Abstract

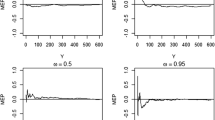

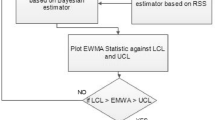

Statistical quality control is an integral part of modern manufacturing, and control charts are widely used to improve and control the performance of a process. However, much of the work related to process monitoring has been done using frequentist approaches, whereas the Bayesian methodology has a practical advantage in process monitoring; that is, it can be used with a small phase-I dataset. In this article, we considered different symmetric and asymmetric loss functions for designing Bayesian control charts and noticed that the performance of the Bayesian charts is biased, i.e., in-control performance of the charts is not equal to the desired value for some loss functions and comparison among different Bayesian charts can be misleading. Therefore, to get the desired in-control performance under different loss functions, we propose a corrected design of the Bayesian control charts. In addition to posterior charts, we also discuss a predictive control chart to monitor the future observations in this study. Besides a simulation study, we also present two real data examples: the first example is to monitor the surface roughness of reamed holes in a particular metal part while the second is about monitoring the measurements of a diameter.

Similar content being viewed by others

References

Montgomery, D.C.: Introduction to Statistical Quality Control, 6th edn. Wiley, New York (2009)

Azam, M.; Arshad, A.; Aslam, M.; Jun, Chi-Hyuck: A control chart for monitoring the process mean using successive sampling over two occasions. Arab. J. Sci. Technol. 42, 2915–2926 (2017)

Hussain, S.; Song, L.; Ahmad, S.; Riaz, M.: New Interquartile range EWMA control charts with applications in continuous stirred tank reactor process. Arab. J. Sci. Technol. 44(3), 2467–2485 (2019). https://doi.org/10.1007/s13369-018-3162-x

Brush, G.G.: A comparison of classical and Bayes producer’s risk. Technometrics 28(1), 69–72 (1986)

Biswas, S.: Statistics of Quality Control. New Central Book Agency (P) Limited, Kolkata (1997)

Sharma, K.K.; Bhuttani, R.K.: A comparison of classical and Bayes risks when quality varies randomly. Microelectron Reliab. 32(4), 493–495 (1992)

Menzefricke, U.: On the evaluation of control chart limits based on predictive distributions. Commun. Stat. Theory Methods 31(8), 1423–1440 (2002)

Menzefricke, U.: Control chart for the generalized variance based on its predictive distribution. Commun. Stat. Theory Methods 36, 1031–1038 (2007)

Sharma, K.K.; Singh, B.; Geol., J.: Analysis of \( \bar{X} \) and \( R \) charts when standards vary randomly. In: Pandey, B.N. (ed.) Statistical Techniques in Life Testing, Reliability, Sampling Theory and Quality Control (2007)

Saghir, A.: Phase-I design scheme for \( \bar{X} \) chart based on posterior distribution. Commun. Stat. Theory Methods 44(3), 644–655 (2015)

Bhat, S.; Gokhale, K.D.: Posterior control chart for process average under conjugate prior distribution. Econ. Qual. Control 29(1), 19–27 (2014)

Saghir, A.: Evaluation of \( \bar{X} \) and S charts when standards vary randomly. Interstat-November 2007#5 (2007)

Wu, X.; Miao, R.; Zhang, X.; Jiang, Z.; Chu, X.: A conjugate Bayesian approach to control chart for multi-batch and low volume production. Int. J. Prod. Res. 53, 2185–2197 (2015). https://doi.org/10.1080/00207543.2014.975857

Riaz, M.; Ali, S.: On process monitoring using location control charts under different loss functions. Trans. Inst. Meas. Control 38(9), 1107–1119 (2016). https://doi.org/10.1177/0142331215583325

Ali, S.; Riaz, M.: Cumulative quantity control chart for the simple and mixture of inverse Rayleigh distribution. Comput. Ind. Eng. 73, 11–20 (2014)

