Abstract

Bacterial cellulose (BC) has garnered attention among biomaterial scientists for its unique physicochemical features and biocompatibility; however, the lack of bioactivity has limited its biomedical applications. Thus, this study describes the in situ preparation of BC/hydroxyapatite (HA) nanocomposite membranes using static and agitated fermentation to enhance the bioactivity of BC. The incorporation of HA increased BC production from 2.31 g/L without HA to 4.10 and 3.26 g/L under static and agitated fermentation, respectively, although the SEM observation indicates the formation of a fibrous structure in BC mesh under both fermentations. It was also observed that the content of HA nanoparticles in BC obtained from agitated fermentation was higher than that obtained from static fermentation. In addition, the average fiber diameter was increased from 56 ± 17 nm for agitated nanocomposites (BC/HA-A) to 145 ± 48 nm for static BC/HA nanocomposites (BC/HA-S) and 122 ± 26 nm for BC. In conclusion, the in situ formation of BC/HA nanocomposite under agitated fermentation appears more convenient in term of BC yield, HA content and distribution, and cytotoxicity against fibroblast cells (BJ1). This strategy will inspire new ways to prepare BC-based materials for medical applications.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

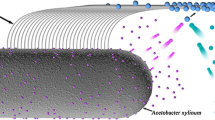

The design of eco-friendly biomaterials is a rapidly growing area of materials research with huge commercial potential in biomedical field such as novel drug formulations, tissue engineering, and even disease diagnoses [1,2,3]. Cellulose is the most widespread, renewable, and biocompatible natural unbranched polymer on the earth, and it is generally recognized as the main component of plant cell wall compared to other natural carbohydrates [4, 5]. It is widely available, renewable, and biocompatible carbohydrate, and can be obtained from a variety of sources such as woods, plant cell wall, bacteria, algae, and even tunicate marines [6, 7]. BC is a bacterial based for production and can be used in almost its pure form (up to 90%) without impurities like hemicellulose and lignin; it is composed of glucose units linked together via glycosidic bonds that form glucan chains with the chemical formula (C6H10O5)n [8]. The unique features of BC, such as high purity, nanofibers structure, interconnected porous structure, high water-holding capability, high mechanical strength, ease chemical modifications, biodegradability, and non-toxicity have attracted attention for medical and technical applications. BC first observed by Brown (1886) during acetic acid fermentation [9]. Several Gram-negative and Gram-positive bacteria have been reported previously for BC production. Especially, Gluconacetobacter xylinus (Komagataeibacter xylinus) as Gram-negative bacteria are widely reported for production of BC and have received significant attention [10]. However, BC production using Gram-positive bacteria is rare, with a few bacteria reported like Lactobacillus hilgardii [11], Lactiplantibacillus plantarum [12], and Bacillus licheniformis [13]. BC-producing strains can be isolated from different sources for example vinegar [14], rotten fruits, and kombucha [11]. For BC production, there really are two different fermentation strategies: static and agitated fermentations [15]. At the upper liquid interface, the white, thick, and gel-like BC pellicle was observed during static fermentation with oxygen limitation and nutrient supply [16]. This strategy is more appropriate for BC application in medical applications [17]. While the randomly distributed BC pellets were observed during agitated fermentation, this strategy is more appropriate for numerous applications [18]. Many strive to maximize the utility of BC-based composites, either by combining BC pellicles with other materials (ex situ) or by functionalizing BC during the biosynthesis process (in situ). Several studies have concerned with in situ BC modification for different applications like, BC/polyaniline/titanium-dioxide as bio-anode in microbial fuel cells [18], BC/calcium carbonate for gas assistance, BC/sodium alginate as drug delivery system [19], BC/cellulose imidazolium as antimicrobial agents [20], and BC/polypyrrole as electrical conductive material [21].

Today, the biomaterials field has shifted paradigms from passive to biologically active biomaterials in order to mimic the structure, composition, and functions of natural living systems [22,23,24]. For example, apatite nanocrystals represent the main inorganic components of hard connective tissues. Therefore, calcium phosphate-based materials have been used to repair bone defects and augmentation of alveolar bone [31,32,33]. HA is one of the most attractive inorganic ceramic material as grafting materials for orthopedic application due to its chemical and structural similarity with native bone mineral [25, 26]. Actually, the calcium phosphate HA obtained from either natural or synthetic origins is regarded as highly biocompatible and osteoconductive ceramic biomaterial [25]. However, HA is an excellent choice as inorganic bone-like material to be used in orthopedic and dental applications; its brittle nature and high elastic modulus have limited its application in guided bone tissue regeneration [27]. In this regard, the development of novel bioactive nanocomposites of polymer/ceramic materials as bone analogue substitutes is currently being explored.

