Abstract

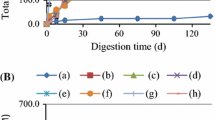

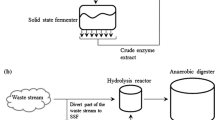

Lignocellulosic biomass residues have attracted attention for the sustainable production of molecules for material and energetic use through biochemical conversion. Their recalcitrant structure prevents a broader use and asks for the development of sustainable techniques that can efficiently separate, recover and valorize the constituting components. In a cascading concept, residual streams of such processes can be further exploited in an attempt to valorize the largest possible fraction of the initial material. Three lignocellulosic substrates, namely dried sugar beet pulp, wheat bran and miscanthus straw, were upstream fractionated by steam explosion to extract the hemicellulose fraction. This study evaluated the valorization of the residual solid fraction through mixed acidogenic fermentation for the production of volatile fatty acids (VFA) as platform chemicals. Batch experiments have been conducted for the reference material (non-treated) and the solid fraction remaining after steam explosion, with and without the addition of an external mixed inoculum. Steam explosion residues contained less hemicellulose than the initial materials. The difference in the fermentation profile between steam explosion residues and non-treated substrates is dependent on the substrate. Maximum total VFA (tVFA) concentration was 18.8 gCOD/kgmixed_liquor, and maximum yield of chemical oxygen demand (COD) conversion into tVFA was 33 % for the case of non-treated inoculated beet pulp.

Similar content being viewed by others

Abbreviations

- W:

-

Wheat bran

- B:

-

Dried sugar beet pulp

- M:

-

Miscanthus straw

- VFA:

-

Volatile fatty acids

- tVFA:

-

Total VFA

- CODs:

-

Soluble chemical oxygen demand

- CODt:

-

Total chemical oxygen demand

- ML:

-

Mixed liquor

- TS:

-

Total solids

- VS:

-

Volatile solids

References

Kaparaju P, Serrano M, Thomsen AB, Kongjan P, Angelidaki I (2009) Bioethanol, biohydrogen and biogas production from wheat straw in a biorefinery concept. Technol 100:2562–2568

Federici F, Fava F, Kalogerakis N, Mantzavinos D (2009) Valorisation of agro-industrial by-products, effluents and waste: concept, opportunities and the case of olive mill wastewaters. J Chem Technol Biotechnol 84:895–900

Zhao X, Zhang L, Liu D (2012) Biomass recalcitrance. Part I: the chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels Bioprod Biorefin 6:465–482

Hendriks ATWM, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100:10–18

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Taherzadeh MJ, Karimi K (2008) Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int J Mol Sci 9:162–1651

Guo P, Mochidzuki K, Cheng W, Zhou M, Gao H, Zheng D, Wang X, Cui Z (2011) Effects of different pretreatment strategies on corn stalk acidogenic fermentation using a microbial consortium. Bioresour Technol 102:7526–7531

Han G, Deng J, Zhang S, Bicho P, Wu Q (2010) Effect of steam explosion treatment on characteristics of wheat straw. Ind Crop Prod 31:28–33

Viola E, Zimbardi F, Cardinale M, Cardinale G, Braccio G, Gambacorta E (2008) Processing cereal straws by steam explosion in a pilot plant to enhance digestibility in ruminants. Bioresour Technol 99:681–689

Wang J, Yue ZB, Chen TH, Peng SC, Yu HQ, Chen HZ (2010) Anaerobic digestibility and fiber composition of bulrush in response to steam explosion. Bioresour Technol 101:6610–6614

Ramos LP (2003) The chemistry involved in the steam treatment of lignocellulosic materials. Quim Nova 26:863–871

Sabiha-Hanim S, Mohd Noor MA, Rosma A (2015) Fractionation of oil palm frond hemicelluloses by water or alkaline impregnation and steam explosion. Carbohydr Polym 115:533–539

Rabetafika HN, Bchir B, Blecker C, Paquot M, Wathelet B (2014) Comparative study of alkaline extraction process of hemicelluloses from pear pomace. Biomass Bioenergy 61:254–264

