Abstract

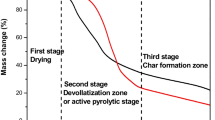

The orange and potato peels can be evaluated as raw materials in pyrolysis process to produce sustainable fuels and chemicals. The present study focuses on determining pyrolysis characteristics and kinetics of orange and potato peels. Thus, thermogravimetric analyses of said peels were studied from ambient temperature to 650°C at 2, 10 and 15°C/min heating rates under N2 atmosphere. The studies revealed that the thermal decomposition of orange peels occurs in four stages whereas potato peels decompose in three stages. The second and third stages of orange peel pyrolysis and the second stage of potato peel pyrolysis were determined as active pyrolysis stages. The kinetic parameters of active pyrolysis stages were calculated by direct Arrhenius plot, Coats-Redfern, Friedman and Kissinger-Akahira-Sunose methods. The average activation energies calculated by all methods were relatively in good agreement for second stages, but the same cannot be said for the third stage of orange peel pyrolysis. Considering the conversion values based on volatiles and the calculated average activation energy values, the orange and potato peels were projected to be valuable and sustainable energy sources which can be evaluated by pyrolysis process.

Similar content being viewed by others

References

Kannan N, Vakeesan D (2016) Solar energy for future world: - a review. Renew Sust Energ Rev 62:1092–1105. https://doi.org/10.1016/j.rser.2016.05.022

Kan S, Chen B, Chen G (2019) Worldwide energy use across global supply chains: decoupled from economic growth? Appl Energy 250:1235–1245. https://doi.org/10.1016/j.apenergy.2019.05.104

Kan SY, Chen B, Wu XF, Chen ZM, Chen GQ (2019) Natural gas overview for world economy: from primary supply to final demand via global supply chains. Energy Policy 124:215–225. https://doi.org/10.1016/j.enpol.2018.10.002

Bermúdez CA, Porteiro J, Varela LG, Chapela S, Patiño D (2020) Three-dimensional CFD simulation of a large-scale grate-fired biomass furnace. Fuel Process Technol 198:106219. https://doi.org/10.1016/j.fuproc.2019.106219

Varma AK, Singh S, Rathore AK, Thakur LS, Shankar R, Mondal P (2020) Investigation of kinetic and thermodynamic parameters for pyrolysis of peanut shell using thermogravimetric analysis. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00972-y

Kothandaraman MP, Somasundaram M (2019) Non-isothermal kinetic study on copyrolysis of Juliflora and low-density polyethylene. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-019-00559-2

Ahmad MS, Mehmood MA, Taqvi STH, Elkamel A, Liu CG, Xu J, Rahimuddin SA, Gull M (2017) Pyrolysis, kinetics analysis, thermodynamics parameters and reaction mechanism of Typha latifolia to evaluate its bioenergy potential. Bioresour Technol 245(Part A):491–501. https://doi.org/10.1016/j.biortech.2017.08.162

Şen AU, Fonseca FG, Funke A, Pereira H, Lemos F (2020) Pyrolysis kinetics and estimation of chemical composition of Quercus cerris cork. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-00964-y

Cai J, Xu D, Dong Z, Yu X, Yang Y, Banks SW, Bridgwater AV (2018) Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: case study of corn stalk. Renew Sust Energ Rev 82(3):2705–2715. https://doi.org/10.1016/j.rser.2017.09.113

Arenas CN, Navarro MV, Martínez JD (2019) Pyrolysis kinetics of biomass wastes using isoconversional methods and the distributed activation energy model. Bioresour Technol 288:121485. https://doi.org/10.1016/j.biortech.2019.121485

Özsin G, Pütün AE (2019) TGA/MS/FT-IR study for kinetic evaluation and evolved gas analysis of a biomass/PVC co-pyrolysis process. Energy Convers Manag 182:143–153. https://doi.org/10.1016/j.enconman.2018.12.060

Ma Z, Chen D, Gu J, Bao B, Zhang Q (2015) Determination of pyrolysis characteristics and kinetics of palm kernel shell using TGA–FTIR and model-free integral methods. Energy Convers Manag 89:251–259. https://doi.org/10.1016/j.enconman.2014.09.074

Amini E, Safdari MS, Weise DR, Fletcher TH (2019) Pyrolysis kinetics of live and dead wildland vegetation from the Southern United States. J Anal Appl Pyrolysis 142:104613. https://doi.org/10.1016/j.jaap.2019.05.002

Christoforou E, Fokaides PA (2016) A review of olive mill solid wastes to energy utilization techniques. Waste Manag 49:346–363. https://doi.org/10.1016/j.wasman.2016.01.012