Nanocomposite materials are explored as potential scaffolding materials and can be utilized to reconstruct damage tissues or organs and design of smart drug delivery systems [28, 29]. Polysaccharides/inorganic materials are promising materials for biomedical and adsorption applications [30, 31]. Among them, cellulose-based composites have attracted a huge attention due to their hydrophilicity, biocompatibility, and biodegradation potential [30, 31]. For instance, the biomimetic mineralization of bioactive cellulose grafted soy protein isolate/calcium phosphate composites was recently assessed. Cellulose oxidation was chemically induced by reacting it with soy protein hydrolysate and the prepared material was soaked in simulated body fluid. The results revealed the formation of calcium phosphate HA rod-like nanocrystals with an average diameter of 50 nm and unique bioactivity upon soaking in simulated body fluid [32].

In this sense, cellulose/calcium phosphate nanostructured materials have emerged as functional safe and bioactive materials for various application fields, such as environmental remediation [33], drug delivery [34], and biomedical materials [35]. Today, BC functionalization with calcium phosphate during the fermentation process (known as in situ fermentation) represents an effective synthesis approach to meet the needs for designing of multifunctional materials using a one-step synthesis strategy. However, there are some studies reported the fabrication BC/HA nanocomposite materials [36, 37]; a detailed study involving the in-situ fermentation for the production of BC/HA has not been reported yet.

Therefore, this study describe the development procedure for preparation of BC/HA nanocomposites through fermentation strategies of static and agitated. The chemical and physicochemical characteristics of the prepared BC/HA nanocomposites membrane were investigated by scanning electron microscopy (SEM), X-ray diffraction (XRD), and Fourier-transform infrared spectrophotometry (FTIR) and in vitro cell viability was assessed using MTT assay against BJ1 fibroblast cells.

2 Materials and methods

2.1 Standard inoculum preparation

Lactiplantibacillus plantarum AS.6 (L. plantarum AS.6) was used as BC producer strain as previously described [12]. A freshly and pure single colony of L. plantarum AS.6 was cultured in Hestrin and Schramm (HS) medium containing: 2% glucose, 0.5% yeast extract, 0.5% peptone, 0.27% disodium hydrogen phosphate, 0.115% citric acid, and 0.5% ethanol at pH 5.5 and incubated at 30 °C for 2 days under agitated condition (200 rpm) as the standard inoculum for further use [38].

2.2 In situ development of BC/HA nanocomposite

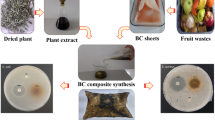

HA nanoparticle was supplied from Sigma-Aldrich and has the following specification: < 200-nm particle size, ≥ 97%, synthetic. HA nanoparticle was evaluated for in situ preparation of BC composites membrane by using L. plantarum AS.6 under static and agitated fermentations as shown in Fig. 1. The HS as the standard media was used for BC production and supplemented with HA (10 g/L) and dispersed in the medium using a very mild sonication (750 wt, 20 KH, pulse 45, Amp 1) for 10 min and adjust the media. pH was adjusted to 5.5 and the medium was inoculated by 10% from standard inoculum and then incubated for 5 days at 30 °C under static fermentation, while other groups of flasks were incubated under agitated fermentation (100 rpm). The production of BC-free HA as control was also produced using the same method without the addition of HA under static fermentation. All of the media used were autoclaved at 121 °C for 20 min, left to cooled, and then inoculated. At the end of the fermentation time, the BC pellicle or pellets were collected from the broth medium and treated numerous times with distilled water to remove excess broth medium. Afterwards, the BC sample was soaked three times in 0.5% NaOH at 90 °C for 30 min, three times, to remove bacterial contaminants and non-immobilized HA nanoparticles on the BC mesh, and then rinsed with distilled water until neutralization. Finally, wet BC samples were freeze-dried and placed in a desiccator to keep the moisture [39].

