Abstract

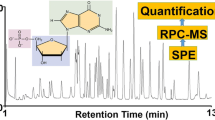

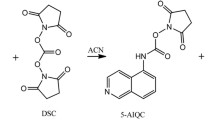

Mass spectrometry-based quantification method has advanced rapidly. In general, the methods for accurate quantification rely on the use of authentic target compounds or isotope-labeled compounds as standards, which might be not available or difficult to synthesize. To tackle this grand challenge, this paper presents a novel approach, based on electrochemistry (EC) combined with mass spectrometry (MS). In this approach, a target compound is allowed to undergo electrochemical oxidation and then subject to MS analysis. The oxidation current recorded from electrochemistry (EC) measurement provides information about the amount of the oxidized analyte, based on the Faraday’s Law. On the other hand, the oxidation reaction yield can be determined from the analyte MS signal changes upon electrolysis. Therefore, the total amount of analyte can be determined. In combination with liquid chromatography (LC), the method can be applicable to mixture analysis. The striking strength of such a method for quantitation is that neither standard compound nor calibration curve is required. Various analyte molecules such as dopamine, norepinephrine, and rutin as well as peptide glutathione in low quantity were successfully quantified using our method with the quantification error ranging from − 2.6 to + 4.6%. Analyte in a complicated matrix (e.g., uric acid in urine) was also accurately measured.

Graphical Abstract

Similar content being viewed by others

Introduction

Mass spectrometry (MS) has become a widely used technique for characterization and identification of both small and large molecules [1,2,3,4,5], due to its capability for determining molecular weight (MW) and molecular structure based on tandem mass analysis. Although MS is powerful in qualitative analysis, accurate quantification by MS has challenges due to the fact that the MS signal fluctuates and the signal intensity in a MS spectrum does not always correlate well with the amount of analyte [6,7,8]. Therefore, accurate MS quantification relies on using standard compounds for calibration or isotope-labeled compound as a reference [9, 10]. To date, a variety of elegant quantitative MS methods have been developed with great successes, such as isotope-coded affinity tags (ICAT) [11,12,13,14,15,16,17], stable isotope labeling with amino acids in cell culture (SILAC) [15, 18,19,20,21], isobaric tags for relative and absolute quantification (iTRAQ) [22,23,24,25], metal element chelated tags (MECT) [26], and isotope-coded protein labeling (ICPL) [27], etc. However, standard or isotope-labeled compounds that are needed for quantification might not be available and sometimes their syntheses are costly and time-consuming [28,29,30,31].

To tackle this challenge, we present a novel approach using MS in combination with electrochemistry (EC) [32,33,34,35] to solve this problem, with the goal of achieving accurate chemical quantification without using any standards or isotope-labeled compounds. Online coupling of EC with MS is versatile and has been shown to have many applications in drug metabolism study, protein structural analysis and electrochemical reaction mechanism elucidation [36,37,38,39,40,41,42,43,44,45]. However, quantification based on electrochemical mass spectrometry has not been reported so far, which is the focus of this study. In our study, a target compound, if it is electroactive, is first introduced to an electrochemical cell for electrochemical redox conversion (oxidation or reduction) followed by MS detection. Electrochemical redox reaction results in an electric current response. The integration of the current peak over time provides information about the amount of the oxidized/reduced analyte, based on the Faraday’s Law. According to the Faraday’s law, the charge Q, the total electric charge responsible for oxidizing/reducing analyte substance in coulombs in the redox reaction, is directly proportional to quantity of the oxidized/reduced substance: Q=nzF, where n is the moles of analyte, Z is the number of electrons transferred per molecule for the redox reaction, and F is the Faraday constant (9.65 × 104 C/mol). Q can be directly measured from the integration of Faradaic current over time. The moles of the analyte that is oxidized or reduced can be calculated as n=Q/zF.

On the other hand, the electroactive species shows reduced intensities in the acquired MS spectra upon oxidation/reduction, and the relative MS intensity change upon redox reaction, ∆i, can reflect the redox conversion yield. In this study, ∆i can be measured in two ways. From the acquired MS spectra before and after electrolysis, ∆i can be the relative change of the target analyte peak intensity (relative to a reference peak) upon electrolysis, as illustrated in Scheme 1a. Alternatively, ∆i can be the relative change of the target analyte peak area in the extracted ion chromatogram (EIC) upon electrolysis, as illustrated in Scheme 1b. Indeed, in a separate experiment, we confirmed that the EIC peak area is proportional to the sample concentration (see discussion in the Supporting Information Figure S1). Thus, the amount of analyte converted, in combination with the conversion yield, can be used to calculate the total amount of analyte. In other words,