Pathak PD, Mandavgane SA, Kulkarni BD (2017) Fruit peel waste: characterization and its potential uses. Curr Sci 113(3):444-454. https://doi.org/10.18520/cs/v113/i03/444-454

Torre I, Martin-Dominguez V, Acedos MG, Esteban J, Santos VE, Ladero M (2019) Utilisation/upgrading of orange peel waste from a biological biorefinery perspective. Appl Microbiol Biotechnol 103:5975–5991. https://doi.org/10.1007/s00253-019-09929-2

Siles JA, Vargas F, Gutiérrez MC, Chica AF, Martín MA (2016) Integral valorisation of waste orange peel using combustion, biomethanisation and co-composting technologies. Bioresour Technol 211:173–182. https://doi.org/10.1016/j.biortech.2016.03.056

Zhang B, Chen J, He Z, Chen H, Kandasamy S (2019) Hydrothermal liquefaction of fresh lemon-peel: parameter optimisation and product chemistry. Renew Energy 143:512–519. https://doi.org/10.1016/j.renene.2019.05.003

Rezzadori K, Benedetti S, Amante ER (2012) Proposals for the residues recovery: orange waste as raw material for new products. Food Bioprod Process 90:606–614. https://doi.org/10.1016/j.fbp.2012.06.002

Negro V, Ruggeri B, Fino D, Tonini D (2017) Life cycle assessment of orange peel waste management. Resour Conserv Recycl 127:148–158. https://doi.org/10.1016/j.resconrec.2017.08.014

Bhatnagar A, Sillanpää M, Witek-Krowiak A (2015) Agricultural waste peels as versatile biomass for water purification – a review. Chem Eng J 270:244–271. https://doi.org/10.1016/j.cej.2015.01.135

De Carvalho WT, De Oliveira TF, Da Silva FA, Caliari M, Soares Júnior MS (2014) Drying kinetics of potato pulp waste. Food Science and Technology 34(1):116–122. https://doi.org/10.1590/S0101-20612014000100017

El-Azazy M, El-Shafie IAA, Al-Sulaiti M, Al-Yafie J, Shomar B, Al-Saad K (2019) Potato peels as an adsorbent for heavy metals from aqueous solutions: eco-structuring of a green adsorbent operating Plackett–Burman design. J Chemother 4926240:1–14. https://doi.org/10.1155/2019/4926240

Arampatzidou AC, Deliyanni EA (2016) Comparison of activation media and pyrolysis temperature for activated carbons development by pyrolysis of potato peels for effective adsorption of endocrine disruptor bisphenol-A. J Colloid Interface Sci 466:101–112. https://doi.org/10.1016/j.jcis.2015.12.003

Bernardo M, Rodrigues S, Lapa N, Matos I, Lemos F, Batista MKS, Carvalho AP, Fonseca I (2016) High efficacy on diclofenac removal by activated carbon produced from potato peel waste. Int J Environ Sci Technol 13:1989–2000. https://doi.org/10.1007/s13762-016-1030-3

Arapoglou D, Varzakas T, Vlyssides A, Israilides C (2010) Ethanol production from potato peel waste (PPW). Waste Manag 30:1898–1902. https://doi.org/10.1016/j.wasman.2010.04.017

Santos CM, Dweck J, Viotto RS, Rosa AH, de Morais LC (2015) Application of orange peel waste in the production of solid biofuels and biosorbents. Bioresour Technol 196:469–479. https://doi.org/10.1016/j.biortech.2015.07.114

De Morais LC, Santos CM, Rosa AH (2015) Thermodynamic parameters of a solid biofuel from orange peel. Chem Eng Trans 43:583–588. https://doi.org/10.3303/CET1543098

Martínez-Vargas DX, Sandoval-Rangel L, Solís-Maldonado C, De La Rosa JR, Lucio-Ortiz CJ, Dimas-Rivera G, Ramos-Delgado NA, Mendoza-Domínguez A (2018) Application of natural minerals for in-situ catalytic pyrolysis of orange peel. J Appl Res Technol 16:404-421. https://doi.org/10.22201/icat.16656423.2018.16.5.736

Lopez-Velazquez MA, Santes V, Balmaseda J, Torres-Garcia E (2013) Pyrolysis of orange waste: a thermo-kinetic study. J Anal Appl Pyrolysis 99:170–177. https://doi.org/10.1016/j.jaap.2012.09.016

Kim Y-M, Jae J, Lee HW, Han TU, Lee H, Park SH, Kim S, Watanabe C, Park Y-K (2016) Ex-situ catalytic pyrolysis of citrus fruit peels over mesoporous MFI and Al-MCM-41. Energy Convers Manag 125:277–289. https://doi.org/10.1016/j.enconman.2016.02.065