2.3 Parameters of BC sample

The BC (g/L), yield (%), and productivity (g/L/d) were recorded as parameters of BC production.

The BC (g/L) = dry weight mass (g)/media volume (L) g/L.

Yield of BC (%) = (BC dry weight mass g/L)/(original sugar g/L) × 100.

Productivity of BC (g/L/d) = (BC dry weight mass g/L)/(production time d).

2.4 Microstructure characterization

The chemical functional groups of the BC and BC/HA nanocomposites membranes were investigated using FTIR (model FT/IR-6100 type A). The spectra of each sample was measured in a spectral range from 400 to 4000 cm−1. The morphology of the prepared BC and BC/HA nanocomposites was examined using field emission scanning electron microscopy (FE-SEM) (JSM 6360LV, JEOL/Noran) at an accelerating voltage of 5 kV, where BC fiber diameters were calculated from SEM images through the angel tool of ImageJ with Java 1.8.0 software. Identification of the crystalline phases in the dried BC and BC/HA films was carried out by X-ray diffraction (XRD) in reflection mode using an X-ray diffractometer (MiniFlex-600, Rigaku Corporation, Japan) operated at 40 kV, step width of 0.02° over a scanning 2θ angle range of 10–70°.

2.5 In vitro cell viability

2.5.1 MTT assay

The cytotoxicity of BC and BC/HA nanocomposite membranes was tested in the presence of normal human fibroblasts (BJ1, Human Normal Fibroblast Cell Line). The viability of BJ1 cells was evaluated with a colorimetric test using MTT assay, which is based on the ability of living cells to reduce the yellow dye tetrazolium salt (MTT) to formazan through the oxidoreductase enzymes present in the mitochondria of living cells. Therefore, the BJ1 cells were suspended in DMEM-F medium containing 1% antibiotics (10,000 units/mL penicillin potassium, 10,000 μg/mL streptomycin sulfate, and 25 μg/mL amphotericin B) and 1% glutamine. The cells were then seeded into cell culture well plates at a concentration of 10,000 cells per well and allowed to adhere overnight at 37 °C (95% humidity, 5% CO). The dishes were examined using an inverted microscope to assess cell confluence and to confirm the absence of bacterial and fungal contaminants. The medium was replaced with fresh medium with different concentrations of the prepared cellulosic materials. After 72 h of incubation, 40 μL of MTT salt (2.5 μg/mL) were added to the medium of each well and incubated for another 4 h at 37 °C under 5% CO2. To stop the reaction and to dissolve the formed formazan crystals, 200 μL of 10% sodium dodecyl sulfate in deionized water was added to each well and incubated overnight at 37 °C. The absorbance of each well was then measured using a multi-well reader (Bio-Rad Laboratories Inc., model 3350, Hercules, CA, USA) at 595 nm and a reference wavelength of 620 nm.

2.5.2 Cell attachment assay

Round disks of BC samples (12-mm diameter and 0.15-mm thickness) were lyophilized at – 20 °C and sterilized with 70% EtOH (10 min), and washed with PBS three times. The fibroblast cells (BJ1) were seeded at a density of 104 cells/cm2 per well in a 48-well plate containing BC samples. After 3 days of culture, the BC disks were immersed several times in PBS to eliminate non-adherent cells and continuously fixed with glutaraldehyde (2%) for 15 min and then thoroughly washed with PBS several times (15 min/wash). The samples were dehydrated with a series of ethanol solutions at 50, 75, 90, 95, and 100% [40]. The BJ1 cells were treated three times in 100% EtOH and washed twice with HDMS. The samples were air-dried and sputtered with gold and examined by SEM.

2.5.3 Statistical analysis

All experiments were performed in triplicate, and the results were introduced as mean ± standard deviation. Statistical data were collected with the one-way ANOVA test, by using Sigma Stat 3.5 software (Dundas Software Ltd., Toronto; Canada).

