Abstract

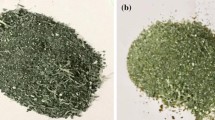

This study investigated pyrolysis and activation of palm rachis and jujube stones at 1073 K to determine the yield of the detailed composition of the released gases, tar, condensable and solid material after each step of the process. The biomasses and their derived materials were characterized using approximate and ultimate analysis and calorimetry analysis in order to carry out the matter and the energy balance of both examined processes. Empirical assumptions were used to mine the collected data. Furthermore, wood was also used in this study for comparison purpose. The carbon weight percentage (%C) was 46.1, 49.3 and 49.2% for palm rachis, jujube stones and wood, respectively. This last parameter becomes 67.3, 91.7 and 87.0% for the same burn-off value (55%) for the activated carbons produced from the cited biomasses, respectively. The global matter balance of the solid materials recovered from the processes was 15.9, 11.6 and 12.5% for activated carbon (at 55% of burn-off) prepared from palm rachis, jujube stones and wood, respectively. The global energy balance was positive for all examined samples with the recovery of close to 70% of the energy initially contained in virgin biomass as combustible gases form. Finally, it was found that rachis palm and jujube stones are efficient as precursor for thermochemical conversion.

Similar content being viewed by others

Abbreviations

- W:

-

Wood

- PR:

-

Palm rachis

- JS:

-

Jujube stones

- AC:

-

Activated carbon

- E:

-

Energy

- M:

-

Mass

- V:

-

Volume

- %Y:

-

Yield

- LHV:

-

Low heating value

- %BO:

-

Burn-off

- Cp:

-

The gases specific heat capacity

- Cv:

-

The constant volume capacity

- ND:

-

Not defined

- Q:

-

Quantity of gas

References

Ahmad MA, Ahmad N, Bello OS (2015) Adsorption kinetic studies for the removal of synthetic dye using durian seed activated carbon. Journal of Dispersion Science and Technology 36(5):670–684

Abd El-Latifa MM, Ibrahim AM (2010) Removal of reactive dye from aqueous solutions by adsorption onto activated carbons prepared from oak sawdust. Desalination and Water Treatment 20(1-3):102–113

Hejazifar M, Azizian S (2012) Adsorption of cationic and anionic dyes onto the activated carbon prepared from grapevine rhytidome. Journal of Dispersion Science and Technology 33(6):846–853

Hirunpraditkoon S, Srinophakun P, Sombun N, Moore EJ (2015) Synthesis of activated carbon from jatropha seed coat and application to adsorption of iodine and methylene blue. Chemical Engineering Communications 202(1):32–47

Ahmad A, Idris A, Hameed B (2013) Organic dye adsorption on activated carbon derived from solid waste. Desalination and Water Treatment 51(13-15):2554–2563

Kula I, Uğurlu M, Karaoğlu H, Celik A (2008) Adsorption of Cd (II) ions from aqueous solutions using activated carbon prepared from olive stone by ZnCl2 activation. Bioresource technology 99(3):492–501

Anastopoulos I, Karamesouti M, Mitropoulos AC, Kyzas GZ (2017) A review for coffee adsorbents. Journal of Molecular Liquids 229:555–565

Emami Z, Azizian S (2014) Preparation of activated carbon from date sphate using microwave irradiation and investigation of its capability for removal of dye pollutant from aqueous media. Journal of Analytical and Applied Pyrolysis 108:176–184

Daoud M, Benturki O, Kecira Z, Girods P, Donnot A (2017) Removal of reactive dye (BEZAKTIV Red S-MAX) from aqueous solution by adsorption onto activated carbons prepared from date palm rachis and jujube stones. Journal of Molecular Liquids 243:799–809

Daoud M, Benturki O, Girods P, Donnot A, Fontana S (2019) Adsorption ability of activated carbons from Phoenix dactylifera rachis and Ziziphus jujube stones for the removal of commercial dye and the treatment of dyestuff wastewater. Microchemical Journal 148:493–502

Girods P, Dufour A, Fierro V, Rogaume Y, Rogaume C, Zoulalian A, Celzard A (2009) Activated carbons prepared from wood particleboard wastes: Characterisation and phenol adsorption capacities. Journal of Hazardous Materials 166(1):491–501

Debal M, Girods P, Lémonon J, Meyer N, Tilloy C, Donnot A, Rogaume Y (2014) CO2 adsorption capacities of active chars prepared from wood laminated flooring waste. International Journal of Energy, Environment and Economics 22(1):9

Benturki O, Addoun F (2007) Use of activated carbons for treatment of water polluted by the phenolic substances. Asian Journal of Chemistry 19(6):4523

Ko DC, Mui EL, Lau KS, McKay G (2004) Production of activated carbons from waste tire–process design and economical analysis. Waste Management 24(9):875–888

Bouras HD, Benturki O, Bouras N, Attou M, Donnot A, Merlin A, Addoun F, Holtz MD (2015) The use of an agricultural waste material from Ziziphus jujuba as a novel adsorbent for humic acid removal from aqueous solutions. Journal of Molecular Liquids 211:1039–1046

González J, Román S, Encinar J, Martínez G (2009) Pyrolysis of various biomass residues and char utilization for the production of activated carbons. Journal of Analytical and Applied Pyrolysis 85(1-2):134–141

El-Sayed SA, Mostafa M (2014) Pyrolysis characteristics and kinetic parameters determination of biomass fuel powders by differential thermal gravimetric analysis (TGA/DTG). Energy conversion and management 85:165–172

Mortari, D.A., Ávila, I., Santos, A.M., Crnkovic, P.C.G.M.: Study of thermal decomposition of ignition temperature of bagasse, coal and their blends. Engenharia Térmica, 81-88 (2010).

