Abstract

As a fossil fuel substitute, bio-jet fuel derived from inedible oilseed crops has the potential to improve energy security, decrease carbon footprint, and promote agricultural economy and social development. The efficient production of bio-jet fuels depends on the identification and characterization of eco-friendly and sustainable feedstocks. Brassica carinata (Arun Braun) cultivars are among the most significant industrial oilseeds that can be utilized as alternative feedstocks in the aviation industry. The study thoroughly evaluated four non-food Brassica carinata cultivars that are indigenous to Ethiopia to determine their suitability as substitute feedstocks for the production of bio-jet fuel. The effects of solvent extraction parameters were studied using response surface methodology with Box-Behnken design in an isothermal batch reactor. Physicochemical characterization, fatty acids profiling, ultimate analysis, analysis of metals and phosphorus concentration, Fourier-transform infrared spectroscopy characterization, and calorific value analyses were performed to characterize the properties of oils. Accordingly, oil yields ranged from 35.93 to 45.25%. Erucic acid (EA) was the most predominant fatty acid in all oils, accounting for 42–50%, of Derash and Yellow Dodolla oils, respectively, making Yellow Dodolla oil a super-high erucic acid oil. In comparison to the other oils, Yellow Dodolla was observed to be the least oxygenated oil, with a 7.80% oxygen content and oxygen to carbon ratio of 0.07, which may enable it to consume a very limited amount of hydrogen gas during hydrodeoxygenation in bio-jet fuel production. It was determined that, except for calcium and phosphorous levels in Tesfa, the concentrations of the metals and phosphorous were very small. Alkanes, alkenes, carboxylic acids, esters, alcohols, aromatics, and olefins were among the most significant and main functional groups identified. Our extraction and characterization results revealed that the Brassica carinata cultivars have very high oil contents, better physicochemical properties, excellent fatty acid profiles, and very low concentrations of heteroatoms (nitrogen, sulfur), metals and phosphorous concentrations, and very low level of oxygen to carbon ratios, making the oils, notably Yellow Dodolla oil, very high quality and promising alternative feedstocks for upgrading of the oils into bio-jet fuels through hydroprocessing pathway.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The aviation industry contributes significantly to the global economy, providing approximately 57 million employment and USD 2.2 trillion in GDP [1]. Presently, it is projected that the worldwide demand for biofuels would increase by 41 billion liters, or 28%, between 2021 and 2026. One fifth of this demand surge is due to a return to pre-COVID-19 consumption levels [2]. However, despite a large rise in production (i.e., from just 7 million liters in 2018), commercial volumes of bio-jet fuel are still rather low (i.e., roughly 140 million liters/year (2019)), which is less than 1% of fuel currently used by the sector. This is associated with several factors, including the sluggish pace of technological advancement and the high price of these fuels [3].

Bio-aviation fuel (also referred to as bio-jet fuel, renewable jet fuel, or aviation biofuel) a kind of biofuel for the air transport industry, is identified as a short- to medium-term strategy for reducing the sector’s overall GHG emissions [1]. Bio-aviation fuel is a biomass-derived synthetic paraffinic kerosene (SPK) that is blended with traditionally petroleum-derived jet fuel [4]. Due to their sustainability and environmental friendliness, these fuels are regarded as a viable alternative to conventional jet fuels [4]. The significant potential for sustainable fuels to decrease the industry’s influence on the environment stems from their potential to cut CO2 emissions by up to 80% over their lifecycle [5]. This has a great contribution to the industry, reaching a 50% decrease in CO2 emissions by 2050 compared to 2005 levels [6]. By eliminating oxygen from biomass, which results in the production of bio-based oxygen-free hydrocarbons, the detrimental impact of oxygen-containing biofuels may be reduced. There are various techniques with varying degrees of complexities that may be used to remove all or some oxygen from bio-based feedstocks for the production of biofuels [7]. The resultant oxygen-free hydrocarbons are compatible with fossil fuels.

The composition of vegetable oil is a key parameter for determining its appropriateness as a feedstock. The composition of the oil, in turn, affects the characteristics of the biofuel produced [8]. Because of the possible benefits such as high energy density, low moisture content, and high relative stability, vegetable oils are promising feedstocks for the production of bio-jet fuels. Moreover, they may also be converted into saturated, unbranched, and long-chain hydrocarbon fuels [9]; however, high viscosity and high freezing point are some of the undesirable qualities of vegetable oils for use as jet fuel [10, 11]. In the production of bio-jet fuels, the first crucial stage is the recovery of high-quality vegetable oil from the oilseeds [12, 13]; accordingly, it is vital to investigate an economical extraction technique for effectively obtaining the necessary oils [14]. The Brassicaceae family comprises one of the most commercially significant plant groups [15]. Brassica carinata (A. Braun) is a plant species under the Brassicaceae family that evolved in the central highlands of Ethiopia at elevations ranging from 2200 to 2800 m above sea level, and it is a high yielding, disease, and pest-resistant oilseed crop [16].

In Ethiopia, the main growing regions include Arsi, Bale, Gonder, Gojam, Wello, Shewa, Sidamo, and Wellega; over the previous 5 years (CSA 2011/12 – 2015/16), 550,000–50,000 quintals were produced from a total area coverage of 30,000 to 45,000 hectares [17]. B. carinata has quite high oil contents (25–47%) [18, 19], and its oil is a non-food vegetable oil having a very long-chain fatty acid composition suitable for conversion to biofuel [20]. Furthermore, B. carinata has a high percentage of erucic acid (35–51%), making it unsuitable for human consumption [21, 22]. Erucic acid (EA) is difficult to digest and absorb in the human body. Both glucosinolates and EA are harmful to health and can induce sickness, hence regulatory organizations have set severe limits on the maximum EA concentration of oils. Researchers have widely focused on increasing the EA level in Brassicaceae oilseeds to meet commercial uses while decreasing the EA concentration to assure food safety [23].

B. carinata provides coproduct molecules with functions apart from fuel that have major potential advantages, which is known as the coproduct-driven carinata bioeconomy strategy [24]. This is the reason why B. carinata oil’s high erucic acid concentration is suitable for industrial use and important raw material for the production of commercial products such as plasticizers, detergents, surfactants, and polyesters among others [25]. Furthermore, the non-edible nature of the oil makes it an important bio-industrial crop that can be used for the production of bio-jet fuels where the 22-carbon chain of the oil may be broken down into two biofuel hydrocarbons, thereby doubling the fuel output for each erucic acid molecule [26, 27].

The existence of naturally appearing impurities in vegetable oils such as phosphorus (P), alkalis (alkali and alkaline-earth metals) (e.g., Ca, Mg, Na, K), and sulfur (S), have great impacts on the deactivation of hydrodeoxygenation catalysts [28]. The occurrence of the alkali in the catalyst deactivation because of their accumulation on the catalyst surface gives rise to blocking/poisoning of active sites. Phosphorus resulted in an even doubling of the consequence; however, they have pointed out that the occurrence of sulfur was observed to markedly increase the stability of the catalyst activity [28]. Calcium was observed to bring about deactivation in hydrogenation, hydrocracking, hydrodesulfurization, and hydrodeoxygenation processes [29].