Total amount of analyte

=(amount of the oxidized/reduced analyte)/(the oxidation/reduction yield)

=(Q/zF)/∆i

=Q/(zF∆i)

Unlike traditional coulometric approach, analyte does not need to undergo complete oxidation or reduction conversion in our approach, which can be advantageous as 100% conversion is often practically difficult to achieve. No limitation to a full redox conversion also allows fast electrolysis, as demonstrated in this study that electrolysis can be performed during the time of sample elution from liquid chromatography (LC). The capability of coupling LC with EC/MS [46] for quantification further makes this method applicable for analysis of both pure compounds and mixtures. In literature, electrochemical detection coupled with LC is a known technique for mixture analysis, where electrochemical oxidation or reduction of LC-separated compounds generates electric current for detection or quantification purpose [47,48,49].

Experimental Section

Chemicals

Dopamine (DA) hydrochloride, (−)-norepinephrine (NE), rutin (RN) hydrate (≥ 94% purity), and uric acid (UA) were purchased from Sigma-Aldrich (St. Louis, MO). Glutathione (GSH) (the reduced form) was purchased from TCI America (Portland, OR). Formic acid and acetonitrile were obtained from Fisher Chemical (Fair Lawn, NJ), and deionized water used for sample preparation was obtained using a Nanopure Diamond Barnstead purification system (Barnstead International, Dubuque, IA).

Apparatus

A Waters ultra-performance liquid chromatography (UPLC, Milford, MA, USA) system equipped with a C18 column was coupled with an electrochemical thin-layer flow cell (Scheme 2). The thin-layer cell used was an Antec ReactorCell™ (Antec BV, Neitherland) equipped with a Magic Diamond (boron doped diamond) disc electrode (i.d., 8 mm) as the working electrode (WE) used for oxidation process. A HyREF™ electrode was used as the reference electrode (RF) and carbon-loaded PTFE was used as a counter electrode (CE). A positive potential (ranging from + 1.2 to + 1.3 V) was applied to the WE electrode for oxidation of the LC-separated target compounds. Mass spectrum data was collected using a high-resolution Q-Executive Plus hybrid quadrupole-Orbitrap mass spectrometer (Thermo Scientific, San Jose, CA). The oxidation current response was monitored and recorded by using a ROXY™ potentiostat (Antec BV, Neitherland). The electric current peak area was integrated by importing the current data point to software OriginPro 8.0, for calculation of the total electric charge Q involved in oxidation reaction. The eluate flowing out of the cell was either collected and subsequently analyzed using nano-electrospray ionization mass spectrometry (nano-ESI-MS, Scheme 2a) or directly monitored online using liquid sample desorption spray ionization mass spectrometry [50] (LS-DESI-MS, Scheme 2b).

For nano-ESI-MS analysis, the emitter tip was pulled using a laser puller (Model P-2000, Sutter Interment, Novato, CA). The sample injection flow rate for nano-ESI ionization was 2 μL/min with + 3.5 kV potential applied to the nano-ESI emitter. Nano-ESI-MS spectra were obtained based on averaging of 50 scans. For online MS analysis, a modified version of liquid sample DESI configuration was adopted (Scheme 2b) and the DESI probe consisted of a piece of inner fused silica capillary (2.6 cm) and a piece of a concentric outer PEEK capillary (2.9 cm). Another piece of fused silica capillary was connected with the electrochemical flow cell in one end and inserted into the PEEK capillary in the other end via a small hole drilled near the outlet of the PEEK capillary (Scheme 2b). This way the sample flowing out of the cell can be introduced into the PEEK capillary in which the sample can be ionized via mixing with the solvent spray coming out of the inner fused silica capillary. Unlike our previously reported LS-DESI configuration [50, 51], the sample capillary outlet and the DESI probe in this new DESI set-up do not need to be aligned so that the operation of DESI source becomes easy. N2 was used as the nebulization gas (160 psi) and the spray solvent for DESI was CH3OH/H2O/HOAc (50:50:1 by volume) and infused at the flow rate of 10 μL/min. To measure the relative area change for target EIC peak before and after electrolysis, the integration time window (t, Scheme 1b) was kept the same.

