Abstract

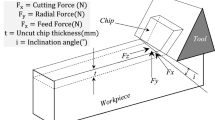

In this research, the main aim is to reduce the unfavorable effects that occurred during machining of the Ti–6Al–4V alloy by perforating the rake face and the flank face of the cutting insert. The main novelty in this research is that machining of Ti–6Al–4V alloy with the micro-hole textured insert helps in the improvement of tribological properties and also reduces cutting temperature at chip–tool interface with proper lubricating effect. To validate the micro-hole textured tools, it is compared with conventionally available insert. The deformation of Ti–6Al–4V alloy with modified cutting inserts was simulated, considering tool as rigid body and workpiece as elasto-plastic material. DEFORM 3D software was used for the simulation of the machining process with the updated Lagrangian formulation. To predict the cutting temperature and chip morphology, the thermo-mechanical analysis was applied using Johnson–Cook material model for the machining process. The turning of the Ti–6Al–4V alloy was carried out with the modified polycrystalline diamond (PCD) cutting inserts (Design 1 and Design 2) and commercially available PCD insert (normal insert). Coconut oil was used as a micro-pool lubricant during the machining process under minimum quantity lubrication environment. In the present work, the turning performance characteristics such as cutting temperature, cutting vibration, tool wear, chip morphology and surface integrity were measured during machining of the Ti–6Al–4V alloy. The experimental results of cutting temperature and chip morphology were validated with the simulation results with better accuracy. The machining results of Design 2 cutting insert showed maximum reduction of 30%, 38%, 45% and 35% in cutting temperature, cutting vibration, tool wear and surface roughness, respectively, when compared with machining under normal insert and Design 1 cutting insert. It is also evident from the results that machining with Design 2 cutting insert significantly improved the process performance of the product quality at higher feed rates.

Similar content being viewed by others

References

Lauro, C.H.; Ribeiro Filho, S.L.; Brandão, L.C.; Davim, J.P.: Analysis of behaviour biocompatible titanium alloy (Ti–6Al–7Nb) in the micro-cutting. Measurement 93, 529–540 (2016)

Veiga, C.; Davim, J.P.; Loureiro, A.J.R.: Review on machinability of titanium alloys: the process perspective. Rev. Adv. Mater. Sci. 34(2), 148–164 (2013)

Khanna, N.; Davim, J.P.: Design-of-experiments application in machining titanium alloys for aerospace structural components. Measurement 61, 280–290 (2015)

Veiga, C.; Davim, J.P.; Loureiro, A.J.R.: Properties and applications of titanium alloys: a brief review. Rev. Adv. Mater. Sci. 32(2), 133–148 (2012)

Davim, J.P. (ed.): Machining of Titanium Alloys, pp. 2–4. Springer, Berlin (2014)

Davim, J.P. (ed.): Machining: Fundamentals and Recent Advances. Springer, Berlin (2008)

Wu, H.; Guo, L.: Machinability of titanium alloy TC21 under orthogonal turning process. Mater. Manuf. Process. 29(11–12), 1441–1445 (2014)

Hartung, P.D.; Kramer, B.M.; Von, Turkovich B.F.: Tool wear in titanium machining. CIRP Ann. Manuf. Technol. 31(1), 75–80 (1982)

Pramanik, A.; Littlefair, G.: Machining of titanium alloy (Ti–6Al–4V)—theory to application. Mach. Sci. Technol. 19(1), 1–49 (2015)

Vijay Sekar, K.S.; Pradeep Kumar, M.: Finite element simulations of Ti–6Al–4V titanium alloy machining to assess material model parameters of the Johnson–Cook constitutive equation. J. Braz. Soc. Mech. Sci. Eng. 33(2), 203–211 (2011)

Umbrello, D.: Finite element simulation of conventional and high speed machining of Ti–6Al–4V alloy. J. Mater. Process. Technol. 196(1–3), 79–87 (2008)

Ducobu, F.; Rivière-Lorphèvre, E.; Filippi, E.: Numerical contribution to the comprehension of saw-toothed Ti6Al4V chip formation in orthogonal cutting. Int. J. Mech. Sci. 81, 77–87 (2014)

Filice, L.; Umbrello, D.; Beccari, S.; Micari, F.: On the FE codes capability for tool temperature calculation in machining processes. J. Mater. Process. Technol. 174(1–3), 286–292 (2006)

Özel, T.; Sima, M.; Srivastava, A.K.; Kaftanoglu, B.: Investigations on the effects of multi-layered coated inserts in machining Ti–6Al–4V alloy with experiments and finite element simulations. CIRP Ann. 59(1), 77–82 (2010)

Zhang, Y.; Outeiro, J.C.; Mabrouki, T.: On the selection of Johnson–Cook constitutive model parameters for Ti–6Al–4V using three types of numerical models of orthogonal cutting. Procedia CIRP 31, 112–117 (2015)