To date, to the best of the authors’ knowledge, no previous research has critically studied the in-depth solvent extraction and characterization of the oils of four B. carinata cultivars that are indigenous to Ethiopia. Objectives of this study was to compare the various solvent extraction parameters, including temperature, solvent-to-solid ratio, time and particle size for oil yield and characterization of the oil properties of different B. carinata cultivars to determine their suitability for use as a feedstock for the production of bio-jet fuel.

2 Materials and methods

2.1 Collection and preparation of samples

Seed samples of four B. carinata cultivars (i.e., Brassica carinata “Yellow Dodolla,” Brassica carinata “Holleta-1,” Brassica carinata “Derash,” and Brassica carinata “Tesfa”) were collected from the Holetta Agricultural Research Centre in Holetta, Ethiopia. In this study, the seed feedstock particle sizes of 150–355, 355–500, and 500–710 µm were prepared and used for the experimental analysis. The local names of the cultivars (i.e., Yellow Dodolla, Holetta-1, Derash, and Tesfa) are used to elucidate them.

2.2 Design of experiments for solvent extraction and statistical analysis

Response surface methodology (RSM) with three levels Box-Behnken design (BBD) was applied to study the effects of extraction parameters (i.e., temperature, solvent-to-solid ratio, time, and particle size) on oil yield. An isothermal batch reactor (Armfield CEX Chemical Reactor) was used to extract the oil. The extraction unit was outfitted with a temperature regulator (thermostat), mixer, and rpm controller. The design parameters were temperature (25, 46.5, 68 °C), solvent-to-solid ratio (6:1, 8:1, 10:1 mL/g), time (30, 60, 90 min), and particle size (150–355, 355–500, 500–710 µm). The solvent, n-hexane, was first added to the unit, heated, and continually stirred. After reaching the required temperature, 25 g of powdered sample was introduced to the unit and left for a fixed period. Following extraction, the oilseed cake was vacuum filtered to separate the mixture of oil and solvent where the oil was then separated from the solvent using a simple distillation method. Extracted oil yields were calculated using Eq. 1.

2.3 Characterization of oils

2.3.1 Physicochemical characterization

Experiments were run in two replicates, and each of the mean ± standard deviation values was reported as numbers corrected to two decimal places. Association of Official Analytical Chemists [30] standards were applied to characterize the properties of the samples.

Physical properties

Approximately 5 g of an oil sample was used to measure the total moisture content (%) by oven drying method according to the methods of Association of Official Analytical Chemists (AOAC 925.10) in an oven (D-6450 Hanau, Heraeus Instruments, Germany). The determination of pH was based on AOAC 960.19 method in a pH meter (Jenway 3505, Fisher Scientific, UK). Two drops of an oil sample were used to measure the refractive index at 20 °C using AOAC 921.08 in a refractometer (RFM960, Bellingham Stanley). The pycnometer method as described in AOAC 920.212 method was applied to determine the density and specific gravity of samples at 15 °C using a 50 cm3 standard volumetric pycnometer. The kinematic viscosity (mm2 s−1) was carried out following American Society for Testing and Materials, ASTM standard D445 using a Vibro viscometer (SV10, A & D Company Ltd, Tokyo, Japan). Kinematic viscosities were measured at three different temperatures (i.e., 25, 40, and 100 °C) to observe the effect of temperature.

Chemical properties

Approximately 10 g of a sample was applied to measure the total ash content following method AOAC 923.03 using an electrically heated Nabertherm furnace (L5/C6, Nabertherm, Gesellschaft mit beschränkter Haftung, GmbH, Germany). Hanus method as defined in AOAC 920.158 method was used to determine the iodine value (IV) of the oils. For the titration, approximately 0.25 g of an oil sample was used. According to the International Organization for Standardisation, ISO 660:2009, ca. 20 g of a sample was used to measure the acid value (AV). The methods AOAC 965.33 and AOAC 920.160 were used to estimate the peroxide value (PV) and saponification value (SV), respectively. Approximately, 5 g of samples were used for each of these analyses.

2.3.2 Fatty acid profiling

AOAC 996.06 was applied for the qualitative and quantitative determination of fatty acid methyl esters (FAMEs) of Brassica carinata (B. carinata) oils in an Agilent Technologies’ gas chromatography (7820A GC) equipped with a mass selective detector (HP 5977), and a DB-5MS capillary column (60 m, 0.25 mm ID., 1.4 µm thickness). Helium was employed as the carrier gas, with a constant flow rate of 1 mL/min, and a 1µL injection volume. The injector and detector temperatures were 250 °C and 280 °C, respectively. The oven temperature was set to 50 °C (isothermal for 4 min), then increased to 280 °C at 30 °C/min for 10 min, isothermal at 280 °C, and the mass scan range was set at 29–800 amu [30].

2.3.3 Ultimate analysis

DIN standards, Deutsches Institut für Normung (German Institute for Standardisation) was employed in the ultimate analysis. DIN 51,732 (2014–07), DIN 51,732 mod. (2014–07), DIN “Europaische Norm” (European standard) EN 14,582 (2016–12), and DIN 51,733 (2016–04), were used for CH, N, S, and O, respectively. Analysis for CHN, S, and O was performed using a CHNS analyzer (Vario EL Cube, Elementar, Germany), bomb calorimeter (C6000, IKA-Werke, Germany), and by difference [i.e., 100 − (C + H + N + S + ash content)], respectively. For CHN and S analyses, approximately 150 mg and 0.5 g of each sample were employed, respectively.

2.3.4 Analysis of metals and phosphorous contents

Concentrations of the various metals (i.e., Na, K, Ca, Mg, Al, Fe, Zn, Ni) and P were determined by DIN ISO 22036:2009–06. Aqua regia flux digestion (DIN EN 13,657 (2003–01)) in a microwave digester (ETHOS. Lab, Germany), followed by inductively coupled-plasma optical emission spectroscopy (ICP-OES) (Vista MPX, Varian Deutschland GmbH, Germany) was used. Approximately 0.3 g of each sample was used for analysis.

2.3.5 FT-IR characterization

An FT-IR Spectrometer (Spectrum 100, PerkinElmer, UK) was used for the qualitative characterization of functional groups, and Spectrum software (Version 6.1.1.0045) was employed for instrument monitoring and data acquisition. The FT-IR was outfitted with a deuterated triglycine sulfate (DTGS) detector that scanned at a resolution of 4 cm−1 over a frequency range of 4000 to 550 cm−1. A single drop of the sample was applied to the diamond surface, a crystal with a high refractive index.

2.3.6 Measurement of calorific value

Samples of known moisture and ash contents were used for the determination of gross calorific value (GCV) and net calorific value (NCV). The determination of these calorific values was performed using DIN 51,900–1 (2000–04 + Correction 2004–02) (C6000, IKA-Werke GmbH & Co. KG, Staufen, Germany) in a bomb calorimeter. Measurements were carried out in two replicate experiments using 0.5 g of each sample.

