Abstract

Pharmaceutically active compounds (PhACs) are frequently detected emerging pollutants in water resources worldwide that provoke pernicious influences on human health and the ecosystem. Developing effective carbonaceous adsorbents from biomass for the efficient removal of PhACs has lately drawn significant research attention. Herein, an efficient and cost-effective activated carbon was produced via ZnCl2-activation, employing orange peels as a precursor (named hereafter as OPAC). OPAC was well-characterized and applied in the sequestration of acetaminophen (N-acetyl-para-aminophenol, APAP), a broadly used non-steroidal anti-inflammatory drug, from water media using the batch technique. OPAC exhibited excellent performance, and more than 95.5% APAP was removed after 90 min, in the pH range of 2.0–8.0, using 1 g/l adsorbent at 25 °C. Additionally, the equilibrium and the kinetic studies outcomes unveiled the suitability of the Langmuir and the pseudo-second-order kinetic models, respectively, to describe the adsorption process. Based on the pH-adsorption dependence and OPAC properties, the presumable mechanism was mainly dominated by non-electrostatic interactions, including hydrogen bonding, π-π interactions, and pore diffusion. Thermodynamically, the process was found to be spontaneous and endothermic. Ultimately, OPAC manifested outstanding recyclability, with at least 95% of the initial efficiency being preserved after five cycles, making it more attractive from the environmental and economic perspectives.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The ubiquitous contamination of the aquatic system by pharmaceutically active compounds (PhACs) has become a grim global ecological issue over the latest two decades [1, 2]. These compounds have been lately pigeonholed as Contaminants of Emerging Concern (CEC) [3, 4]. The presence of these noxious pollutants, even in trace concentrations, can provoke pernicious influences on both human health and the ecosystem [5, 6]. In general, PhACs contaminate the aquatic system through various routes, including the excretion of drug-treated animals and people, the effluents from hospitals, and pharmaceutical industries wastewater [7, 8]. Unfortunately, the traditional water purification technologies fail to completely eliminate most of these PhACs [9]. Accordingly, developing efficient and low-cost decontamination techniques to purify aquatic environments from PhACs impurities has become a major thrust in environmental research [1, 5]. To this end, several purification techniques have been employed through the years, the most important of which are adsorption [10, 11], photocatalytic degradation [5], advanced oxidation [6, 12], and ultrasonic treatment [13]. Among various decontamination approaches to date, adsorption on porous materials has earned high popularity since it enables the facile and efficient removal of these hazards from the water matrix at ambient conditions at a relatively low cost [2, 10, 14–18].

Currently, diverse porous materials with different physicochemical properties are being appraised for the adsorptive removal of PhACs from water media. They comprise graphene oxide [19], zeolites [20], activated carbon [1, 2], mesoporous silicas [21], biosorbent [9], and metal–organic frameworks (MOFs) [22]. Studies developed in recent years have ventured the superiority of activated carbons over other porous materials, which was believed to be a result of their exceptional properties, which include significant internal surface areas, the presence of ample surface functionalities, chemical stability, and uncomplicated production technologies [1, 2, 10, 23–26]. Despite these positive aspects, the high production cost of activated carbon poses a grave impediment to the successful commercialization of activated carbon-based adsorption technology [1, 18, 24, 27, 28]. The economic production of activated carbon might be realized by using the cheap and abundantly available agriculture and frosty residues such as sugar cane bagasse, spent tea leaves, brewer’s spent grain, nutshells, avocado seed, and bamboo chip, as activated carbon precursors [1, 4, 10, 24, 26, 29, 30]. AC production from these precursors can be accomplished via two well-known technologies: chemical and physical activation. The chemical activation route is more preferred over the latter, where better carbon yields are obtained at lower pyrolysis temperatures and significantly shorter times using an easier work-up procedure [30–32]. The most prevalent chemicals used for activating carbonaceous materials are H3PO4 [4], KOH [24], and ZnCl2 [1, 33]. ZnCl2 is one of the broadly utilized chemical activators for producing biomass-derived activated carbon since it results in activated carbon having elevated surface area with a considerable fraction of mesoporosity, and hence high adsorption capacity, in a high yield [34–38]. Several recent reports have highlighted the effective purification of PhACs-loaded wastewater by activated carbon derived from agricultural residues through the ZnCl2 activation route [1, 4, 10, 29, 30, 34, 38].

According to the Food and Agriculture Organization (FAO), Egypt is the world’s seventh largest producer of orange, with production totaling 3,197,046 tonnes in the harvest season 2018/19 [39]. Peels, which amounted to almost half of the entire fruit weight, are produced in considerable amounts during household usage and the orange processing industry [40]. Currently, most of the orange peels are thrown into dumps, which would not only pose a possible peril to the environment but also present a loss of a potentially useful resource [41]. Therefore, searching for proper utilization of this waste is of extreme importance from both the ecological and the economic viewpoints. In this study, activated carbon was obtained via chemical activation with ZnCl2 involving orange peels as a precursor and then evaluated concerning its efficacy in the adsorptive removal of acetaminophen from water media. Since approved in 1951, acetaminophen (or paracetamol, APAP), one of the most well-known non-steroidal anti-inflammatory drugs (NSAID), has been broadly used worldwide for lowering fever, and the treatment of inflammation and body aches of mild to moderate severity, owing to its efficacy, good safety profile as well as low price [5, 10, 42, 43]. A plethora of research groups have reported the presence of APAP in a diversity of aquatic matrices, including surface water, wastewater effluent, and even in the treated drinking water in many territories of the world [5, 15, 24, 28]. Characterization techniques, including X-ray diffraction analysis (XRD), Raman spectroscopy, Fourier transform infrared spectroscopy (FTIR), N2 measurements at − 296 °C, scanning electron microscope (SEM), and transmission electron microscopy (TEM), were undertaken to gain insight into the structural and morphological features of orange peels–derived activated carbon (OPAC). The isotherm, kinetic, and thermodynamic aspects of the APAP adsorption onto the OPAC were delineated. In addition, the plausible mechanism underlying the removal adsorption of APAP was also discussed and deciphered. Ultimately, the potential reusability of the material through multiple adsorption–desorption cycles was examined. Interestingly, about 95% of the first cycle removal efficiency was retained after 5 cycles, demonstrating outstanding recyclability of OPAC.

2 Experimental

2.1 Materials and chemicals

The reagents used for the preparation as well as APAP adsorption tests were obtained from Honeywell Fine Chemicals, except for ZnCl2, which was obtained from Sigma-Aldrich. Acetaminophen (APAP, N-(4-hydroxyphenyl)acetamide) was obtained from the Egyptian Group For Pharmaceutical Industries. The structural formula of APAP is manifested in Table 1.

The raw material, orange peels, was collected from the home kitchen after juice extraction. They were washed with distilled water several times and subsequently oven-dried before being milled to a fine powder with a particle size less than 1 mm using a kitchen chopper. The obtained sample was denoted as OP.