3 Results and discussions

3.1 In situ development of BC/HA nanocomposites through static and agitated ferminations

Many factors such as strain, media composition, and other culture conditions that influence on the BC production [40]. Here, HA nanoparticles were directly dispersed in the culture medium. Therefore, their low stability resulted in the subsequent particle aggregation and then settled down at the bottom of the medium after several days of cultivation and evaluated for BC production as summarized in Table 1. This study used two methods to produce BC production: static and agitated fermentation. We can observe in Table 1 the addition of HA to fermentation media under static conditions (4.10 g/L) significantly enhanced the production of BC compared to agitated fermentation (3.26 g/L), resulting in a BC/HA composite that increases BC production during static fermentation by about 1.25-folds compared to those obtained during agitated fermentation. This result is consistent with another study, who report that the static fermentation enhanced the BC production (1.94 g/L) rather than agitated conditions (0.44 g/L) when using HS media [41]. Under static conditions, the BC grows at the interface between the air (rich in oxygen) and the liquid medium forming the gel-like membane. During an agitated condition, bacterial strains have access to the oxygen dissolved in the medium, and an excessive oxygen feed reduces BC production [41, 42]. Other reports explain that the productivity of BC decreased due to the resulting non-cellulosic mutants and genetically instable bacteria under the agitated conditions [8]. On the contrary, the BC production was significantly enhanced under static conditions, and the incorporation of HA in the media during BC production was enhanced about 1.7-folds over standard media (without HA). Several studies found that the supplementation of BC production media with macro- and micronutrients as in situ model also plays important role to improve the BC production as presented in Table 2. Several supplements can have a major impact on the production of BC by either enhancing the activities of the producing microorganisms or providing a supplementary nutritional source [43]. Sherif and Keshk reported that the BC productivity by Gluconacetobacter xylinus was increased in the presence of vitamin C (0.5% w/w); the average BC enhancement reached 88% under static conditions at 28 °C and pH 6 for 7 days; and these results are nearly in agreement with the present study [44]. Other research has reported that adding 0.04% sodium alginate to production media under agitated conditions of 200 rpm and 29 °C for 3 days increased BC production to 62%, which is higher than the data obtained in the current study [44]. HA nanoparticles may be could effectively immobilize bacterial cells and might accelerate their reproduction; therefore, more BC was produced when compared with HA-free media.

3.2 Chemical and physicochemical characterization

3.2.1 SEM analysis

As shown in Fig. 2, the BC and BC/HA under static and agitated conditions before and after purification (treated with 0.5 M NaOH), as well the SEM images for purified BC samples and histogram of obtained nanofiber diameters. BC is usually treated with NaOH to remove non-cellulosic components including impurities and other microbial metabolites that could block the interconnected porous structure of BC. The SEM image reveals not only the complete removal of impurities along the nonwoven random fibrous structure of BC, but also indicates the infiltration of HA nanoparticles within the BC fibers. In addition, SEM images in Fig. 2 exhibited that the agitated sample reveals a compact structure with diminished porous structure compared to BC obtained under static condition. In contrast to BC, the average nanofiber dimeter was recorded as 122.9, 154.4, and 56.17 nm for BC control, BC/HA-S, and BC/HA-A, respectively, as illustrated in fiber diameter measurements. Therefore, this study found that agitation fermentation enables the infiltration of HA nanoparticles through the BC characteristic interconnected porous structure and results in an effective facial approach involving incorporate nanoparticles at molecular level to improve structural uniformity and to enhance interfacial-bonding between inorganic and organic materials.

3.2.2 FTIR spectroscopy

The FTIR spectra of BC, BC/HA-S, and BC/HA-A are shown in Fig. 3. The spectrum of BC showed characteristic peaks of pure BC: OH stretching at 3149 cm−1, CH stretching at 2902 cm−1, H–O–H bending of absorbed water at1633 cm−1, CH2 deformation at 1432 cm−1, and CH3 deformation at 1391 cm−1. Compared to pure BC, the composite had a lower peak intensity that obtained from pure BC. Consequently, the crystallinity degree of cellulose decreased after hybridization. The BC/HA-S sample exhibited characteristic peaks at 1049 and 1152 cm−1 (P–O ν3 mode), 554 cm−1 (P–O ν4 mode), and 897 cm−1 (P–O ν1 mode) which are assigned to different vibration modes of PO43− groups. On contrary, compared to the BC/HA-S spectrum, an increase in the intensity of the PO43− peaks was observed in the case of BC/HA-A. This phenomenon suggested that BC/HA-A sample contains more HA nanoparticle content than BC/HA-S. The broad band at 3500 cm−1 which assigned to OH symmetric stretching vibration and inter- and intra-molecular hydrogen bonds of BC becomes sharper for BC/HA-S and BC/HA-A. This change is a significant indication for the incorporation of new hydroxyl groups which originated from the presence of HA.