3 Results and discussion

Storage of seeds of B. carinata cultivars, statistical data analysis for solvent extraction, and characterization of the oils are the three main components of this section.

3.1 Storage of B. carinata cultivars

In the present work, since the mean moisture and oil contents were determined, based on previously reported seed storage potential factors, the moisture and oil contents can indicate how long the seeds of the cultivars may be stored. Several variables affect seed quality during storage, including environmental conditions at the time of seed production, pests, diseases, oil content, moisture content, mechanical damage to seed during processing, packaging materials, pesticides, air temperature, and relative air humidity [31]. However, during storage, seeds also age primarily through autoxidation. This autoxidation happens as a result of the peroxidation of polyunsaturated fatty acids (FA), which produce free radicals and reactive oxygen species (ROS). Changes in the concentrations of saturated and unsaturated fatty acids were attributable mostly to oxidative degradation during storage. Due to the lack of double bonds in their structure, the saturated fatty acids content was only marginally impacted. Changes in the unsaturated fatty acid proportion, however, were more apparent [32].

In addition, due to the direct relationship between free fatty acid level and seed vigor and viability, its measurement is a valuable qualitative indication of seed degradation during storage [33]. Seeds with high oil content could be kept for 4–5 years at temperatures ranging from 0 to 35 °C, with an average of 18 °C. The recommended moisture content of seeds with high oil content was less than 5% moisture content [34]. The cultivars of the current study are very high oil content oilseed crops and their mean moisture contents were found to be ca. 5%. Therefore, because of the various potential seed storage factors, especially aging and improper storage, the quality of bio-jet fuel produced from these cultivars may be significantly impacted.

3.2 Statistical data analysis for solvent extraction

3.2.1 Model fitting and ANOVA analysis

Mathematical models were fitted to the observed data to generate regression models, and second-order polynomial equations (Table 1) were presented for each of the oil yields. For the oil yields of Yellow Dodolla, Holetta-1, Derash, and Tesfa, the coefficients of determination (R2) were determined to be 0.9522, 0.9756, 0.9551, and 0.9589, respectively, with a non-significant lack of fit at p > 0.05. The model F-value and the lack of fit F-value were used to determine the relevance of each of the coefficient terms, probability value (p value).

3.2.2 Diagnostic analysis for model validation

Diagnostic analysis was used to check the validity and reliability of the developed models. Figures 1a, 2a, 3a, and 4a show that the normal probability plot of residuals was adequately approximated along a straight line with no sign of non-normality, showing that the normality plot of residuals fulfilled the requirement for model adequacy tests. The experimental values were well fit by the model equations (Table 1) as evidenced by the random scatter and uniform distribution of residuals (i.e., plots of residuals versus predicted values) shown in Figs. 1b, 2b, 3b, and 4b. Another significant test for determining the adequacy of predictive models is a comparison of predicted and actual values based on the coefficient of determination values (R2). Since the linear correlation plots between the predicted and experimental values were quite close to the regressed diagonal line, the values of R2 were very high. This confirmed that the goodness of fit was excellent (p < 0.0001), indicating a high level of agreement between the predicted and actual values.

3.2.3 Analysis of response surface and contour plots

For all types of oil yields, the single factor particle size (i.e., 150–355 µm) was shown to be statistically highly significant (p < 0.0001). The solvent-to-solid ratio was also shown to be significant for Yellow Dodolla (p = 0.0005), Holetta-1 (p = 0.0001), and Tesfa (p = 0.0003) oil yields. Figure 5a–d show 3D response surface plots that reveal statistically significant two-parameter interactions. Among the two-parameter interactions, the 3D surface plots of the combined effects of temperature and time (p = 0.0329) (Yellow Dodolla), particle size and time (p = 0.0247) (Holetta-1), temperature and solvent to solid ratio (p = 0.0396) (Holetta-1), particle size and time (p = 0.0303) (Derash), and temperature and time (p = 0.0238) (Tesfa) were significant factors. Table 2 shows the optimum parameters and their corresponding optimum oil yields. According to the study, further increase above the optimum values (e.g., solvent-to-solid ratios) has not brought any changes in the oil yields. This might be owing to mass transfer resistances that occurred after the optimal levels were reached. This was confirmed by a previously reported work, where higher solvent-to-solid ratios resulted in a greater concentration gradient during mass transfer within solids, leading to faster diffusion rates [35]. The combined effects of temperature and time, and particle size and time were significant. Higher temperatures and longer extraction times, increase solvent vaporization losses and reduce extraction yields [36]. The maximum and optimum oil yields were obtained at temperatures somewhat higher than room temperature (35.52–38.94℃), particle size (150–355 µm), shorter extraction times (30.00–39.38 min), and relatively lower solvent to solid ratios (8.63–9.20 mL/g). Since Soxhlet extraction is a time-consuming extraction process (6‒24 h) [37], in the current study, however, an isothermal batch reactor was employed and it was possible to drastically reduce the long Soxhlet extraction time to an extremely low extraction time (i.e., 30 min). According to the results (Table 2), very short extraction times were achieved, and maximum oil yields were obtained without reaching hexane's boiling point [38]. This confirmed that lower temperatures close to room temperatures can be applied to extract oils, and hence, the technique can also be used for the extraction of heat-sensitive compounds. Even though recovery of products by filtration is a drawback when compared to Soxhlet extraction, it is simple to use and requires no thimbles. For validation of the optimization results, experiments with the optimum parameters were carried out, and the mean ± standard deviation verification values for Yellow Dodolla, Holetta-1, Derash, and Tesfa oil yields were determined to be 45.65 ± 0.47, 35.85 ± 0.16, 44.28 ± 0.10, and 44.05 ± 03, respectively, in percentages.

3.3 Characterization of oils

3.3.1 Physicochemical characterization

Table 3 shows the characterization results of the B. carinata oils. Table 3 also includes the literature values for mustard and jatropha oils. The B. carinata oils have very low moisture contents (i.e., < 1%), and nearly the same pH values which make them less strong acid oils. The refractive index (RI) of oils is affected by molecular weight, fatty acid chain length, degree of unsaturation, and degree of conjugation [39]. The RI of B. carinata oils is higher than that of the reported values of Jatropha curcas and mustard measured at 28 °C and 25 °C, respectively. The RI of the oils is also greater than that of soybean [40] measured at 30 °C (1.459 ± 0.00). The kinematic viscosities (mm2 s−1) of the oils were determined at 25, 40, and 100 °C. At 25 °C, the oils are more viscous than those from jatropha and mustard, while the temperature of mustard was not specified. At 40 °C, the kinematic viscosities of Holetta-1 and Derash were very close to the kinematic viscosity of B. carinata oil (61.85 mm2 s−1) [41]; however, Yellow Dodolla was found to be slightly more viscous than this reported value and Tesfa is the least viscous one compared to the reported value of B. carinata oil. On the other hand, the kinematic viscosities of Holetta-1 and Tesfa were close to the kinematic viscosity of B. carinata oil (55.07 mm2 s−1) [42]; however, Yellow Dodolla and Derash were slightly more viscous than these reported values.

