Abstract

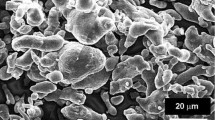

Powder injection molding (PIM) is a promising manufacturing technology for the net-shape production of small, complex, and precise metal or ceramic components. In order to manufacture high quality magnets using PIM, the magneto-rheological (MR) properties of the PIM feedstock, i.e. magnetic powder-binder mixture, should be investigated experimentally and theoretically. The current research aims at comprehensive understanding of the rheological characteristics of the PIM feedstock. The feedstock used in the experiment consists of strontium ferrite powder and paraffin wax. Steady and oscillatory shear tests have been carried out using a plate-and-plate rheometer, under the influence of a uniform magnetic field applied externally. Rheological properties of the PIM feedstock have been measured and characterized for various conditions by changing the temperature, the powder fraction and the magnetic flux density.

Similar content being viewed by others

References

Chaudhuria, A., N.M. Wereleya, S. Kothab, R. Radhakrishnanb, and N.M. Sudarshanb, 2005, Iscometric characterization of cobalt nanoparticle-based magnetorhelogical fluids using genetic algorithms, Journal of Magnetism and Magnetic Materials 293, 206–214.

Claracq, J., J. Sarrazin, and J. Montfort, 2004, Viscoelastic properties of magnetorheological fluids, Rheol. Acta 43, 38-49.

Cox, W.P. and E.H. Merz, 1958, Journal of Polymer Science 28, 619.

German, R. M. and A. Bose, 1997, Injection Molding of Metals and Ceramics Metal Powder Industries Federation, Princeton, NJ.

Jolly, M. R., J. D. Carlson, and B. C. Munoz, 1996, A Model of the Behavior of Magnetorheological Materials, Smart Materials and Structures 5, 607–614.

Kang, T. G., M. A. Hulsen, and J. M. J. den Toonder, 2012, Phys. Fluids 24, 042001.

Keentok, M., 1982, The measurement of the yield stress of liquids, Rheol. Acta 21, 325–332.

Keentok, M. and H. See, 2007, Behaviour of field-responsive suspensions under oscillatory shear flow, Korea-Australia Rheology Journal 19, 117–123.

Kim, S. J. and T. H. Kwon, 1995, Development of numerical simulation methods and analysis of extrusion processes of particle-filled plastic materials subject to slip at the wall, Powder Technology 85, 227–239

Klingenberg, D.J. and C.J. Zukoski, 1990, Studies on the steady-shear behavior of electrorheological suspensions, Langmuir 6, 15–24.

Kwon, T.H., C.S. Kim, S.J. Kim,, D.M. Shin,, T.S. Yoon, and S.H. Ahn, 1992, Proc. In. Conf. on Transport phenomena in Processing, Hawaii, U.S.A., 1159–1169.

Liu, Z.Y., D. Kent, and G.B. Schaffer, 2009, Powder injection molding of Al-(Steel and Magnet) hybrid components, Metallurgical and Materials Transactions A 40A, 2785–2788.

Macosko, Christopher W., 1994, Rheology: Principles, Measurements, and Applications, John Wiley & Sons Inc, New York.

Marrucci, G. and G. Ianniruberto, 1996, Proceedings of the Royal Society — Unilever — Indo/UK Forum on the Dynamics of Complex Fluids, Cambridge, UK.

Milner, S., 1996, Relating the shear-thinning curve to the molecular weight distribution in linear polymer melts, Journal of Rheology 40, 303.

Murillo, N., J. Gonzalez, C. Guraya, M. Gutierrez, and F.J. Seco, 1999, Structural and magnetic properties of sintered Sr-ferrites fabricated by powder injection molding, Journal of Magnetism and Magnetic Materials 203, 165–168.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.H., Kim, S.J., Park, S.J. et al. Rheological behavior of magnetic powder mixtures for magnetic PIM. Korea-Aust. Rheol. J. 24, 121–127 (2012). https://doi.org/10.1007/s13367-012-0014-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-012-0014-1