Abstract

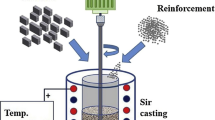

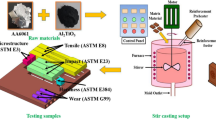

The development of hybrid agro-metallic alloy and its composites has increased in the last few years to overcome the shortcomings of monolithic alloys. Using hard ceramic reinforcements would enhance the strength of the alloys and its composites during component building. One such ceramic reinforcement is the Titania (TiO2) powder, which possesses more strength than other ceramics materials, but the cost is a little higher. To overcome this, eco-friendly, calcined eggshell (CES) particulates are added to TiO2 reinforcement to enhance the strength of the hybrid composite at a reduced cost. The main novelty of the present study is the employment of CES and TiO2 particulates in the Al 6061 matrix during the development of hybrid Al 6061 composites. This increases the strength of the fabricated composites at a reduced cost and results in the development of eco-friendly agro-metallic composites. Samples were produced individually in groups with varying proportions of CES at 3, 6, 9 and 12 wt% and combined with fixed proportions of TiO2 at 3, 6, 9 and 12 wt% individually with groups such as A (3 wt% of TiO2 + 3, 6, 9 and 12 wt% of CES), B, C and C and D, respectively. Microstructural characterization through FESEM and phase identification through XRD analysis are conducted to justify the uniform dispersion of reinforcements in the matrix. Developed samples were subjected to tensile, flexural and hardness tests, and the results proved that the mechanical properties of composites were enhanced when combining 3, 6, 9 and 12 wt% CES with 3 and 6 wt% of TiO2 compared with unreinforced Al 6061. The enhancement is linked to the uniform dispersion of the particles and good interaction between the particles. However, the 3, 6, 9 and 12 wt% CES with 9 and 12 wt% of TiO2 yielded inferior strength performance relative to the reference mix due to particle clustering and agglomeration formation. This acts as a yielding point for stress concentration. Therefore, it was concluded that a combination of 3, 6, 9 and 12 wt% CES with TiO2 should not exceed 6 wt% of TiO2.

Similar content being viewed by others

Data availability

All data employed in support to the outcomes in the study are included in this article.

References

Xiong H, Su L, Kong C, Yu H (2021) Development of high performance of Al alloys via cryo-forming: a review Adv. Eng Mater 23:1–19

Weiss D (2019) Improved high-temperature aluminum alloys containing cerium. J Mater Eng Perform 28:1903–1908

Anika L, Annika B, Rüdiger R and Frank V 2020 Mechanical properties of high strength aluminum alloy EN AW-7075 additively manufactured by directed energy deposition Metals (Basel). 10(5):579

Varshney D, Kumar K (2021) Application and use of different aluminium alloys with respect to workability, strength and welding parameter optimization. Ain Shams Eng J 12:1143–52

Venkatesan K, Ramanujam R, Joel J, Jeyapandiarajan P, Vignesh M, Tolia DJ, Krishna RV (2014) Study of cutting force and surface roughness in machining of Al alloy hybrid composite and optimized using response surface methodology Procedia Eng 97:677–686

Ranganath G, Sharma SC, Krishna M, Muruli MS (2002) A study of mechanical properties and fractography of Za-27/titanium-dioxide metal matrix composites. J Mater Eng Perform 11:408–413

Efthymiou E, Cöcen ON, Ermolli SR (2010) Sustainable aluminium systems Sustainability 2:3100–3109

Mostafa A, Adaileh W, Awad A, Kilani A (2021) Mechanical properties of commercial purity aluminum modified by zirconium micro-additives Crystals 11:1–14

Kumar A, Mehmood A (2018) Investigation of mechanical properties of pure aluminum by variation of copper content Int. Res J Eng Technol 5:29–36

Rana RS, Purohit R, Das S (2012) Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites Int. J Sci Res Publ 2:1–7

Sahoo B, Joseph J, Sharma A, Paul J (2019) Particle size and shape effects on the surface mechanical properties of aluminium coated with carbonaceous materials. J Compos Mater 53:261–270

