Abstract

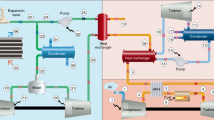

In this study, evaporation line and steam and power production unit in a sugar processing plant were investigated by means of energetic, exergetic, and exergoeconomic (3E) analyses. 3E parameters for each subsystem in both units were computed via coding in EES software. For a more detailed analysis, the heat losses from the surfaces of the subsystems were computed using thermography data. The results revealed that from a thermodynamic viewpoint, the steam and power production unit had a weaker performance compared with evaporation line, such that its energy loss rate and exergy destruction rate were 2.68 and 24.50 times those of the evaporation line, respectively. However, from an exergoeconomic viewpoint, the operational cost rate of the evaporation line was 2.31 times that of the steam unit. Furthermore, the cost of heat losses from the surfaces of the subsystems in the evaporation line was found to be 13299.84 USD.year−1. In conclusion, to reduce the cost of the final product, it is highly recommended that the reduction of thermodynamic inefficiencies in the evaporation line be given priority over the steam and power production unit; besides, it can be noted that the cost of heat losses from the surfaces of the subsystems is a considerable amount that should not be ignored.

Similar content being viewed by others

Abbreviations

- g :

-

Gravitational acceleration (m s−2)

- \( \dot{m} \) :

-

Mass flow rate (kg s−1)

- P:

-

Pressure (kPa)

- s :

-

Specific entropy (kJ kg−1 K−1)

- T:

-

Temperature (K also °C)

- A :

-

Heat transfer area (m2)

- Ċ :

-

Cost rate (USD hr−1)

- Z :

-

Capital cost (USD)

- Ż :

-

Capital cost rate (USD hr−1)

- N :

-

Annual factory operation hours (hr)

- n :

-

Number of operation years mole number

- c :

-

Cost per unit exergy (USD GJ−1)

- \( \dot{Q} \) :

-

Heat transfer rate (kW)

- h :

-

Heat transfer coefficient of convection (W m−2 K−1) also specific enthalpy (kJ kg−1)

- k :

-

Heat transfer coefficient of conduction (W m−1 K−1)

- F:

-

Fuel

- P:

-

Product

- tot:

-

Total

- cond:

-

Conduction

- conv:

-

Convection

- rad:

-

Radiation

- i :

-

Inlet also interest rate (decimal)

- e:

-

Exit

- D:

-

Destroyed

- ch:

-

Chemical

- ∞:

-

Infinity

- L:

-

Loss

- 0:

-

Dead state

- L:

-

Characteristics length (m)

- C P :

-

Specific heat capacity (kJ kg−1 K−1)

- Ėx:

-

Exergy rate (kW)

- ex:

-

Specific exergy (kJ kg−1)

- Ėn:

-

Energy rate (kW)

- Ẇ :

-

Power (kW)

- ε i :

-

Standard chemical exergy (kJ mole−1)

- X i :

-

Mole fraction

- CRF:

-

Capital recovery factor

- Ra:

-

Rayleigh number

- Nu:

-

Nusselt number

- SPECO:

-

Specific Exergy Costing

- LHV:

-

Lower heat value (kJ/kg)

- EES:

-

Engineering Equation Solver

- ρ :

-

Density (kg m−3)

- α:

-

Thermal diffusivity (m2 s−1)

- β:

-

Thermal expansion coefficient (K−1)

- ϑ:

-

Kinematic viscosity (m2 s−1)

- ε:

-

Emissivity

- σ:

-

Stefan-Boltzmann constant

- ξ:

-

Fuel quality factor

- \( \mathcal{R} \) :

-

Gas constant (kJ kmol−1 K−1)

- φ:

-

Maintenance factor

- v :

-

Specific volume

- mpg:

-

100 kg of beet per minute

References

Taner T, Sivrioglu M (2015) Energy-exergy analysis and optimisation of a model sugar factory in Turkey. Energy 93:641–654. https://doi.org/10.1016/j.energy.2015.09.007

Kanoğlu M, Çengel YA, Dinçer İ (2012) Efficiency, environment, and sustainability

Miller J, Foxon T, Sorrell S (2016) Exergy accounting: a quantitative comparison of methods and implications for energy-economy analysis. Energies 9:947. https://doi.org/10.3390/en9110947

Dincer I, Rosen MA (2005) Thermodynamic aspects of renewables and sustainable development. Renew Sust Energ Rev 9:169–189. https://doi.org/10.1016/j.rser.2004.02.002

Ganjehsarabi H, Dincer I, Gungor A (2014) Exergoeconomic analysis of a heat pump tumbler dryer. Dry Technol 32:352–360. https://doi.org/10.1080/07373937.2013.829853

Bayrak M, Midilli A, Nurveren K (2003) Energy and exergy analyses of sugar production stages. Int J Energy Res 27:989–1001. https://doi.org/10.1002/er.916