LC/EC with Offline MS Analysis

For DA and NE analysis, an isocratic elution program was employed using 95% A for 10 min (mobile phase A: water containing 0.1% formic acid and mobile phase B: ACN containing 0.1% formic acid). The mobile phase flow rate was 100 μL/min, and the sample injection volume was 6 μL for DA and 3 μL for NE, respectively. Both DA and NE samples were prepared in ACN/H2O (5:95 by volume) containing 0.1% formic acid. Control data were also collected using ACN/H2O (5:95 by volume) containing 0.1% formic acid without DA or NE as a blank sample. + 1.3 V was applied for DA oxidation, and + 1.2 V was applied for NE oxidation.

After sample was injected into the LC/EC instrument, the electrochemical cell was either turned off or on. As the sample flowed out of the electrochemical cell, the eluate was collected. The collected un-oxidized and oxidized sample solutions were adjusted to the same volume (e.g., 100 μL) and then spiked with 1 μL of arginine (spiked as a reference compound, the final arginine concentration was 10 μM), for subsequent nano-ESI-MS analysis. The comparison in the recorded MS sample signals (relative to the spiked arginine) for un-oxidized and oxidized samples provided information about the oxidation reaction yield.

LC/EC with Online MS Analysis

Rutin and GSH were analyzed using online LC/EC/DESI-MS apparatus, and the mobile phase flow rate was set as 300 μL/min. An isocratic elution program using 70% A for 10 min was used for rutin, and 80% A isocratic elution program for 10 min was used for GSH. Rutin was dissolved in DMSO first and then diluted with a solvent containing 30% ACN and 0.1% formic acid. GSH solution was directly prepared using a solvent containing 20% ACN and 0.1% formic acid. The injected concentrations of rutin and GSH samples were 50 μM and 200 μM, respectively; the injection volume for both rutin and GSH was 6 μL.

Quantitation of urine acid in urine sample was also attempted using our method. A urine sample was first filtrated using 0.2 μm WWPTFE membrane, and then diluted 8 times using water containing 0.1% formic acid. In the LC/EC/DESI-MS analysis of urine sample, + 1.3 V was applied to the cell for uric acid oxidation, and the mobile phase flow rate for the UPLC separation was 300 μL/min. The injection urine sample volume was 6 μL. The elution program was 100 to 95% A in the first 4 min, and 95 to 70% A in the following 2 min.

The measurement result for uric acid using LC/EC/DESI-MS was compared with traditional LC/UV-Vis method. In the LC/UV-Vis experiment, a Surveyor HPLC System equipped with Surveyor PDA detector (Thermo Finnigan, San Diego, CA) was used. The detection wavelength used was 280 nm. The column used was a reversed phase C18 column (4.6 mm × 150 mm, Waters, Milford, MA). Standard uric acid solutions (pH was adjusted to 7 using ammonia) were prepared in order to generate the calibration curve. The elution program was 100% A for 3 min, then 100% A to 40% A for 7 min, 40% A to 100% A for 5 min, and finally 100% A for 10 min.

Results and Discussion

LC/EC with Offline MS Analysis

To demonstrate the viability of our method, several organic molecules were chosen as test samples. Dopamine (DA), a known neurotransmitter, was tested first. The DA and other compounds tested in this study are representative electroactive species and they were often used to evaluate new electrochemical analysis methods. DA is known to undergo electrochemical oxidation via a two-electron transfer reaction to produce dopamine o-quinone (DQ, Scheme 3a). In our experiment, 50 μM of DA in ACN/H2O (5:95 by volume) containing 0.1% formic acid was injected into LC and then flowed through the electrochemical cell.

Figure 1a displays the current response for a blank sample (solvent only). A tiny peak was noted at 3.0 min, probably due to oxidation of impurities in the blank sample (Figure 1a). When DA sample was injected for oxidation (oxidation potential + 1.3 V), a sharp electric current peak at 3.2 min was seen (Figure 1b–d). In the triplicate measurements, the DA peak retention times and integrated areas were consistent (the total electric charge of Q involved in oxidation was measured to be 1.08~1.09 × 10−5 C, Figure 1b–d and Table S2, Supporting Information). By integrating the measured current areas, the calculated amount of the oxidized dopamine on average was 56.1 pmol.