The higher level of unsaturation from monounsaturated fatty acids, which will be addressed in the following sections, may be the reason for the B. carinata oils’ higher viscosities, especially, that of Yellow Dodolla. The oils have a little lower density than jatropha but a slightly higher density than mustard. The iodine value (IV) of the oils, an indication of the degree of unsaturation, may be primarily derived from the erucic acid and is much lower than soybean [40] (127.55 ± 0.74 g I2/ 100 g), but much higher than the different mustard oilseed varieties such as BARI Sarisha-15, BARI Sarisha-16, and BARI Sarisha-17 whose IV are 72.50, 70.60, and 73.44, respectively, [45]. Although lower than the Mustard oil [44], the IV of the oils is in good accord with that of jatropha. The IV of the oils is slightly lower than that of B. carinata (111.7 g I2/ 100 g) and Brassica napus (B. napus) (100.1 g I2/ 100 g) [46], but much lower than that of B. juncea (125.3 ± 0.32 g I2/100 g) [47]. The B. carinata oils have also very low ash levels, indicating that the oils’ inorganic content is quite low, and this can be related to the lower metals’ concentrations. Except for Tesfa oil [43], the oils’ acid values, which is the susceptibility to rancidity for higher values as free fatty acids, are identical to that of Mustard [44] but lower than that of jatropha (Table 3), mustard (3.82 ± 0.10 mg KOH/g oil) [48], and B. juncea oils (3.90 ± 0.32 KOH/g) [47]. The peroxide values (PV) of Holetta-1 and Tesfa are much higher than those of soybean (2.1 ± 0.11 meq. O2/kg oil) [40], jatropha, and mustard oils [44]. The higher acidic and peroxide values of Tesfa may be due to the possible oxidation of the oil. The reported saponification values (SV) of B. carinata (177.60 mg KOH/g) and B. napus (190.95 mg KOH/g) [46] are higher than that of the experimental oils; however, the SV of B. carinata are much lower when compared to that of soybean (225.56 ± 0.42 mg KOH/g) [40]. The B. carinata oils have high-quality physicochemical properties which enable them to be applied in the production of bio-aviation fuels.

3.3.2 Fatty acid profiling

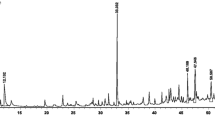

The characteristics of vegetable oils, notably fatty acid profiles (FAP), are affected by oilseed species, oil extraction processes, and processing conditions [9]. Fatty acids may impact the properties of vegetable oil, such as viscosity, oxidative stability, boiling point, and combustion energy; consequently, vegetable oil with a high FAP can be readily converted into a suitable hydrocarbon fuel at a low cost and with high efficiency [49, 50]. Fatty acid profiles of the B. carinata oils (i.e., Yellow Dodolla, Holetta-1, Derash, and Tesfa) are shown in Tables 4, 5, 6, and 7, respectively. The mass spectrum of the various fatty acids (FA) illustrated in Fig. 6a–d showed narrow elution times, but the separation was adequate to avoid coelution.

Based on the qualitative analysis of the FA, carbon lengths of C16:0, C18:0, C18:1, C18:2, C18:3, C20:1, and C22:1 are found in the B. carinata oils (Tables 4, 5, 6, and 7); however, carbon lengths of 16:0, 18:0, 18:1, 18:2 in algal [51], 16:0, 18:0, 18:1, 18:2, 18:3 in Jatropha curcas [52], and 16:0, 18:0, 18:1cis-9, 18:1, 18:2, 18:3 in Castor oils [53] are found. Palmitic (C16:0, 51%) [51], oleic (C18:1, 43%) [52], ricinoleic (C18:1, 87.7%) [53], and erucic acids (C22:1, 42.00–49.69%) are the highest concentrations of fatty acids found in algal, jatropha, castor, and the experimental B. carinata oils, respectively. The total saturated fatty acid (SFA) content of the B. carinata oils (3.01–5.66%) is nearly the same as the SFA of Moroccan castor seed oil (5.2%) [54]. In addition, the total unsaturated fatty acid (UFA) content of this seed oil is also approximately the same as the UFA (94.34–96.99%) of the B. carinata oils. The presence of erucic acid in the B. carinata oils, therefore, makes them industrially significant feedstocks where these significant fatty acids are not common in many of the edible and non-edible oils.

Among all the different varieties and species of the Brassicaceae family, there are variations in the concentrations of fatty acids. This is mainly due to the intended purposes of the breeding programs. B. carinata, for example, are mostly developed either to have no erucic acid which will be used for human consumption, or developed to have high erucic acid or linoleic acid contents which will be applied in the biofuel processing industries [55, 56]. The erucic acid content of the B. carinata oils is compared with other previously reported B. carinata cultivars. As a result, the oils, and Yellow Dodolla oil, in particular, had somewhat greater erucic acid contents than what was reported (40.7–42.9%) by [57]. In the present study, erucic acid, eluted after 35 min, was the most prevalent FA in all oils, accounting for the lowest value (42.00%) from Derash to the highest level (49.69%) from Yellow Dodolla, making Yellow Dodolla a super-high erucic acid oil. After erucic acid, the next most dominant FA in Yellow Dodolla, Holetta-1, Derash, and Tesfa oils were linoleic (24.89%), linoleic (25.47%), linolelaidic (28.74%), and oleic (27.44%), respectively. The overall quantity of unsaturated (mono and poly) FA in each of the oils outnumbers the total number of saturated FA. Yellow Dodolla has the greatest percentage (96.99%) of total unsaturated FA (UFA) with > 61% coming from total monounsaturated FA (MUFA), primarily, from erucic acid.

Since Yellow Dodolla is slightly more viscous at 25 and 40 °C than the other oils, this feature could be attributed to the maximum level of unsaturation, and hence to the lengthy carbon chains and big molecules containing oxygen atoms. In comparison to the other oils, this oil has the lowest total saturated FA content (SFA) (3.01%), which is even lower than the low saturated fatty acids (≤ 6%) found in other B. carinata oils [58]. Yellow Dodolla’s combined qualities (i.e., lowest total SFA and highest total UFA) make it a suitable feedstock for the production of bio-jet fuels and biochemicals. Figures 7 and 8 indicate a comparison of compositions, and the degrees of saturation and unsaturation of the various FA, respectively. The highest UFA and lowest SFA levels of the oils, especially Yellow Dodolla, have a wide range of practical applications. This is backed up by the following previously reported work. Because of the highly reactive properties of B. carinata oils UFA, they can easily form cycloparaffin and aromatic compounds, and their larger molecular weights resulted in more hydrocarbon fuel products and chemicals when compared to vegetable oils with longer 18-carbon chains, such as soybean, canola, or jatropha oils [24]. In each of the experimental oils, total monounsaturated fatty acid (MUFA) content > total polyunsaturated fatty acid (PUFA) content > total SFA content. Table 8 shows a comparison of saturated, unsaturated, total mono- and polyunsaturated FA, as well as their important ratios. Yellow Dodolla is indeed the most prominent cultivar among the four B. carinata cultivars due to its superior fatty acid profile for the production of bio-jet fuel.

