Abstract

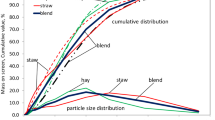

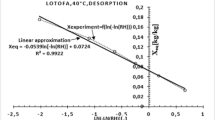

The aim of this paper was to study the moisture sorption characteristics of mixed biomass pellets. The pellets were developed using a mixture of woody (spruce or pine) and agricultural (reed canary grass or hay) biomass with a ratio of 1:1. The pellets were stored in a controlled environment until reaching the equilibrium moisture content. The temperature of the controlled environment was varied between 15 and 25 \(^{\circ }\hbox {C}\) and relative humidity between 20 to 90%. The experimental results showed this temperature range had no effect on the moisture sorption isotherms. However, the equilibrium moisture content at higher relative humidity was found dependent on the type of the material and was higher for spruce-hay pellets compared to the other tested pellets. Oswin, Guggenheim-Anderson-de Boer, Henderson and Peleg models were tested for the prediction of the moisture isotherms. With a coefficient of determination varying between 0.998 and 0.995, a standard error between 0.054 and 0.071 and chi-square error ranging between 0.009 and 0.015, Oswin model was found more suitable to predict the moisture sorption isotherms of all biomass pellets. This result was further confirmed using the residuals plot, showing a more uniform distribution for Oswin model compared to the other models.

Similar content being viewed by others

References

Murray, G.: International pellet markets and Canadian industry update. http://www.pellet.org/images/2014-06-13_G_Murray_IBCES.pdf (June 2014)

Natural Resources Canada. http://cfs.nrcan.gc.ca/coupes-selectives/57?lang=en_CA. Last update December 2014.

Tooyserkani, Z.; Sokhansanj, S.; Bi, X.; Lim, J.; Lau, A.; Saddler, J.; Kumar, L.; Lam, P.S.; Melin, S.: Steam treatment of four softwood species and bark to produce terrified wood. Appl. Energy 103, 514–521 (2013)

Lehtikangas, P.: Storage effects on pelletised sawdust, logging residues and bark. Biomass Bioenergy 19(5), 287–293 (2000)

Temmerman, M.; Rabier, F.; Jensen, P.D.; Hartmann, H.; Böhm, T.: Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 30(11), 964–972 (2006)

Whittaker, C.; Shield, I.: Factors affecting wood, energy, grass and straw pellet durability - A review. Renew. Sustain. Energy Rev. 71, 1–11 (2017)

Wang, S.; Yuan, X.; Li, C.; Huang, Z.; Leng, L.; Zeng, G.; Li, H.: Variation in the physical properties of wood pellets, and emission of aldehyde, ketone under different storage conditions. Fuel 183, 314–321 (2016)

Sultana, A.; Kumar, A.: Ranking of biomass pellets by integration of economic, environmental and technical factors. Biomass Bioenergy 39, 344–355 (2012)

Kaliyan, N.; Morey, R.V.: Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 33(3), 337–359 (2009)

Graham, S.; Eastwick, C.; Snape, C.; Quick, W.: Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 160, 143–151 (2017)

Järvinen, T.; Agar, D.: Experimentally determined storage and handling properties of fuel pellets made from torrefied whole-tree pine chips, logging residues and beech stem wood. Fuel 129, 330–339 (2014)

Obernberger, I.; Thek, G.: Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behavior. Biomass Bioenergy 27(6), 653–669 (2004)

Núnez, C.A.F.; Jochum, J.; Vargas, F.E.S.: Characterization and feasibility of biomass fuel pellets made of Colombian timber, coconut and oil palm residues regarding European standards. Environ. Biotechnol. 8(2), 67–76 (2012)

Lee, J.S.; Sokhansanj, S.; Lau, A.K.; Lim, C.J.; Bi, X.T.: The effect of storage on the net calorific value of wood pellets. Can. Biosyst. Eng. 57, 8.5–8.12 (2015)

Nilsson, D.; Bernesson, S.; Hansson, P.A.: Pellet production from agricultural raw materials—a systems study. Biomass Bioenergy 35(1), 679–689 (2011)

Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D.: Physical properties of pellets made from sorghum stalk, corn stover, wheat straw and big bluestem. Ind. Crops Prod. 33(2), 325–332 (2011)

Fasina, O.O.: Physical properties of peanut hull pellets. Bioresour. Technol. 99(5), 1259–1266 (2008)

Mani, S.; Tabil, L.G.; Sokhansanj, S.: Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30(7), 648–654 (2006)