Şahin HM, Acir A, Altunok T, Baysal E, Koçyiğit E (2010) Analysis of exergy and energy of sugar production process in sugar plant. J Energy Inst 83:178–185. https://doi.org/10.1179/014426010X12759937396911

Tekin T, Bayramoğlu M (1998) Exergy analysis of the sugar production process from sugar beets. Int J Energy Res 22:591–601. https://doi.org/10.1002/(SICI)1099-114X(19980610)22:7<591::AID-ER360>3.0.CO;2-D

Bapat SM, Majali VS, Ravindranath G (2016) Exergy and sustainability analysis of quintuple effect evaporation unit in a sugar industry - a case study. Int J Renew Energy Technol 7:46. https://doi.org/10.1504/ijret.2016.073401

Erbay Z, Koca N (2012) Energetic, exergetic, and exergoeconomic analyses of spray-drying process during white cheese powder production. Dry Technol 30:435–444. https://doi.org/10.1080/07373937.2011.647183

Erbay Z, Koca N (2014) Exergoeconomic performance assessment of a pilot-scale spray dryer using the specific exergy costing method. Biosyst Eng 122:127–138. https://doi.org/10.1016/j.biosystemseng.2014.04.006

Gungor A, Erbay Z, Hepbasli A (2011) Exergoeconomic analyses of a gas engine driven heat pump drier and food drying process. Appl Energy 88:2677–2684. https://doi.org/10.1016/j.apenergy.2011.02.001

Hepbasli A, Colak N, Hancioglu E, Icier F, Erbay Z (2010) Exergoeconomic analysis of plum drying in a heat pump conveyor dryer. Dry Technol 28:1385–1395. https://doi.org/10.1080/07373937.2010.482843

Singh G, Singh PJ, Tyagi VV, Barnwal P, Pandey AK (2019) Exergy and thermo-economic analysis of ghee production plant in dairy industry. Energy 167:602–618. https://doi.org/10.1016/j.energy.2018.10.138

Singh G, Singh PJ, Tyagi VV, Pandey AK (2019) Thermal and exergoeconomic analysis of a dairy food processing plant. J Therm Anal Calorim 136:1365–1382. https://doi.org/10.1007/s10973-018-7781-y

Carlomagno GM, Cardone G (2010) Infrared thermography for convective heat transfer measurements

Carlomagno GM, de Luca L, Cardone G, Astarita T (2014) Heat flux sensors for infrared thermography in convective heat transfer

Simionescu Ş-M, Düzel Ü, Esposito C, et al (2015) The 9th International Symposium on Advanced Topics in Electrical Engineering Heat Transfer Coefficient Measurements using Infrared Thermography Technique. 0–5

Forero-Núñez CA, Sierra-Vargas FE (2016) Heat losses analysis using infrared thermography on a fixed bed downdraft gasifier. Int Rev Mechan Eng 10:239–245. https://doi.org/10.15866/ireme.v10i4.8935

Marino BM, Muñoz N, Thomas LP (2017) Estimation of the surface thermal resistances and heat loss by conduction using thermography. Appl Therm Eng 114:1213–1221. https://doi.org/10.1016/j.applthermaleng.2016.12.033

Chatzipanagiotou P, Chatziathanasiou V, De Mey G, Więcek B (2017) Influence of soil humidity on the thermal impedance, time constant and structure function of underground cables: a laboratory experiment. Appl Therm Eng 113:1444–1451. https://doi.org/10.1016/j.applthermaleng.2016.11.117

Díaz Pérez ÁA, Escobar Palacio JC, Venturini OJ, Martínez Reyes AM, Rúa Orozco DJ, Silva Lora EE, Almazán del Olmo OA (2018) Thermodynamic and economic evaluation of reheat and regeneration alternatives in cogeneration systems of the Brazilian sugarcane and alcohol sector. Energy 152:247–262. https://doi.org/10.1016/j.energy.2018.03.106

Çengel YA, Ghajar AJ Heat and mass transfer

Lambert C, Laulan B, Decloux M, Romdhana H, Courtois F (2018) Simulation of a sugar beet factory using a chemical engineering software (ProSimPlus®) to perform Pinch and exergy analysis. J Food Eng 225:1–11. https://doi.org/10.1016/j.jfoodeng.2018.01.004

Dincer I, Rosen MA, Ahmadi P (2017) Optimization of energy systems. John Wiley & Sons, Ltd, Chichester

Akbari N (2018) Introducing and 3E (energy, exergy, economic) analysis of an integrated transcritical CO2 Rankine cycle, Stirling power cycle and LNG regasification process. Appl Therm Eng 140:442–454. https://doi.org/10.1016/j.applthermaleng.2018.05.073

