Abstract

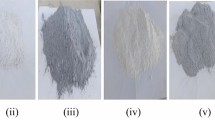

Blending of a large amount of waste materials such as fly ash, silica fume, rice husk ash (RHA), etc. is being done in large extents in the manufacture of cement and cementitious products. A lot of work has been done on replacement of cement with fly ash and RHA, which have shown good results with respect to strength and durability. In addition, Limestone Powder (LP), produced as by-product of stone crushers in limestone quarries, is also used as partial replacement of Ordinary Portland Cement. High amount of powders is being collected and utilization of this by-product is a big problem from the aspects of disposal, environmental pollution and health hazards. The existing blending methodology of binary blending (mixing one Supplementary Cementitious Material (SCM) with cement) and ternary blending (mixing two SCMs with cement) has improved the performance of concrete. The objective of this study aims to characterize the optimum percentage of SCMs fly ash, RHA and LP in a quaternary mix, with respect to strength and durability. As expected, the quaternary mix is very effective in enhancing the compressive, tensile and flexural strength along with durability of the concrete.

Similar content being viewed by others

References

Isaia, G.C.: Synergic action of fly ash ternary mixtures with silica fume and rice husk ash: pozzolanic activity. In: Justnes, H. (ed.) Int. Cong. on the Chem. of Cem.; 10th, Gothenburg, 1997, Proceedings vol. 4, Amarkai AB p. 8 (1997)

Tsivilis S., Batis G., Chaniotakis E., Grigoriadis Gr., Theodossis D.: Properties and behaviour of limestone. Cem. Concr. Mortar. Cem. Concr. Res. 30, 1679–1683 (2000)

Matschei T., Lothenbach B., Glasser FP.: The role of calcium carbonate in cement hydration. Cem. Concr. Res. 3, 559–564 (2007)

Bentz D.P.: Modelling the influence of limestone filler on cement hydration using CEMHYD3D. Cem. Concr. Compos. 28, 124–129 (2006)

Skaropoulou A., Tsivilis S., Kakali G., Sharp J.H., Swamy R.N.: Thaumasite form of sulfate attack in limestone cement mortars: a study on long term efficiency of mineral admixtures. Constr. Build. Mater. 23, 2338–2345 (2009)

Yılmaz B., Olgun A.: Studies on cement and mortar containing low-calcium fly ash, limestone, and dolomitic limestone. Cem. Concr. Compos. 30, 194–201 (2008)

Chindaprasirt P., Kanchanda P., Sathonsaowaphak A., Cao H.T.: Sulfate resistance of blended cements containing fly ash and RHA. Constr. Build. Mater. 21, 1356–1361 (2007)

Ganesan K., Rajagopal K., Thangavel K., Ganesan K., Rajagopal K., Thangavel K.: RHA blended cement: assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 22, 1675–1683 (2008)

Zhang M.H., Lastra R., Malhotra V.M.: Rice-husk ash paste and concrete: some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste. Cem. Concr. Res. 26, 963–977 (1996)

Ghrici M., Kenai S., Said-Mansour M.: Mechanical properties and durability of mortar and concrete containing natural pozzolana and limestone blended cements. Cem. Concr. Res. 29, 542–549 (2007)

Chindaprasirt P., Rukzon S.: Strength, porosity and corrosion resistance of ternary blend Portland cement, RHA and fly ash mortar. Constr. Build. Mater. 22, 1601–1606 (2008)

IS 8112-1989, Indian Standard Specification for 43 Grade Ordinary Portland Cement

IS 383-1978 (Reaffirmed 1997) Indian Standard Specification for coarse and fine aggregate from natural sources for concrete

IS 10262-2009, Indian Standard Guidelines for concrete mix design proportioning

Ramezanianpour A.A., Ghiasvand E., Nickseresht I., Mahdikhani M., Moodi F.: Influence of various amounts of LP on performance of Portland limestone cement concretes. Cem. Concr. Compos. 31, 715–720 (2009)

Moayad N., Al-Khalaf H., Yousif A.: Use of RHA in concrete. Int. J. Cem. Compos. Lightweight Concr. 6, 241–248 (1984)

IS 516-1959 (Reaffirmed 1999) Edition 1.2 (1991-07, Indian Standard Methods of Tests for Strength of Concrete

ASTM C496-96, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens, American Society of Testing and Materials, Philadelphia

ASTM C78/C78 M −10 Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). American Society of Testing and Materials, Philadelphia

ASTM C642-06, Standard Test Method for Density, Absorption, and Voids in Hardened Concrete, American Society of Testing and Materials, Philadelphia

ASTM C1202-10 Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration, American Society of Testing and Materials, Philadelphia

Song H.W., Saraswathy V., Muralidharan S., Lee C.H., Thangavel K.: Corrosion performance of steel in composite concrete system admixed with chloride and various alkaline nitrites. Corros. Eng. Sci. Technol. 44, 408–415 (2009)

ASTM C876-09 Standard Test Method for Half-Cell Potentials of Uncoated Reinforcing Steel in Concrete. American Society of Testing and Materials, Philadelphia

ASTM G1-03 Standard Practices for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, American Society of Testing and Materials, Philadelphia

Schmidt T., Lothenbach B., Romer M., Neuenschwander J., Scrivener K.: Physical and microstructural aspects of sulfate attack on ordinary and limestone blended Portland cements. Cem. Concr. Res. 39, 1111–1121 (2009)

Ye G., Liu X., De Schutter G., Poppe A.M., Taerwe L.: Influence of LP used as filler in SCC on hydration and microstructure of cement pastes. Cem. Concr. Compos. 29, 94–102 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kathirvel, P., Saraswathy, V., Karthik, S.P. et al. Strength and Durability Properties of Quaternary Cement Concrete Made with Fly Ash, Rice Husk Ash and Limestone Powder. Arab J Sci Eng 38, 589–598 (2013). https://doi.org/10.1007/s13369-012-0331-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-012-0331-1