3.2.3 XRD analysis

To determine the effect of HA nanoparticles on the crystallinity of BC, XRD analysis of BC, BC/HA-S, and BC/HA-A composite membranes were conducted. Pure BC has a highly crystalline structure with typical diffraction peaks at 14.6°, 16.9°, and 22.7° [51], which are attributed to the (100), (010), and (110) crystal planes of cellulose Ια, respectively (Fig. 4a). The XRD patterns of BC/HA-S and BC/HA-A composites are shown in Fig. 4b and C. The two composites showed the characteristic peaks of the HA phase. However, the BC/HA-A peaks were sharp and may reflect the high HA nanoparticles content and these peaks occurred at 2-Theta 31.96, 33.11, 34.2, 39.41, 39.95, 42.2, 46.84, 48.19, 49.59, 50.64, 51.34, 52.19, 53.29, and 55.98°. Moreover, there was an obvious decrease of crystalline BC characteristic peaks at 14.6°, 16.9°, and 22.7° for BC/HA-A sample. This change could be due to the increase of HA nanoparticles content under agitation condition which has effectively reduced the hydrogen bonding between cellulose chains and destroyed the crystalline structure of BC. These results are consistent with the FTIR spectra and SEM of BC/HA composites.

3.2.4 Morphology of BC and BC/HA nanocomposites

As depicted in Fig. 5A, the surface morphology of the BC hydrogel was uniform and smooth with an interconnected three-dimensional (3-D) microporous architecture, as reported previously for lyophilized BC hydrogels. As illustrated in Fig. 5, compared to pure BC sample, BC/HA-S composite showed a small HA particle with non-homogeneous distribution of small HA nanoparticles inside the BC hydrogel network. However, in the case of BC/HA-A, homogeneous and dense distribution of HA nanoparticles was observed in the BC hydrogel network. The great difference between the composites obtained by the static and agitated fermentation method in terms of morphology is expected to evaluate the composites for bone tissue engineering. The dense structure of BC/HA-A composites could be due to the greater cross-linking in BC with HA nanoparticles obtained from continuous shaking. Although the condense structure of BC/HA-A composites, we should refer to the presence of pores and network structure in the formed composite which plays a vital role in composite functions such as the swelling behavior, and compressibility [52], drug delivery [53], cell adhesion, and nutrient diffusion [54]. The energy dispersive X-ray spectra of the BC and the prepared composites are shown in Fig. 5D, E, and F. BC exhibits the presence of C and O only. However, BC/HA-S and BC/HA-A composites consisted of Ca, P, O, and C. Carbon originates from the natural polymers; Ca and P originate from HA. Moreover, atomic percentage of Ca and P was higher in the case of BC/HA-A than BC/HA-S which confirms the mineralization efficiency in case agitation method than static technique. The amount of HA in both fermentations is equal, but the production of BC under agitated conditions has more contact with HA, so a greater amount of HA will be incorporated into the fiber of BC. On the contrary, under static fermentation, the HA has little contact with the BC during the production process, so the Ca and P ratios are higher in agitated conditions than those obtained under static conditions.

3.3 Cell viability and attachment

The viability of human normal fibroblast cells (BJ1) upon incubation with the obtained neat BC and BC/HA composites are shown in Fig. 6. It was observed that all samples did not show significant effect on the cell viability over 3 days of incubation period. The proliferation activates of the cell incubated with BC/HA composites was significantly differed from that of neat BC, in which the highest proliferation activity was observed (106 ± 5.4%) for the cell incubated with BC/HA-A composite which could be due to the increased of calcium phosphate content. These results demonstrated the good compatibility of the BC and BC/HA composites with the BJ1 cells, and their non-cytotoxic effect on these cells.

The BJ1 cells were cultured with BC and BC/HA composite to evaluate the adhesion by SEM at 1 day after seeding (Fig. 7). SEM analysis of the surface morphology and microstructure of each sample is presented in Fig. 7A–B. It was observed that BJ1 cells were attached on the surface of the BC samples with morphology typical for the culture of fibroblast cells. The cells on BC/HA composite appears much thicker as compared to those on BC (Fig. 7A).