3.3.3 Ultimate analysis

Results (Table 9) of the concentrations of C, H, N, S, O, H/C, and O/C atomic ratios indicated that each of these elements and atomic ratios differed according to C (77.6–79.8%), H (12.0–12.3%), N (0.01–0.14%), S (0.004%), O (7.80–10.30%), H/C (1.84–1.86), and O/C (0.07–0.10) (Fig. 9). These results were compared to edible and non-edible vegetable oils, and bio-oil published in the literature. There were no significant variations in carbon and hydrogen concentrations when compared to the reported values of the edible oil, canola oil [59, 60]; however, the concentrations of each of N, S, and O were smaller than that of canola oil [59, 60], but higher than that of refined rapeseed oil (0.0003%) [60]. Additionally, the oils’ C, H, O, and H/C ratios were compared to that of pongamia oil, whose values are presented in [61].

Although pongamia oil has a little higher oxygen concentration than the B. carinata oils, its C, H, and H/C ratios are in good agreement with that of these oils. As can be seen in Table 9, the ultimate analysis results of the oils are also compared to the literature values of B. carinata [62] and biomass-pyrolysis oils [63], where except for the nitrogen content of the B. carinata oil, which is slightly higher than that of the experimental oils, the B. carinata and these experimental oils have nearly the same C, H, and O contents. This is not the case with biomass pyrolysis oil, though. The C and H concentrations of the experimental oils are significantly greater than those of the pyrolysis oil, and their oxygen level is substantially smaller. The oxygen concentration of the oils is similarly quite low when compared to liquid fuels such as bioethanol (35%), and FAME biodiesel (11%) [64]. Based on the foregoing discussion, B. carinata oils have excellent ultimate analysis results with greater H/C and lower O/C atomic ratios, as well as very low N and S levels, all of which make the oils very useful feedstocks.

Comparisons were also performed among the B. carinata oils, where significant variations were not observed in their C, H, S, N, and H/C atomic ratio results except for the value of N, which is slightly greater in Yellow Dodolla oil. Although the N content of Yellow Dodolla appears to be slightly greater when compared to the other oils, its value is still lower than that of the edible canola oil [59, 60]. The oils have very small and identical S contents; however, the solvent-extracted oilseed meals of these cultivars have higher S concentrations, which will be further investigated in our upcoming work. Even though the oils have lower O concentrations, the concentration of O in Yellow Dodolla is the lowest. The B. carinata oils, in general, offer excellent ultimate analysis results, especially, their lower O levels require reduced hydrogen gas consumption during upgrading in the deoxygenation of the oils.

3.3.4 Analysis of metals and phosphorous contents

Table 10 shows the Inductively coupled plasma optical emission spectroscopy (ICP-OES) results of metals and phosphorous concentrations. These results are also shown in Fig. 10. Regardless of their concentrations, all these elements were found in all of the B. carinata oils. The concentrations of the elements Na, K, Ca, Mg, Al, Fe, Zn, Ni, and P were compared to previously reported values of edible NRO (neat rapeseed oil, fresh oil after extraction) [28], non-edible (e.g., B. carinata and waste rapeseed oil (WRO)) and used cooking oils (UCO) (Table 10). Na levels in the B. carinata oils are less than those in NRO, but they are practically identical to those in Waste Rapeseed Oil (WRO) (4.5 mg/kg) [28]. Except for Tesfa oil, the K content in the B. carinata oils is lower than that found in NRO but almost equivalent to that of WRO (4.00 mg/kg) [28]. The oils have relatively higher Ca contents than that of B. carinata oil and UCO, although the concentrations are quite low compared to the value in NRO. The Mg concentration is comparatively larger than that of WRO (0.91 mg/kg) [28], B. carinata, and UCO [65].

The concentrations of Al in Yellow Dodolla, Holetta-1, and Derash are similar to those observed in B. carinata and UCO (Table 10), with just minor differences. The Ni content in the oils is quite low and is comparable to that of the B. carinata and UCO (Table 10). The concentration of Fe in the oils did not vary significantly, but it is somewhat higher than the levels reported for these B. carinata and UCO. Although Yellow Dodolla has a relatively higher Zn content, Zn was not detected in Tesfa. Even though the concentration of P in all the B. carinata oils, except for its value in Tesfa, was found to be close to the reported P level in a B. carinata oil (59 mg/kg) [55], and WRO (37.90 mg/kg) [28], its concentration was much smaller than what was reported for NRO. In general, the lower concentrations of the metals of the B. carinata oils may be correlated to the lower total ash contents of the oils discussed in the previous sections.

3.3.5 FT-IR characterization

Since FT-IR is a versatile analytical approach for the evaluation of a broad variety of materials, particularly for identifying unknown compounds [66], it provides details on unique chemical bonds and functional groups [67]. Based on research performed on hydrocarbons, the physical and chemical characteristics are highly reliant on the functional groups, and the spectrum-functional group interactions offer the theoretical background for employing mid-IR spectra to determine fuel qualities [68]. Vegetable oils are not stable, particularly in the presence of oxygen, heat, light, and humidity, and experience a variety of chemical reactions of degradation, causing their conservation difficult, making the production and storage methods key stages in ensuring their quality [69]. As a result, this qualitative analysis may be used to estimate the relative purity of the oils.

Figures 11, 12, 13, and 14 show the FT-IR spectra of the B. carinata oils. Strong, medium, and weak infrared bands have been observed in all types of B. carinata oils, with the majority of the peaks being quite sharp (i.e., not broad) and quite strong, suggesting that the oil samples are exceptionally pure. The presence of an alkene was verified by the presence of a C-H stretching vibration, which is attributed to the medium peaks at 3008 cm−1. The existence of an asymmetrical –CH2 stretching vibration [70] indicated the presence of an alkane, which gives off a very strong peak at 2922 cm−1. Likewise, the presence of a symmetrical –CH2 stretching vibration, which is responsible for the strong and sharp peaks at 2853 cm−1, showed the presence of an alkane [71]. Because of the presence of carboxylic acids [72], the oils show a peak at 1744 cm−1, confirming quite sharp and quite strong vibration of –C = O bonds. The C = C stretching vibration that attributes to the variable peak at 1654 cm−1 shows the presence of an alkene. The presence of C–C stretching vibration that leads to a peak at 1463 cm−1 confirmed the presence of an aromatic ring.

