Abstract

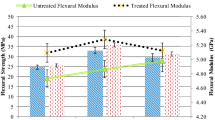

Natural fibres hold numerous advantages over synthetic ones: eco-friendly, minimal health hazards, lesser density, low cost, biodegradability, and availability. The effect of bio-oil derived from palm oil manages the macro-porosity within the composite material, guarantees adequate cohesion between fibres and matrix, and ensures proper impregnation of fibre pull. In this present work, the effect of bio-oil of palm oil in natural fillers of basalt is added in kenaf fibres in mat form reinforced with epoxy matrix hybrid biocomposite which was fabricated by hand lay-up technique. Five different sequences were followed with varying fibre filler weight fractions. The composite ratio of 1:1 was followed through reinforcement, and matrix materials were experimentally investigated by mechanical properties of tensile, flexural, and impact strength. This study also examined the impact of the impregnation process on the mechanical properties of hybrid composite. The results show an average of 5% improved mechanical properties are 28.24 MPa, 31.26 MPa in tensile and flexural strength; and 74 shore D hardness number was observed in sample A and 15 J impact energy in sample E of biocomposites due to the bio-oil impregnation process. Furthermore, bio-oil-impregnated biocomposite absorbs additional weight during the structural loading. Scanning electron microscopic (SEM) analysis was conducted to examine the surface morphology of biocomposites and identify the failure mode during mechanical testing.

Similar content being viewed by others

Data availability

Not applicable

References

Yogeshwaran S, Natrayan L, Udhayakumar Gobikrishnan, Godwin G, Yuvaraj L (2021) Effect of waste tyre particles reinforcement on mechanical properties of jute and abaca fiber-epoxy hybrid composites with pre-treatment. Mater Today Proc 37:1377–1380. https://doi.org/10.1016/j.polymdegradstab.2015.02.008

González García P, Ramírez-Aguilar R, Torres M, Franco-Urquiza Edgar A, May-Crespo J (2018) Mechanical and thermal behavior dependence on graphite and oxidized graphite content in polyester. Composites 06:56–69. https://doi.org/10.1016/j.polymer.2018.06.069

Natrayan L, Merneedi Anjibabu (2021) Experimental investigation on wear behaviour of bio-waste reinforced fusion fiber composite laminate under various conditions. Mater Today Proc 37:1486–1490

Akil HM, Omar MF, Mazuki AAM, Safiee S, Ishak ZAM, Abu Bakar A (2011) Kenaf fibre reinforced composites: A review. Mater Des 32(8–9):4107–4121. https://doi.org/10.1016/j.matdes.2011.04.008

Akil HM, Omar MF, Mazuki AAM, Safiee S, Ishak ZAM, Abu Bakar A (2011) Kenaf fibre reinforced composites: a review. Mater Des 32(8–9):4107–4121. https://doi.org/10.1016/j.matdes.2011.04.008

Sathish T, Palani K, Natrayan L, Merneedi A, De Poures MV, Singaravelu DK (2021) Synthesis and characterization of polypropylene/Ramie fiber with hemp fiber and coir fiber natural biopolymer composite for biomedical application. Int J Polym Sci 2021:1–8. https://doi.org/10.1155/2021/2462873

Thandavamoorthy R, Palanivel A (2020) Testing and evaluation of tensile and impact strength of neem/banyan fibre-reinforced hybrid composite. J Test Eval 48(1):647–655. https://doi.org/10.1520/JTE20180640

Raja T, Anand P, Sundarraj M, Karthick M, Kannappan A (2018) Failure analysis of natural fibre reinforced polymer composite leaf spring. Int J Mech Eng 9(2):686–689

Nor AFM, Hassan MZ, Rasid ZA, Aziz SAA, Sarip S, MdDaud MY (2021) Optimization on tensile properties of kenaf/multi-walled CNT hybrid composites with Box-Behnken design. Appl Compos Mater 28(3):607–632