2.2 Sample preparation

Activated carbon was obtained from OP adopting the ZnCl2 chemical activation route. In brief, 5 g of OP were added to 20 ml aqueous solution containing different concentrations of ZnCl2 (1.8–7.3 M), which are equivalent to mass ratios ZnCl2:OP of 1:1 to 4:1, and left to stir at ambient temperature overnight. After evaporating excess water in a vacuum at 100 °C, the resulting OP-loaded ZnCl2 samples were annealed under nitrogen at 500 °C for 2 h. After being cooled naturally to room temperature, the products of the carbonization process were extensively washed with 1 M HCl aqueous solution to get rid of surplus ZnCl2 and other zinc-containing impurities and thereafter, with deionized water until neutrality. The targeted OP-derived activated carbons were obtained after vacuum drying at 60 °C for 12 h. As shown in Table S1, both the surface area and total pore volume of the obtained OP-derived activated carbons increased with ZnCl2:OP mass ratio up to a mass ratio of 3:1 and decreased beyond this value. So, the carbon sample obtained employing ZnCl2:OP mass ratio of 3:1 was picked for the continuation of this study and was nominated as OPAC. Additionally, OP was directly carbonized using similar conditions as above without ZnCl2-activation and the resulting carbon material, which was designated as OP-500, served as the control sample. The yield of the resulting OPAC was computed on the basis of the following equation [44]:

where wf and wi are the dry weights (g) of the obtained OPAC and the OP precursor, respectively.

2.3 Characterization

At first, the OP precursor and resultant activated carbon were subjected to proximate (volatile matter, ash, and moisture content) and ultimate analysis (C, H, N, S, and O). The moisture, volatile matter, and ash content were determined following ASTM D2867, ASTM D5832-98, and ASTM D2866-94 protocols, respectively. The fixed carbon content was calculated by deducting from 100% the sum of the contents of moisture, volatile matter, and ash [45]. The determination of C, H, N, and S content was carried out using an Elemental Vario Macro cube elemental analyzer, whereas the oxygen content was calculated by difference.

The crystal structure was scrutinized using a Bruker AXS D8-ADVANCE X-ray diffractometer (XRD) operating with Cu Kα radiation (λ = 0.15406 nm). Raman spectroscopic analysis was accomplished by using a Sentera spectrometer operated with a 532-nm laser. The nature of surface functionalities was scrutinized employing Fourier transform infrared (FTIR) spectroscopy analysis, which was recorded on an ATI unicam (Mattson 936) Bench Top spectrophotometer in the range of 450 to 4000 cm−1 adopting the classical KBr pellet procedure. The nitrogen sorption isotherms at − 196 °C were obtained by using Quantachrome Nova 3200 S apparatus. Prior to testing, the dried samples were outgassed overnight at 300 °C under nitrogen. The classical multipoint BET procedure was employed to determine the surface area, whereas the total pore volume (Vt) was measured from the volume of nitrogen taken at the relative pressure of 0.99. Pore size distribution (PSD) of OPAC was determined from N2 adsorption data based on the BJH model. Furthermore, the morphological features of the materials were unveiled employing a Zeiss Ultra 60 FE-SEM and a JEOL JEM-2100 HR-TEM. The point of zero charge (PZC) of OPAC was estimated using the mass titration recipe [1].

2.4 Adsorption experiments for aqueous APAP solution

A stock solution of APAP having a concentration of 1000 mg/l was prepared by dissolving 1 g of in 1000 ml of distilled water. The solutions of various APAP concentrations utilized in the adsorption tests were obtained by successive dilution of this stock solution using distilled water.

For the isotherm investigation, about 10 mg of the OPAC and 10 ml of APAP solution having different APAP initial concentrations varying from 20 to 150 mg/l were placed into 25-ml bottles and mixed on a temperature-controlled water bath shaker at an agitation speed of 200 rpm. After 90 min of agitation at ambient temperature, the mixtures underwent centrifugation at 5000 rpm for 5 min to harvest OPAC. The resulting supernatant obtained upon centrifugation was analyzed for the measurement of residual APAP by UV–visible spectrophotometer at 243 nm, employing a pre-constructed calibration curve for the drug. All adsorption isotherm experiments were conducted at a fixed pH of about 6.3. Equation (2) was employed to compute the amount of APAP adsorbed per g of OPAC at equilibrium (qe, mg/g). As for the kinetic study, a set of experiments were conducted following conditions similar to the ones used for the isotherm study, except that the initial APAP concentration was kept constant at 20 mg/l in all experiments. The mixtures were left to shake for different time intervals covering a range from 10 to180 min. The amount of APAP adsorbed per gram OPAC (qt, mg/g) and the APAP removal efficiency (R%) can be estimated based on Eqs. (3) and (4), respectively. Likewise, in the thermodynamic study, adsorption studies were carried out over the temperature ranges of 25–60 °C. Twenty milligrams per liter of APAP solution was used in these experiments for 90 min at a pH value of 6.3. The adsorbent dose was 1 g/l.

The effect of pH of the APAP solution was examined by carrying out the adsorption process under different pH values ranging from 2 to 10 in accordance with the abovementioned procedure. The initial pH value of the APAP solution was controlled by adding 0.1 M NaOH or 0.1 M HCL aqueous solutions. In these experiments, the adsorption temperature, contact time, OPAC dose, and the initial concentration of the APAP solution were set to 25 °C, 1 g/l, 90 min, and 20 mg/l, respectively. Similarly, the effect of adsorbent dose was studied through varying the dose of the adsorbent from 0.25 to 1.25 g/l, while preserving the other parameters experimental variables unaltered, i.e., initial concentration of APAP: 20 mg/l, contact time: 90 min, adsorbent dose: 1 g/l, pH: 6.3, and temperature: 25 °C. A set of adsorption experiments were also conducted at different temperatures from 25 to 70 °C to study the process thermodynamics.

To check the recycling property of the synthesized adsorbent, five adsorption/desorption cycles were conducted. Firstly, OPAC was utilized for adsorbing APAP from an aqueous solution at 25 °C, an initial APAP concentration of 20 mg/l, pH = 6.3, and 1 g/l OPAC. After equilibrium time (90 min), the APAP-loaded OPAC was regenerated through washing with 0.1 M NaOH in the presence of ultrasonic irradiation for 15 min at 60 °C followed by distilled water (until pH-neutrality) and the subsequent drying in vacuum at 60 °C overnight. This cycle was repeated five times.

3 Results and discussion

3.1 Materials characterization

The yield of AC from a given biomass precursor, which is the percentage of the residual weight of the precursor obtained at the end of the chemical activation and carbonization stage, is a principal criterion to judge the practicability of the production method [46, 47]. The yield of OPAC was around 49 wt%; that is, OP will yield about 500 kg of OPAC per ton. This value is quite consistent with those reported by other researchers for AC from various agricultural and forestry residues [33, 48, 49].

The proximate and ultimate analyses of raw OP and OPAC were determined, and the results are compiled in Table 2. As can be seen in this Table, OP manifested high volatile matter content of about 70.2 wt%. Since the release of volatiles from the biomass precursor throughout the carbonization and activation step promotes pore formation within the resultant carbonaceous structure, the high content of volatile matters in OP would be advantageous for the production of porous activated carbon with a large specific surface area and pore volume, which are crucial requisites for efficient adsorption process [50–53]. Please note that lignocellulosic biomass precursors, including OP, contain a considerably higher proportion of volatile matter (70–80%) than the traditional carbon precursors, coal, and lignite; hence, lower activated carbon yields are obtained with biomass precursors [54–56]. Nevertheless, unlike coal, these feedstocks are inexpensive, highly available, sustainable, and their use has almost no adverse environmental consequences [57]. At the same time, the ash content of OP was as low as 3.5 wt%, which is a coveted feature for an AC precursor [51, 58]. The fixed carbon content of OP was determined to be 17.2 wt%, which is on par with other biomass raw materials used for the production of activated carbon [59–63].