The other absorption bands lower than 1463 cm−1 (Figs. 11, 12, 13, 14) are also discussed as follows: except for the peaks at 1160, 1099, and 721 cm−1, all other peaks are not strong. There is an aromatic ring (C–C stretching) in 1418 cm−1, a methyl (C-H symmetrical bending) in 1377 cm−1 [73], an α, β-unsaturated ester (C–O stretching) in ca. 1236 cm−1, a tertiary alcohol (C–O stretching) in ca. 1160 cm−1, an ester (C–O stretching) in the peaks 1119 cm−1 and ca. 1099 cm−1 [71]. Furthermore, the appearance of C–H bending vibration at a peak of 967 cm−1 confirms the presence of trans-olefins produced from mono- or polyunsaturated groups [74]; however, these olefins are not observed in Yellow Dodolla oil. There is a –(CH2)n rocking vibration at a peak of 721 cm−1 [70]. There are intricate patterns of absorptions that are peculiar to the chemical compounds or molecules in the so-called fingerprint region, which lies within the wavelength range of about 1500–500 cm−1 [75]. In the current study, the differences in the patterns of B. carinata oils are relatively insignificant outside of this region (i.e., bands above 721 cm−1); thus, they share the same functional groups and identical chemical compositions; yet, there are slight variations in the patterns of the oils in the fingerprint region (Figs. 11, 12, 13, 14), suggesting that the oils have different properties.

3.3.6 Analysis of calorific values

The gross calorific values (GCVs) of the oils were determined to vary from 39.97 ± 0.32 (Holetta-1) to 40.08 ± 0.24 MJ/kg (Yellow Dodolla), and the net calorific values (NCV) of the oils were found to be closely identical, 37.45 MJ/kg. The GCV and NCV of the oils were compared to edible and non-edible vegetable oils, including those from B. napus, B. carinata, and Jatropha curcas oils. In light of this, the GCV of the present B. carinata oils is nearly comparable to that of B. napus (39.55 MJ/kg), B. carinata (39.93 MJ/kg) [46], and Jatropha curcas (38.8 MJ/kg) [76], although slightly higher than that of Pongamia oil (35.18 ± 0.12 MJ/kg) [61]. Similarly, the NCV of the B. carinata oils is nearly identical to that of B. carinata (37.39 MJ/kg) and B. napus (37.01 MJ/kg) [46]. In general, the higher calorific values of the oils mentioned thus far make them suitable alternative feedstocks for the production of bio-aviation fuels.

4 Conclusions

Response surface methodology (RSM) with three levels Box-Behnken design (BBD) in an isothermal batch reactor was applied for extraction of B. carinata oils. Powdered samples (150–710 µm) were heated and continuously stirred in n-hexane. Both heat energy and continuous mixing were applied, and hence, the potential mass transfer resistances (i.e., solid–solid, solid–liquid, and liquid–liquid) might have been greatly reduced and enhanced the rate of extraction. Accordingly, very short extraction times (30.00–39.38 min), and lower temperatures higher than room temperature (35.52–38.94 °C) were achieved to recover the maximum and optimum oil yields (35.93–45.25%) using particle sizes of 150–355 µm without reaching hexane's boiling point (ca. 69 °C). The application of this extraction technique can result in the following significant benefits: (a) it is not necessary to raise the boiling point of the solvent; (b) it reduces the amount of time required to boil, condense, and reach the surface of the sample; (c) it avoids the potential solvent loss while boiling; (d) there is no evaporation, no solvent loss, and hence, no potential reduction in extraction yield; (e) it saves energy for boiling; (f) it may also be applied for the extraction of heat-sensitive components at temperatures slightly higher than room temperature. Moreover, it is also simple to use and requires no thimbles even though recovery of products by vacuum filtration is a drawback when compared to the Soxhlet extraction method. Characterization results confirmed that the oils’ better physicochemical properties, excellent fatty acid profiles (such as their high erucic acid contents, 42–50%), ultimate analysis (such as their low heteroatom contents and O/C ratio), lower metals and phosphorous concentrations, FT-IR characterization (which demonstrates the presence of various functional groups in the oils), and high gross and net calorific values make them promising alternatives to existing feedstocks in the aviation industry. These findings suggested that the oils, in particular Yellow Dodolla oil, a super-high erucic acid oil, would be used in our subsequent investigation of a hydroprocessing pathway for the production of bio-jet fuel because of their ideal properties. Yellow Dodolla is among the most significant cultivated non-food B. carinata oilseed crops introduced in 1986 by the Holetta Agricultural Research Centre in Holetta, Ethiopia. Normal hexane was used for oil extraction, and it was determined to be a suitable solvent to obtain maximum oil yields; however, iso-propanol was also tested for extraction, and it resulted in very low oil yields. Furthermore, higher yields of viscous and semi-solid-like components were extracted. Depending on the need (i.e., maximum oil content or the viscous and semi-solid-like components), we propose that future studies extract and evaluate these iso-propanol soluble components for they may be very valuable feedstocks for the production of significant industrial products.

Data availability

Data and materials will be made available upon request to the corresponding author.

References

Doliente SS, Narayan A, Tapia JFD, Samsatli NJ, Zhao Y, Samsatli S (2020) Bio-aviation fuel: a comprehensive review and analysis of the supply chain components. Front Energy Res 8:1–38

IEA, Renewables 2021, Int Energy Agency Publ Int 167, 2021

IRENA, Reaching zero with renewables: bio-jet fuels. Abu Dhabi, 2021

Yang J, Xin Z, Corscadden K, Niu H (2019) An overview on performance characteristics of bio-jet fuels. Fuel 237(1):916–936

IATA (2021) Carbon offsetting for international aviation, 77th IATA Annual General Meeting, Boston, USA, pp 1–4

Pavlenko N, Kharina A (2018) Policy and environmental implications of using HEFA for aviation. Int Counc Clean Transp 9:1–9

Bezergianni S, Dagonikou V, Sklari S (2016) The suspending role of H2O and CO on catalytic hydrotreatment of gas-oil; myth or reality? Fuel Process Technol 144:20–26

Gui MM, Lee KT, Bhatia S (2008) Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 33(11):1646–1653

Ionescu G (2016) Transportation and the environment: assessments and sustainability, 1st edn. Apple Academic Press, New Jersey

Rao TVM, Clavero MM, Makkee M (2010) Effective gasoline production strategies by catalytic cracking of rapeseed vegetable oil in refinery conditions. Chemsuschem 3:807–810

Demirbas AH, Demirbas I (2007) Importance of rural bioenergy for developing countries. Energy Convers Manag 48(2386–2398):2007

Pinzi S, Gandía LM, Arzamendi G, Ruiz JJ, Dorado MP (2011) Influence of vegetable oils fatty acid composition on reaction temperature and glycerides conversion to biodiesel during transesterification. Bioresour Technol 102(2):1044–1050

Bezergianni S, Voutetakis S, Kalogianni A (2009) Catalytic hydrocracking of fresh and used cooking oil. Ind Eng Chem Res 48(18):8402–8406

Zhao X, Wei L, Julson J (2014) First stage of bio-jet fuel production: non-food sunflower oil extraction using cold press method. AIMS Energy 2(2):193–209

Oecd T (2016) Brassica crops (Brassica species). In: Safety assessment of transgenic organisms in the environment, 5. OECD Publishing, Paris, pp 151–291

Getinet A, Rakow G, Raney JP, Downey RK (1994) Development of zero erucic acid Ethiopian mustard through an interspecific cross with zero erucic acid Oriental mustard. Can J plant Sci 74(4):793–795