On the other hand, the oxidation yield was measured by MS analysis of samples before and after electrolysis. In this experiment, DA was collected after it flowed through LC and the electrochemical cell, spiked with arginine as a reference compound, injected for nano-ESI-MS analysis. The ion signal of DA (relative to arginine) with electrolysis, in comparison to that without electrolysis, provides the oxidation yield. In the collected nano-ESI-MS spectrum of DA sample without electrolysis (Figure 1e), the protonated arginine and protonated DA were detected at m/z 175 and 154, respectively. In contrast, dopamine quinone (DQ), an oxidized DA product, was seen at m/z 152 in the nano-ESI-MS spectrum of DA sample with electrolysis (Figure 1f). The ratio of [m/z 154]/[m/z 175] in Figure 1f dropped by 18.6% (based on triplicate measurement, see data in Table S2, Supporting Information), in comparison to the ratio of [m/z 154]/[m/z 175] in Figure 1e, indicating that the oxidation yield was 18.6%. Based on the oxidation yield (18.6%) and the amount of oxidized DA (56.1 pmol), the amount of the injected DA measured by our method was 301.5 pmol. In comparison to the actual injection amount of DA (6 μL × 50 μM = 300 pmol), our quantification measurement error was only 0.5%.

(-)-Norepinephrine (NE), another neurotransmitter compound, was tested, too. The NE is known to undergo electrochemical oxidation via a two-electron transfer reaction to form norepinephrine o-quinone (NQ, Scheme 3b). Figure S2b-d (Supporting Information) displays the electric current diagram in which it showed a sharp peak at 1.6 min resulting from the NE oxidation. In contrast, this peak was absent in the control experiment of using blank sample (Figure S2a, Supporting Information). Integration of the oxidation peak showed the amount of oxidized NE to be 22.3 pmol (Table S3, Supporting Information). On the other hand, the oxidation yield was measured to be 7.37% by MS analysis of the NE compound before and after electrolysis (Table S3). Therefore, the measured amount of NE was 302.7 pmol. In comparison to the injection amount of 300 pmol (3 μL of 100 μM of NE was injected for analysis), our measurement error was only 0.9%.

The results for the DA and NE measurements show that our electrochemical mass spectrometry is feasible for chemical quantification, without using standard analyte. Encouraged by this result, we further proceeded to test more organic compounds such as rutin, as discussed below. However, we reasoned that online MS analysis would expedite the analysis process and thereby took online MS analysis protocol.

LC/EC with Online MS Analysis

Rutin, a glycoside of the flavonoid quercetin containing two glucose units (structure shown in Scheme 3c), was examined. Rutin is known to undergo a two-electron electrochemical oxidation at 3′ and 4′ phenol groups to form rutin quinone (RQ) by losing two H atoms. Indeed, before electrolysis (Figure 2a), the protonated rutin was seen at m/z 611. After electrolysis (Figure 2b), a peak at m/z 609 was observed, corresponding to the oxidized rutin product RQ. Figure 2c, d shows the EIC (m/z 611, the protonated rutin) of 50 μM rutin with an injection volume of 6 μL (injected amount: 300 pmol) at the mobile flow rate of 300 μL/min with the applied potential of 0 V and + 1.3 V, respectively, in which the rutin peak was observed at 1.4 min. The integrated area for the peak shown in Figure 2d was smaller by 2.5%, in comparison with that of the peak shown in Figure 2c, indicating that the oxidation yield for rutin was 2.5% (see data in Table S4, Supporting Information). On the other hand, the rutin oxidation current peak was detected, as shown in Figure 2f–h (Figure 2e shows the background current diagram for blank solvent sample as a contrast). Based on the integration of the current peak area (Figure 2f–h), the amount of the oxidized rutin on average was calculated to be 7.3 pmol. Therefore, our measured amount of rutin was 7.3 pmol/2.5% = 292 pmol, which was close to the injection amount of 300 pmol with the measurement error to be − 2.6%.

Online DESI-MS spectra of rutin when the applied potential was (a) 0 V and (b) +1 .3 V. the peak of the oxidation product of rutin, RQ, was seen at m/z 609 in (b). EIC of rutin recorded when the applied potential was (c) 0 V and (d) + 1.3 V. electric current responses (e) due to the blank solvent and (f–h) the oxidation of rutin sample in triplicate measurements

We also tested peptide quantification using our approach, based on the electrochemical oxidation conversion of thiols into disulfides. Glutathione (GSH) was chosen as the test example. GSH is a thiol-containing peptide and it can be oxidized into glutathione disulfide (GSSG, Scheme 3d). Indeed, before electrolysis (Figure S3c, Supporting Information), the protonated GSH was detected at m/z 308. After electrolysis (Figure S3d), a peak at m/z 307 was observed, corresponding to + 2 ion of GSSG product. Figure S3a and S3b show the EIC (m/z 308, the protonated GSH) of 200 μM GSH with an injection volume of 6 μL (injected amount: 1200 pmol) with the applied potential of 0 V and + 1.3 V, respectively. The integrated area for the peak shown in Figure S3b was smaller by 16.0%, in comparison with that of the peak shown in Figure S3a, indicating that the oxidation yield for GSH was 16.0% (see data in Table S5, Supporting Information). On the other hand, the GSH oxidation current peak was detected, as shown in Figure S3f, S3 g and S3 h (Figure S3e shows the background current diagram for blank solvent sample as a contrast). Based on the integration of the current peak area, the amount of the oxidized GSH on average was calculated to be 200.9 pmol. Therefore, our measured amount of GSH was 1256 pmol, which was close to the injection amount of 1200 pmol with the measurement error to be 4.6%.

