bai JW, Xiao HW, Le MH, Zhou CS (2018) Artificial neural network modeling of drying kinetics and color changes of ginkgo biloba seeds during microwave drying process. J Food Qual. https://doi.org/10.1155/2018/3278595

Kaiser A, Kammerer DR, Carle R (2013) Impact of blanching on polyphenol stability and antioxidant capacity of innovative coriander (Coriandrum sativum L.) pastes. Food Chem 140:332–339. https://doi.org/10.1016/J.FOODCHEM.2013.02.077

Tontul I, Topuz A (2017) Effects of different drying methods on the physicochemical properties of pomegranate leather (pestil). LWT Food Sci Technol 80:294–303. https://doi.org/10.1016/j.lwt.2017.02.035

Brooker DB, Bakker-Arkema FW, Hall CW (1992) Drying and storage of grains and oilseeds. Springer Science & Business Media, New York, NY, USA

Kalaivani K, Chitra Devi V (2013) Mathematical modeling on drying of Syzygium cumini (L.). Int J Agric Biol Eng 6:96–103. https://doi.org/10.3965/j.ijabe.20130604.011

Diamante LM, Munro PA (1993) Mathematical modelling of the thin layer solar drying of sweet potato slices. Sol Energy 51:271–276

Mutuli GP, Mbuge DO (2015) Drying characteristics and energy requirement of drying cowpea leaves and jute mallow vegetables. Agric Eng Int CIGR J 17:265–272

Sobukola OP, Dairo OU, Sanni LO et al (2007) Thin layer drying process of some leafy vegetables under open sun. Food Sci Technol Int 13:35–40. https://doi.org/10.1177/1082013207075953

Kaur K, Singh AK (2014) Drying kinetics and quality characteristics of beetroot slices under hot air followed by microwave finish drying. Afr J Agric Res 9:1036–1044. https://doi.org/10.5897/ajar2013.7759

Singh SK, Samsher, Singh BR et al (2021) Drying characteristics and prediction of best fitted drying model for coriander leaves. Environ Conserv J 22:243–251. https://doi.org/10.36953/ecj.2021.22329

Dincer I, Dost S (1995) An analytical model for moisture diffusion in solid objects during drying. Drying Technol 13:425–435

Akpinar EK, Dincer I (2005) Moisture transfer models for slabs drying. Int Commun Heat Mass Transfer 32:80–93. https://doi.org/10.1016/J.ICHEATMASSTRANSFER.2004.04.037

Beigi M (2016) Influence of drying air parameters on mass transfer characteristics of apple slices. Heat Mass Transf 52:2213–2221. https://doi.org/10.1007/s00231-015-1735-8

Chicco D, Warrens MJ, Jurman G (2021) The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. PeerJ Comput Sci 7:1–24. https://doi.org/10.7717/PEERJ-CS.623

Kalsi BS, Singh S, Alam MS, Bhatia S (2023) Microwave drying modelling of Stevia rebaudiana leaves using artificial neural network and its effect on color and biochemical attributes. J Food Qual. https://doi.org/10.1155/2023/2811491

Shewale SR, Rajoriya D, Bhavya ML, Hebbar HU (2021) Application of radiofrequency heating and low humidity air for sequential drying of apple slices: Process intensification and quality improvement. LWT 135:109904. https://doi.org/10.1016/J.LWT.2020.109904

Pathare PB, Opara UL, Al-Said FAJ (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioproc Tech 6:36–60. https://doi.org/10.1007/s11947-012-0867-9

Kalsi BS, Singh S, Alam MS (2023) Influence of ultrasound processing on the quality of guava juice. J Food Process Eng 46:e14163. https://doi.org/10.1111/jfpe.14163

De Ancos B, Sgroppo S, Plaza L, Pilar Cano M (2002) Possible nutritional and health-related value promotion in orange juice preserved by high-pressure treatment. J Sci Food Agric 82:790–796. https://doi.org/10.1002/jsfa.1093

McDonald S, Prenzler PD, Antolovich M, Robards K (2001) Phenolic content and antioxidant activity of olive extracts. Food Chem 73:73–84. https://doi.org/10.1016/S0308-8146(00)00288-0

de Tarso Carvalho P, Clemente E (2004) The influence of the broccoli (Brassica oleracea var itálica) fill weight on postharvest quality. Food Sci Technol - SciELO Brasil 24:646–651

Nagata M, Yamashita I (1992) Simple method for simultaneous determination of chlorophyll and carotenoids in tomato fruit. Nippon Shokuhin Kogyo Gakkaishi 39:925–928

Márquez-Cardozo CJ, Caballero-Gutiérrez BL, Ciro-Velázquez HJ, Restrepo-Molina DA (2021) Effect of pretreatment and temperature on the drying kinetics and physicochemical and techno-functional characteristics of pumpkin (Cucurbita maxima). Heliyon 7:e06802. https://doi.org/10.1016/J.HELIYON.2021.E06802