Tesfaye M, Weyessa B, Debele T (2019) Breeding for Yellow Seeded Ethiopian Mustard (Brassica Carinata) with high seed yield and oil content at Holetta Agricultural Research Center, Ethiopia. Int J Res Stud Agric Sci 5(3):1–7

Xin H, Theodoridou K, Yu P (2014) Implication of modified molecular structure of lipid through heat-related process to fatty acids supply in Brassica carinata seed. Ind Crops Prod 62:204–211

Taylor DC, Falk KC, Palmer CD, Hammerlindl J, Mietkiewska VBE, Jadhav A, Marillia E-F, Francis T, Hoffman TE, Giblin M, Katavic V, Keller WA (2010) Brassica carinata – a new molecular farming platform for delivering bio-industrial oil feedstocks: case studies of genetic modifications to improve very long-chain fatty acid and oil content in seeds. Biofuels Bioprod Biorefining 4:538–561

Marillia E-F, Francis T, Falk KC, Smith M, Taylor DC (2014) Palliser’s promise: Brassica carinata, an emerging western Canadian crop for delivery of new bio-industrial oil feedstocks. Biocatal Agric Biotechnol 3(1):65–74

Alemayehu N, Becker HC (2001) Variation and inheritance of erucic acid content in Brassica carinata germplasm collections from Ethiopia. Plant Breed 120(4):331–335

Getinet A, Rakow G, Raney JP, Downey RK (1997) The inheritance of erucic acid content in Ethiopian mustard. Can J Plant Sci 77(1):33–41

Wang P, Xiong X, Zhang X, Wu G, Liu F (2022) A review of erucic acid production in Brassicaceae oilseeds: progress and prospects for the genetic engineering of high and low-erucic acid rapeseeds (Brassica napus). Front Plant Sci 13:1–13

George S, Seepaul R, Geller D, Dwivedi P, DiLorenzo N, Altman R, Coppola E, Miller SA, Bennett R, Johnston G, Streit L, Csonka S, Field J, Marois J, Wright D, Small IM, Philippidis GP (2021) A regional inter-disciplinary partnership focusing on the development of a carinata-centered bioeconomy. GCB Bioenergy 13(7):1018–1029

Sharafi Y, Majidi MM, Goli SAH, Rashidi F (2015) Oil content and fatty acids composition in Brassica Species. Int J Food Prop 18(10):2145–2154

Hagos R, Shaibu AS, Zhang L, Cai X, Liang J, Wu J, Lin R, Wang X (2020) Ethiopian mustard (Brassica carinata A. Braun) as an alternative energy source and sustainable crop. Sustainability 12:7492

Seepaul R, Small IM, Mulvaney MJ, George S, Leon RG, Paula-Moraes SV, Geller D, Marois JJ, Wright DL (2019) Carinata, the sustainable crop for a bio-based economy: 2018–2019 production recommendations for the southeastern United States, Univ. Florida, IFAS Ext, pp 1–12

Kubička D, Horáček J (2011) Deactivation of HDS catalysts in deoxygenation of vegetable oils. Appl Catal A Gen 394:9–17

Cable TL, Massth FE (1985) A Basic study of catalyst aging in the H-coal process. Fuel Process Technol 10(2):105–120

AOAC (2000) Oils and fats. In: AOAC International (ed.) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Gaithersburg

Singh J, Paroha S, Mishra RP (2017) Factors affecting oilseed quality during storage with special reference to soybean (Glycine max) and Niger (Guizotia abyssinica) seeds. Int J Curr Microbiol Appl Sci 6(10):2215–2226

López-Fernández MP, Moyano L, Correa MD, Vasile F, Burrieza HP, Maldonado S (2018) Deterioration of Willow seeds during storage. Sci Rep 8(1):1–11

Koskosidis A, Khah EM, Pavli OI, Vlachostergios DN (2022) Effect of storage conditions on seed quality of soybean (Glycine max L.) germplasm. AIMS Agric Food 7(2):387–402

Chai JF, Ma RY, Li LZ, Du YY (1998) Optimum moisture contents of seeds stored at ambient temperatures. Seed Sci Res 8:23–28

Cacace JE, Mazza G (2003) Mass transfer process during extraction of phenolic compounds from milled berries. J Food Eng 59(4):379–389

Lu Y, Foo LY, Wong H (1999) Sagecoumarin, a novel caffeic acid trimer from Salvia officinalis. Phytochemistry 52(6):1149–1152

Pawliszyn J (2012) Comprehensive sampling and sample preparation: analytical techniques for scientists, 1st edn. Academic Press, New York

Javed F, Ahmad SW, Rehman A, Zafar S, Malik SR (2014) Recovery of rice bran oil using solid-liquid extraction technique. J Food Process Eng 38(4):1–6

Sikorski ZZE, Kolakowska A (2002) Chemical and functional properties of food lipids, 1st edn. CRC Press, Boca Raton

Makeri MU, Karim R, Abdulkarim MS, Ghazali HM, Miskandar MS, Muhammad K (2016) Comparative analysis of the physico-chemical, thermal, and oxidative properties of winged bean and soybean oils. Int J Food Prop 19(12):2769–2787

Bouaid A, Martinez M, Aracil J (2009) Production of biodiesel from bioethanol and Brassica carinata oil: Oxidation stability study. Bioresour Technol 100(7):2234–2239

Bouaid A, Diaz Y, Martinez M, Aracil J (2005) Pilot plant studies of biodiesel production using Brassica carinata as raw material. Catal Today 106(1–4):193–196

Serouti A, Korichi M, Ben Mya O (2021) Characterization and fatty acid profile analysis of Jatropha curcas L. oil cultivated in the Algerian desert. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-02013-8

Yeasmin MS (2021) Physico-chemical properties and GC-MS analyses of indigenous rice bran and mustard seed oils and their blends. Biomed J Sci Tech Res 34(5):27167–27172

Sharif R, Paul R, Bhattacharjya D, Ahmed K (2017) Physicochemical characters of oilseeds from selected mustard genotypes. J Bangladesh Agric Univ 15(1):27–40

Toscano G, Maldini E (2007) Analysis of the physical and chemical characteristics of vegetable oils as fuel. J Agric Eng 38(3):1–39

Nwokonkwo DC, Nwaolisa SU, Odo HA (2016) Comparative physicochemical study of the oils from the seeds of Cussonia Bateri (JANSA) and Brasssica Juncea (MUSTARD). Int J Appl Chem 12(1):51–58

Fadhil AB, Abdulahad WS (2014) Transesterification of mustard (Brassica nigra) seed oil with ethanol: purification of the crude ethyl ester with activated carbon produced from de-oiled cake. Energy Convers Manag 77:495–503

Choudhary TV, Phillips CB (2011) Renewable fuels via catalytic hydrodeoxygenation. Appl Catal A Gen 397(1–2):1–12

Ma Z, Wei L, Qu W, Juson J, Zhu Q, Wang X (2013) The effect of support on the catalytic performance for bio-oil upgrading. Adv Mater Res 609:350–355