The data in Table 2 unveiled that OPAC manifested significantly higher fixed carbon content but lower volatile matter content compared to the OP precursor. Besides, the ash content in the OPAC sample was estimated to be around 3.9 wt%, which is slightly higher than that of OP. These changes can be likely the result of the liberation of the volatile substances during the chemical activation process, leaving behind a carbonization product with high carbon content [51, 64]. Please note that ash content in OPAC was enormously lower than the maximum permissible content of ash in AC of 15 wt% [DIN EN 12903]. High ash content would not only unfavorably affect the adsorption performance of AC, but also reduce its regeneration efficiency during recycling [46, 65, 66]. Furthermore, OPAC carbon had a low moisture content of around 5.8 wt%, which lies within the admissible limit in activated carbon (3–6 wt%) [67]. Consequently, the results of the proximate analysis inferred that OP is an ideal lignocellulosic precursor for the production of high-quality activated carbon.

The element composition of the raw material and OPAC are also provided in Table 2. Results of the elemental analysis designated that carbon and oxygen were the main elements detected besides low contents of hydrogen and nitrogen. OP possesses a high carbon content of 43.5 wt% registering its potential to be utilized as a precursor for manufacturing AC [64]. After activation, the content of carbon was considerably improved (from 43.5 to 78.3 wt%), while the contents of the rest elements declined (O, H, and N). Again, this can be ascribed to the evolution of the oxygen-rich volatiles from OP during activation leaving behind stable carbon. Notably, the elemental analysis showed the absence of sulfur in both the OP precursor and the OPAC, which is desirable from the environmental perspective.

The crystal structure of OPAC was scrutinized with powder X-ray diffraction, and the resultant diffractogram is manifested in Fig. 1a. As shown, OPAC presented two hump-like diffraction peaks at around 2θ values of 24.35° and 43.33°, matching with the reflections of the (002) and (100) planes of carbon (JCPDS 75–1621), respectively [1]. The broadening of these peaks declares that OPAC is highly amorphous in nature. The typical Raman spectrum of the obtained OPAC material in the range of 500–2000 cm−1 is depicted in Fig. 1b. Two main peaks can be obviously discerned at wave-numbers around 1326 and 1586 cm−1, assignable to the well-defined D-(disordered or defective carbon) and G-bands (ordered or crystalline carbon), respectively [1]. The integral intensities ratio of the D and G peaks (ID/IG) aids in quantifying the number of defects in the developed carbon matrix, which for our sample equals 1.4, purporting the presence of a high amount of structural defects rivaling with the above XRD results.

The synthesized OPAC material was additionally characterized by N2 adsorption–desorption measurements to gain further information about its textural features. The resultant N2 isotherm, Fig. 2a, manifested a hybrid type I/IV shape with an apparent hysteresis loop in the relative pressure range from 0.4 to 0.95, characteristic of porous materials with combined micro- and meso-porosities. BJH pore size distribution (Fig. 2b) is harmonious with the conclusion deduced from the N2 isotherm, unveiling the presence of micropores (3.6 nm) in addition to mesopores (1.5 nm). It was discovered that the synthesized OPAC material manifested a high surface area of ∼1069 m2g−1 and a large total pore volume of ∼1.29 cm3g−1, respectively. Noticeably, based on the t-plot analysis of the adsorption branch of the isotherm, 71.5% (764.7 m2g−1) of its surface area and 88% (1.13 cm3g−1) of its pore volume originates from the mesopores. Thus, OPAC featured high internal surface area simultaneously with abundant mesoporosity, which will favor its contact with the drug molecules. In contradiction with OPAC, OP-500, which was obtained via the directly carbonized orange peel without ZnCl2-activation, possessed a poor specific surface area and pore volume of 18.4 m2/g and 0.021 cm3/g, respectively. These findings verified the indispensable role that ZnCl2 has on porosity development in the obtained activated carbon. Importantly, the textural properties of the adsorbent in this work, including surface area, pore volume, and mesoporous fraction, are on par with or even surpassing those of other previously reported carbon adsorbents derived from diverse agricultural and forestry residues, as declared in Table S2.

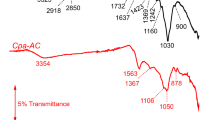

Besides the porous properties, the adsorption performance of carbon-based adsorbents depends heavily on the nature of the functional groups present on their surface [68]. In the existing study, the identification of the various surface functional groups of OP and OPAC was accomplished employing FTIR spectroscopic analysis (Fig. 3). From this figure, it is obvious that the surface chemistry of the two materials was different. In other words, the surface functionalities of OP were strongly influenced by ZnCl2 activation. Some absorption peaks were significantly weakened or even vanished in OPAC compared with those of the raw OP.

The FTIR spectrum of OP in Fig. 3a manifests a wide peak in the 3100–3600 cm−1 region, which signified the presence of O–H stretching vibration of surface hydroxyl groups [69]. The intensity of this peak was observed to be lower in the FTIR spectrum of OPAC, Fig. 3b, implying the elimination of considerable portions of hydrogen and oxygen atoms during the activation process [36]. The decline in hydrogen and oxygen content after activation is also obvious from elemental analysis, where the hydrogen and oxygen contents declined to 2.04% and 19.331%, respectively, as seen in Table 1. Additionally, aliphatic C–H stretches may account for the absorption bands that emerged around 2900 cm−1 [1]. For OPAC, these peaks were largely weakened because of the damage of cellulose, hemicellulose, and lignin in OP during the high-temperature chemical activation process [36, 70]. The peak for the C = O stretching vibrations from carbonyl groups of ketones, aldehydes, lactones, or carboxyl groups was discerned at 1650 cm−1 [70]. This peak vanished in the FTIR spectrum of OPAC, which corresponds to the discharge of volatile matter from the precursor as a result of chemical activation [36, 71]. As can be seen from Table 1, only 15% of the volatile matter was retained in OPAC after ZnCl2 activation. For OP, the absorption due to stretching vibrations of C–O bond in acids, alcohols, phenols, ethers, and esters was typically positioned at 1000–1100 cm−1 [2], whereas the prominent peaks at 1390 and 1550 cm−1 are likely to arise from the stretching vibrations of phenolic hydroxyl, C–O, or aromatic C = C [1]. A decrease was observed in the intensities of these peaks for OPAC compared to the raw OP material. The bands present in the region below 1000 cm−1 pointed towards the aromatic –CH–bending vibrations modes [72].

The FE-SEM image (Fig. 4a) unveiled that the surface of OPAC was uneven and rough. Plenty of nanoscale pores of diverse sizes and shapes were perceived on the surface, which endowed OPAC with a high surface area for the effective removal of acetaminophen. These void spaces were developed throughout the chemical activation and carbonization stage as a consequence of the release of volatiles as gases from the raw material (orange peels) [73]. The OPAC sample was additionally characterized by HR-TEM. OPAC has disordered hierarchical porosity comprising large quantities of micro- and mesopores appearing as bright spots embedded in the amorphous matrix, as observed in the TEM image (Fig. 4b). In addition, lattice fringes were not perceived in the magnified TEM image of OPAC manifested in Fig. 4c. This result clearly designates the amorphous character of activated carbon derived from orange peels, in consistency with the XRD and Raman spectroscopy observations.

3.2 Adsorption

3.2.1 Effect of adsorbent dose

The effect of adsorbent dose on APAP removal by OPAC was scrutinized, and the results are declared in Fig. 5. The APAP sorption rate was discerned to increase from 44.5 to 95.5% with increasing the adsorbent dose from 0.25 to 1.25 g/l. The positive effect of the OPAC dose was essentially linked to the expected rise in the contact area available for APAP sorption as well as the entire amount of the exposed binding sites [74]. Thus, more APAP could be captured by OPAC to result in higher APAP removal. Notwithstanding, a further increase in the adsorbent dose above 1.0 g/l results in almost no change in the sorption rate. Considering these findings, OPAC dose of 1.0 g/l was selected for the continuation of the study.