The results above show that it is feasible to use our method for chemical quantification using online LC/EC/MS technique. In particular, the success for GSH quantification suggests the possibility of using our approach for proteins carrying thiols or disulfide bonds. For example, a cysteine-containing protein could be digested enzymatically into peptides carrying thiol groups, which can be analyzed using our method. Such an investigation is underway and will be reported on due course. Since our method involves the use of LC, we reasoned that it could be used for direct quantitation of chemical existing in a mixture. We therefore chose the uric acid (UA) analysis as an example to demonstrate such strength of our method.

Urine Analysis

Elevated uric acid level in blood can lead to its aggregation in joints and trigger gout. Uric acid is also related to kidney disease [52]. Therefore, it is crucial to determine the uric acid level in urine. Urine acid is known to undergo a two-electron electrochemical oxidation to generate a diimine (Scheme 3e) [53]. In our experiment, raw urine sample was diluted by eightfold using solvent and then injected into LC/EC/MS for analysis. Uric acid was eluted out at 2 min with a gradient elution program (Figure 3a, b) and was detected as an ion of m/z 169 via protonation. The electric current response due to the uric acid oxidation is shown in Figure 3d–f, in which a sharp peak at 2 min was observed. In contrast, this oxidation current peak was absent in the blank solvent sample (Figure 3c). Integration of the electric current peak tells that the oxidized amount of uric acid on average was 109.7 pmol (Table S6, Supporting Information). Meanwhile, the comparison of the EIC peaks shown in Figure 3a, b shows the oxidation yield of 4.6% (Table S6, Supporting Information). This suggests that the amount of uric acid in the diluted urine sample was 2399 pmol. In consideration of the fact that the injection volume of urine was 6 μL and the dilution factor was 8, the concentration of uric acid in the raw urine was determined to be 3.2 mM. This measured result is in line with the report that the normal level of uric acid is 1.5–4.4 mM in urine [54].

To further check our measurement accuracy, the sample was also measured using LC/UV-Vis method, a traditional “gold” standard for quantification. In a separate experiment, 6 μL of the diluted urine sample was injected into LC/UV-Vis instrument and the elution of uric acid was monitored by UV-Vis detector. The concentration of uric acid in the diluted urine sample was quantified to be 385.6 μM, based on a calibration cure acquired by injecting standard uric acid sample solutions for the LC/UV analysis (Figure S4, Supporting Information). That means that the injected urine sample contains 385.6 μM × 6 μL = 2314 pmol, which only differed from the value of 2399 pmol as measured by our LC/EC/MS method by 3.7%, emphasizing the accuracy of our proposed approach.

Furthermore, we spiked the urine sample with known amount of uric acid and then re-analyze the sample to test the accuracy of our measurement. Based on the measured mentioned above, 6 μL of the diluted urine sample contained 2399 pmol of uric acid. We further spiked the same urine sample with 600 pmol of standard uric acid and measured the spiked sample with our LC/EC/DESI-MS method. The uric acid in the spiked sample was measured to be 3038 pmol, which is fairly close to the sum of original uric acid in urine and the added standard (2999 pmol), with the deviation of 1.3%, validating the uric acid quantification in urine by our method. Table S7 (Supporting Information) summarizes the experimental result of this spiking experiment. This result confirms that our method is applicable to mixture analysis.

The amount of sample used in the experiments above varied from 300 to 3000 pmol. To further evaluate the sensitivity of our method, a low amount of DA sample (3 μL of 10 μM DA, 30 pmol) was also analyzed by using LC/EC/MS setup. The sample was quantified as 31 pmol using our method, which differed with the theoretical value of 30 pmol by 3.8% (Figure S5 and Table S8, Supporting Information). This result suggests that our method has a reasonably good sensitivity.

Note that a competitive side reaction could be an issue for our quantitation, particularly if the number of electrons per molecule involved in the competitive side reaction is different from that of the expected oxidation (or reduction) reaction. In such cases, the applied potential needs to be controlled to avoid the occurrence of competitive side oxidation (or reduction).