Mäki-Arvela P, Martínez-Klimov M, Murzin DY (2021) Hydroconversion of fatty acids and vegetable oils for production of jet fuels. Fuel 306:121673

Molefe M, Nkazi D, Mukaya HE (2019) Method selection for biojet and biogasoline fuel production from castor oil: a review. Energy Fuels 33(7):5918–5932

Osorio-González CS, Gómez-Falcon N, Sandoval-Salas F, Saini R, Brar SK, Ramírez AA (2020) Production of biodiesel from castor oil: a review. Energies 13(10):1–22

Gharby S, Harhar H, Bouzoubaa Z, Asdadi A, El Yadini A, Charrouf Z (2016) Chemical characterization and oxidative stability of castor oil grown in Morocco. Moroccan J Chem 4(2):279–284

Cardone M, Mazzoncini M, Menini S, Rocco V, Senatore A, Seggiani M, Vitolo S (2003) Brassica carinata as an alternative oil crop for the production of biodiesel in Italy: Agronomic evaluation, fuel production by transesterification and characterization. Biomass Bioenerg 25(6):623–636

Kumar S, Seepaul R, Mulvaney MJ, Colvin B, George S, Marois JJ, Bennett R, Leon R, Wright DL, Small IM (2020) Brassica carinata genotypes demonstrate potential as a winter biofuel crop in South East United States. Ind Crop Prod 150:1–10

Seepaul R, Marois J, Small IM, George S, Wright DL (2019) Carinata dry matter accumulation and nutrient uptake responses to nitrogen fertilization. Agron J 111(4):2038–2046

Zhao X, Wei L, Julson J (2016) Effects of cold press operating conditions on vegetable oil fatty acid profiles. Int J Green Energy 13(10):990–999

Wang H, Farooqi H, Chen J (2015) Co-hydrotreating light cycle oil-canola oil blends. Front Chem Sci Eng 9(1):64–76

Šimáček P, Kubička D, Šebor G, Pospíšil M (2010) Fuel properties of hydroprocessed rapeseed oil. Fuel 89(3):611–615

Fu J, Summers S, Morgan TJ, Turn SQ, Kusch W (2021) Fuel properties of pongamia (Milletia pinnata) seeds and pods grown in Hawaii. ACS Omega 6(13):9222–9233

Zhao X, Wei L, Cheng S, Cao Y, Julson J, Gu Z (2015) Catalytic cracking of carinata oil for hydrocarbon biofuel over fresh and regenerated Zn/Na-ZSM-5. Appl Catal A Gen 507:44–55

Ajam M, Woolard C, Viljoen CL (2013) Biomass pyrolysis oil as a renewable feedstocks for bio-jet fuel, IASH 2013, 13th International Symposium on Stability, handling and use of liquid fuels, Rhodes, Greece

Karatzos S, van Dyk JS, McMillan JD, Saddler J (2017) Drop-in biofuel production via conventional (lipid/fatty acid) and advanced (biomass) routes. Part I. Biofuels Bioprod Biorefining 11(2):344–362

Martínez S, Sánchez R, Lefevre J, Todolí JL (2020) Multielemental analysis of vegetable oils and fats by means of ICP-OES following a dilution and shot methodology. J Anal At Spectrom 35(9):1897–1909

Kowalczuk D, Pitucha M (2019) Application of FTIR method for the assessment of immobilization of active substances in the matrix of biomedical materials. Materials (Basel) 12(18):1–13

Agoston A, Schneidhofer C, Dörr N, Jakoby B (2008) A concept of an infrared sensor system for oil condition monitoring. Elektrotechnik und Informationstechnik 125(3):71–75

Wang Y, Ding Y, Wei W, Cao Y, Davidson DF, Hanson RK (2019) On estimating physical and chemical properties of hydrocarbon fuels using mid-infrared FTIR spectra and regularized linear models. Fuel 255:115715

de Souza TRP, Olenka L, Peternella WS (2020) A study of degradation in vegetable oils by exposure to sunlight using fourier transform infrared spectroscopy. Mater Sci Appl 11(10):678–691

Wu Z, Li H, Tu D (2015) Application of Fourier Transform Infrared (FT-IR) spectroscopy combined with chemometrics for analysis of rapeseed oil adulterated with refining and purificating waste cooking oil. Food Anal Methods 8(10):2581–2587

Nisar J, Razaq R, Farooq M, Iqbal M, Khan RA, Sayed M, Shah A, ur Rahman I (2017) Enhanced biodiesel production from Jatropha oil using calcined waste animal bones as catalyst. Renew Energy 101:111–119

Guillén MD, Cabo N (1997) Characterization of edible oils and lard by fourier transform infrared spectroscopy. Relationships between composition and frequency of concrete bands in the fingerprint region. J Am Oil Chem Soc 74(10):1281–1286

Lu Y, Du C, Shao Y, Zhou J (2014) Characterization of rapeseed oil using FTIR-ATR spectroscopy. J Food Sci Eng 4:244–249

Guillén MD, Cabo N (2004) Study of the effects of smoke flavourings on the oxidative stability of the lipids of pork adipose tissue by means of Fourier transform infrared spectroscopy. Meat Sci 66(3):647–657

Hu H, Yang X, Zhai F, Hu D, Liu R, Liu K, Sun Z, Dai Q (2016) Far-field nanoscale infrared spectroscopy of vibrational fingerprints of molecules with graphene plasmons. Nat Commun 7(12334):1–8

Blin J, Brunschwig C, Chapuis A, Changotade O, Sidibe SS, Noumi ES, Girard P (2013) Characteristics of vegetable oils for use as fuel in stationary diesel engines - Towards specifications for a standard in West Africa. Renew Sustain Energy Rev 22:580–597

Acknowledgements

We would like to thank the Holetta Agricultural Research Center for providing us with the cultivated B. carinata seed samples. We also would like to thank the Ethiopian Ministry of Science and Higher Education and the German Academic Exchange Service (DAAD) for funding the scholarship. The time, efforts, comments, and recommendations of the anonymous reviewers and the Editor-in-Chief, Martin Kaltschmitt, are greatly acknowledged.

Funding

The author, Zinnabu Tassew Redda, is grateful to Addis Ababa Institute of Technology, Addis Ababa University, Ethiopia (grant no. Ph.D. RG-GSR/1466/10) for the other financial and technical support provided.

Author information

Authors and Affiliations

Contributions

Zinnabu Tassew Redda was involved in the conceptualization, project administration, procuring of resources, and writing the original draft. The authors Asnakech Laß-Seyoum and Abubeker Yimam were involved in supervision and investigation. Mirko Barz was involved in the data curation. Zinnabu Tassew Redda and S Anuradha Jabasingh were involved with the formal analysis, methodology, reviewing of the data, and writing and editing.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Redda, Z.T., Laß-Seyoum, A., Yimam, A. et al. Solvent extraction and characterization of Brassica carinata oils as promising alternative feedstock for bio-jet fuel production. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03343-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03343-x