Abstract

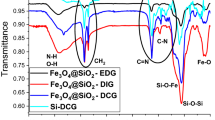

As a kind of non-edible vegetable oil, castor oil has attracted considerable interest in developing bio-based products due to its unique structure, among which polyol ricinoleates are considered as promising alternatives to mineral oil-based lubricants. In this article, a Brønsted acid-functionalized silica-coated magnetic catalyst (Fe3O4@SiO2-IM-SO3H) was developed as the efficient heterogeneous catalyst for the preparation of polyol ricinoleates via the esterification of ricinoleic acid with trimethylolpropane (TMP), neopentyl glycol (NPG), and pentaerythritol (PE), respectively. The structure and magnetic property of the catalyst were characterized by Fourier infrared spectroscopy (FT-IR), X-ray diffractometer technology (XRD), element analysis (CHN), and vibrating sample magnetometer (VSM). As a result, the sulfonic group was proposed to promote the esterification and the magnetism facilitated the catalyst separation. Notably, the yield of polyol ricinoleates attained successfully up to 99.5%, and the catalyst was recycled for at least five times without obvious activity reduction. This work about the utilization of magnetic nanoparticles supported acid catalysts in polyol ricinoleates preparation features clean and sustainability, providing an example of developing green products.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available in the supplementary material of this article.

References

Maity SK (2015) Opportunities, recent trends and challenges of integrated biorefinery: Part I. Renew Sustain Energy Rev 43:1427–1445. https://doi.org/10.1016/j.rser.2014.11.092

Ghosh P, Hoque M, Karmakar G (2017) Castor oil as potential multifunctional additive in the formulation of eco-friendly lubricant. Polym Bull 75:501–514. https://doi.org/10.1007/s00289-017-2047-6

Erhan SZ, Asadauskas S (2000) Lubricant basestocks from vegetable oils. Ind Crop Prod 11:277–282. https://doi.org/10.1016/S0926-6690(99)00061-8

Adhvaryu A, Erhan SZ, Perez JM (2004) Tribological studies of thermally and chemically modified vegetable oils for use as environmentally friendly lubricants. Wear 257:359–367. https://doi.org/10.1016/j.wear.2004.01.005

Nie J, Shen J, Shim YY, Tse TJ, Reaney MJT (2020) Synthesis of trimethylolpropane esters by base-catalyzed transesterification. Eur J Lipid Sci Technol 122:1900207. https://doi.org/10.1002/ejlt.201900207

Cheryl-Low YL, Lee HV, Abd Hamid SB (2017) Catalytic upgrading of bio oil model compound into polyol ester via green alginate catalyzed esterification reaction. Process Saf Envion 111:160–169. https://doi.org/10.1016/j.psep.2017.06.021

Xue W, Shi L, Chen X, Qiu M, Zhou C, Liu H, Li S, Sun Y (2019) The direct synthesis of a bio-lubricant by the oligomerization of methyllinoleate via castor oil. Green Chem 21:6658–6666. https://doi.org/10.1039/C9GC03257F

Sun S, Wang G, Wang P (2018) A cleaner approach for biodegradable lubricants production by enzymatic glycerolysis of castor oil and kinetic analysis. J Cleaner Prod 188:530–535. https://doi.org/10.1016/j.jclepro.2018.04.015

Padmaja KV, Rao BVSK, Reddy RK, Bhaskar PS, Singh AK, Prasad RBN (2012) 10-Undecenoic acid-based polyol esters as potential lubricant base stocks. Ind Crop Prod 35:237–240. https://doi.org/10.1016/j.indcrop.2011.07.005

Barbaro P, Liguori F (2009) Ion Exchange Resins: Catalyst Recovery and Recycle. Chem Rev 109:515–529. https://doi.org/10.1021/cr800404j

Nikolla E, Román-Leshkov Y, Moliner M, Davis ME (2011) “One-Pot” Synthesis of 5-(Hydroxymethyl)furfural from Carbohydrates using Tin-Beta Zeolite. ACS Catal 1:408–410. https://doi.org/10.1021/cs2000544

Gao S, Ren FY, Xie WH, He LN, Li HR (2021) Heterogeneous esterification of ricinoleic acid with polyol for the synthesis of polyol ricinoleates as biomass-based lubricant base oil. J Am Oil Chem Soc 99:91–99. https://doi.org/10.1002/aocs.12554