3.2.2 Adsorption mechanism

The study of the effect of pH of the external environment on the removal efficacy is of prominent importance since it provides relevant information regarding the plausible adsorption mechanism [1, 2]. The effect of pH on the adsorption of APAP on OPAC was scrutinized within the range 1–10. Figure 6a unveiled that the degree of adsorption was remained essentially invariant till pH 8 and then sharply declined to ∼50% at pH 10. A similar trend for the pH-adsorption dependence was described for the adsorption of APAP on biomass-derived activated carbons [4, 75, 76]. Thus, OPAC can be employed for the treatment of APAP-polluted wastewater at its natural pH value (5.5–6.5) without any pH adjustment, thus avoiding the use of the toxic and costly acids and bases and making the treatment process more convenient from both the economic and ecological viewpoint.

The reliance of adsorption efficiency on the pH value of the external environment is associated with the point of zero charge (pHPZC) of the adsorbent (OPAC) as well as the acid dissociation constants (pKa) of the drug molecules (APAP). Herein, the value of the pHPZC of OPAC, the pH point at which the charge over the surface of the adsorbent has the value of zero, was determined adopting the pH-drift recipe, the results of which are provided in Fig. 6b. As depicted in this figure, OPAC showed a pHPZC value of about 5.7, designating the dominance of acidic functionalities on its surface [46]. Thus, the surface charge of our carbon material becomes positive for pH values below 5.7, whereas it becomes negative for pH values above 5.7. As for the adsorbate, APAP is a weak acid having a pKa value of around 9.38 [4], and therefore APAP mainly presents in its neutral undissociated state to a pH 9.3, while at higher pH values, APAP is deprotonated, and the anionic state dominates. Thus, at pH ~ 10, the negatively charged OPAC surface electrostatically repelled the incoming APAP anions, impeding their sorption [4, 19]. Furthermore, the competition of OH − for the active binding sites on OPAC with the APAP anions may contribute to the perceived obvious decrease in the adsorption degree at highly alkaline pH ~ 10 [4, 75, 77].

In addition, the pH-adsorption dependence implied that the high APAP removal efficiency over OPAC up to pH 8 could not be ascribed to electrostatic interactions and other non-electrostatic interactions governed the adsorption mechanism [19, 78]. It is because APAP molecules are almost neutral in this pH region [19]. The non-electrostatic interactions could include H-bonding, π–π interactions, n–π electron donor–acceptor interactions, and hydrophobic–hydrophobic interactions.

Several studies have suggested H-bonding interactions to be the main driving force for the adsorption of a large diversity of noxious aromatic contaminants from water media by carbon-based adsorbents [1, 78, 79]. Herein, OPAC contains various surface polar functionalities, including –COOH and –OH that can interact with the –OH, and –NH moieties in APAP species via H-bond formation [24]. The uptake of APAP on the OPAC surface may also be via π − π interactions that can be developed between the π electrons of the fused conjugated aromatic moieties in OPAC (donor) and the π electrons in the benzene ring of the drug molecule (acceptor) [78], and n–π electron donor–acceptor interaction between the lone pair of electrons on the oxygen of the surface carbonyl functionalities of OPAC (electron donors) and the benzene ring of APAP (electron acceptor) [15]. Please note that the significant contribution of the π-π mechanism to the sorption of APAP can be further confirmed by the almost unaltered adsorption capacity with varying pH conditions, considering the fact that π-π interaction is pH-independent [80]. Besides, the adsorption may also be favored by the attractive hydrophobic interaction between the aromatic components of APAP species and OPAC [19, 76]. It is important to note that, in addition to the abovementioned mechanisms, pore diffusion was expected to play a considerable role during the uptake of APAP. The analysis of the results of N2 physisorption measurements revealed that OPAC has a high surface area, large pore volume, simultaneously with dominant mesoporous structure, and it will be, therefore, easy for the APAP molecules to diffuse through [78, 79]. Several recent studies have highlighted the significance of pore diffusion in PhACs sorption on carbon-based adsorbents [78, 81, 82]. Figure 7 manifests the probable mechanisms that might contribute to APAP uptake. The unadjusted pH of APAP, i.e., pH 6.3, was chosen for all experiments.

3.2.3 APAP adsorption isotherms

The study of equilibrium adsorption isotherm is of crucial importance for understanding the mechanism underlying the adsorption process. The adsorption isotherms, obtained by plotting the equilibrium adsorption capacity (qe) against APAP concentration (Ce), are manifested in Fig. 8A. The results revealed that the quantities of APAP adsorbed onto the material increased swiftly at lower APAP concentrations, then improved at a slower rate, and eventually plateaued. To obtain more understanding of the interactions between APAP species and the OPAC surface, three models, namely the Langmuir (Eq. 5), Freundlich (Eq. 6), and Temkin (Eq. 7) isotherms, were used in this study to analyze the experimental adsorption data. The fitting results are shown in Fig. 8B, C, and D, and the relevant parameters are outlined in Table 3.

where qmax (mg/g) is the maximum adsorption capacity; KL (l/mg) stands for Langmuir equilibrium constant related to the energy of adsorption; KF (l/g) denotes the Freundlich constant representing the maximum adsorption capacity; n constants related to the favorability of the adsorption process, A (mg L−1) is the equilibrium constant related to the binding energy, and B is the Temkin constant related to the adsorption heat.

The data in Table 3 indicate that the Langmuir model can be used to illustrate the equilibrium data more precisely than the Freundlich and Temkin models. This assumes that APAP species were adsorbed as a monolayer over an even adsorbent surface and the adsorption of each APAP molecule has nearly identical activation energies [83, 84]. For the Langmuir adsorption isotherm, no lateral interaction took place between the adsorbed species [1]. The positive value of the Langmuir constant, b, suggested the theoretical maximum adsorption capacity of APAP onto OPAC adsorbent was not attained in the experiments [85].

Besides, information about the favorability of the current sorption process can be obtained from the value of a dimensionless constant associated with the Langmuir model, separation factor, RL [86]. The RL values at different APAP initial concentrations were computed based on Eq. 8 and are presented in Fig. 8E. The RL value in the present study was found to range from 0.027 to 0.26, assuming that the sorption of APAP species onto OPAC is a favorable sorption process for all of the studied concentrations [86]. Furthermore, the observed decrease in RL value along with the increase in the initial concentration of APAP implied that the adsorption occurs more readily at higher initial concentrations of APAP [2].

3.2.4 Thermodynamics

It has been widely accepted that adsorption temperature is one of the most critical process parameters governing the sorption process. The effect of temperature on the adsorption of APAP on OPAC was studied by varying the temperature between 25 and 70 °C, while maintaining the initial APAP concentration (20 ppm), contact time (90 min), and adsorbent dose (1 g/l) constant. The experimental results are presented in Fig. 9A. It was observed that the adsorption efficiency of APAP decreased from 95.5 to 30.0% with the increase in the sorption temperature in the range of 25 to 70 °C, indicating the exothermic nature of the adsorption process. This will be further discussed in relation to thermodynamic parameters. Considering the results obtained, 25 °C was the most suitable sorption temperature, and therefore will be used in the subsequent studies.

In order to fully understand the nature of the adsorption process, the thermodynamics parameters including free Gibbs energy change (ΔG°), enthalpy change (ΔH°), and entropy change (ΔS°) for the adsorption of APAP on OPAC were also calculated and discussed.

The change in Gibbs free energy (ΔG°) for APAP adsorption on was evaluated from the values of Langmuir constant (KL) at various adsorption temperatures using the following expression [87]:

where R is the universal gas constant (0.008314 kJ mol−1 K−1), KL is Langmuir constant (L mol−1), and T is the temperature (K).