Anjibabu Merneedi M, Natrayan L, Kaliappan S, Veeman Dhinakaran, Angalaeswari S, Srinivas Chidurala, Paramasivam Prabhu (2021) Experimental investigation on mechanical properties of carbon nanotube-reinforced epoxy composites for automobile application. J Nanomater 2021:2021 Article ID 4937059, 7

Asyraf MRM, Ishak MR, Agusril Syamsir, Nurazzi NM, Sabaruddinf FA, Shazleend SS, Norrrahim MNF, Rafidah M, Ilyasi RA, AbdRashid Mohamad Zakir, Razmanl MR (2022) Mechanical properties of oil palm fibre-reinforced polymer composites: a review. J Mater Res Technol 17:33–65

Ravichandran B, Sasikumar M (2016) Mechanical, ablative, and thermal properties of cenosphere-filled ceramic/phenolic composites. Polym Compos 37(6):1906–13. https://doi.org/10.1002/pc.23369

Yogeshwaran S, Natrayan L, Rajaraman S, Parthasarathi S, Nestro S (2021) Experimental investigation on mechanical properties of epoxy/graphene/fish scale and fermented spinach hybrid bio composite by hand lay-up technique. Mater Today Proc 37:1578–1583

Pragadish N, Kaliappan S, Subramanian M et al (2022) Optimization of cardanol oil dielectric-activated EDM process parameters in machining of silicon steel. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-02268-1

Yashas Gowda TG, Sanjay MR, Subrahmanya Bhat K, Madhu P, Senthamaraikannan P, YogeshaDuc Pham B (2018) Polymer matrix-natural fibre composites: an overview. Cogent Eng 5:1. https://doi.org/10.1080/23311916.2018.1446667

Raja T, Anand P, Karthik K, Udaya Prakash J (2021) Mechanical properties and moisture behaviour of neem/banyan fibres reinforced with polymer matrix hybrid composite. Adv Mater Process Technol https://doi.org/10.1080/2374068X.2021.1912530

Raja T, Anand P (2021) Investigations on dynamic mechanical analysis and crystalline effect of neem/banyan fibre–reinforced hybrid polymer composite. J Test Eval 50(1):20200580. https://doi.org/10.1520/JTE20200580

Veeman Dhinakaran, Varsha Shree M, Sureshkumar P, Jagadeesha T, Natrayan L, Ravichandran M, Paramasivam Prabhu (2021) Sustainable development of carbon nanocomposites: synthesis and classification for environmental remediation. J Nanomater 2021:5840645, 21 pages

Ravikumar S, et al. (2022) Multi-objective optimization of performance and emission characteristics of a CRDI diesel engine fueled with sapota methyl ester/diesel blends. Energy 123709. https://doi.org/10.1016/j.energy.2022.123709

Subramanian B, Lakshmaiya N, Ramasamy D, Devarajan Y (2022) Detailed analysis on engine operating in dual fuel mode with different energy fractions of sustainable HHO gas. Environ Prog Sustain Energy. https://doi.org/10.1002/ep.13850

Vaidya G, Munuswamy DB, Devarjan Y, Choubey G, Nagappan B, & Bibin C (2022) Detailed analysis on reducing wastage and exploiting the production process of bio-oil from in-edible and waste Sinapisarvensis Seed Oil. Chem Eng Process - Process Intensification, 108879. https://doi.org/10.1016/j.cep.2022.108879

Nalla BT, Devarajan Y, Subbiah G, Sharma DK, Krishnamurthy V, Mishra R (2022) Investigations of combustion, performance, and emission characteristics in a diesel engine fueled with Prunus domestica methyl ester and n-butanol blends. Environ Prog Sustain Energy e13811 https://doi.org/10.1002/ep.13811