Gawande MB, Brancoa PS, Varma RS (2013) Nano-magnetite (Fe3O4) as a support for recyclable catalysts in the development of sustainable methodologies. Chem Soc Rev 42:3371–3393. https://doi.org/10.1039/c3cs35480f

Lin YS, Wu SH, Hung Y, Chou YH, Chang C, Lin ML, Tsai CP, Mou CY (2006) Multifunctional composite nanoparticles: magnetic, luminescent, and mesoporous. Chem Mater 18:5170–5172. https://doi.org/10.1021/cm061976z

Graf C, Dembski S, Hofmann A, RÜhl E, (2006) General method for the controlled embedding of nanoparticles in silica colloids. Langmuir 22:5604–5610. https://doi.org/10.1021/la060136w

Polshettiwar V, Luque R, Fihri A, Zhu H, Bouhrara M, Basset JM (2011) Magnetically recoverable nanocatalysts. Chem Rev 111:3036–3075. https://doi.org/10.1021/cr100230z

Dam B, Nandi S, Pal AK (2014) An efficient ‘on-water’ synthesis of 1,4-dihydropyridines using Fe3O4@SiO2 nanoparticles as a reusable catalyst. Tetrahedron Lett 55:5236–5240. https://doi.org/10.1016/j.tetlet.2014.08.002

Wang H, Lu Y, Liu H, Yin Y, Liang J (2020) Preparation and application of magnetic nano-solid acid catalyst Fe3O4-PDA-SO3H. Energies 13. https://doi.org/10.3390/en13061484

Yu S, Zhang H (2020) Preparation of rosin pentaerythritol ester over an Fe3O4-supported ZnO catalyst. Catal Lett 150:3359–3367. https://doi.org/10.1007/s10562-020-03237-5

Xie W, Wang H (2020) Immobilized polymeric sulfonated ionic liquid on core-shell structured Fe3O4/SiO2 composites: a magnetically recyclable catalyst for simultaneous transesterification and esterifications of low-cost oils to biodiesel. Renew Energ 145:1709–1719. https://doi.org/10.1016/j.renene.2019.07.092

Soleimani E, Yaesoobi N, Ghasempour HR (2017) MgBr2 supported on Fe3O4@SiO2~urea nanoparticle: an efficient catalyst for ortho-formylation of phenols and oxidation of benzylic alcohols. Appl Organomet Chem 32:1–12. https://doi.org/10.1002/aoc.4006

ASTM (2017) ASTM D664–17 standard test method for acid number of petroleum product by potentiometric titration. West Conshohocken, PA: ASTM International

Xu Z et al (2019) Pentaerythritol rosin ester as an environmentally friendly multifunctional additive in vegetable oil-based lubricant. Tribol Int 135:213–218. https://doi.org/10.1016/j.triboint.2019.02.038

Nagendramma P (2011) Study of pentaerythritol tetraoleate ester as industrial gear oil. Lubr Sci 23(8):355–362. https://doi.org/10.1002/ls.161

Padmaja KV et al (2012) 10-Undecenoic acid-based polyol esters as potential lubricant base stocks. Ind Crop Prod 35(1):237–240. https://doi.org/10.1016/j.indcrop.2011.07.005

Zhu L et al (2016) A novel phosphate ionic liquid plays dual role in synthetic ester oil: From synthetic catalyst to anti-wear additive. Tribol Int 97:192–199. https://doi.org/10.1016/j.triboint.2015.12.047

Funding

This work is supported by the National Natural Science Foundation of China (21975135), Natural Science Foundation of Tianjin Municipal Science and Technology Commission (21JCZDJC00100), and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Contributions

Heng Li: Investigation, Writing – original draft. Song Gao: Methodology, Investigation, Writing – original draft. Wei-Hang Xie: Investigation, Writing – original draft. Liang-Nian He: Project administration, Supervision, Writing – review and editing. Hong-Ru Li: Methodology, Writing – review and editing.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Gao, S., Xie, WH. et al. Brønsted acid-functionalized silica-coated magnetic catalyst for the preparation of polyol ricinoleates. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03791-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03791-z