Angelidaki I, Karakashev D, Batstone DJ, Plugge CM, Stams AJM (2011) Biomethanation and its potential. Methods Enzymol 494:327–351

de la Rubia MA, Raposo F, Rincón B, Borja R (2009) Evaluation of the hydrolytic-acidogenic step of a two-stage mesophilic anaerobic digestion process of sunflower oil cake. Bioresour Technol 100:4133–4138

Doğan E, Demirer GN (2009) Volatile fatty acid production from organic fraction of municipal solid waste through anaerobic acidogenic digestion. Environ Eng Sci 26:1443–1450

Kim W, Hwang K, Shin SG, Lee S, Hwang S (2010) Effect of high temperature on bacterial community dynamics in anaerobic acidogenesis using mesophilic sludge inoculum. Bioresour Technol 101(Suppl 1):S17–22

Alkaya Eand Demirer GN (2011) Anaerobic acidification of sugar-beet processing wastes: Effect of operational parameters. Biomass Bioenergy 35:32–39

Lee WS, Chua ASM, Yeoh HK, Ngoh GC (2014) A review of the production and applications of waste-derived volatile fatty acids. Chem Eng J 235:83–99

Singhania RR, Patel AK, Christophe G, Fontanille P, Larroche C (2013) Biological upgrading of volatile fatty acids, key intermediates for the valorization of biowaste through dark anaerobic fermentation. Bioresour Technol 145:166–174

Zacharof MP, Lovitt RW (2013) Complex effluent streams as a potential source of volatile fatty acids. Waste Biomass Valor 4:557–581

Temudo MF, Poldermans R, Kleerebezem R, van Loosdrecht MCM (2008) Glycerol fermentation by (open) mixed cultures: A chemostat study. Biotechnol Bioeng 100:1088–1098

Schmidt JK, Riedele C, Regestein L, Rausenberger J, Reichl U (2011) A novel concept combining experimental and mathematical analysis for the identification of unknown interspecies effects in a mixed culture. Biotechnol Bioeng 108:1900–1911

Reisinger M, Tirpanalan O, Prückler M, Huber F, Kneifel W, Novalin S (2013) Wheat bran biorefinery - A detailed investigation on hydrothermal and enzymatic treatment. Bioresour Technol 144:179–185

Kracher D, Oros D, Yao W, Preims M, Rezic I, Haltrich D, Rezic T (2014) Fungal secretomes enhance sugar beet pulp hydrolysis. Biotechnol J 9:483–492

Mayer F, Gerin P, Noo A et al (2014) Assessment of energy crops alternative to maize for biogas production in the Greater Region. Bioresour Technol 166:358–367

Wu MM, Chang K, Gregg DJ, Boussaid A, Beatson RP, Saddler JN (1999) Optimization of steam explosion to enhance hemicellulose recovery and enzymatic hydrolysis of cellulose in softwoods. Appl Biochem Biotechnol 77:47–54

Vignon MR, Garcia-Jaldon C, Dupeyre D (1995) Steam explosion of woody hemp chènevotte. Int J BiolMacromol 17:395–404

Liu H, Wang J, Liu X, Fu B, Chen J, Yu HQ (2012) Acidogenic fermentation of proteinaceous sewage sludge: Effect of pH. Water Res 46:799–807

Clescerl LS, Greenberg AE, Eaton AD (1999) Standard Methods for Examination of Water & Wastewater, 20th edn. Am Public Health Assoc, Washington, DC

Escarnot E, Agneessens R, Wathelet B, Paquot M (2010) Quantitative and qualitative study of spelt and wheat fibres in varying milling fractions. Food Chem 122:857–863

Vanderghem C, Brostaux Y, Jacquet N, Blecker C, Paquot M (2012) Optimization of formic/acetic acid delignification of Miscanthus × giganteus for enzymatic hydrolysis using response surface methodology. Ind Crop Prod 35:280–286

Combo AMM, Aguedo M, Quiévy N, Danthine S, Goffin D, Jacquet N, Blecker C, Devaux J, Paquot M (2013) Characterization of sugar beet pectic-derived oligosaccharides obtained by enzymatic hydrolysis. Int J Biol Macromol 148:52–156