Srivyas PD, Charoo MS (2018) Aluminum metal matrix composites a review of reinforcement; mechanical and tribological behavior. Int J Eng Technol 7:117–122

VijayaRamnath B, Parswajinan C, Dharmaseelan R, Thileepan K, Nithin Krishna K (2020) A review on aluminium metal matrix composites Mater. Today Proc 46:4341–4343

Vignesh M, Ramanujam R, Rajyalakshmi G and Bhattacharya S (2021) Application of Grey Theory and Fuzzy Logic to Optimize Machining Parameters of Zircon Sand Reinforced Aluminum Composites. In Advances in Fluid Dynamics: Selected Proceedings of ICAFD 2018 (pp. 653–662). Springer Singapore.

Vignesh M, Venkatesan K, Ramanujam R, Vijayan S (2015) Tool wear analysis of Al 6061 reinforced with 10 wt% Al2O3 Using high hardened inserts Appl. Mech Mater 787:643–647

Sharma AK, Bhandari R, Aherwar A, Rimašauskiene R (2020) Matrix materials used in composites: a comprehensive study Mater. Today Proc 21:1559–1562

Naik GM, Sachin B, Badiger RI, Hebbale AM (2019) Microstructure and mechanical properties of TiO2reinforced ZA22 metal matrix composite Mater. Today Proc 35:303–307

Seah KHW, Sharma SC, Krishna M (2003) Mechanical properties and fracture mechanism of ZA-27/TiO2 particulate metal matrix composites Proc. Inst. Mech. Eng Part L J Mater Des Appl 217:201–206

Badiger RI, Narendranath S, Srinath MS (2018) Microstructure and mechanical properties of Inconel-625 welded joint developed through microwave hybrid heating Proc. Inst. Mech Eng Part B J Eng Manuf 232:2462–2477

Shaikh MBN, Raja S, Ahmed M, Zubair M, Khan A, Ali M (2019) Rice Husk Ash reinforced aluminium matrix composites: fabrication, characterization, statistical analysis and artificial neural network modelling Mater. Res Express 6:056518

Thiagarajan G, Latif NA, Farahin N, Joharudin M (2020) Advanced research in natural fibers preliminary study on crystallinity of rice husk ash reinforcement for metal matrix composite Adv. Res Nat Fibers 2:21–24

Olawale Ibrahim K (2021) Particulate mollusc shells as reinforcements for aluminium matrix composites: a review Covenant. J Eng Technol 5:1–11

Asafa TB, Durowoju MO, Oyewole AA, Solomon SO, Adegoke RM, Aremu OJ (2015) Potentials of snailshell as a reinforcement for discarded aluminum based materials Int. J Adv Sci Technol 84:1–8

Nadzri SNIHA, Sultan MTH, Shah AUM, Safri SNA, Talib ARA, Jawaid M, Basri AA (2020) A comprehensive review of coconut shell powder composites: preparation, processing, and characterization. J Thermoplast Compos Mater 35:2641–2664

Mangalore P, Akash UA, Abhiram SJ, Advaith, (2019) Mechanical properties of coconut shell ash reinforced aluminium metal matrix composites AIP Conf. Proc 2080:020014

Anjali MR, Bhandari S, Pant A, Saxena A, Seema KN, Chotrani N, Gunwant D, Sah PL (2017) Fabrication and mechanical testing of egg shell particles reinforced Al-Si composites Int. J Math Eng Manag Sci 2:53–62

Jannet S, Raja R, Rajesh Ruban S, Khosla S, Sasikumar U, Sai NB, Teja PM (2021) Effect of egg shell powder on the mechanical and microstructure properties of AA 2024 metal matrix composite Mater. Today Proc 44:135–140

Adediran AA, Akinwande AA, Balogun OA, Olorunfemi BJ, M S K, (2021) Optimization studies of stir casting parameters and mechanical properties of TiO2 reinforced Al 7075 composite using response surface methodology Sci. Rep 11:1–20

