Abstract

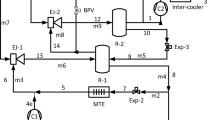

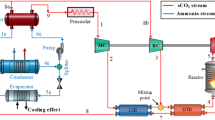

The present investigation aims to reuse the heat rejected in the condenser unit of an NH3-based dairy plant to preheat the groundwater used for pasteurization of milk. A detailed thermodynamic analysis (both energetic and exergetic) of the refrigeration unit of an existing dairy plant and the boiler unit used for pasteurization is carried out in the current work. The chemical exergy of the air–water vapour mixture and the standard Indian coal is considered while analysing the evaporative condenser and the boiler unit. Cascading of the existing system with a transcritical vapour compression cycle is proposed to effectively use the heat rejected by the combined system to preheat the boiler feed water. A comparative study for different modifications, such as the inclusion of an expander and an ejector in place of the throttle valve in the top cycle of the proposed cascade system, is carried out. Additionally, the cascade systems are being analysed for two different refrigerants, i.e., CO2 and N2O. The study demonstrates that the cascade system with an expander employing N2O as the refrigerant gives the maximum benefit in terms of saving of $16.5 to $21.5 per day, 1.5 to 2% reduction in total CO2 emission, and a 2.5% reduction in total exergy destruction, as compared to the existing NH3 system.

Similar content being viewed by others

Abbreviations

- c p :

-

Specific heat at constant pressure, kJ/kg K

- \(\dot{I}\) :

-

Exergy destruction rate/Irreversibility rate, kW

- \(\dot{m}\) :

-

Mass flow rate, kg/s

- \(\dot{Q}\) :

-

Heat transfer rate, kW

- \(\dot{W}\) :

-

Power, kW

- h :

-

Enthalpy, kJ/kg

- h fg :

-

Latent heat of vaporization, kJ/ kg

- s :

-

Entropy, kJ/kg K

- u :

-

Velocity, m/s

- v :

-

Specific volume, m3/kg

- x :

-

Dryness fraction

- \(\alpha_{{{\text{stoi}}}}\) :

-

Stoichiometric air requirement, kg/kg

- \(\Phi\) :

-

Non flow exergy, kJ/kg

- \(\varphi_{{{\text{dry}}}}\) :

-

Ratio of standard chemical exergy to NCV of fossil fuel

- \(\eta\) :

-

Efficiency

- \(\eta_{{{\text{II}}}}\) :

-

Second law efficiency

- \(\phi\) :

-

Relative humidity

- \(\omega\) :

-

Specific humidity, kgw/kga

- \({\varepsilon }_{\mathrm{s}}^{0}\) :

-

Standard exergy of sulphur, kJ/kg

- ∆:

-

Difference

- µ :

-

Entrainment ratio

- ψ :

-

Flow exergy, kJ/kg

- amb:

-

Ambient

- CC:

-

Cascade condenser

- com:

-

Compressor

- cond:

-

Condenser

- CT:

-

Compressor of top cycle

- diff:

-

Diffuser

- EV:

-

Expansion valve

- evp:

-

Evaporator

- EX:

-

Expander

- GC:

-

Gas cooler

- HP:

-

High pressure

- in:

-

Inflow

- LP:

-

Low pressure

- mix:

-

Mixing zone

- noz:

-

Nozzle

- out:

-

Outflow

- p:

-

Primary

- s:

-

Secondary

- sat:

-

Saturated

- v:

-

Vapour

- APH:

-

Air preheater

- DBT:

-

Dry bulb temperature

- EVC:

-

Evaporative condenser

- GW:

-

Groundwater

- NCV:

-

Net calorific value

- WPH:

-

Water preheater

- WBT:

-

Wet bulb temperature

References

http://www.fao.org/india/fao-in-india/india-at-a-%20glance/en/

Singh, S.; Dasgupta, M. S.: A trans-critical CO2 heat pump system for waste heat utilization in warm weather condition applied to a milk refrigeration plant. In: Proceedings of 16th International Refrigeration and Air Conditioning Conference at Purdue, July 11–14, 2016 (2016)

Liu, Y.; Groll, E.A.; Yazawa, K.; Kurtulus, O.: Energy-saving performance and economics of CO2 and NH3 heat pumps with simultaneous cooling and heating applications in food processing: Case studies. Int. J. Refrig. 73, 111–124 (2017)

Çomakli, Ö.; Yüksel, B.; Kara, Y.A.; Çaǧlar, A.; Tülek, Y.: Heat pump utilization in milk pasteurization. Energy Convers. Manage. 35(2), 91–96 (1994)

Singh, S.; Dasgupta, M.S.: CO2 heat pump for waste heat recovery and utilization in dairy industry with ammonia based refrigeration. Int. J. Refrig. 78, 108–120 (2017)

Ahammed, M.E.; Bhattacharyya, S.; Ramgopal, M.: Thermodynamic design and simulation of a CO2 based transcritical vapour compression refrigeration system with an ejector. Int. J. Refrig. 45, 177–188 (2014)

Ahammed, M.E.; Bhattacharyya, S.; Ramgopal, M.: Analysis of CO2 based refrigeration systems with and without ejector for simultaneous pasteurization and chilling of milk. Int. J. Refrig. 95, 61–72 (2018)

Liu, J.; Liu, Y.; Yu, J.: Performance analysis of a modified dual-ejector and dual-evaporator transcritical CO2 refrigeration cycle for supermarket application. Int. J. Refrig. 131, 109–118 (2021)

Vutukuru, R.; Pegallapati, A.S.; Maddali, R.: Thermodynamic studies on a solar assisted transcritical CO2 based tri-generation system with an ejector for dairy applications. Int. J. Refrig. 108, 113–123 (2019)