Devarajan Y, Munuswamy DB, Nalla BT, Choubey G, Mishra R, Vellaiyan S (2022) Experimental analysis of Sterculia foetida biodiesel and butanol blends as a renewable and eco-friendly fuel. Ind Crops Prod 178:114612. https://doi.org/10.1016/j.indcrop.2022.114612

Gayatri Vaidya N, Teja Bhanu, Sharma Dilip Kumar, Thangaraja Jeyaseelan, Devarjan Yuvarajan (2022) Production of biodiesel from Phoenix sylvestris oil: process optimization technique. Sustain Chem Pharm 22:100497. https://doi.org/10.1016/j.scp.2022.100636

Bibin Chidambaranathan, Devarajan Y, Bharadwaj Alok, Patil Y (2022) Detailed analysis on nonedible waste feedstock as a renewable cutting fluid for a sustainable machining process. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-02248-5

Vellaiyan Suresh, Subbiah Arunkumar, Kuppusamy Shanmugavel, Subramanian Saravanan, Devarajan Yuvarajan (2022) Water in waste-derived oil emulsion fuel with cetane improver: formulation, characterization and its optimization for efficient and cleaner production. Fuel Process Technol 228:107141. https://doi.org/10.1016/j.fuproc.2021.107141

Członka S, Strąkowska A, Kairytė A (2020) The impact of hemp shives impregnated with selected plant oils on mechanical, thermal, and insulating properties of polyurethane composite foams. Materials. 13(21):4709. https://doi.org/10.3390/ma13214709

Karthik K, Raja T, Prabu S, Ganesh R (2015) Mechanical properties of carbon-epoxy with ceramic particles on composite. Int J Appl Eng Res 10(13):33826–3383

Bharath KN, Sanjay MR (2019) Mohammad Jawaid, Harisha, S Basavarajappa and Suchart Siengchin, Effect of stacking sequence on properties of coconut leaf sheath/jute/E-glass reinforced phenol formaldehyde hybrid composites. J Ind Text 49(1):3–32. https://doi.org/10.1177/1528083718769926

Abhishek S, Sanjay MR, George Raji, Siengchin Suchart, Parameswaranpillai Jyotishkumar, Pruncu Catalin Iulian (2018) Development of new hybrid Phoenix, pusilla/carbon/fish bone filler reinforced polymer composites. J Chi Adv Mater Soc 1522599 https://doi.org/10.1080/22243682.2018.1522599

Ganesan K, Kailasanathan C, Sanjay MR, Senthamaraikannan P, Saravanakumar SS (2018) A new assessment on mechanical properties of jute fibre mat with egg shell powder/nanoclay-reinforced polyester matrix composites. J Nat Fibres 1500340 https://doi.org/10.1080/15440478.2018.1500340

Teo Siew Cheng, Lan Du Ngoc Uy, Teh Pei Leng, Tran Le Quan Ngoc (2016) Mechanical behavior of palm oil–based composite foam and its sandwich structure with a flax–epoxy composite. J Appl Polym Sci 133:45. https://doi.org/10.1002/app.43977

Kumaran P, Mohanamurugan S, Madhu1 S, Vijay R, Singaravelu D Lenin, Vinod A, Sanjay MR, Siengchin Suchart (2019) Investigation on thermo-mechanical characteristics of treated/untreated Portunus sanguinolentus shell powder-based jute fabrics reinforced epoxy composites. J Ind Text 1–33 https://doi.org/10.1177/1528083719832851

Madhu P, Sanjay MR, Senthamaraikannan P, Pradeep S, Saravanakumar SS, Yogesha B (2018) A review on synthesis and characterization of commercially available natural fibres: Part-I. J Nat Fibres 1453433 https://doi.org/10.1080/15440478.2018.1453433

Vasiliauskienė D, Balčiūnas G, Boris R, Kairytė A, Kremensas A, Urbonavičius J (2020) The effect of different plant oil impregnation and hardening temperatures on physical-mechanical properties of modified biocomposite boards made of hemp shives and corn starch. Materials. 13(22):5275. https://doi.org/10.3390/ma13225275

