Abstract

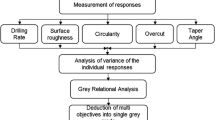

Drilling precise micro-holes in glass material has brought a new challenge, primarily due to its application in microfluidic devices. It is required to reduce machining time and simultaneously achieve repeatability of the process. The machined hole should have minimum overcut to get desired hole diameter. Maximum hole circularity and minimum heat-affected zone are the essential hole characteristics to achieve controlled machining. The multi-criteria decision-making (MCDM) method is quite effective in selection of best possible combination of outputs from several alternative solutions. The experimental data from the previously published paper is used in the current study. As input parameters, the experiment data include voltage, tool feed rate, and machining time. The radial overcut (ROC), circularity of the machined hole and heat-affected zone (HAZ) were calculated as output responses. The experiments were conducted using copper and nickel-coated copper tools in previous study and response data were used in current work. The present study uses the methods which include hybrid grey relational analysis (GRA), technique for order performance by similarity to ideal solution (TOPSIS), and VIšekriterijumsko KOmpromisno Rangiranje (VIKOR) methods for the selection of the best combination of process parameters in drilling to obtain the optimal geometric characteristic of a hole, i.e. optimal values of ROC, circularity and HAZ, in glass using electrochemical discharge machining (ECDM). In this study, weight calculation for MCDM was proposed using entropy and analytic hierarchy process (AHP) methods and combined to get final weights using the fuzzy logic tool, which determines the importance of AHP and entropy weights using the expert opinion. The final weights were used to calculate the ranks from each MCDM method and determine optimal process parameter selection in ECDM hole drilling with copper and nickel-coated copper tools. The fuzzy logic method determined that the weight contribution from AHP is 0.586 in the present study. Genetic algorithm-based multi-objective optimization was conducted, and a non-dominated Pareto front was generated. The Spearman correlation method was used to determine the relationship between different MCDM methods. The current study will be helpful in selecting the best combination of process parameters in drilling holes during ECDM machining using MCDM methods.

Similar content being viewed by others

Availability of Data and Materials

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Kim, T.; Kwon, K.K.; Chu, C.N.; Song, K.Y.: Experimental investigation on CO2 laser-assisted micro-slot milling characteristics of borosilicate glass. Precis. Eng. 63(February), 137–147 (2020). https://doi.org/10.1016/j.precisioneng.2020.02.004

Park, D.: Micro-grooving of glass using micro-abrasive jet machining. J. Mater. Process. Technol. 146, 234–240 (2004). https://doi.org/10.1016/j.matprotec.2003.11.013

Haghbin, N.; Ahmadzadeh, F.; Papini, M.: Masked micro-channel machining in aluminum alloy and borosilicate glass using abrasive water jet micro-machining. J. Manuf. Process. 35(August), 307–316 (2018). https://doi.org/10.1016/j.jmapro.2018.08.017

Wüthrich, R.; Fascio, V.: Machining of non-conducting materials using electrochemical discharge phenomenon: an overview. Int. J. Mach. Tools ManufManuf 45(9), 1095–1108 (2005). https://doi.org/10.1016/j.ijmachtools.2004.11.011

Fascio, V.; Wüthrich, R.; Bleuler, H.: Spark assisted chemical engraving in the light of electrochemistry. Electrochim. Acta. Acta 49(22–23), 3997–4003 (2004). https://doi.org/10.1016/J.ELECTACTA.2003.12.062

Vogt, H.: Contribution to the interpretation of the anode effect. Electrochim. Acta. Acta 42(17), 2695–2705 (1997). https://doi.org/10.1016/S0013-4686(97)00013-3

Furutani, K.; Maeda, H.: Machining a glass rod with a lathe-type electro-chemical discharge machine. J. Micromechanics Microengineering (2008). https://doi.org/10.1088/0960-1317/18/6/065006

Singh, T.; Dvivedi, A.; Arya, R.K.: Fabrication of micro-slits using W-ECDM process with textured wire surface: an experimental investigation on kerf overcut reduction and straightness improvement. Precis. Eng. 59, 211–223 (2019). https://doi.org/10.1016/J.PRECISIONENG.2019.05.008

Jawalkar, C.S.; Sharma, A.K.; Kumar, P.; Variable, D.C.: Micromachining with ECDM: research potentials and experimental investigations. Int. J. Mech. Mechatronics Eng. 6(1), 340–345 (2012)