Blakeney AB, Harris PJ, Henry RJ, Stone BA (1983) A simple and rapid preparation of alditol acetates for monosaccharide analysis. Carbohydr Res 113:291–299

Chang J, Cheng W, Yin Q, Zuo R, Song A, Zheng Q, Wang P, Wang X, Liu J (2012) Effect of steam explosion and microbial fermentation on cellulose and lignin degradation of corn stover. Bioresour Technol 104:587–592

Estevez MM, Linjordet R, Morken J (2012) Effects of steam explosion and co-digestion in the methane production from Salix by mesophilic batch assays. Bioresour Technol 104:749–756

Ahring BK, Jensen K, Nielsen P, Bjerre AB, Schmidt AS (1996) Pretreatment of wheat straw and conversion of xylose and xylan to ethanol by thermophilic anaerobic bacteria. Bioresour Technol 58:107–113

Chen Y, Jiang S, Yuan H, Zhou Q, Gu G (2007) Hydrolysis and acidification of waste activated sludge at different pHs. Water Res 41:683–689

Rajagopal R, Béline F (2011) Anaerobic hydrolysis and acidification of organic substrates: determination of anaerobic hydrolytic potential. Bioresour Technol 102:5653–5658

Bruni E, Jensen AP, Angelidaki I (2010) Steam treatment of digested biofibers for increasing biogas production. Bioresour Technol 101:7668–7671

Borja R, Sánchez E, Rincón B, Raposo R, Martı́n MA, Martı́n A (2005) Study and optimisation of the anaerobic acidogenic fermentation of two-phase olive pomace. Process Biochem 40:281–291

Horiuchi JI, Shimizu T, Tada K, Kanno T, Kobayashi M (2002) Selective production of organic acids in anaerobic acid reactor by pH control. Bioresour Technol 82:209–213

Parawira W, Murto M, Read JS, Mattiasson B (2004) Volatile fatty acid production during anaerobic mesophilic digestion of solid potato waste. J Chem Technol Biotechnol 79:673–677

Han SK, Shin SH (2002) Enhanced acidogenic fermentation of food waste in a continuous-flow reactor. Waste Manag Res 20:110–118

Jones DTand Woods DR (1986) Acetone-butanol fermentation revisited. Microbiol Rev 50:484–524

Batstone DJ, Keller J, Angelidaki I et al (2002) Anaerobic Digestion Model No 1 (ADM1). IWA Publishing, London

Batstone DJ and Jensen PD (2011) Anaerobic Processes. In:Wilderer P (ed) Treatise on water science. Elsevier, Oxford, pp 615‑639

Bengtsson S, Hallquist J, Werker A, Welander T (2008) Acidogenic fermentation of industrial wastewaters: Effects of chemostat retention time and pH on volatile fatty acids production. Biochem Eng J 40:492–499

Traverso P, Pavan P, Bolzonella D, Innocenti L, Cecchi F, Mata-Alvarez J (2000) Acidogenic fermentation of source separated mixtures of vegetables and fruits wasted from supermarkets. Biodegradation 11:407–414

Paulova L, Pátákova P, Branská B, Rychtera M, Melzoch K (2014) Lignocellulosic ethanol: Technology design and its impact on process efficiency. Biotechnol Adv. doi:10.1016/j.biotechadv.2014.12.002

López-Garzón CS, Straathof AJJ (2014) Recovery of carboxylic acids produced by fermentation. Biotechnol Adv 32:873–904

Acknowledgments

The authors thank the Walloon Region for financial support in the frame of the LIGNOFUEL and WAL-AID programs (convention no. 716721 and 6089, respectively). We thank Matthieu Leclercq for his technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Perimenis, A., van Aarle, I.M., Nicolay, T. et al. Metabolic profile of mixed culture acidogenic fermentation of lignocellulosic residues and the effect of upstream substrate fractionation by steam explosion. Biomass Conv. Bioref. 6, 25–37 (2016). https://doi.org/10.1007/s13399-015-0164-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-015-0164-8