Then, values of enthalpy change (ΔH°) and the entropy change (ΔS°) were calculated from the intercept and slope of the straight line (see Fig. 9B) obtained by plotting of the linear plot of ΔG° versus T, respectively, according to the following relationship [88]:

The values of ΔG°, ΔH°, and ΔS° for are listed in Table 4. Inspection of Table 4 revealed that:

-

(1)

The ΔG° values at all sorption temperatures are negative, implying that the adsorption of APAP on the surface of OPAC adsorbent was thermodynamically feasible and spontaneous. Moreover, the value of ΔG° becomes less negative with the rise in adsorption temperature, indicating that the adsorption process becomes less favorable at higher adsorption temperatures.

-

(2)

The negative value of ∆H° is also an indication of the exothermic nature of the adsorption process, which is supported by the decrease in the removal efficiency of APAP with increasing adsorption temperature, as shown previously in Fig. 9A.

-

(3)

Furthermore, the observed negative change in entropy indicates the decrease in the degree of randomness at the solid-solute interface during the adsorption of APAP on OPAC.

3.2.5 APAP adsorption kinetics

The variation of the adsorption of APAP on by OPAC as a function of the contact time is manifested in Fig. 10A. It can be observed from the figure that the rate of APAP removal was fast, and adsorption equilibrium could be established within 90 min. Obviously, the adsorption rate was fast in the first 20 min and then gradually slowed with the elapse of time before finally attaining equilibrium after 90 min and reaching a plateau. This behavior can be ascribed to the fact that occupation of the surface-active binding sites was low at the onset of the process, and APAP molecules could easily access the binding centers and adsorbed rapidly [1]. As the adsorption goes on, the number of the free unoccupied active binding sites became fewer, and APAP molecules on the OPAC surface would electrostatically repel those that are free in the solution.

In this research, the kinetic data of APAP removal by OPAC were fitted to the pseudo-first-order, pseudo-second-order, and Elovich models. Equations 11, 12, and 13 express the linear formula of these models. Figure 10B–D manifests the fitting adsorption data to the three kinetic models. The values of kinetic parameters and the determination coefficients, R2, were computed from data displayed in Fig. 10B–D and compiled in Table 5. Based on the values of R2, the pseudo-second-order kinetic model seems to better match the real data for APAP adsorption, and the calculated qe value (qe,cal) derived from this kinetic model was compatible with the experimental qe value (qe,exp). These findings highlight the dominant role played by chemisorption in the adsorption process of the drug molecules in this study [1, 2].

where k1 (min−1) and k2 (g/mg·min) are the equilibrium rate constants of pseudo-first- and pseudo-second-order rate equation, respectively, β (g/mg) is the desorption constant, and α (mg/g.min) is the initial adsorption rate.

The experimental data of APAP adsorption were further analyzed by Webber-Morris intraparticle diffusion model (Eq. 14) to gain deeper insights into the adsorption mechanism and the rate-limiting step [89]. Fig. S1 depicts the linearized plot of this model, t1/2 against qt.

kp (mg g−1 min−1/2) is the intraparticle diffusion rate constant, and C is a constant related to the thickness of the boundary layer.

As revealed in Fig. S1 the t1/2 against qt plot consists of three linear segments, signifying that the entire adsorption process took place via three separate diffusion steps. The first step is liquid film diffusion, which involves the quick movement of the drug molecules from water through the boundary layer to the exterior surface of OPAC [90, 91]. The intraparticle diffusion ruled the APAP uptake rate in the second step, where APAP molecules diffused slowly into the interior of OPAC and occupied the active binding centers [90, 91]. The third step described the adsorption equilibrium stage [92].

Overall, the kinetic study outcomes revealed that APAP removal on OPAC was a chemisorption process, and both liquid film diffusion and intraparticle diffusion played an influential role in controlling the adsorption rate under the experimental conditions adopted in this study.

3.2.6 Reusability

From a practical application standpoint, reusability is another significant concern that must be taken into consideration when evaluating the adsorption performance of a material. Herein, the adsorption behavior of OPAC was appraised for five sequential experiments of sorption–desorption, and the results of these experiments are shown in Fig. 11. After five sequential runs, the adsorption efficiencies of APAP on OPAC encountered only a 5% drop from 95.5% (after the first run) to 90.7 (after the fifth run), parading the high operational stability and reusability of OPAC during the adsorption of APAP.

3.2.7 Comparison study

The performance of the OPAC adsorbent was compared with those of other carbon adsorbents derived from various agricultural and forestry residues reported in the literature in terms of the achieved maximum uptake capacities for APAP (Table 6). The maximum uptake capacity of APAP on OPAC was 118 mg/g, being on par with or even greater than those of the adsorbents reported in Table 6. Thus, the activated carbon synthesized from orange peels (OPAC) using ZnCl2 activation exhibited the benefits of uncomplicated synthesis procedure, superb saturation adsorption capacity, fast adsorption kinetics, and excellent reusability, which rendered it attractive for the removal APAP from water media.

4 Conclusions

In this work, we report the synthesis of a cost-effective activated carbon adsorbent (OPAC) employing orange peel as a carbon source via chemical activation with ZnCl2. OPAC was used to adsorb acetaminophen (APAP) from water in a batch mode. Adsorption attained equilibrium after 90 min and followed the pseudo-second-order kinetic model. The equilibrium data for the adsorption of APAP on OPAC followed the Langmuir isotherm model, with an uptake capacity of about 118 mg/g. Besides, the thermodynamic parameters unveiled the spontaneity and endothermic nature of the sorption process. Non-electrostatic interactions were found to dominate the pharmaceutical sorption. Ultimately, the OPAC adsorbent was reusable towards APAP removal for up to 5 cycles.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Abo El Naga A, El Saied M, Shaban S, El Kady F (2019) Fast removal of diclofenac sodium from aqueous solution using sugar cane bagasse-derived activated carbon. J Mol Liq 285:9–19

Youssef N, Amer E, Abo El Naga A, Shaban S (2020) Molten salt synthesis of hierarchically porous carbon for the efficient adsorptive removal of sodium diclofenac from aqueous effluents. J Taiwan Inst Chem Eng 113:114–125

Patel M, Kumar R, Kishor K, Mlsna T, Pittman C, Mohan D (2019) Pharmaceuticals of emerging concern in aquatic systems: chemistry, occurrence, effects, and removal methods. Chem Rev 119(6):3510–3673

Wong S, Lim Y, Ngadi N, Mat R, Hassan O, Inuwa I, Mohamed N, Low J (2018) Removal of acetaminophen by activated carbon synthesized from spent tea leaves: equilibrium, kinetics and thermodynamics studies. Powder Technol 338:878–886

Czech B, Tyszczuk-Rotko K (2018) Visible-light-driven photocatalytic removal of acetaminophen from water using a novel MWCNT-TiO2-SiO2 photocatalysts. Sep Purif Technol 206:343–355

Park C, Heo J, Wang D, Su C, Yoon Y (2018) Heterogeneous activation of persulfate by reduced graphene oxide–elemental silver/magnetite nanohybrids for the oxidative degradation of pharmaceuticals and endocrine disrupting compounds in water. Appl Catal B 225:91–99

Zaib Q, Mansoor B, Ahmad F (2013) Photo-regenerable multi-walled carbon nanotube membranes for the removal of pharmaceutical micropollutants from water. Environ Sci Process Impacts 15(8):1582

Khadir, A., Mollahosseini, A., Tehrani, R. and Negarestani, M., 2020. A review on pharmaceutical removal from aquatic media by adsorption: understanding the influential parameters and novel adsorbents. Nanotechnol Life Sci 207–265.