Abou Ziki, J.D.; Fatanat Didar, T.; Wüthrich, R.: Micro-texturing channel surfaces on glass with spark assisted chemical engraving. Int. J. Mach. Tools Manuf 57, 66–72 (2012). https://doi.org/10.1016/j.ijmachtools.2012.01.012

Zheng, Z.P.; Su, H.C.; Huang, F.Y.; Yan, B.H.: The tool geometrical shape and pulse-off time of pulse voltage effects in a Pyrex glass electrochemical discharge microdrilling process. J. Micromechanics Microengineering 17(2), 265–272 (2007). https://doi.org/10.1088/0960-1317/17/2/012

Singh, M.; Singh, S.; Kumar, S.: Experimental investigation for generation of micro-holes on silicon wafer using electrochemical discharge machining process. SILICON 12(7), 1683–1689 (2020). https://doi.org/10.1007/s12633-019-00273-8

Arab, J.; Dixit, P.: Influence of tool electrode feed rate in the electrochemical discharge drilling of a glass substrate. Mater. Manuf. Process. (2020). https://doi.org/10.1080/10426914.2020.1784936

Chak, S.K.; Venkateswara Rao, P.: The drilling of Al2O3 using a pulsed DC supply with a rotary abrasive electrode by the electrochemical discharge process. Int. J. Adv. Manuf. Technol. 39(7–8), 633–641 (2008). https://doi.org/10.1007/s00170-007-1263-x

Saranya, S.; Ravi Sankar, A.: Fabrication of precise micro-holes on quartz substrates with improved aspect ratio using a constant velocity-feed drilling technique of an ECDM process. J. Micromechanics Microengineering (2018). https://doi.org/10.1088/1361-6439/aae8f5

Abou Ziki, J.D.; Wüthrich, R.: Forces exerted on the tool-electrode during constant-feed glass micro-drilling by spark assisted chemical engraving. Int. J. Mach. Tools Manuf 73, 47–54 (2013). https://doi.org/10.1016/j.ijmachtools.2013.06.008

Mousa, M.; Allagui, A.; Ng, H.D.; Wüthrich, R.: The effect of thermal conductivity of the tool electrode in spark-assisted chemical engraving gravity-feed micro-drilling. J. Micromechanics Microengineering (2009). https://doi.org/10.1088/0960-1317/19/1/015010

Yang, C.K.; Cheng, C.P.; Mai, C.C.; Cheng Wang, A.; Hung, J.C.; Yan, B.H.: Effect of surface roughness of tool electrode materials in ECDM performance. Int. J. Mach. Tools Manuf 50(12), 1088–1096 (2010). https://doi.org/10.1016/j.ijmachtools.2010.08.006

Saini, G.; Manna, A.; Sethi, A.S.: Investigations on performance of ECDM process using different tool electrode while machining e-glass fibre reinforced polymer composite. Mater. Today Proc. 28, 1622–1628 (2020). https://doi.org/10.1016/j.matpr.2020.04.853

Behroozfar, A.; Razfar, M.R.: Experimental study of the tool wear during the electrochemical discharge machining. Mater. Manuf. Process. 31(5), 574–580 (2016). https://doi.org/10.1080/10426914.2015.1004685

Tiwari, A.K.; Panda, S.S.: Optimization of process parameters in ECDM machining using Taguchi based grey relation analysis. Meas. J. Int. Meas. Confed. 216, 112971 (2023). https://doi.org/10.1016/j.measurement.2023.112971

Arab, J.; Pawar, K.; Dixit, P.: Effect of tool-electrode material in through-hole formation using ECDM process. Mater. Manuf. Process. 36(9), 1019–1027 (2021). https://doi.org/10.1080/10426914.2021.1885700

Bhargav, K.V.J.; Balaji, P.S.; Sahu, R.K.; Katiyar, J.K.: Multi-response optimization and effect of tool rotation on micromachining of PMMA using an in-house developed µ-ECDM system. CIRP J. Manuf. Sci. Technol. 38, 473–490 (2022). https://doi.org/10.1016/j.cirpj.2022.05.020

Rajput, V.; Pundir, S.S.; Goud, M.; Suri, N.M.: Multi-response optimization of ECDM parameters for silica (quartz) using grey relational analysis. SILICON 13(5), 1619–1640 (2021). https://doi.org/10.1007/s12633-020-00538-7

Singh, T.; Dvivedi, A.: On prolongation of discharge regime during ECDM by titrated flow of electrolyte. Int. J. Adv. Manuf. Technol. 107(3–4), 1819–1834 (2020). https://doi.org/10.1007/s00170-020-05126-y