Mohanavel V, Raja T, Yadav A, Ravichandran M, Wilczek J (2021) Evaluation of mechanical and thermal properties of Jute and Ramie reinforced epoxy-based hybrid composites. J Nat Fibres 1–11. https://doi.org/10.1080/15440478.2021.1958432

Raja T, Mohanavel V, Sathish T, Djearamane S, Velmurugan P, Karthick A, Nasif O, Alfarraj S, Shing Wong L, Sureshkumar S, Ravichandran M (2021) Thermal and flame retardant behavior of neem and banyan fibres when reinforced with a bran particulate epoxy hybrid composite. Polym J 13(22):3859. https://doi.org/10.3390/polym13223859

Salman SD, Leman Z, Sultan MTH, Ishak MR, Cardona F (2015) The effects of orientation on the mechanical and morphological properties of woven kenaf-reinforced poly vinyl butyral film. BioResources 11(1). https://doi.org/10.15376/biores.11.1.1176-1188

Mohd Radzuan NA, Ismail NF, Fadzly Md Radzi MK, Razak ZB, Tharizi IB Sulong AB, Che Haron CH, Muhamad N (2019) Kenaf composites for automotive components: enhancement in machinability and moldability. Polymers 11(10):1707 https://doi.org/10.3390/polym11101707

Strąkowska A, Członka S, Kairytė A (2020) Rigid polyurethane foams reinforced with POSS-impregnated sugar beet pulp filler. Materials 13(23):5493. https://doi.org/10.3390/ma13235493

Ali Temiz, Gaye Kose, Dmitri Panov, Nasko Terziev, Mehmet Hakkı Alma, Sabrina Palanti, Selcuk Akbas (2013) Effect of bio-oil and epoxidized linseed oil on physical, mechanical, and biological properties of treated wood. J Appl Polym Sci 130(3):1562–1569 https://doi.org/10.1002/app.39334

Norhasnan NHA, Hassan MZ, Nor AFM, Zaki SA, Dolah R, Jamaludin KR, Aziz SA (2021) Physicomechanical properties of rice husk/coco peat reinforced acrylonitrile butadiene styrene blend composites. Polymers. 13(7):1171. https://doi.org/10.3390/polym13071171

Ibrahim MI, Hassan MZ, Dolah R, Yusoff MZM, Salit MS (2018) Tensile behaviour for mercerization of single kenaf fibre. Malays J Fundam Appl Sci 14:437–439 https://doi.org/10.11113/mjfas.v14n4.1099

Hassan MZ, Roslan SA, Sapuan S, Rasid ZA, Nor AFM, MdDaud MY, Dolah R, Zuhri MYM (2020) Mercerization optimization of bamboo (bambusa vulgaris) fibre-reinforced epoxy composite structures using a box–behnken design. Polymers 12:1367. https://doi.org/10.3390/polym12061367

Chen RS, Ab Ghani MH, Ahmad S, Mou'ad AT, Gan S (2021) Tensile, thermal degradation and water diffusion behaviour of gamma-radiation induced recycled polymer blend/rice husk composites: experimental and statistical analysis. Compos Sci Technol 108748. https://doi.org/10.1016/j.compscitech.2021.108748

Author information

Authors and Affiliations

Contributions

Raja Thandavamoorthy and Yuvarajan Devarajan conceived of the experiential idea and conducted the experiments.

Dinesh Babu Munuswamy and Rusal Raj Francis have contributed to the manuscript.

Gayatri Vaidya and Sathish Sundararaman helped in the interpretation of the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raja, T., Munuswamy, D.B., Francis, R.R. et al. Experimental investigations on the effect of palm oil in kenaf fibre–reinforced basalt particulate hybrid biocomposite. Biomass Conv. Bioref. 14, 5345–5355 (2024). https://doi.org/10.1007/s13399-022-02714-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02714-8