Conclusions

In this study, several organic compounds were successfully quantified using combined electrochemistry and mass spectrometry. The striking strength of this method is that no standard analyte compounds are needed for the measurement. The method is applicable for both offline and online MS analyses. Mixture analysis is also possible. Unlike traditional electrochemical method, no full redox conversion is in need, making this method fast and simple. In addition, the use of MS provides a mean to identify the electrochemical reaction products, which is difficult to achieve by using electrochemical technologies only. The determination of redox reaction product is essential to confirm the conversion of analyte to determine n (i.e., the number of electrons that are involved in redox conversion of each molecule) in the application of the Faraday’s law for quantification. In our study, the utilization of thiol oxidation for quantifying peptide GSH indicates that our method could find valuable applications in quantitation of large molecules such as proteins. Such an investigation is underway.

References

Cooks, R.G., Yan, X.: Mass spectrometry for synthesis and analysis. Annu. Rev. Anal. Chem. 11, 1–28 (2018)

Loo, J.A.: Studying noncovalent protein complexes by electrospray ionization mass spectrometry. Mass Spectrom. Rev. 16, 1–23 (1997)

Cui, W., Rohrs, H.W., Gross, M.L.: Top-down mass spectrometry: recent developments, applications and perspectives. Analyst. 136, 3854 (2011)

Zhang, H., Cui, W., Gross, M.L., Blankenship, R.E.: Native mass spectrometry of photosynthetic pigment-protein complexes. FEBS Lett. 587, 1012–1020 (2013)

Brodbelt, J.S.: Photodissociation mass spectrometry: new tools for characterization of biological molecules. Chem. Soc. Rev. 43, 2757–2783 (2014)

Aebersold, R., Mann, M.: Mass spectrometry-based proteomics. Nature. 422, 198–207 (2003)

Clough, T., Key, M., Ott, I., Ragg, S., Schadow, G., Vitek, O.: Protein quantification in label-free LC-MS experiments. J. Proteome Res. 8, 5275–5284 (2009)

Sohn, C.H., Lee, J.E., Sweredoski, M.J., Graham, R.L.J., Smith, G.T., Hess, S., Czerwieniec, G., Loo, J.A., Deshaies, R.J., Beauchamp, J.L.: Click chemistry facilitates formation of reporter ions and simplified synthesis of amine-reactive multiplexed isobaric tags for protein quantification. J. Am. Chem. Soc. 134, 2672–2680 (2012)

Hopfgartner, G., Tonoli, D., Varesio, E.: High-resolution mass spectrometry for integrated qualitative and quantitative analysis of pharmaceuticals in biological matrices. Anal. Bioanal. Chem. 402, 2587–2596 (2012)

Verplaetse, R., Henion, J.: Quantitative determination of opioids in whole blood using fully automated dried blood spot desorption coupled to on-line SPE-LC-MS/MS. Drug Test. Anal. 8, 30–38 (2016)

Heck, A.J., Krijgsveld, J.: Mass spectrometry-based quantitative proteomics. Expert Rev. Proteomics. 1, 317–326 (2004)

Sechi, S., Oda, Y.: Quantitative proteomics using mass spectrometry. Curr. Opin. Chem. Biol. 7, 70–77 (2003)

Righetti, P.G., Campostrini, N., Pascali, J., Hamdan, M., Astner, H.: Quantitative proteomics: a review of different methodologies. Eur. J. Mass Spectrom. 10, 335–348 (2004)

Gygi, S.P., Rist, B., Gerber, S.A., Turecek, F., Gelb, M.H., Aebersold, R.: Quantitative analysis of complex protein mixtures using isotope-coded affinity tags. Nat. Biotechnol. 17, 994–999 (1999)

Ong, S.-E., Foster, L.J., Mann, M.: Mass spectrometric-based approaches in quantitative proteomics. Methods. 29, 124–130 (2003)

Tao, W.A., Aebersold, R.: Advances in quantitative proteomics via stable isotope tagging and mass spectrometry. Curr. Opin. Biotechnol. 14, 110–118 (2003)

Ong, S.-E., Mann, M.: Mass spectrometry–based proteomics turns quantitative. Nat. Chem. Biol. 1, 252–262 (2005)

Ong, S.-E., Blagoev, B., Kratchmarova, I., Kristensen, D.B., Steen, H., Pandey, A., Mann, M.: Stable isotope labeling by amino acids in cell culture, SILAC, as a simple and accurate approach to expression proteomics. Mol. Cell. Proteomics. 1, 376–386 (2002)