Lin, Z.C.; Yang, C.B.: Evaluation of machine selection by the AHP method. J. Mater. Process. Technol. 57(3–4), 253–258 (1996). https://doi.org/10.1016/0924-0136(95)02076-4

Soba, M.; Ersoy, Y.; Tarakcioǧlu Altinay, A.; Erkan, B.; Şik, E.: Application of multiple criteria decision-making methods in assignment place selection. Math. Probl. Eng.Probl. Eng. (2020). https://doi.org/10.1155/2020/6748342

Prakash, C.; Barua, M.K.: Integration of AHP-TOPSIS method for prioritizing the solutions of reverse logistics adoption to overcome its barriers under fuzzy environment. J. Manuf. Syst. 37, 599–615 (2015). https://doi.org/10.1016/j.jmsy.2015.03.001

Ersoy, Y.; Dogan, N.Ö.: An integrated model of fuzzy AHP/Fuzzy DEA for measurement of supplier performance: a case study in textile sector. Int. J. Supply Oper. Manag. 7(1), 17–38 (2020). https://doi.org/10.22034/IJSOM.2020.1.2

Pradhan, M.K.: Optimisation of EDM process for MRR, TWR and radial overcut of D2 steel: a hybrid RSM-GRA and entropy weight-based TOPSIS approach. Int. J. Ind. Syst. Eng. 29(3), 273–302 (2018). https://doi.org/10.1504/IJISE.2018.093047

Bakhoum, E.S.; Brown, D.C.: A hybrid approach using AHP-TOPSIS-entropy methods for sustainable ranking of structural materials. Int. J. Sustain. Eng. 6(3), 212–224 (2013). https://doi.org/10.1080/19397038.2012.719553

Namin, F.S.; Ghadi, A.; Saki, F.: A literature review of multi criteria decision-making (MCDM) towards mining method selection (MMS). Resour. Policy. Policy 77, 102676 (2022). https://doi.org/10.1016/j.resourpol.2022.102676

Asjad, M.; Talib, F.: Selection of optimal machining parameters using integrated MCDM approaches. Int. J. Adv. Oper. Manag. 10(2), 109–129 (2018). https://doi.org/10.1504/IJAOM.2018.10014273

Abhilash, P.M.; Chakradhar, D.: Multi-response optimization of wire EDM of Inconel 718 using a hybrid entropy weighted GRA-TOPSIS method. Process Integr. Optim. Sustain. 6(1), 61–72 (2022). https://doi.org/10.1007/s41660-021-00202-6

Phipon, R.: Optimization of electro-chemical discharge machining process using genetic algorithm. IOSR J. Eng. 02(09), 106–115 (2012). https://doi.org/10.9790/3021-0291106115

Ladeesh, V.G.; Manu, R.: Performance evaluation and multi-response optimization of grinding-aided electrochemical discharge drilling (G-ECDD) of borosilicate glass. J. Braz. Soc. Mech. Sci. Eng. 40(12), 1–19 (2018). https://doi.org/10.1007/s40430-018-1489-6

Panda, M.C.; Yadava, V.: Intelligent modeling and multiobjective optimization of die sinking electrochemical spark machining process. Mater. Manuf. Process. 27(1), 10–25 (2012). https://doi.org/10.1080/10426914.2010.544812

Bellubbi, S.; Sathisha, N.; Mallick, B.: Multi response optimization of ECDM process parameters for machining of microchannel in silica glass using Taguchi–GRA technique. SILICON 14(8), 4249–4263 (2022). https://doi.org/10.1007/s12633-021-01167-4

Bhattacharyya, B.; Doloi, B.N.; Sorkhel, S.K.: Experimental investigations into electrochemical discharge machining (ECDM) of non-conductive ceramic materials. J. Mater. Process. Technol. 95(1–3), 145–154 (1999). https://doi.org/10.1016/S0924-0136(99)00318-0

Opricovic, S.; Tzeng, G.H.: Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res.Oper. Res. 156(2), 445–455 (2004). https://doi.org/10.1016/S0377-2217(03)00020-1

Małgorzata Gerus-Go´sciewska and D. Go´sciewski: Grey relational analysis (GRA) as an effective method of research into social preferences in urban space planning, Land. 11(1):102 (2022). https://doi.org/10.3390/land11010102

Hwang, C.-L., Yoon, K.: Methods for multiple attribute decision making. in: multiple attribute decision making, In: Lecture Notes in Economics and Mathematical Systems, (1981). doi: https://doi.org/10.1007/978-3-642-48318-9_2