4 Conclusion

In summary, novel bottom-up approach was used to prepare BC/HA composites under static and agitation fermentation. A comparison between the two methods was conducted through evaluating the obtained composites by FTIR, SEM–EDX, and XRD analysis. The results demonstrate that the calcium phosphate content is a function in production technique, increase through agitation fermentation. The proliferation activates of the BJ1 cell was enhanced with HA nanoparticles addition, in which the highest proliferation activity was recorded at 106% for the BJ1 cell incubated with agitated BC/HA-A. The preliminary findings of in vitro cell culture experiments, in terms of cell viability and attachment, could serve as a template for improving the biological performance of BC for bone tissue engineering and regeneration.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Biswal T, BadJena SK, Pradhan D (2020) Sustainable biomaterials and their applications: a short review. Mater Today: Proc 30:274–282

Fragassa C (2017) Marine applications of natural fibre-reinforced composites: a manufacturing case study. Adv Appl Ind Biomater, Springer, Cham, pp 21–47

Reshmy R, Philip E, Madhavan A, Arun K, Binod P, Pugazhendhi A, Awasthi MK, Gnansounou E, Pandey A, Sindhu R (2021) Promising eco-friendly biomaterials for future biomedicine: cleaner production and applications of Nanocellulose. Environ Technol Innov 24:101855

Salama A (2017) New sustainable hybrid material as adsorbent for dye removal from aqueous solutions. J Colloid Interface Sci 487:348–353

Salama A, Hesemann P (2020) Recent trends in elaboration, processing, and derivatization of cellulosic materials using ionic liquids. ACS Sustain Chem Eng 8(49):17893–17907

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44(22):3358–3393

Lynd LR, Weimer PJ, Van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66(3):506–577

Huang, Zhu C, Yang J, Nie Y, Chen C, Sun D (2014) Recent advances in bacterial cellulose. Cellulose 21(1):1–30

Brown AJ (1886) XIX.—The chemical action of pure cultivations of bacterium aceti. J Chem Soc, Trans 49:172–187

Dubey S, Sharma RK, Agarwal P, Singh J, Sinha N, Singh R (2017) From rotten grapes to industrial exploitation: Komagataeibacter europaeus SGP37, a micro-factory for macroscale production of bacterial nanocellulose. Int J Biol Macromol 96:52–60

Khan H, Kadam A, Dutt D (2020) Studies on bacterial cellulose produced by a novel strain of Lactobacillus genus. Carbohydr Polym 229:115513

Saleh AK, El-Gendi H, Soliman NA, El-Zawawy WK, Abdel-Fattah YR (2022) Bioprocess development for bacterial cellulose biosynthesis by novel Lactiplantibacillus plantarum isolate along with characterization and antimicrobial assessment of fabricated membrane. Sci Rep 12(1):1–17

Bagewadi ZK, Bhavikatti JS, Muddapur UM, Yaraguppi DA, Mulla SI (2020) Statistical optimization and characterization of bacterial cellulose produced by isolated thermophilic Bacillus licheniformis strain ZBT2. Carbohydr Res 491:107979

Zhu B, Zhang Z, Wang H, Ma X (2021) Isolation and culture conditions optimization of a new bacterial cellulose producing strain Komagataeibacter intermedius 6–5. IOP Conf Ser: Earth Environ Sci 632:032040

Sharma C, Bhardwaj NK, Pathak P (2021) Static intermittent fed-batch production of bacterial nanocellulose from black tea and its modification using chitosan to develop antibacterial green packaging material. J Clean Prod 279:123608

Portela R, Leal C, Almeida P, Sobral R (2019) Bacterial cellulose: a versatile biopolymer for wound dressing applications. Microb Biotechnol 12(4):586–610

Wasim M, Shi F, Liu J, Zhang H, Zhu K, Tian Z (2022) Synthesis and characterization of curcumin/MMT-clay-treated bacterial cellulose as an antistatic and ultraviolet-resistive bioscaffold. J Polym Res 29(10):1–18

Truong DH, Dam MS, Bujna E, Rezessy-Szabo J, Farkas C, Vi VNH, Csernus O, Nguyen VD, Gathergood N, Friedrich L (2021) In situ fabrication of electrically conducting bacterial cellulose-polyaniline-titanium-dioxide composites with the immobilization of Shewanella xiamenensis and its application as bioanode in microbial fuel cell. Fuel 285:119259