Lehtikangas, P.: Storage effects on pelletised sawdust, logging residues and bark. Biomass Bioenergy 19(5), 287–293 (2000)

Hartley, I.D.; Wood, L.J.: Hygroscopic properties of densified softwood pellets. Biomass Bioenergy 32(1), 90–93 (2008)

Singh, R.N.: Equilibrium moisture content of biomass briquettes. Biomass Bioenergy 26(3), 251–253 (2004)

Fasina, O.; Sokhansanj, S.; Tyler, R.: Thermodynamics of moisture sorption in alfalfa pellets. Dry. Technol. 15(5), 1153–1570 (1997)

Fasina, O.O.; Sokhansanj, S.: Equilibrium moisture relations and heat of sorption of alfalfa pellets. J. Agric. Eng. Res. 56(1), 51–63 (1993)

Yub Harun, N.; Afzal, M.T.: Chemical and mechanical properties of pellets made from agricultural and woody biomass. In: American Society of Agricultural and Biological Engineers Annual International Meeting, vol. 5, pp. 3776–3784 (2014)

ASTM D4442-07. Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials. ASTM International, West Conshohocken, PA . www.astm.org (2007)

Karunanithy, C.; Muthukumarappan, K.; Donepudi, A.: Moisture sorption characteristics of switchgrass and prairie cord grass. Fuel 103, 171–178 (2013)

Krupińska, B.; Strømmen, I.; Pakowski, Z.; Eikevik, T.M.: Modeling of sorption isotherms of various kinds of wood at different temperature conditions. Dry. Technol. 25(9), 1463–1470 (2007)

Doymaz, I.: Air-drying characteristics of tomatoes. J. Food Eng. 78(4), 1291–1297 (2007)

Ando, Y.; Mizutani, K.; Wakatsuki, N.: Electrical impedance analysis of potato tissues during drying. J. Food Eng. 121, 24–31 (2014)

Ait Mohamed, L.; Kouhila, M.; Lahsasni, S.; Jamali, A.; Idlimam, A.; Rhazi, M.; Aghfir, M.; Mahrouz, M.: Equilibrium moisture content and heat of sorption of Gelidium sesquipedale. J. Stored Prod. Res. 41(2), 199–209 (2005)

Bennamoun, L.; Crine, M.; Léonard, A.: Convective drying od wastewater sludge: Introduction of shrinkage effect in mathematical modeling. Dry. Technol. 31(6), 643–654 (2003)

Al-Muhtaseb, A.H.; McMinn, W.A.M.; Magee, T.R.A.: Moisture sorption isotherm characteristics of food products: a review. Food Bioprod. Process. 80(2), 118–128 (2002)

Panchariya, P.C.; Popovic, D.; Ssharma, A.L.: Modeling of desorption isotherm of black tea. Dry. Technol. 19(6), 1177–1188 (2001)

Kuisma, E.; Palonen, P.; Yli-Halla, M.: Reed canary grass straw as a substrate in soilless cultivation of strawberry. Sci. Hortic. 178, 217–223 (2014)

Behgar, M.; Valizadeh, R.; Mirzaee, M.; Naserian, A.A.; Nasiri, M.R.: Correlation between the physical and chemical properties of some forage and non-forage fiber sources. J. Anim. Vet. Adv. 8(11), 2280–2285 (2009)

Desmorieux, H.; Decaen, N.: Convective drying of spirulina in thin layer. J. Food Eng. 66(4), 497–503 (2005)

Belahmdi, E.; Belghit, A.; Mira, A.; Kaoua, A.: Approche expérimentale de la cinétique de séchage des produits agroalimentaires. Application aux peaux d’oranges et à la pulpe de betteraves. Revue Générale de Thermique 32(380–381), 444–453 (1993)

Chen, C.: Evaluation of equilibrium sorption isotherm equations. Open Chem. Eng. J. 7, 24–44 (2013)

Nilsson, D.; Svennerstedt, B.; Wretfors, C.: Adsorption equilibrium moisture contents of flax straw, hemp stalks and reed canary grass. Biosyst. Eng. 91(1), 35–43 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bennamoun, L., Harun, N.Y. & Afzal, M.T. Effect of Storage Conditions on Moisture Sorption of Mixed Biomass Pellets. Arab J Sci Eng 43, 1195–1203 (2018). https://doi.org/10.1007/s13369-017-2808-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-017-2808-4