Krijgsveld, J., Ketting, R.F., Mahmoudi, T., Johansen, J., Artal-Sanz, M., Verrijzer, C.P., Plasterk, R.H.A., Heck, A.J.R.: Metabolic labeling of C. elegans and D. melanogaster for quantitative proteomics. Nat. Biotechnol. 21, 927–931 (2003)

Wu, C.C., MacCoss, M.J., Howell, K.E., Dwight, E., Matthews, A., Yates, J.R.: Metabolic labeling of mammalian organisms with stable isotopes for quantitative proteomic analysis. Anal. Chem. 76, 4951–4959 (2004)

Gruhler, A., Schulze, W.X., Matthiesen, R., Mann, M., Jensen, O.N.: Stable isotope labeling of Arabidopsis thaliana cells and quantitative proteomics by mass spectrometry. Mol. Cell. Proteomics. 4, 1697–1709 (2005)

Sturm, R.M., Lietz, C.B., Li, L.: Improved isobaric tandem mass tag quantification by ion mobility mass spectrometry. Rapid Commun. Mass Spectrom. 28, 1051–1060 (2014)

Thompson, A., Schäfer, J., Kuhn, K., Kienle, S., Schwarz, J., Schmidt, G., Neumann, T., Hamon, C.: Tandem mass tags: a novel quantification strategy for comparative analysis of complex protein mixtures by MS/MS. Anal. Chem. 75, 1895–1904 (2003)

Zhang, H., Li, X., Martin, D.B., Aebersold, R.: Identification and quantification of N-linked glycoproteins using hydrazide chemistry, stable isotope labeling and mass spectrometry. Nat. Biotechnol. 21, 660–666 (2003)

Ross, P.L., Huang, Y.N., Marchese, J.N., Williamson, B., Parker, K., Hattan, S., Khainovski, N., Pillai, S., Dey, S., Daniels, S., Purkayastha, S., Juhasz, P., Martin, S., Bartlet-Jones, M., He, F., Jacobson, A., Pappin, D.J.: Multiplexed protein quantitation in Saccharomyces cerevisiae using amine-reactive isobaric tagging reagents. Mol. Cell. Proteomics. 3, 1154–1169 (2004)

Liu, H., Zhang, Y., Wang, J., Wang, D., Zhou, C., Cai, Y., Qian, X.: Method for quantitative proteomics research by using metal element chelated tags coupled with mass spectrometry. Anal. Chem. 78, 6614–6621 (2006)

Schmidt, A., Kellermann, J., Lottspeich, F.: A novel strategy for quantitative proteomics using isotope-coded protein labels. Proteomics. 5, 4–15 (2005)

Bantscheff, M., Schirle, M., Sweetman, G., Rick, J., Kuster, B.: Quantitative mass spectrometry in proteomics: a critical review. Anal. Bioanal. Chem. 389, 1017–1031 (2007)

Bantscheff, M., Lemeer, S., Savitski, M.M., Kuster, B.: Quantitative mass spectrometry in proteomics: critical review update from 2007 to the present. Anal. Bioanal. Chem. 404, 939–965 (2012)

Boyd, B., Basic, C., Bethem, R.: Trace Quantitative Analysis by Mass Spectrometry. Wiley (2008)

Korfmacher, W.A.: Mass Spectrometry for Drug Discovery and Drug Development. Wiley (2013)

Hammerich, O., Speiser, B.: Organic Electrochemistry. CRC Press (2015)

Bard, A.J., Faulkner, L.R.: Electrochemical Methods : Fundamentals and Applications. Wiley (2001)

Flanagan, R.J., Perrett, D., Whelpton, R.: Electrochemical Detection in HPLC: Analysis of Drugs and Poisons. Royal Society of Chemistry, Cambridge (2005)

Horvai, G., Pungor, E.: Electrochemical detectors in HPLC and ion chromatography. Crit. Rev. Anal. Chem. 21, 1–28 (1989)

Pelivan, K., Frensemeier, L.M., Karst, U., Koellensperger, G., Heffeter, P., Keppler, B.K., Kowol, C.R.: Comparison of metabolic pathways of different α-N-heterocyclic thiosemicarbazones. Anal. Bioanal. Chem. 410, 2343–2361 (2018)

Gun, J., Bharathi, S., Gutkin, V., Rizkov, D., Voloshenko, A., Shelkov, R., Sladkevich, S., Kyi, N., Rona, M., Wolanov, Y., Rizkov, D., Koch, M., Mizrahi, S., Pridkhochenko, P.V., Modestov, A., Lev, O.: Highlights in coupled electrochemical flow cell-mass spectrometry, EC/MS. Isr. J. Chem. 50, 360–373 (2010)