Vera M, Juela D, Cruzat C, Vanegas E (2021) Modeling and computational fluid dynamic simulation of acetaminophen adsorption using sugarcane bagasse. J Environ Chem Eng 9(2):105056

Lima D, Hosseini-Bandegharaei A, Thue P, Lima E, de Albuquerque Y, dos Reis G, Umpierres C, Dias S, Tran H (2019) Efficient acetaminophen removal from water and hospital effluents treatment by activated carbons derived from Brazil nutshells. Colloids SurfA: Physicochem Eng Asp 583:123966

Mashayekh-Salehi A, Moussavi G (2015) Removal of acetaminophen from the contaminated water using adsorption onto carbon activated with NH4Cl. Desalin Water Treat 57(27):12861–12873

Yaghmaeian K, Moussavi G, Mashayekh-Salehi A, Mohseni-Bandpei A, Satari M (2017) Oxidation of acetaminophen in the ozonation process catalyzed with modified MgO nanoparticles: effect of operational variables and cytotoxicity assessment. Process Saf Environ Prot 109:520–528

Chu K, Al-Hamadani Y, Park C, Lee G, Jang M, Jang A, Her N, Son A, Yoon Y (2017) Ultrasonic treatment of endocrine disrupting compounds, pharmaceuticals, and personal care products in water: a review. Chem Eng J 327:629–647

Bernal V, Giraldo L, Moreno-Piraján J (2020) Thermodynamic analysis of acetaminophen and salicylic acid adsorption onto granular activated carbon: Importance of chemical surface and effect of ionic strength. Thermochi Acta 683:178467

Nguyen D, Tran H, Juang R, Dat N, Tomul F, Ivanets A, Woo S, Hosseini-Bandegharaei A, Nguyen V, Chao H (2020) Adsorption process and mechanism of acetaminophen onto commercial activated carbon. J Environ Chem Eng 8(6):104408

Almhana NM, Ali SAK, Al-Najjar SZ, Al-Sharify ZT (2020) Assessment of cobalt ions removal in synthetic wastewater using broad bean peels. J Green Eng 10(11):10157–10173

Lahieb Faisal M, Al-Najjar SZ, Al-Sharify ZT (2020) Modified orange peel as sorbent in removing of heavy metals from aqueous solution. J Green Eng 10(11):10600–10615

Al-Sharify ZT, Faisal LMA, Al-Sharif TA, Al-Sharify NT, Faisal FMA (2018) Removal of analgesic paracetamol from wastewater using dried olive stone. Int J Mech Eng Technol 9(13):293–299

Moussavi G, Hossaini Z, Pourakbar M (2016) High-rate adsorption of acetaminophen from the contaminated water onto double-oxidized graphene oxide. Chem Eng J 287:665–673

Dávila-Estrada M, Ramírez-García J, Solache-Ríos M, Gallegos-Pérez J, 2018. Kinetic and equilibrium sorption studies of ceftriaxone and paracetamol by surfactant-modified zeolite. Water, Air, Soil Pollut, 229(4).

Kim Y, Bae J, Park J, Suh J, Lee S, Park H, Choi H (2014) Removal of 12 selected pharmaceuticals by granular mesoporous silica SBA-15 in aqueous phase. Chem Eng J 256:475–485

Baeza, P., Astudillo, C., Diaz, M., Matus, C., Ramírez, M., Aguila, G. and Ojeda, J., 2020. Effect of the incorporation of Ni in the adsorption capacity of paracetamol (N-acetyl-P-aminophenol) on MIL-101(Cr). Water, Air, Soil Pollut, 231(5).

Ocampo-Perez R, Aguilar-Madera C, Díaz-Blancas V (2017) 3D modeling of overall adsorption rate of acetaminophen on activated carbon pellets. Chem Eng J 321:510–520

de Araújo T, Quesada H, Bergamasco R, Vareschini D, de Barros M (2020) Activated hydrochar produced from brewer’s spent grain and its application in the removal of acetaminophen. Bioresour Technol 310:123399

Ghosh S, Falyouna O, Malloum A, Othmani A, Bornman C, Bedair H, Onyeaka H, Al-Sharify ZT, Jacob AO, Miri T, Osagie C, Ahmadi S (2022) A general review on the use of advance oxidation and adsorption processes for the removal of furfural from industrial effluents. Micropor Mesopor Mat 331:111638

Al-Qaisi MQ, Lahieb Faisal MA, Al-Sharify ZT, Al-Sharify TA (2018) Possibility of utilizing from lemon peel as a sorbent in removing of contaminant such as copper ions from simulated aqueous solution. Int J Civil Eng Technol 9(11):571–579

Razak ZA, Rushdi S, Gadhban MY, Al-Najjar SZ, Al-Sharify ZT (2020) Possibility of utilizing the lemon peels in removing of red reactive (RR) dye from simulated aqueous solution. J Green Eng 10(10):7343–7359

Galhetas M, Mestre A, Pinto M, Gulyurtlu I, Lopes H, Carvalho A (2014) Carbon-based materials prepared from pine gasification residues for acetaminophen adsorption. Chem Eng J 240:344–351

Leite A, Saucier C, Lima E, dos Reis G, Umpierres C, Mello B, Shirmardi M, Dias S, Sampaio C (2017) Activated carbons from avocado seed: optimisation and application for removal of several emerging organic compounds. Environ Sci Pollut Res 25(8):7647–7661

Jawad A, Abdulhameed A (2020) Statistical modeling of methylene blue dye adsorption by high surface area mesoporous activated carbon from bamboo chip using KOH-assisted thermal activation. Energy Ecol Environ 5(6):456–469

Samantray R, Karnan M, Vivekanand, Subramani K, Anjeline C, Mishra S, Sathish M (2021) A facile approach to fabricate Saccharum spontaneum-derived porous carbon-based supercapacitors for excellent energy storage performance in redox active electrolytes. Sustain Energy Fuels 5(2):518–531

Supong A, Bhomick P, Baruah M, Pongener C, Sinha U, Sinha D (2019) Adsorptive removal of Bisphenol A by biomass activated carbon and insights into the adsorption mechanism through density functional theory calculations. Sustain Chem Pharm 13:100159

Hussein M, Abo El Naga A, El Saied M, AbuBaker M, Shaban S, El Kady F (2021) Potato peel waste-derived carbon-based solid acid for the esterification of oleic acid to biodiesel. Environ Technol Innov 21:101355

Hong D, Zhou J, Hu C, Zhou Q, Mao J, Qin Q (2019) Mercury removal mechanism of AC prepared by one-step activation with ZnCl2. Fuel 235:326–335

Varila T, Bergna D, Lahti R, Romar H, Hu T, Lassi U (2017) Activated carbon production from peat using ZnCl2: characterization and applications. BioResources 12(4):8078–8092

Paredes-Laverde M, Salamanca M, Diaz-Corrales J, Flórez E, Silva-Agredo J, Torres-Palma R (2021) Understanding the removal of an anionic dye in textile wastewaters by adsorption on ZnCl2 activated carbons from rice and coffee husk wastes: a combined experimental and theoretical study. J Environ Chem Eng 9(4):105685

Wu S, Yan P, Yang W, Zhou J, Wang H, Che L, Zhu P (2021) ZnCl2 enabled synthesis of activated carbons from ion-exchange resin for efficient removal of Cu2+ ions from water via capacitive deionization. Chemosphere 264:128557

Liu J, Wang S, Yang J, Liao J, Lu M, Pan H, An L (2014) ZnCl2 activated electrospun carbon nanofiber for capacitive desalination. Desalination 344:446–453

http://www.fao.org/faostat/en/#data/QC Accessed 14 August 2021.