Ali, M.H.; Khidhir, B.A.; Mohamed, B.; Oshkour, A.A.: Prediction of high cutting speed parameters for Ti–6Al–4V by using finite element modeling. Int. J. Model. Optim. 2(1), 31 (2012)

Kovacevic, R.; Cherukuthota, C.; Mazurkiewicz, M.: High pressure waterjet cooling/lubrication to improve machining efficiency in milling. Int. J. Mach. Tools Manuf. 35, 1459–1473 (1995)

Palanisamy, S.; McDonald, S.D.; Dargusch, M.S.: Effects of coolant pressure on chip formation while turning Ti6Al4V alloy. Int. J. Mach. Tools Manuf. 49, 739–743 (2009)

Su, Y.; He, N.; Li, L.; Li, X.L.: An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of Ti–6Al–4V. Wear 261, 760–766 (2006)

Bermingham, M.J.; Palanisamy, S.; Kent, D.; Dargusch, M.S.: A comparison of cryogenic and high pressure emulsion cooling technologies on tool life and chip morphology in Ti–6Al–4V cutting. J. Mater. Process. Technol. 212, 752–765 (2012)

Campbell Jr., F.C.: Manufacturing Technology for Aerospace Structural Materials. Elsevier, Amsterdam (2011)

Ezugwu, E.O.: High speed machining of aero-engine alloys. J. Braz. Soc. Mech. Sci. Eng. 26, 1–11 (2004)

Ezugwu, E.O.; Bonney, J.; Yamane, Y.: An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 134, 233–253 (2003)

Sachin, B.; Narendranath, S.; Chakradhar, D.: Effect of cryogenic diamond burnishing on residual stress and microhardness of 17-4 PH stainless steel. Mater. Today Proc. 5(9), 18393–18399 (2018)

Sachin, B.; Narendranath, S.; Chakradhar, D.: Experimental evaluation of diamond burnishing for sustainable manufacturing. Mater. Res. Express 5(10), 106514 (2018)

Sachin, B.; Narendranath, S.; Chakradhar, D.: Sustainable diamond burnishing of 17-4 PH stainless steel for enhanced surface integrity and product performance by using a novel modified tool. Mater. Res. Express. 6(4), 046501 (2019)

Sachin, B.; Narendranath, S.; Chakradhar, D.: Effect of working parameters on the surface integrity in cryogenic diamond burnishing of 17-4 PH stainless steel with a novel diamond burnishing tool. J. Manuf. Process. 38, 564–571 (2019)

Sachin, B.; Narendranath, S.; Chakradhar, D.: Selection of optimal process parameters in sustainable diamond burnishing of 17-4 PH stainless steel. J. Braz. Soc. Mech. Sci. 41(5), 219 (2019)

Sharma, V.S.; Dogra, M.; Suri, N.M.: Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 49, 435–453 (2009)

Le Coz, G.; Marinescu, M.; Devillez, A.; Dudzinski, D.; Velnom, L.: Measuring temperature of rotating cutting tools: application to MQL drilling and dry milling of aerospace alloys. Appl. Therm. Eng. 36, 434–441 (2012)

Rahim, E.A.; Sasahara, H.: A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol. Int. 44, 309–317 (2011)

Dhar, N.R.; Islam, M.W.; Islam, S.; Mithu, M.A.H.: The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. J. Mater. Process. Technol. 171, 93–99 (2006)

Machado, A.R.; Wallbank, J.: The effect of extremely low lubricant volumes in machining. Wear 210, 76–82 (1997)

Khan, M.M.A.; Mithu, M.A.H.; Dhar, N.R.: Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Process. Technol. 209, 5573–5583 (2009)

Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I.: Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 33(3), 248–254 (2009)

Koshy, P.; Tovey, J.: Performance of electrical discharge textured cutting tools. CIRP Ann. Manuf. Technol. 60(1), 153–156 (2011)

Obikawa, T.; Kani, B.: Micro ball end milling of titanium alloy using a tool with a microstructured rake face. J. Adv. Mech. Des. Syst. 6(7), 1121–1131 (2012)

Wu, Z.; Deng, J.; Su, C.; Luo, C.; Xia, D.: Performance of the micro-texture self-lubricating and pulsating heat pipe self-cooling tools in dry cutting process. Int. J. Refract. Metals Hard Mater. 45, 238–248 (2014)

Arrazola, P.J.; Garay, A.; Iriarte, L.M.; Armendia, M.; Marya, S.; Le, Maitre F.: Machinability of titanium alloys (Ti6Al4V and Ti555.3). J. Mater. Process. Technol. 209(5), 2223–2230 (2009)

Sugihara, T.; Enomoto, T.: Development of a cutting tool with a nano/micro-textured surface-improvement of anti-adhesive effect by considering the texture patterns. Precis. Eng. 33(4), 425–429 (2009)

Lei, S.; Devarajan, S.; Chang, Z.: A study of micropool lubricated cutting tool in machining of mild steel. J. Mater. Process. Technol. 209(3), 1612–1620 (2009)