Ji L, Zhang F, Zhu L, Jiang J (2021) An in-situ fabrication of bamboo bacterial cellulose/sodium alginate nanocomposite hydrogels as carrier materials for controlled protein drug delivery. Int J Biol Macromol 170:459–468

El-Gendi H, Salama A, El-Fakharany EM, Saleh AK (2023) Optimization of bacterial cellulose production from prickly pear peels and its ex situ impregnation with fruit byproducts for antimicrobial and strawberry packaging applications. Carbohydr Polym 302:120383

Müller D, Rambo C, Recouvreux D, Porto L, Barra G (2011) Chemical in situ polymerization of polypyrrole on bacterial cellulose nanofibers. Synth Met 161(1–2):106–111

Montoya C, Du Y, Gianforcaro AL, Orrego S, Yang M, Lelkes PI (2021) On the road to smart biomaterials for bone research: Definitions, concepts, advances, and outlook. Bone Res 9(1):1–16

Rodrigo-Navarro A, Sankaran S, Dalby MJ, del Campo A, Salmeron-Sanchez M (2021) Engineered living biomaterials. Nat Rev Mater 6(12):1175–1190

Wang Y, Chen G, Zhang H, Zhao C, Sun L, Zhao Y (2021) Emerging functional biomaterials as medical patches. ACS Nano 15(4):5977–6007

Ghiasi B, Sefidbakht Y, Mozaffari-Jovin S, Gharehcheloo B, Mehrarya M, Khodadadi A, Rezaei M, RanaeiSiadat SO, Uskoković V (2020) Hydroxyapatite as a biomaterial–a gift that keeps on giving. Drug Dev Ind Pharm 46(7):1035–1062

Müller WE, Tolba E, Schröder HC, Muñoz-Espí R, Diehl-Seifert B, Wang X (2016) Amorphous polyphosphate–hydroxyapatite: a morphogenetically active substrate for bone-related SaOS-2 cells in vitro. Acta Biomater 31:358–367

Mueller WE, Ackermann M, Al-Nawas B, Righesso LA, Munoz-Espi R, Tolba E, Neufurth M, Schroeder HC, Wang X (2020) Amplified morphogenetic and bone forming activity of amorphous versus crystalline calcium phosphate/polyphosphate. Acta Biomater 118:233–247

Bharadwaz A, Jayasuriya AC (2020) Recent trends in the application of widely used natural and synthetic polymer nanocomposites in bone tissue regeneration. Mater Sci Eng, C 110:110698

Carrow JK, Gaharwar AK (2015) Bioinspired polymeric nanocomposites for regenerative medicine. Macromol Chem Phys 216(3):248–264

Hassan H, Salama A, El-Ziaty AK, El-Sakhawy M (2019) New chitosan/silica/zinc oxide nanocomposite as adsorbent for dye removal. Int J Biol Macromol 131:520–526

Salama A, Hesemann P (2018) New N-guanidinium chitosan/silica ionic microhybrids as efficient adsorbent for dye removal from waste water. Int J Biol Macromol 111:762–768

Salama A, Abou-Zeid RE, Cruz-Maya I, Guarino V (2020) Soy protein hydrolysate grafted cellulose nanofibrils with bioactive signals for bone repair and regeneration. Carbohydr Polym 229:115472

Chen F, Zhu Y-JJCN (2014) Multifunctional calcium phosphate nanostructured materials and biomedical applications. Curr Nanosci 10(4):465–485

Sukul M, Nguyen TBL, Min Y-K, Lee S-Y, Lee B-TJTEPA (2015) Effect of local sustainable release of BMP2-VEGF from nano-cellulose loaded in sponge biphasic calcium phosphate on bone regeneration. Tissue Eng Part A 21(11–12):1822–1836

Lin D, Wang N, Li Z, Li Y (2014) Characterizations of bacterial cellulose producing strain Gluconoacetobacter hansenii CGMCC3917. J Bioprocess Biotech 4(4):1

Na Y, Chen S-Y, Ouyang Y, Lian T, Yang J-X, Wang H-PJPINSMI (2011) Biomimetic mineralization synthesis of hydroxyapatite bacterial cellulose nanocomposites. Prog Nat Sci: Mater Int 21(6):472–477