ASTM E384 − 17 (2017) Standard test method for microindentation hardness of materials. ASTM Int, 384:1–40

ASTM E8 (2010) Standard test methods for tension testing of metallic materials Annu. B. ASTM Stand. 4:1–27

ASTM C1161 − 13 (2008) Standard test method for flexural strength of advanced ceramics at ambient Annu. B. ASTM Stand.11:1–16

Kumar GV, VenkateshChowdary G, Surya Vamsi M, Jayarami Reddy K, Nagaral M, Naresh K (2022) Effects of addition of titanium diboride and graphite particulate reinforcements on physical, mechanical and tribological properties of Al6061 alloy based hybrid metal matrix composites Adv. Mater Process Technol 8:2259–2276

Domínguez C, Moreno López MV, Ríos-Jara D (2002) The influence of manganese on the microstructure and the strength of a ZA-27 alloy. J Mater Sci 37:5123–5127

Adediran AA, Alaneme KK, Oladele IO and Akinlabi ET (2021) Microstructural characteristics and mechanical behaviour of aluminium matrix composites reinforced with Si-based refractory compounds derived from rice husk Cogent Eng 8(1):1897928

Sam M, Radhika N, Pavan Sai K (2020) Effect of heat treatment on mechanical and tribological properties of aluminum metal matrix composites Proc. Inst. Mech. Eng Part C J Mech Eng Sci 234:4493–4504

Kumar S, Vasumathi M (2020) Applying visualization techniques to study the fluid flow pattern and the particle distribution in the casting of metal matrix composites. J Manuf Process 58:668–676

El-Mahallawi I S, Shash A Y and Amer A E (2015) Nanoreinforced cast Al-Si alloys with Al2O3, TiO2 and ZrO2 nanoparticles Metals 5(2):802–821

Kumar MS, Begum SR, Pruncu CI, Asl MS (2021) Role of homogeneous distribution of SiC reinforcement on the characteristics of stir casted Al–SiC composites. J Alloys Compd 869:159250

Ravi Kumar K, Kiran K, Sreebalaji VS (2017) Micro structural characteristics and mechanical behaviour of aluminium matrix composites reinforced with titanium carbide. J Alloys Compd 723:795–801

Jojith R, Radhika N (2019) Mechanical and tribological properties of LM13/TiO2/MoS2 hybrid metal matrix composite synthesized by stir casting Part. Sci Technol 37:570–582

Olorunyolemi OC, Ogunsanya OA, Akinwande AA, Balogun OA and Saravana Kumar M (2022) Enhanced mechanical behaviour and grain characteristics of aluminium matrix composites by cold rolling and reinforcement addition (Rice husk ash and Coal fly ash). Proceedings of the Institution of Mechanical Engineers, Part E: J Proc Mech Engr, 09544089221124462.

Saravanakumar A, Sasikumar P (2018) Flexural behavior and microstructure of hybrid metal matrix composites. J Mater Environ Sci 9:2951–2955

Ogunsanya OA, Akinwande AA, Balogun OA, Romanovski V, Kumar MS (2023) Mechanical and damping behavior of artificially aged Al 6061/TiO2 reinforced composites for aerospace applications Part. Sci Technol 41:196–208

Radhika N, Raghu R (2017) Investigation on mechanical properties and analysis of dry sliding wear behavior of Al LM13/AlN metal matrix composite based on Taguchi’s technique. J Tribol 139:1–10

Bhowmik A, Meher A, Biswas S, Dey D, Kumar MS, Biswas A, Alsharabi RM (2022) Synthesis and characterization of borosilicate glass powder-reinforced novel lightweight aluminum matrix composites Adv. Mater Sci Eng 2022:1–11

Author information

Authors and Affiliations

Contributions

All the authors contributed equally to the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, M.S., Akinwande, A.A., Yang, CH. et al. Investigation on mechanical behaviour of Al–Mg-Si alloy hybridized with calcined eggshell and TiO2 particulates. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04215-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04215-8