Enomoto, T.; Sugihara, T.; Yukinaga, S.; Hirose, K.; Satake, U.: Highly wear-resistant cutting tools with textured surfaces in steel cutting. CIRP Ann. Manuf. Technol. 61(1), 571–574 (2012)

Ma, C.; Zhu, H.: An optimum design model for textured surface with elliptical-shape dimples under hydrodynamic lubrication. Tribol. Int. 44(9), 987–995 (2011)

Sugihara, T.; Enomoto, T.: Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis. Eng. 36(2), 229–237 (2012)

Xie, J.; Luo, M.J.; Wu, K.K.; Yang, L.F.; Li, D.H.: Experimental study on cutting temperature and cutting force in dry turning of titanium alloy using a non-coated micro-grooved tool. Int. J. Mach. Tools Manuf. 73, 25–36 (2013)

Da Silva, W.M.; Suarez, M.P.; Machado, A.R.; Cost, H.L.: Effect of laser surface modification on the micro-abrasive wear resistance of coated cemented carbide tools. Wear 302(1–2), 1230–1240 (2013)

Xu, S.; Shimada, K.; Mizutani, M.; Kuriyagawa, T.: Fabrication of hybrid micro/nano-textured surfaces using rotary ultrasonic machining with one-point diamond tool. Int. J. Mach. Tools Manuf. 86, 12–17 (2014)

Li, L.; He, N.: A FEA study on mechanisms of saw-tooth chip deformation in high speed cutting of Ti–6Al–4V alloy. In: Fifth International Conference on High Speed Machining (HSM) Metz, France, 2006, pp. 14–16

Karpat, Y.: Temperature dependent flow softening of titanium alloy Ti6Al4V: an investigation using finite element simulation of machining. J. Mater. Process. Technol. 211(4), 737–749 (2011)

Charitha, R.; Shrikantha, R.; Mervin, H.: Performance improvement studies for cutting tools with perforated surface in turning of titanium alloy. MATEC Web Conf. EDP Sci. 144, 03003 (2018)

Rao, C.M.; Rao, S.S.; Herbert, M.A.: Development of novel cutting tool with a micro-hole pattern on PCD insert in machining of titanium alloy. J. Manuf. Process. 36, 93–103 (2018)

Nouari, M.; Makich, H.: Experimental investigation on the effect of the material microstructure on tool wear when machining hard titanium alloys: Ti–6Al–4V and Ti-555. Int. J. Refract. Metals Hard Mater. 41, 259–269 (2013)

Feng, C.; Gen, X.U.; Xu, G.P.: Thermal residual stress of polycrystalline diamond compacts. Trans. Nonferrous Metals Soc. China 20(2), 227–232 (2010)

Jianxin, D.; Ze, W.; Yunsong, L.; Ting, Q.; Jie, C.: Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes. Int. J. Refract. Metals Hard Mater. 30(1), 164–172 (2012)

D’Mello, G.; Pai, S.: Prediction of surface roughness in high speed machining: a comparison. Int. J. Res. Eng. Technol. 1, 519–525 (2014)

Wan, Z.P.; Zhu, Y.E.; Liu, H.W.; Tang, Y.: Microstructure evolution of adiabatic shear bands and mechanisms of saw-tooth chip formation in machining Ti–6Al–4V. Mater. Sci. Eng. A 531, 155–163 (2012)

Chetan; Ghosh, S.; Rao, P.V.: Environment friendly machining of Ni–Cr–Co based super alloy using different sustainable techniques. Mater. Manuf. Process. 31(7), 852–859 (2016)

Bordin, A.; Sartori, S.; Bruschi, S.; Ghiotti, A.: Experimental investigation on the feasibility of dry and cryogenic machining as sustainable strategies when turning Ti–6Al–4V produced by additive manufacturing. J. Clean. Prod. 142, 4142–4151 (2017)

Kaynak, Y.; Robertson, S.W.; Karaca, H.E.; Jawahir, I.S.: Progressive tool-wear in machining of room-temperature austenitic NiTi alloys: the influence of cooling/lubricating, melting, and heat treatment condition. J. Mater. Process. Technol. 215, 95–104 (2015)

Maity, K.P.; Swain, P.K.: An experimental investigation of hot-machining to predict tool life. J. Mater. Process. Technol. 198(1–3), 344–349 (2008)

Che-Haron, C.H.; Jawaid, A.: The effect of machining on surface integrity of titanium alloy Ti–6% Al–4% V. J. Mater. Process. Technol. 166(2), 188–192 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rao, C.M., Rao, S.S. & Herbert, M.A. An Experimental and Numerical Approach to Study the Performance of Modified Perforated Cutting Tools on Machining of Ti–6Al–4V Alloy. Arab J Sci Eng 45, 1191–1206 (2020). https://doi.org/10.1007/s13369-019-04268-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04268-w