Paramasivan M, Kumar TSS, Chandra TJS (2022) Microbial synthesis of hydroxyapatite-nanocellulose nanocomposites from symbiotic culture of bacteria and yeast pellicle of fermented kombucha tea. Sustainability 14(13):8144

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58(2):345

Hsieh J-T, Wang M-J, Lai J-T, Liu H-S (2016) A novel static cultivation of bacterial cellulose production by intermittent feeding strategy. J Taiwan Inst Chem Eng 63:46–51

Hiep NT, Lee B-T (2010) Electro-spinning of PLGA/PCL blends for tissue engineering and their biocompatibility. J Mater Sci - Mater Med 21(6):1969–1978

Algar I, Fernandes SC, Mondragon G, Castro C, Garcia-Astrain C, Gabilondo N, Retegi A, Eceiza A (2015) Pineapple agroindustrial residues for the production of high value bacterial cellulose with different morphologies. J Appl Polym Sci 132(1):41237

Wang J, Tavakoli J, Tang Y (2019) Bacterial cellulose production, properties and applications with different culture methods–A review. Carbohydr Polym 219:63–76

Ul-Islam M, Ha JH, Khan T, Park JK (2013) Effects of glucuronic acid oligomers on the production, structure and properties of bacterial cellulose. Carbohyd Polym 92(1):360–366

Keshk SM (2014) Vitamin C enhances bacterial cellulose production in Gluconacetobacter xylinus. Carbohydr Polym 99:98–100

Tian D, Shen F, Hu J, Renneckar S, Saddler JN (2018) Enhancing bacterial cellulose production via adding mesoporous halloysite nanotubes in the culture medium. Carbohydr Polym 198:191–196

Żywicka A, Junka AF, Szymczyk P, Chodaczek G, Grzesiak J, Sedghizadeh PP, Fijałkowski K (2018) Bacterial cellulose yield increased over 500% by supplementation of medium with vegetable oil. Carbohydr Polym 199:294–303

Gao G, Cao Y, Zhang Y, Wu M, Ma T, Li G (2020) In situ production of bacterial cellulose/xanthan gum nanocomposites with enhanced productivity and properties using Enterobacter sp. FY-07. Carbohydr Polym 248:116788

Keshk S, Sameshima K (2006) Influence of lignosulfonate on crystal structure and productivity of bacterial cellulose in a static culture. Enzyme Microb Technol 40(1):4–8

Bae S, Sugano Y, Shoda M (2004) Improvement of bacterial cellulose production by addition of agar in a jar fermentor. J Biosci Bioeng 97(1):33–38

Zhou L, Sun D, Hu L, Li Y, Yang J (2007) Effect of addition of sodium alginate on bacterial cellulose production by Acetobacter xylinum. J Ind Microbiol Biotechnol 34(7):483

Salama A, El-Sakhawy M (2016) Regenerated cellulose/wool blend enhanced biomimetic hydroxyapatite mineralization. Int J Biol Macromol 92:920–925

Edwards SL, Church JS, Alexander DL, Russell SJ, Ingham E, Ramshaw JA, Werkmeister JA (2011) Modeling tissue growth within nonwoven scaffolds pores. Tissue Eng Part C: Methods 17(2):123–130

Almeida I, Pereira T, Silva N, Gomes F, Silvestre A, Freire C, Lobo JS, Costa P (2014) Bacterial cellulose membranes as drug delivery systems: an in vivo skin compatibility study. Eur J Pharm Biopharm 86(3):332–336

Choi SM, Rao KM, Zo SM, Shin EJ, Han SS (2022) Bacterial cellulose and its applications. Polym 14(6):1080

Acknowledgements

We would like to thank National Research Centre, Egypt for providing the facilities required for preparation and microstructure characterization of the prepared samples.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors conceived the work and performed the experiment and preparation section. All authors carried out the writing, analyses, discussion, and revisions of the manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

This article does not contain any studies with human participants. All applicable international, national, and/or institutional guidelines for the care and use of animals were followed.

Informed consent

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saleh, A.K., Tolba, E. & Salama, A. In situ development of bacterial cellulose/hydroxyapatite nanocomposite membrane based on two different fermentation strategies: characterization and cytotoxicity evaluation. Biomass Conv. Bioref. 14, 18857–18867 (2024). https://doi.org/10.1007/s13399-023-03940-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-023-03940-4