Abstract

The iron and steel industry is known as the largest energy-consuming and CO2-emitting manufacturing sector in the world. Therefore, investigation, development and deployment of alternative energy-efficient iron-making breakthrough technologies along with CO2 capture technology are receiving high priority to mitigate environmental concerns by reducing pollutants and greenhouse gas emissions of around level 50 % by 2050 compared to 2007. This research evaluates the CCS systems in the iron and steel industry considering four prominent aspects (engineering, economic, environmental and social) of sustainability using questionnaire with group of experts having relevant experience. A novel hybrid multi-criteria decision model is proposed integrating Delphi, 2-tuple decision-making trial and evaluation laboratory, and extent analysis method on fuzzy AHP to select the dimensions and critical factors for evaluating alternative iron-making technologies with CCS systems. Case studies are conducted in iron and steel industries in Malaysia and Bangladesh to illustrate the proposed framework and to demonstrate its usefulness and validity.

Similar content being viewed by others

References

Helle, H.: Towards Sustainable Iron-and Steelmaking with Economic Optimization. National Library of Finland, University of Helsinki (2014)

Huitu K. et al.: Optimization of steelmaking using fastmet direct reduced iron in the blast furnace. ISIJ Int. 53(12), 2038–2046 (2013)

Patel P., Seetharaman S.: A test of the steel industry’s metal. MRS Bull. 38(09), 680–681 (2013)

Remus, R., et al.: Best Available Techniques (BAT) Reference Document for Iron and Steel Production: Industrial Emissions Directive 2010/75/EU: Integrated Pollution Prevention and Control. Publications Office, Netherlands (2013)

Mandil C.: Tracking Industrial Energy Efficiency and CO2 Emissions. IEA, Paris (2007)

Kuramochi T. et al.: Techno-economic assessment and comparison of CO2 capture technologies for industrial processes: Preliminary results for the iron and steel sector. Energy Proc. 4, 1981–1988 (2011)

Iea U.: Technology Roadmap Carbon Capture and Storage in Industrial Applications. OECD Publishing, Paris (2011)

Birol, F.: World Energy Outlook 2010. International Energy Agency, Paris, France (2010)

Tanaka N.: Energy Technology Perspectives 2008-Scenarios and Strategies to 2050. OECD/IEA, Paris (2008)

Agency I.E.: Technology Roadmap—Carbon Capture and Storage in Industrial Applications. International Energy Agency (IEA), Paris (2013)

Pardo N., Moya J.A.: Prospective scenarios on energy efficiency and CO2 emissions in the European iron & steel industry. Energy 54, 113–128 (2013)

Milford R.L. et al.: The roles of energy and material efficiency in meeting steel industry CO2 targets. Environ. Sci. Technol. 47(7), 3455–3462 (2013)

Wilday J., Bilio M.: Safety issues for carbon capture and storage. Process Saf. Environ. Prot. 92(1), 1–2 (2014)

Spigarelli, B.P.; Kawatra, S.K.: Opportunities and challenges in carbon dioxide capture. J. CO2 Util. 1, 69–87 (2013)

Sreenivasulu B. et al.: A journey into the process and engineering aspects of carbon capture technologies. Renew. Sustain. Energy Rev. 41, 1324–1350 (2015)

Watson J., Kern F., Markusson N.: Resolving or managing uncertainties for carbon capture and storage: Lessons from historical analogues. Technol. Forecast. Soc. Change 81, 192–204 (2014)

Prabhu T.R., Vizayakumar K.: Technology choice using FHDM: a case of iron-making technology. IEEE Trans. Eng. Manag. 48(2), 209–222 (2001)

Prabhu T.R., Vizayakumar K.: Technology choice using FHDM: a case of iron-making technology. IEEE Trans. Eng. Manag. 48(2), 209–222 (2001)

Hansmann R., Mieg H.A., Frischknecht P.: Principal sustainability components: empirical analysis of synergies between the three pillars of sustainability. Int. J. Sustain. Dev. World Ecol. 19(5), 451–459 (2012)

Gabus A., Fontela E.: World Problems, an Invitation to Further Thought Within the Framework of DEMATEL. Battelle Geneva Research Center, Geneva (1972)

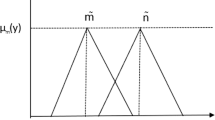

Zadeh L.A.: Fuzzy sets. Inf. Control 8(3), 338–353 (1965)

Kahraman C., Cebeci U., Ruan D.: Multi-attribute comparison of catering service companies using fuzzy AHP: the case of Turkey. Int. J. Prod. Econ. 87(2), 171–184 (2004)