Cengel YA (2011) Thermodynamics: an engineering approach Introduction and Basic Concepts, 8th Editio edn, pp 1–59

Mojarab Soufiyan M, Aghbashlo M (2017) Application of exergy analysis to the dairy industry: a case study of yogurt drink production plant. Food Bioprod Process 101:118–131. https://doi.org/10.1016/j.fbp.2016.10.008

Yildirim N, Genc S (2017) Energy and exergy analysis of a milk powder production system. Energy Convers Manag 149:698–705. https://doi.org/10.1016/j.enconman.2017.01.064

Balli O, Aras H, Hepbasli A (2007) Exergetic performance evaluation of a combined heat and power (CHP) system in Turkey. Int J Energy Res 31:849–866. https://doi.org/10.1002/er.1270

Mojarab Soufiyan M, Aghbashlo M, Mobli H (2016) Exergetic performance assessment of a long-life milk processing plant: a comprehensive survey. J Clean Prod 30:1–18. https://doi.org/10.1016/j.jclepro.2015.11.066

Bühler F, Van Nguyen T, Jensen JK et al (2018) Energy, exergy and advanced exergy analysis of a milk processing factory. Energy 162:576–592. https://doi.org/10.1016/j.energy.2018.08.029

Ahmadi GR, Toghraie D (2016) Energy and exergy analysis of Montazeri Steam Power Plant in Iran. Renew Sust Energ Rev 56:454–463. https://doi.org/10.1016/j.rser.2015.11.074

Jokandan MJ, Aghbashlo M, Mohtasebi SS (2015) Comprehensive exergy analysis of an industrial-scale yogurt production plant. Energy 93:1832–1851. https://doi.org/10.1016/j.energy.2015.10.003

Szargut J, Morris D, Steward F (1988) Exergy analysis of thermal, chemical, and metallurgical processes. Hemisphere Publishing Corporation, Washington DC

Tsatsaronis G (1993) Thermoeconomic analysis and optimization of energy systems. Prog Energy Combust Sci 19:227–257. https://doi.org/10.1016/0360-1285(93)90016-8

Xiang JY, Cali M, Santarelli M (2004) Calculation for physical and chemical exergy of flows in systems elaborating mixed-phase flows and a case study in an IRSOFC plant. Int J Energy Res 28:101–115. https://doi.org/10.1002/er.953

Behbahani-Nia A, Shams S (2016) Energy equipment and systems thermoeconomic optimization and exergy analysis of transcritical CO 2 refrigeration cycle with an ejector. Energyequipsys 4:43–52

Elsayed ML, Mesalhy O, Mohammed RH, Chow LC (2018) Exergy and thermo-economic analysis for MED-TVC desalination systems. Desalination 447:29–42. https://doi.org/10.1016/j.desal.2018.06.008

Ahmadi P, Dincer Y (2018) Comprehensive energy systems. Elsevier, Amsterdam https://www.sciencedirect.com/referencework/9780128149256/comprehensive-energy-systems.

Ameri M, Ahmadi P, Hamidi A (2009) Energy, exergy and exergoeconomic analysis of a steam power plant: a case study. Int J Energy Res 33:499–512. https://doi.org/10.1002/er.1495

Yilmaz C, Kanoglu M, Abusoglu A (2015) Exergetic cost evaluation of hydrogen production powered by combined flash-binary geothermal power plant. Int J Hydrog Energy 40:14021–14030. https://doi.org/10.1016/j.ijhydene.2015.07.031

Behzadi A, Gholamian E, Ahmadi P, Habibollahzade A, Ashjaee M (2018) Energy, exergy and exergoeconomic (3E) analyses and multi-objective optimization of a solar and geothermal based integrated energy system. Appl Therm Eng 143:1011–1022. https://doi.org/10.1016/j.applthermaleng.2018.08.034

Hafdhi F, Khir T, Ben Yahia A, Ben Brahim A (2018) Exergoeconomic optimization of a double effect desalination unit used in an industrial steam power plant. Desalination 438:63–82. https://doi.org/10.1016/j.desal.2018.03.020

Maroulis ZB, Saravacos GD (2003) Food process design. CRC, Boca Raton

Lorenz F (2008) Improving energy efficiency in sugar processing. Woodhead Publishing Limited, Cambridge

Todorović MN, Živković DS, Mančić MV, Ilić GS (2014) Primena energetske i eksergetske analize za poboljŠanje efikasnosti vrelovodnog kotla. Chem Ind Chem Eng Q 20:511–521. https://doi.org/10.2298/CICEQ130716033T

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Piri, A., Nikbakht, A.M., Hazervazifeh, A. et al. Role of 3E analysis in detection of thermodynamic losses in the evaporation line and steam and power production unit in the sugar processing plant. Biomass Conv. Bioref. 13, 3049–3069 (2023). https://doi.org/10.1007/s13399-021-01348-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01348-6