Liang S, Han Y, Wei L, McDonald AG (2015) Production and characterization of bio-oil and bio-char from pyrolysis of potato peel wastes. Biomass Conversion and Biorefinery 5:237–246. https://doi.org/10.1007/s13399-014-0130-x

Önal E, Uzun BB, Pütün AE (2012) An experimental study on bio-oil production from co-pyrolysis with potato skin and high-density polyethylene (HDPE). Fuel Process Technol 104:365–370. https://doi.org/10.1016/j.fuproc.2012.06.010

Önal EP, Uzun BB, Pütün AE (2011) Steam pyrolysis of an industrial waste for bio-oil production. Fuel Process Technol 92:879–885. https://doi.org/10.1016/j.fuproc.2010.12.006

Gupta S, Gupta GK, Mondal MK (2020) Thermal degradation characteristics, kinetics, thermodynamics, and reaction mechanism analysis of pistachio shell pyrolysis for its bioenergy potential. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01104-2

Mishra RK, Mohanty K (2018) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol 251:63–74. https://doi.org/10.1016/j.biortech.2017.12.029

Pradhan RR, Garnaik PP, Regmi B, Dash B, Dutta A (2017) Pyrolysis kinetics of Sal (Shorea robusta) seeds. Biomass Conversion and Biorefinery 7:237–246. https://doi.org/10.1007/s13399-017-0240-3

Singh Chouhan AP, Sarma AK (2013) Critical analysis of process parameters for bio-oil production via pyrolysis of biomass: a review. Recent Pat Eng 7(2):98–114. https://doi.org/10.2174/18722121113079990005

Kyzas GZ, Deliyanni EA, Matis KA (2016) Activated carbons produced by pyrolysis of waste potato peels: cobalt ions removal by adsorption. Colloids Surf A Physicochem Eng Asp 490:74–83. https://doi.org/10.1016/j.colsurfa.2015.11.038

Mohan D, Pittman CU, Steele P (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuel 20:848–889. https://doi.org/10.1021/ef0502397

Waters CL, Janupala RR, Mallinson RG, Lobban LL (2017) Staged thermal fractionation for segregation of lignin and cellulose pyrolysis products: an experimental study of residence time and temperature effects. J Anal Appl Pyrolysis 126:380–389. https://doi.org/10.1016/j.jaap.2017.05.008

Einhorn-Stoll U, Kunzek H (2009) Thermoanalytical characterisation of processing-dependent structural changes and state transitions of citrus pectin. Food Hydrocoll 23(1):40–52. https://doi.org/10.1016/j.foodhyd.2007.11.009

Xue J, Ceylan S, Goldfarb JL (2015) Synergism among biomass building blocks? Evolved gas and kinetics analysis of starch and cellulose co-pyrolysis. Thermochim Acta 618:36–47. https://doi.org/10.1016/j.tca.2015.09.002

Qiao Y, Wang B, Ji Y, Xu F, Zong P, Zhang J, Tian Y (2019) Thermal decomposition of castor oil, corn starch, soy protein, lignin, xylan, and cellulose during fast pyrolysis. Bioresour Technol 278:287–295. https://doi.org/10.1016/j.biortech.2019.01.102

Wu W, Mei Y, Zhang L, Liu R, Cai J (2014) Effective activation energies of lignocellulosic biomass pyrolysis. Energy Fuel 28:3916–3923. https://doi.org/10.1021/ef5005896

Radojević M, Janković B, Jovanović V, Stojiljković D, Manić N (2018) Comparative pyrolysis kinetics of various biomasses based on model-free and DAEM approaches improved with numerical optimization procedure. PLoS One 13(10):e0206657. https://doi.org/10.1371/journal.pone.0206657

Becidan M, Várhegyi G, Hustad JE, Skreiberg Ø (2007) Thermal decomposition of biomass wastes. A kinetic study. Ind Eng Chem Res 46:2428–2437. https://doi.org/10.1021/ie061468z

Vuppaladadiyam AK, Liu H, Zhao M, Soomro AF, Memon MZ, Dupont V (2019) Thermogravimetric and kinetic analysis to discern synergy during the co-pyrolysis of microalgae and swine manure digestate. Biotechnology for Biofuels 12:170. https://doi.org/10.1186/s13068-019-1488-6

Acknowledgements

The author would like to thank Dr. Gözde Gözke Açıkalın for her continuous support during the studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Açıkalın, K. Evaluation of orange and potato peels as an energy source: a comprehensive study on their pyrolysis characteristics and kinetics. Biomass Conv. Bioref. 12, 501–514 (2022). https://doi.org/10.1007/s13399-021-01387-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01387-z