Li P, Xia J, Nie Z, Shan Y (2015) Saccharification of orange peel wastes with crude enzymes from new isolated Aspergillus japonicus PJ01. Bioprocess Biosyst Eng 39(3):485–492

Fernandez M, Nunell G, Bonelli P, Cukierman A (2014) Activated carbon developed from orange peels: batch and dynamic competitive adsorption of basic dyes. Ind Crops Prod 62:437–445

ChandrashekarKollarahithlu S, Balakrishnan R (2021) Adsorption of pharmaceuticals pollutants, ibuprofen, acetaminophen, and streptomycin from the aqueous phase using amine functionalized superparamagnetic silica nanocomposite. J Clean Prod 294:126155

Lahieb Faisal, M., Al-Sharify, Z.T., Farah Faisal, M. Role of rice husk as natural sorbent in paracetamol sorption equilibrium and kinetics (2020) IOP Conf Ser: Mater Sci Eng, 870 (1), art. no. 012053.

Khalili S, Khoshandam B, Jahanshahi M (2015) Optimization of production conditions for synthesis of chemically activated carbon produced from pine cone using response surface methodology for CO2 adsorption. RSC Adv 5(114):94115–94129

Azuara M, Kersten S, Kootstra A (2013) Recycling phosphorus by fast pyrolysis of pig manure: concentration and extraction of phosphorus combined with formation of value-added pyrolysis products. Biomass Bioenerg 49:171–180

Patawat C, Silakate K, Chuan-Udom S, Supanchaiyamat N, Hunt A, Ngernyen Y (2020) Preparation of activated carbon from Dipterocarpus alatus fruit and its application for methylene blue adsorption. RSC Adv 10(36):21082–21091

Fernandez M, Ledesma B, Román S, Bonelli P, Cukierman A (2015) Development and characterization of activated hydrochars from orange peels as potential adsorbents for emerging organic contaminants. Biores Technol 183:221–228

El Saied M, El Naggar A, Elhosiny F, El Kady F (2019) A comprehensive investigation on biomass solid waste conversion to a novel catalyst for hydrothermal production of bio-fuel feedstock. J Clean Prod 218:157–166. https://doi.org/10.1016/j.jclepro.2019.01.320

Theydan S, Ahmed M (2012) Optimization of preparation conditions for activated carbons from date stones using response surface methodology. Powder Technol 224:101–108. https://doi.org/10.1016/j.powtec.2012.02.037

Niu T, Zhou J, Zhang C, Li S (2018) Fast removal of methylene blue from aqueous solution using coal-based activated carbon. RSC Adv 8(47):26978–26986

Xie L, Sun G, Su F, Guo X, Kong Q, Li X, Huang X, Wan L, Song W, Li K, Lv C, Chen C (2016) Hierarchical porous carbon microtubes derived from willow catkins for supercapacitor applications. J Mater Chem A 4(5):1637–1646

Jjagwe, J., Olupot, P., Menya, E. and Kalibbala, H., 2021. Synthesis and application of granular activated carbon from biomass waste materials for water treatment: a review. J Bioresour Bioprod.

Yao P, Cen J, Fang M, Wang T, Wang Q (2018) A study on the preparation of pitch-based high-strength columnar activated carbon and mechanism of phenol adsorption from aqueous solution. RSC Adv 8(31):17558–17568

Saeed M, Andrews G, Phylaktou H, Gibbs B (2016) Global kinetics of the rate of volatile release from biomasses in comparison to coal. Fuel 181:347–357

Riaza J, Khatami R, Levendis Y, Álvarez L, Gil M, Pevida C, Rubiera F, Pis J (2014) Combustion of single biomass particles in air and in oxy-fuel conditions. Biomass Bioenerg 64:162–174

Gil M, Casal D, Pevida C, Pis J, Rubiera F (2010) Thermal behaviour and kinetics of coal/biomass blends during co-combustion. Biores Technol 101(14):5601–5608

Yek P, Liew R, Osman M, Lee C, Chuah J, Park Y, Lam S (2019) Microwave steam activation, an innovative pyrolysis approach to convert waste palm shell into highly microporous activated carbon. J Environ Manage 236:245–253

Castro C, Viau L, Andrade J, Mendonça T, Gonçalves M (2018) Mesoporous activated carbon from polyethyleneterephthalate (PET) waste: pollutant adsorption in aqueous solution. New J Chem 42(17):14612–14619

Zhou S, Wei Y, Li B, Wang H (2019) Cleaner recycling of iron from waste copper slag by using walnut shell char as green reductant. J Clean Prod 217:423–431

Uysal T, Duman G, Onal Y, Yasa I, Yanik J (2014) Production of activated carbon and fungicidal oil from peach stone by two-stage process. J Anal Appl Pyrol 108:47–55

Kayiwa R, Kasedde H, Lubwama M, Kirabira J (2021) Characterization and pre-leaching effect on the peels of predominant cassava varieties in Uganda for production of activated carbon. Curr Res Green Sustain Chem 4:100083

Ahmad M, Eusoff M, Oladoye P, Adegoke K, Bello O (2020) Statistical optimization of Remazol Brilliant Blue R dye adsorption onto activated carbon prepared from pomegranate fruit peel. Chem Data Collect 28:100426

Indulekha, J., Gokul Siddarth, M., Kalaichelvi, P. and Arunagiri, A., 2017. Characterization of citrus peels for bioethanol production. Mater Energy Environ Eng, 3–12.

Zakaria R, Jamalluddin N, Abu Bakar M (2021) Effect of impregnation ratio and activation temperature on the yield and adsorption performance of mangrove based activated carbon for methylene blue removal. Results Mater 10:100183

Bello O, Adegoke K, Akinyunni O (2015) Preparation and characterization of a novel adsorbent from Moringa oleifera leaf. Appl Water Sci 7(3):1295–1305

Bello O, Ahmad M (2012) Coconut (Cocos nucifera) shell based activated carbon for the removal of malachite green dye from aqueous solutions. Sep Sci Technol 47(6):903–912

Gumus R, Okpeku I (2015) Production of activated carbon and characterization from snail shell waste (Helix pomatia). Adv Chem Eng Sci 05(01):51–61

Kharrazi S, Soleimani M, Jokar M, Richards T, Pettersson A, Mirghaffari N (2021) Pretreatment of lignocellulosic waste as a precursor for synthesis of high porous activated carbon and its application for Pb (II) and Cr (VI) adsorption from aqueous solutions. Int J Biol Macromol 180:299–310

Nasrullah A, Khan A, Bhat A, Din I, Inayat A, Muhammad N, Bakhsh E, Khan S (2021) Effect of short time ball milling on physicochemical and adsorption performance of activated carbon prepared from mangosteen peel waste. Renewable Energy 168:723–733

Mbarki F, Selmi T, Kesraoui A, Seffen M (2022) Low-cost activated carbon preparation from corn stigmata fibers chemically activated using H3PO4, ZnCl2 and KOH: study of methylene blue adsorption, stochastic isotherm and fractal kinetic. Ind Crops Prod 178:114546

Mahmood T, Ali R, Naeem A, Hamayun M, Aslam M (2017) Potential of used Camellia sinensis leaves as precursor for activated carbon preparation by chemical activation with H3PO4; optimization using response surface methodology. Process Saf Environ Prot 109:548–563

Ahmad, M., Mohamad Yusop, M., Zakaria, R., Karim, J., Yahaya, N., Mohamed Yusoff, M., Hashim, N. and Abdullah, N., 2021. Adsorption of methylene blue from aqueous solution by peanut shell based activated carbon. Mater Today: Proc.