Wilson L, Yang W, Blasiak W, John GR, Mhilu CF (2011) Thermal characterization of tropical biomass feedstocks. Energy Conversion and Management 52(1):191–198

Bining A, Jenkins B (1992) Thermochemical reaction kinetics for rice straw from an approximate integral technique. American Society of Agricultural Engineers. Meeting, USA). no. 92-6001/92-6040

Pütün AE (2002) Biomass to bio-oil via fast pyrolysis of cotton straw and stalk. Energy Sources 24(3):275–285

Sun S, Tian H, Zhao Y, Sun R, Zhou H (2010) Experimental and numerical study of biomass flash pyrolysis in an entrained flow reactor. Bioresource technology 101(10):3678–3684

Wang G, Li W, Li B, Chen H (2008) TG study on pyrolysis of biomass and its three components under syngas. Fuel 87(4-5):552–558

Gaunt JL, Lehmann J (2008) Energy balance and emissions associated with biochar sequestration and pyrolysis bioenergy production. Environmental science & technology 42(11):4152–4158

Dufour A, Girods P, Masson E, Rogaume Y, Zoulalian A (2009) Synthesis gas production by biomass pyrolysis: effect of reactor temperature on product distribution. international journal of hydrogen energy 34(4):1726–1734

Kecira, Z., Benturki, A., Daoud, M., Benturki, O.: Effect of chemical activation on the surface properties of apricot stones based activated carbons and its adsorptive properties toward aniline. In: International Symposium on Materials and Sustainable Development 2017, pp. 228-240. Springer

Peláez-Cid A-A, Herrera-González A-M, Salazar-Villanueva M, Bautista-Hernández A (2016) Elimination of textile dyes using activated carbons prepared from vegetable residues and their characterization. Journal of environmental management 181:269–278

Nzihou JF, Hamidou S, Bouda M, Koulidiati J, Segda BG (2014) Using Dulong and Vandralek formulas to estimate the calorific heating value of a household waste model. Int. J. Sci. Eng. Res 5(1):1878–1883

Puig-Arnavat M, Bruno JC, Coronas A (2010) Review and analysis of biomass gasification models. Renewable and sustainable energy reviews 14(9):2841–2851

Zanzi R, Sjöström K, Björnbom E (2002) Rapid pyrolysis of agricultural residues at high temperature. Biomass and Bioenergy 23(5):357–366

Shaaban A, Se S-M, Dimin M, Juoi JM, Husin MHM, Mitan NMM (2014) Influence of heating temperature and holding time on biochars derived from rubber wood sawdust via slow pyrolysis. Journal of Analytical and Applied Pyrolysis 107:31–39

Abnisa F, Daud WW, Husin W, Sahu J (2011) Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass and Bioenergy 35(5):1863–1872

Demirbas A (2004) Effects of temperature and particle size on bio-char yield from pyrolysis of agricultural residues. Journal of analytical and applied pyrolysis 72(2):243–248

Girods, P.: Procédé multi-étagé de valorisation de déchets bois type panneaux de particules. Nancy 1 (2008)

Girods P, Dufour A, Rogaume Y, Rogaume C, Zoulalian A (2008) Pyrolysis of wood waste containing urea-formaldehyde and melamine-formaldehyde resins. Journal of Analytical and Applied Pyrolysis 81(1):113–120

Williams PT, Besler S (1996) The influence of temperature and heating rate on the slow pyrolysis of biomass. Renewable energy 7(3):233–250

Efika CE, Onwudili JA, Williams PT (2018) Influence of heating rates on the products of high-temperature pyrolysis of waste wood pellets and biomass model compounds. Waste Management 76:497–506

Cunliffe AM, Williams PT (1999) Influence of process conditions on the rate of activation of chars derived from pyrolysis of used tires. Energy & Fuels 13(1):166–175

Daugaard DE, Brown RC (2003) Enthalpy for pyrolysis for several types of biomass. Energy & fuels 17(4):934–939

Arregi A, Amutio M, Lopez G, Bilbao J (2018) Olazar, M.:Evaluation of thermochemical routes for hydrogen production from biomass: a review. Energy conversion and management 165:696–719

Chiodini A, Bua L, Carnelli L, Zwart R, Vreugdenhil B (2017) Vocciante, M.:Enhancements in biomass-to-liquid processes: gasification aiming at high hydrogen/carbon monoxide ratios for direct Fischer-Tropsch synthesis applications. Biomass and bioenergy 106:104–114

Tijmensen MJ, Faaij AP, Hamelinck CN, van Hardeveld MR (2002) Exploration of the possibilities for production of Fischer Tropsch liquids and power via biomass gasification. Biomass and Bioenergy 23(2):129–152

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Daoud, M., Benturki, O., Fontana, S. et al. Energy and matter balance of process of activated carbon production from Algerian agricultural wastes: date palm rachis and jujube stones. Biomass Conv. Bioref. 11, 1537–1554 (2021). https://doi.org/10.1007/s13399-019-00543-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00543-w