Maskan A, Kaya S, Maskan M (2002) Hot air and sun drying of grape leather (pestil). J Food Eng 54:81–88

Ochoa-Martínez CI, Quintero PT, Ayala AA, Ortiz MJ (2012) Drying characteristics of mango slices using the Refractance Window™ technique. J Food Eng 109:69–75. https://doi.org/10.1016/j.jfoodeng.2011.09.032

Castoldi M, Zotarelli MF, Durigon A et al (2015) Production of tomato powder by refractance window drying. Drying Technol 33:1463–1473. https://doi.org/10.1080/07373937.2014.989327

Soysal Y (2004) Microwave drying characteristics of parsley. Biosyst Eng 89:167–173. https://doi.org/10.1016/J.BIOSYSTEMSENG.2004.07.008

Frabetti ACC, Durigon A, Laurindo JB (2018) Effect of process variables on the drying of guava pulp by cast-tape drying. LWT Food Sci Technol 96:620–626. https://doi.org/10.1016/j.lwt.2018.06.021

Fellows PJ (2022) Dehydration. In: Food processing technology: principles and practice. Woodhead publishing, p 415–449

Iqbal MJ, Akbar MW, Aftab R et al (2019) Heat and mass transfer modeling for fruit drying: a review. MOJ Food Process Technol 7:69–73. https://doi.org/10.15406/mojfpt.2019.07.00222

Rajoriya D, Shewale SR, Hebbar HU (2019) Refractance window drying of apple slices: mass transfer phenomena and quality parameters. Food Bioproc Tech 12:1646–1658. https://doi.org/10.1007/s11947-019-02334-7

Akinola AA, Ezeorah SN (2019) Moisture diffusivity and activation energy estimation of white yam (Dioscorea rotundata) slices using drying data from a refractance windowTM dryer. FUOYE J Eng Technol 4:102–106. https://doi.org/10.46792/fuoyejet.v4i1.319

Shi J, Pan Z, McHugh TH et al (2008) Drying and quality characteristics of fresh and sugar-infused blueberries dried with infrared radiation heating. LWT Food Sci Technol 41:1962–1972. https://doi.org/10.1016/J.LWT.2008.01.003

Santos S de JL, da SILVA LHM, Rodrigues AM da C (2022) Prediction of mass transfer parameters and thermodynamic properties using the refractance WindowTM technique for drying of Yam (Dioscorea trifida) paste. Food Sci Technol (Brazil) 42. https://doi.org/10.1590/fst.67021

Surendhar A, Sivasubramanian V, Vidhyeswari D, Deepanraj B (2019) Energy and exergy analysis, drying kinetics, modeling and quality parameters of microwave-dried turmeric slices. J Therm Anal Calorim 136:185–197. https://doi.org/10.1007/s10973-018-7791-9

Prabhanjan DG, Ramaswamy HS, Raghavan GSV (1995) Microwave-assisted convective air drying of thin layer carrots. J Food Eng 25:283–293. https://doi.org/10.1016/0260-8774(94)00031-4

Khaled AY, Kabutey A, Selvi KÇ et al (2020) Application of computational intelligence in describing the drying kinetics of persimmon fruit (Diospyros kaki) during vacuum and hot air drying process. Processes 8. https://doi.org/10.3390/PR8050544

Selvi KÇ, Alkhaled AY, Yıldız T (2022) Application of artificial neural network for predicting the drying kinetics and chemical attributes of linden (Tilia platyphyllos Scop.) during the Infrared Drying Process. Processes 10. https://doi.org/10.3390/pr10102069

Tarafdar A, Shahi NC, Singh A (2019) Freeze-drying behaviour prediction of button mushrooms using artificial neural network and comparison with semi-empirical models. Neural Comput Appl 31:7257–7268. https://doi.org/10.1007/S00521-018-3567-1/METRICS

Tarafdar A, Jothi N, Kaur BP (2021) Mathematical and artificial neural network modeling for vacuum drying kinetics of Moringa olifera leaves followed by determination of energy consumption and mass transfer parameters. J Appl Res Med Aromat Plants 24:100306. https://doi.org/10.1016/J.JARMAP.2021.100306

Taghinezhad E, Kaveh M, Szumny A (2021) Optimization and prediction of the drying and quality of turnip slices by convective-infrared dryer under various pretreatments by rsm and anfis methods. Foods 10:284. https://doi.org/10.3390/foods10020284

Rajoriya D, Shewale SR, Bhavya ML, Hebbar HU (2020) Far infrared assisted refractance window drying of apple slices: comparative study on flavour, nutrient retention and drying characteristics. Innov Food Sci Emerg Technol 66:102530. https://doi.org/10.1016/j.ifset.2020.102530