Vu D, Seo J, Lee H, Lee J (2017) Activated carbon with hierarchical micro–mesoporous structure obtained from rice husk and its application for lithium–sulfur batteries. RSC Adv 7(7):4144–4151

Liu L, Huang Y, Zhang S, Gong Y, Su Y, Cao J, Hu H (2019) Adsorption characteristics and mechanism of Pb(II) by agricultural waste-derived biochars produced from a pilot-scale pyrolysis system. Waste Manage 100:287–295

Liu H, Ning W, Cheng P, Zhang J, Wang Y, Zhang C (2013) Evaluation of animal hairs-based activated carbon for sorption of norfloxacin and acetaminophen by comparing with cattail fiber-based activated carbon. J Anal Appl Pyrol 101:156–165

Sumalinog D, Capareda S, de Luna M (2018) Evaluation of the effectiveness and mechanisms of acetaminophen and methylene blue dye adsorption on activated biochar derived from municipal solid wastes. J Environ Manage 210:255–262

Al-Khateeb L, Almotiry S, Salam M (2014) Adsorption of pharmaceutical pollutants onto graphene nanoplatelets. Chem Eng J 248:191–199

Patel M, Kumar R, Pittman C, Mohan D (2021) Ciprofloxacin and acetaminophen sorption onto banana peel biochars: environmental and process parameter influences. Environ Res 201:111218

Liu S, Pan M, Feng Z, Qin Y, Wang Y, Tan L, Sun T (2020) Ultra-high adsorption of tetracycline antibiotics on garlic skin-derived porous biomass carbon with high surface area. New J Chem 44(3):1097–1106

Park J, Kim C, Jhung S (2021) Melamine/polyaniline-derived carbons with record-high adsorption capacities for effective removal of phenolic compounds from water. Chem Eng J 420:127627

Peiris C, Gunatilake S, Mlsna T, Mohan D, Vithanage M (2017) Biochar based removal of antibiotic sulfonamides and tetracyclines in aquatic environments: a critical review. Biores Technol 246:150–159

Rajapaksha A, Vithanage M, Zhang M, Ahmad M, Mohan D, Chang S, Ok Y (2014) Pyrolysis condition affected sulfamethazine sorption by tea waste biochars. Biores Technol 166:303–308

Mahmoud A, Youssef N, Osama A, Selim M (2019) Removal of lead ions from industrial wastewater using magnetite loaded on silica support. Egypti Chem 0(0):0–0

Adewuyi A (2020) Chemically modified biosorbents and their role in the removal of emerging pharmaceutical waste in the water system. Water 12(6):1551

Liang X, Ouyang X, Wang S, Yang L, Huang F, Ji C, Chen X (2019) Efficient adsorption of Pb(II) from aqueous solutions using aminopropyltriethoxysilane-modified magnetic attapulgite@chitosan (APTS-Fe3O4/APT@CS) composite hydrogel beads. Int J Biol Macromol 137:741–750

Rashid J, Saleemi F, Akram B, Wang L, Hussain N, Xu M (2021) Facile synthesis of g-C3N4/MoO3 nanohybrid for efficient removal of aqueous diclofenac sodium. Nanomaterials 11(6):1564

Quesada H, Cusioli L, Obezerra C, Baptista A, Nishi L, Gomes R, Bergamasco R (2019) Acetaminophen adsorption using a low-cost adsorbent prepared from modified residues of Moringa oleifera Lam. seed husks. J Chem Technol Biotechnol 94(10):3147–3157

Mphahlele K, Onyango M, Mhlanga S (2015) Adsorption of aspirin and paracetamol from aqueous solution using Fe/N-CNT/β-cyclodextrin nanocomopsites synthesized via a benign microwave assisted method. J Environ Chem Eng 3(4):2619–2630

Weber WJ Jr, Morris JC, Sanit J (1963) Kinetics of adsorption on carbon from solution Journal of the Sanitary Engineering Division,. Am Soc Civil Eng 89:31

Wang Y, Lin C, Liu X, Ren W, Huang X, He M, Ouyang W (2021) Efficient removal of acetochlor pesticide from water using magnetic activated carbon: adsorption performance, mechanism, and regeneration exploration. Sci Total Environ 778:146353

Zhao Z, Sun W, Ray M (2022) Adsorption isotherms and kinetics for the removal of algal organic matter by granular activated carbon. Sci Total Environ 806:150885

Zong E, Guo B, Yang J, Shi C, Jiang S, Ma Z, Liu X (2020) Reusable hyperbranched polyethylenimine-functionalized ethyl cellulose film for the removal of phosphate with easy separation. ACS Omega 6(1):505–515

García-Mateos F, Ruiz-Rosas R, Marqués M, Cotoruelo L, Rodríguez-Mirasol J, Cordero T (2015) Removal of paracetamol on biomass-derived activated carbon: modeling the fixed bed breakthrough curves using batch adsorption experiments. Chem Eng J 279:18–30

Nourmoradi H, Moghadam K, Jafari A, Kamarehie B (2018) Removal of acetaminophen and ibuprofen from aqueous solutions by activated carbon derived from Quercus Brantii (Oak) acorn as a low-cost biosorbent. J Environ Chem Eng 6(6):6807–6815

Ferreira RC, De Lima HHC, Cândido AA, Couto OM, Arroyo PA, De Carvalho KQ, Gauze GF, Barros MA (2015) Adsorption of paracetamol using activated carbon of dende and babassu coconut mesocarp. World Acad Sci Eng Technol Int J Biotechnol Bioeng 9:717–722

Nche N-AG, Bopda A, Tchuifon DRT, Ngakou CS, Kuete I-HT, Gabche AS (2017) Removal of paracetamol from aqueous solution by adsorption onto activated carbon prepared from rice husk. J Chem Pharm Res 9(3):56–68

Ferreira R, Couto Junior O, Carvalho K, Arroyo P, Barros M (2015) Effect of solution pH on the removal of paracetamol by activated carbon of dende coconut mesocarp. Chem Biochem Eng Quart J 29:47–53

Paredes-Laverde M, Salamanca M, Silva-Agredo J, Manrique-Losada L, Torres-Palma R (2019) Selective removal of acetaminophen in urine with activated carbons from rice (Oryza sativa) and coffee (Coffea arabica) husk: effect of activating agent, activation temperature and analysis of physical-chemical interactions. J Environ Chem Eng 7(5):103318

Quesada-Peñate I, Julcour-Lebigue C, Jáuregui-Haza U, Wilhelm A, Delmas H (2012) Degradation of paracetamol by catalytic wet air oxidation and sequential adsorption – catalytic wet air oxidation on activated carbons. J Hazard Mater 221–222:131–138

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This work was financially supported by the Egyptian Petroleum Research Institute (EPRI), Egypt.

Author information

Authors and Affiliations

Contributions

Mohamed El Saied: methodology, formal analysis, investigation, validation; Seham A. Shaban: formal analysis, investigation, supervision; Mohsen S. Mostafa: supervision; Ahmed O. Abo El Naga: conceptualization, formal analysis, investigation, project administration, writing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saied, M.E., Shaban, S.A., Mostafa, M.S. et al. Efficient adsorption of acetaminophen from the aqueous phase using low-cost and renewable adsorbent derived from orange peels. Biomass Conv. Bioref. 14, 2155–2172 (2024). https://doi.org/10.1007/s13399-022-02541-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02541-x