Chan F.T., Kumar N.: Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega 35(4), 417–431 (2007)

Kilincci O., Onal S.A.: Fuzzy AHP approach for supplier selection in a washing machine company. Expert Syst. Appl. 38(8), 9656–9664 (2011)

Chang D.-Y.: Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 95(3), 649–655 (1996)

Rowe, G.; Wright, G.: Expert opinions in forecasting: the role of the Delphi technique. In: Principles of Forecasting, pp. 125–144. Springer, Berlin (2001)

Rowe G., Wright G.: The Delphi technique as a forecasting tool: issues and analysis. Int. J. Forecast. 15(4), 353–375 (1999)

Clayton M.J.: Delphi: a technique to harness expert opinion for critical decision-making tasks in education. Educ. Psychol. 17(4), 373–386 (1997)

Zopounidis, C.; Pardalos, P.: Handbook of Multicriteria Analysis, vol. 103. Springer, Berlin (2010)

Chalmers H. et al.: Analysing uncertainties for CCS: from historical analogues to future deployment pathways in the UK. Energy Proc. 37, 7668–7679 (2013)

Sano F. et al.: Analysis of CCS diffusion for CO2 emission reduction considering technology diffusion barriers in the real world. Energy Proc. 37, 7582–7589 (2013)

Rhee C.H. et al.: Process analysis for ammonia-based CO2 capture in ironmaking industry. Energy Proc. 4, 1486–1493 (2011)

Yincheng G., Zhenqi N., Wenyi L.: Comparison of removal efficiencies of carbon dioxide between aqueous ammonia and NaOH solution in a fine spray column. Energy Proc. 4, 512–518 (2011)

Han K., Ahn C.K., Lee M.S.: Performance of an ammonia-based CO2 capture pilot facility in iron and steel industry. Int. J. Greenh. Gas Control 27, 239–246 (2014)

Saima W.H., Mogi Y., Haraoka T.: Development of PSA system for the recovery of carbon dioxide and carbon monoxide from blast furnace gas in steel works. Energy Proc. 37, 7152–7159 (2013)

Eide J., Herzog H., Webster M.: Rethinking CCS-developing quantitative tools for analyzing investments in CCS. Energy Proc. 37, 7647–7667 (2013)

Koelbl B. et al.: Uncertainty in the deployment of carbon capture and storage (CCS): a sensitivity analysis to techno-economic parameter uncertainty. Int. J. Greenh. Gas Control 27, 81–102 (2014)

Arasto A. et al.: Costs and potential of carbon capture and storage at an integrated steel mill. Energy Proc. 37, 7117–7124 (2013)

Zapp P. et al.: Overall environmental impacts of CCS technologies—a life cycle approach. Int. J. Greenh. Gas Control 8, 12–21 (2012)

Corsten M. et al.: Environmental impact assessment of CCS chains–lessons learned and limitations from LCA literature. Int. J. Greenh. Gas Control 13, 59–71 (2013)

Mao X. et al.: Co-control of local air pollutants and CO2 in the Chinese iron and steel industry. Environ. Sci. Technol. 47(21), 12002–12010 (2013)

Petrakopoulou F., Tsatsaronis G.: Can carbon dioxide capture and storage from power plants reduce the environmental impact of electricity generation?. Energy Fuels 28(8), 5327–5338 (2014)

Burchart-Korol D.: Life cycle assessment of steel production in Poland: a case study. J. Clean. Prod. 54, 235–243 (2013)

Karayannis V., Charalampides G., Lakioti E.: Socio-economic aspects of CCS technologies. Proc. Econ. Finance 14, 295–302 (2014)

Steeper T.: CO2CRC otway project social research: assessing CCS community consultation. Energy Proc. 37, 7454–7461 (2013)

Watson J., Kern F., Markusson N.: Resolving or managing uncertainties for carbon capture and storage: lessons from historical analogues. Technol. Forecast. Soc. Change 81, 192–204 (2014)

IEAGHG: Incorporation Future Technological Improvements in Existing CO2 Post Combustion Capture Plants: Technical Review. IEA Greenhouse Gas R&D Program, Report 2013/TR5 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quader, M.A., Ahmed, S. A Hybrid Fuzzy MCDM Approach to Identify Critical Factors and CO2 Capture Technology for Sustainable Iron and Steel Manufacturing. Arab J Sci Eng 41, 4411–4430 (2016). https://doi.org/10.1007/s13369-016-2134-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-016-2134-2