Deng, J.Q.; Jiang, P.X.; Lu, T.; Lu, W.: Particular characteristics of transcritical CO2 refrigeration cycle with an ejector. Appl. Therm. Eng. 27(2–3), 381–388 (2007)

Hajidavalloo, E.; Eghtedari, H.: Performance improvement of air-cooled refrigeration system by using evaporatively cooled air condenser. Int. J. Refrig. 33(5), 982–988 (2010)

Kruse, H.; Rüssmann, H.: The natural fluid nitrous oxide—an option as substitute for low temperature synthetic refrigerants. Int. J. Refrig. 29(5), 799–806 (2006)

Kauf, F.: Determination of the optimum high pressure for transcritical CO2-refrigeration cycles. Int. J. Therm. Sci. 38(4), 325–330 (1999)

Gautam; Kumar, G.; Sahoo, S.: Performance improvement and comparisons of CO2 based adsorption cooling system using modified cycles employing various adsorbents: a comprehensive study of subcritical and transcritical cycles. Int. J. Refrig. 112, 136–154 (2020)

Gautam; Sahoo, S.: A Comprehensive thermodynamic analysis and performance evaluation of a transcritical ejector expansion CO2 adsorption refrigeration system integrated with thermoelectric sub-cooler. J. Supercrit. Fluids 182, 105517 (2022)

Fernandez, N.; Hwang, Y.; Radermacher, R.: Comparison of CO2 heat pump water heater performance with baseline cycle and two high COP cycles. Int. J. Refrig. 33(3), 635–644 (2010)

Sarkar, J.; Bhattacharyya, S.; Gopal, M.R.: Optimization of a transcritical CO2 heat pump cycle for simultaneous cooling and heating applications. Int. J. Refrig. 27(8), 830–838 (2004)

Tamura, T.; Yakumaru, Y.; Nishiwaki, F.: Experimental study on automotive cooling and heating air conditioning system using CO2 as a refrigerant. Int. J. Refrig. 28(8), 1302–1307 (2005)

Yu, B.; Yang, J.; Wang, D.; Shi, J.; Chen, J.: An updated review of recent advances on modified technologies in transcritical CO2 refrigeration cycle. Energy 189, 116147 (2019)

Dasi, K.; Singh, S.; Guruchethan, A.M.; Maiya, M.P.; Hafner, A.; Banasiak, K.; Neksa, P.: Performance evaluation of ejector based CO2 system for simultaneous heating and cooling application in an Indian dairy industry. Therm. Sci. Eng. Progress 20, 100626 (2020)

Lata, M.; Gupta, D.K.: Simulation and performance evaluation of trans-critical CO2 refrigeration system with modified evaporative cooled finned tube gas cooler in Indian context. Appl. Therm. Eng. 186, 116500 (2021)

Liu, Y.; Groll, E.A.; Yazawa, K.; Kurtulus, O.: Theoretical analysis of energy-saving performance and economics of CO2 and NH3 heat pumps with simultaneous cooling and heating applications in food processing. Int. J. Refrig. 65, 129–141 (2016)

Ozyurt, O.; Comakli, O.; Yilmaz, M.E.H.M.E.T.; Karslı, S.: Heat pump use in milk pasteurization: an energy analysis. Int. J. Energy Res. 28(9), 833–846 (2004)

Vidal, M.; Martin, L.; Martin, M.: Can exergy be a useful tool for the dairy industry. In: 24th European Symposium Computer Aided Process Engineering—ESCAPE, at Budapest, Hungary, June 15–18, 2014, Vol. 24, pp. 1603–1608. (2014)

Yildirim, N.; Genc, S.: Energy and exergy analysis of a milk powder production system. Energy Convers. Manage. 149, 698–705 (2017)

Nemati, A.; Nami, H.; Yari, M.: A comparison of refrigerants in a two-stage ejector-expansion transcritical refrigeration cycle based on exergoeconomic and environmental analysis. Int. J. Refrig. 84, 139–150 (2017)

Bejan, A.: Advanced Engineering Thermodynamics. John Wiley & Sons, Hoboken (2016)

Shijaz, H.; Attada, Y.; Patnaikuni, V.S.; Vooradi, R.; Anne, S.B.: Analysis of integrated gasification combined cycle power plant incorporating chemical looping combustion for environment-friendly utilization of Indian coal. Energy Convers. Manage. 151, 414–425 (2017)

Kotas, T.J.: The Exergy Method of Thermal Plant Analysis. Elsevier, Amsterdam (2013)

Li, D.; Groll, E.A.: Transcritical CO2 refrigeration cycle with ejector-expansion device. Int. J. Refrig. 28(5), 766–773 (2005)

Keenan, J.H.; Neumann, E.P.; Lustwerk, F.: An investigation of ejector design by analysis and experiment. J. Appl. Mech. 17(3), 299–309 (1950)

Robinson, D.M.; Groll, E.A.: Efficiencies of transcritical CO2 cycles with and without an expansion turbine: rendement de cycles transcritiques au CO2 avec et sans turbine d’expansion. Int. J. Refrig. 21(7), 577–589 (1998)

Acknowledgements

The authors would like to acknowledge the Department of Science and Technology (Science and Engineering Research Board), Govt. of India [Grant No. ECR/2018/000141] for financial assistance provided to carry out the present research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gorai, B., Sahoo, S. & Gautam Comparative Exergy Analysis and Environmental Impact of a Dairy Plant Integrated with a Transcritical Heat Pump System: A Feasibility of Throttle Valve, Expander, and an Ejector as Expansion Devices. Arab J Sci Eng 48, 3503–3521 (2023). https://doi.org/10.1007/s13369-022-07147-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07147-z