Kumar, R.; Bilga, P.S.; Singh, S.: Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. J. Clean. Prod. 164, 45–57 (2017). https://doi.org/10.1016/j.jclepro.2017.06.077

Series, S.: Selection of rapid prototyping process in rapid product development. (2007). doi: https://doi.org/10.1007/978-1-84628-819-7_16

Tehci, A.; Ersoy, Y.: Firms and consumer attitudes in the digital market: analytical hierarchy process approach, insights, innovation, and analytics for optimal customer engagement. IGI Global (2021). https://doi.org/10.4018/978-1-7998-3919-4.ch008

Ersoy, Y.; Tehci, A.: Relationship marketing orientation in healthcare organisations with the AHP method. Internal and external customer perspective. Oper. Res. Decis. 33(1), 35–45 (2023). https://doi.org/10.37190/ord230103

Çalişkan, H.; Kurşuncu, B.; Kurbanoĝlu, C.; Güven, ŞY.: Material selection for the tool holder working under hard milling conditions using different multi criteria decision making methods. Mater. Des. 45, 473–479 (2013). https://doi.org/10.1016/J.MATDES.2012.09.042

Shanian, A.; Savadogo, O.: TOPSIS multiple-criteria decision support analysis for material selection of metallic bipolar plates for polymer electrolyte fuel cell. J. Power. Sources 159(2), 1095–1104 (2006). https://doi.org/10.1016/j.jpowsour.2005.12.092

Selamzade, F.; Ersoy, Y.; Ozdemir, Y.; Celik, M.Y.: Health efficiency measurement of OECD countries against the COVID-19 pandemic by using DEA and MCDM methods. Arab. J. Sci. Eng. 48(11), 15695–15712 (2023). https://doi.org/10.1007/s13369-023-08114-y

Opricovic, S.: Multicriteria optimization of civil engineering systems. Fac. Civ. Eng. Belgrade 2(1), 5–21 (1998)

Yoon, K.: A reconciliation among discrete compromise solutions. J. Oper. Res. Soc.Oper. Res. Soc. 38(3), 277–286 (1987)

San Cristóbal, J.R.: Multi-criteria decision-making in the selection of a renewable energy project in spain: The Vikor method. Renew. Energy 36(2), 498–502 (2011). https://doi.org/10.1016/j.renene.2010.07.031

Khare, V.; Yao, X.; Deb, K.: Performance scaling of multi-objective evolutionary algorithms. Lect. Notes Comput. Sci. (including Subser. Lect. Notes Artif. Intell. Lect. Notes Bioinformatics) 2632, 376–390 (2003). https://doi.org/10.1007/3-540-36970-8_27

Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.: A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput.Evol. Comput. 6(2), 182–197 (2002). https://doi.org/10.1109/4235.996017

Mandal, D.; Pal, S.K.; Saha, P.: Modeling of electrical discharge machining process using back propagation neural network and multi-objective optimization using non-dominating sorting genetic algorithm-II. J. Mater. Process. Technol. 186(1–3), 154–162 (2007). https://doi.org/10.1016/j.jmatprotec.2006.12.030

Lu, C.; Fuh, J.Y.H.; Wong, Y.S.: Advanced assembly planning approach using a multi-objective genetic algorithm. Collab. Prod. Assem. Des. Assem. Plan. (2011). https://doi.org/10.1533/9780857093882.107

Defuzzification Methods: MATLAB and Simulink. https://www.mathworks.com/help/fuzzy/defuzzification-methods.html Accessed 30 June 2023

Aich, U.; Banerjee, S.: A simple procedure for searching Pareto optimal front in machining process: electric discharge machining. Model. Simul. Eng. (2014). https://doi.org/10.1155/2014/594054

Saravanan, K.G.; Thanigaivelan, R.; Soundarrajan, M.: Comparison of electrochemical micromachining performance using TOPSIS, VIKOR and GRA for magnetic field and UV rays heated electrolyte. Bull. Polish Acad. Sci. Tech. Sci. 69(5), 1–10 (2021). https://doi.org/10.24425/bpasts.2021.138816

Ersoy, Y.: Equipment selection for an e-commerce company using Entropy-based TOPSIS, EDAS and CODAS methods during the COVID-19. LogForum 17(3), 341–358 (2021). https://doi.org/10.17270/J.LOG.2021.603

Funding

Funding information is not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tiwari, A.K., Panda, S.S. Application of Multi-Criteria Decision Model to Develop an Optimized Geometric Characteristic in Electrochemical Discharge Machining. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-023-08636-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-023-08636-5