Diehl, G., Karst, U.: On-line electrochemistry – MS and related techniques. Anal. Bioanal. Chem. 373, 390–398 (2002)

Permentier, H., Bruins, A., Bischoff, R.: Electrochemistry-mass spectrometry in drug metabolism and protein research. Mini-Reviews Med. Chem. 8, 46–56 (2008)

Zhou, F., Van Berkel, G.J.: Electrochemistry combined online with electrospray mass spectrometry. Anal. Chem. 67, 3643–3649 (1995)

Zheng, Q., Zhang, H., Tong, L., Wu, S., Chen, H.: Cross-linking electrochemical mass spectrometry for probing protein three-dimensional structures. Anal. Chem. 86, 8983–8991 (2014)

Cai, Y., Wang, J., Zhang, Y., Li, Z., Hu, D., Zheng, N., Chen, H.: Detection of fleeting amine radical cations and elucidation of chain processes in visible-light-mediated [3 + 2] annulation by online mass spectrometric techniques. J. Am. Chem. Soc. 139, 12259–12266 (2017)

Li, J., Dewald, H.D., Chen, H.: Online coupling of electrochemical reactions with liquid sample desorption electrospray ionization-mass spectrometry. Anal. Chem. 81, 9716–9722 (2009)

Brown, T.A., Chen, H., Zare, R.N.: Detection of the short-lived radical cation intermediate in the electrooxidation of N , N -dimethylaniline by mass spectrometry. Angew. Chemie Int. Ed. 54, 11183–11185 (2015)

Zhang, Y., Cui, W., Zhang, H., Dewald, H.D., Chen, H.: Electrochemistry-assisted top-down characterization of disulfide-containing proteins. Anal. Chem. 84, 3838–3842 (2012)

Zhang, Y., Yuan, Z., Dewald, H.D., Chen, H.: Coupling of liquid chromatography with mass spectrometry by desorption electrospray ionization (DESI). Chem. Commun. 47, 4171 (2011)

Pedro, A., Soares, R.F., Oppolzer, D., Santos, F., Rocha, L., Gonçalves, A., Bonifacio, M., Queiroz, J., Gallardo, E., Passarinha, L.: An improved HPLC method for quantification of metanephrine with coulometric detection. J Chromatogr. Separat Tech. 5, 217 (2014)

Schiavo, S., Ebbel, E., Sharma, S., Matson, W., Kristal, B.S., Hersch, S., Vouros, P.: Metabolite identification using a nanoelectrospray LC-EC-array-MS integrated system. Anal. Chem. 80, 5912–5923 (2008)

Dewald, H.D., Worst, S.A., Butcher, J.A., Saulinskas, E.F.: Separation and identification of isoflavones with on-line liquid chromatography-electrochemistry-thermospray mass spectrometry. Electroanalysis. 3, 777–782 (1991)

Miao, Z., Chen, H.: Direct analysis of liquid samples by desorption electrospray ionization-mass spectrometry (DESI-MS). J. Am. Soc. Mass Spectrom. 20, 10–19 (2009)

Zheng, Q., Chen, H.: Development and applications of liquid sample desorption electrospray ionization mass spectrometry. Annu. Rev. Anal. Chem. 9, 411–448 (2016)

Mohandas, R., Johnson, R.J.: Uric acid levels increase risk for new-onset kidney disease. J. Am. Soc. Nephrol. 19, 2251–2253 (2008)

Brown, T.A., Chen, H., Zare, R.N.: Identification of fleeting electrochemical reaction intermediates using desorption electrospray ionization mass spectrometry. J. Am. Chem. Soc. 137, 7274–7277 (2015)

Dungchai, W., Chailapakul, O., Henry, C.S.: Use of multiple colorimetric indicators for paper-based microfluidic devices. Anal. Chim. Acta. 674, 227–233 (2010)

Supporting Information

Additional electrochemical and mass spectrometric measurement data are included.

Funding

This work was supported by NSF (CHE-1455554 and CHE-1709075).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Compliance with Eethical Sstandards

ESM 1

(DOCX 328 kb)

Rights and permissions

About this article

Cite this article

Xu, C., Zheng, Q., Zhao, P. et al. A New Quantification Method Using Electrochemical Mass Spectrometry. J. Am. Soc. Mass Spectrom. 30, 685–693 (2019). https://doi.org/10.1007/s13361-018-2116-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13361-018-2116-6