Maravelakis, P.E.; Panaretos, J.; Psarakis, S.: Effect of estimation of the process parameters on the control limits of the univariate control charts for process dispersion. Commun. Stat. Simul. Comput. 31(3), 443–461 (2002)

Zhang, L.; Bebbington, M.S.; Lai, C.D.; Govindaraju, K.: On statistical design of the S2 control chart. Commun. Stat. Theory Methods 34(1), 229–244 (2005)

Guo, B.; Wang, B.: The design of the ARL-unbiased S2 chart when the in-control variance is estimated. Qual. Reliab. Eng. Int. 31(3), 501–511 (2015)

Eprecht, E.K.; Loureiro, L.D.; Chakraborti, S.: Effect of the amount of Phase I data on the Phase II performance of S2 and S control charts. J. Qual. Technol. 47(2), 139–155 (2015)

Faraz, A.; Woodall, W.H.; Heuchenne, C.: Guaranteed conditional performance of the S2 control chart with estimated parameters. Int. J. Prod. Res. 53(14), 4405–4413 (2015)

Castagliola, P.; Figueiredo, F.O.: The median chart with estimated parameters. Eur. J. Ind. Eng. 7(5), 594–614 (2013)

Castagliola, P.; Oprime, P.C.; Khoo, M.B.C.: The double sampling S2 chart with estimated process variance. Commun. Stat. Theory Methods 46(7), 3556–3573 (2017). https://doi.org/10.1080/03610926.2015.1066814

Chen, T.; Morris, J.; Martin, E.: Bayesian control limits for statistical process monitoring. In: International Conference on Control and Automation ICCA Budapest, Hungary, vol. 1, pp. 409–414 (2005). https://doi.org/10.1109/icca.2005.1528154

Woodward, W.P.; Naylor, C.J.: An application to Bayesian methods in SPC. Statistician 42(4), 461–469 (1993)

Zhang, J.; He, C.; Li, Z.; Wang, Z.: Likelihood ratio test-based chart for monitoring the process variability. Commun. Stat.-Simul. Comput. 46(1), 704–728 (2017). https://doi.org/10.1080/03610918.2014.957845

Garcia-Diaz, J.C.: The effective variance control chart for monitoring the dispersion process with missing data. Eur. J. Ind. Eng. 1(1), 40–55 (2007)

Omar, M.H.; Joarder, A.H.; Riaz, M.: On a correlated variance ratio distribution and its industrial application. Commun. Stat.-Theory Methods 44(2), 261–274 (2015)

Aslam, M.; Haq, A.: On the prior selection for variance of normal distribution. Interstat (May 2009#1) (2009)

Does, R.J.M.M.; Roes, K.C.B.; Trip, A.: Statistical Process Control in Industry. Kluwer Academic, Dordrecht (1999). ISBN 0-7923-5570-9

Riaz, M.: Monitoring of process parameters using Bayesian methodology. Int. J. Agric. Stat. Sci. 7(1), 1–7 (2011)

Ali, S.: On the Bayesian estimation of weighted Lindley distribution. J. Stat. Comput. Simul. 85(5), 855–880 (2015). https://doi.org/10.1080/00949655.2013.847442

Duncan, A.: Quality control and industrial statistics, vol. 3. Richard D. Irwin Inc, Homewood (1965)

Zhang, G.: Improved R and S control charts for monitoring the process variance. J. Appl. Stat. 41(6), 1260–1273 (2014). https://doi.org/10.1080/02664763.2013.864264

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, S., Riaz, M. On Designing a New Bayesian Dispersion Chart for Process Monitoring. Arab J Sci Eng 45, 2093–2111 (2020). https://doi.org/10.1007/s13369-019-04036-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04036-w

Keywords

- Average run length

- Control charts

- Loss functions

- Posterior distribution

- Predictive monitoring

- Variability parameter