Izli N, Isik E (2014) Effect of different drying methods on drying characteristics, colour and microstructure properties of mushroom. J Food Nutr Res 53:105–116

Ahmed J, Shivhare US, Singh P (2004) Colour kinetics and rheology of coriander leaf puree and storage characteristics of the paste. Food Chem 84:605–611. https://doi.org/10.1016/S0308-8146(03)00285-1

Shende D, Shrivastav A, Datta AK (2016) Effects of thickness of mango puree on refractance window drying to make mango leather. In: Emerging Technologies in Agricultural & Food Engineering (ETAE 2016). Excel India Publisher, New Delhi, India, IIT Kharagpur, p 170–177

Akther S, Jothi JS, Badsha MdR et al (2022) Drying methods effect on bioactive compounds, phenolic profile, and antioxidant capacity of mango powder. J King Saud Univ Sci 102370. https://doi.org/10.1016/J.JKSUS.2022.102370

López-Vidaña EC, Figueroa IP, Cortés FB et al (2017) Effect of temperature on antioxidant capacity during drying process of mortiño (Vaccinium meridionale Swartz). Int J Food Prop 20:294–305. https://doi.org/10.1080/10942912.2016.1155601

Mejia-Meza EI, Yanez JA, Davies NM et al (2008) Improving nutritional value of dried blueberries (Vaccinium corymbosum L.) combining microwave-vacuum, hot-air drying and freeze drying technologies. Int J Food Eng 4:1–6. https://doi.org/10.2202/1556-3758.1364

López-Vidaña EC, Pilatowsky Figueroa I, Cortés FB et al (2017) Effect of temperature on antioxidant capacity during drying process of mortiño (Vaccinium meridionale Swartz). Int J Food Prop 20:294–305. https://doi.org/10.1080/10942912.2016.1155601

Kaur K, Pandiselvam R, Kothakota A et al (2022) Impact of ozone treatment on food polyphenols – a comprehensive review. Food Control 109207. https://doi.org/10.1016/J.FOODCONT.2022.109207

Gümüşay ÖA, Borazan AA, Ercal N, Demirkol O (2015) Drying effects on the antioxidant properties of tomatoes and ginger. Food Chem 173:156–162. https://doi.org/10.1016/J.FOODCHEM.2014.09.162

Pal L, Giri SK, Mohapatra D et al (2023) Mass transfer parameters and quality characteristics of aonla slices under refractance window drying. Drying Technol. https://doi.org/10.1080/07373937.2023.2234473

Sen S, De B, Devanna N, Chakraborty R (2013) Total phenolic, total flavonoid content, and antioxidant capacity of the leaves of Meyna spinosa Roxb., an Indian medicinal plant. Chin J Nat Med 11:149–157. https://doi.org/10.1016/S1875-5364(13)60042-4

Hihat S, Remini H, Madani K (2017) Effect of oven and microwave drying on phenolic compounds and antioxidant capacity of coriander leaves. Int Food Res J 24:503–509

Yap ESP, Uthairatanakij A, Laohakunjit N, Jitareerat P (2022) Influence of hot air drying on capsaicinoids, phenolics, flavonoids and antioxidant activities of ‘Super Hot’ chilies. PeerJ 10. https://doi.org/10.7717/peerj.13423

Mokhtarian M, Kalbasi-Ashtari A, Hamedi H (2020) Effects of shade and solar drying methods on physicochemical and sensory properties of Mentha piperita L. Food and Health 3:25–32

Chaves RPF, Araújo AL de, Lopes AS, Pena R da S (2023) Convective drying of purple basil (Ocimum basilicum L.) leaves and stability of chlorophyll and phenolic compounds during the process. Plants 12. https://doi.org/10.3390/plants12010127

Acknowledgements

The authors acknowledge the resources and facilities provided by Punjab Agricultural University, Ludhiana, India, for carrying out this research work. Also, the authors express their gratitude to the University Grant Commission, India, for awarding the Savitribai Jyotirao Phule Fellowship for Single Girl Child (SJSGC).

Author information

Authors and Affiliations

Contributions

Ruchika Zalpouri: conceptualization, methodology, software, formal analysis, writing — original draft and writing — review and editing.

Manpreet Singh: conceptualization, resources, supervision and writing — review and editing.

Preetinder Kaur: conceptualization, resources and writing — review and editing.

Sukhmeet Singh: validation and writing — review and editing.

Satish Kumar: supervision and writing — review and editing.

Amrit Kaur: software and writing — review and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zalpouri, R., Singh, M., Kaur, P. et al. Mathematical and artificial neural network modelling for refractance window drying kinetics of coriander (Coriandrum sativum L.) followed by the determination of energy consumption, mass transfer parameters and quality. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05013-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05013-y