Abstract

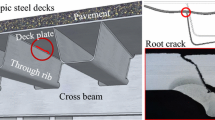

A common practice for the manufacture of orthotropic steel decks in Japan is to use 75% partial joint penetration welds between closed ribs and deck plates. To evaluate the effectiveness of the proposed 100% penetration on improving the fatigue strength of rib-to-deck welded joints in orthotropic steel bridge decks, four full-scale orthotropic deck specimens were subjected to laboratory testing. Specimens, consisting of a 12-mm-thick deck plate and 6-mm-thick rib, with one closed rib, were fabricated with 75% and 100% penetration. Fatigue test results showed that fatigue cracks initiated from the weld toe inside the rib in the 100% penetration specimens, but from weld root inside the rib in the 75% penetration specimens. To investigate this fatigue behavior, strain measurements were taken at 5 mm from the rib-to-deck weld line. Results of finite element analysis using the effective notch stress method indicate that a deeper partial penetration results in a slightly higher effective notch stress at the weld root of the partial penetration weld. The effective notch stress at the crack initiation location with 100% penetration is lower than that obtained with partial penetration. The open angle appears to have a significant effect on the effective notch stress at the upper weld toe when using 100% penetration. Therefore, the proposed 100% penetration appeared to have a positive effect on enhancing the fatigue resistance of rib-to-deck welded joints.

Similar content being viewed by others

References

AASHTO (2010). LRFD bridge design specifications. 5th edition, AASHTO, Washington, DC.

Bocchieri, W. J. and Fisher, J. W. (1998). “WilliamsburgBridge replacement orthotropic deck as-built fatigue test.” ATLLSS Rep. No. 5, Lehigh University, Bethlehem,PA.

Heiskanen, M. (2008). “A parametric fracture mechanicsstudy of the effect of a cold lap defect on fatiguestrength.” Journal of Structural Mechanics, 41(3), pp.119–136.

Hobbacher, A. (2009). IIW Recommendations for fatiguedesign of welded joints and components. WRC Bulletin520, The Welding Research Council, New York.

JRA (2002). Fatigue design guidelines for steel highwaybridges. Japan Road Association, Tokyo, Japan.

Mori, T. (2003). “Influence of weld penetration of fatiguestrength of single-sided fillet welded joints.” Journal ofConstruction Steel of JSSC, 10(40), pp. 9–15 (in Japanese).

Miki, C. (2006). “Fatigue damage in orthotropic steel bridgedecks and retrofit works.” International Journal of SteelStructures, 6(4), pp. 255–267.

Nishida, N., Sakano, M., Tabata, A., Sugiyama, Y., Okumura, M., and Natsuaki, Y. (2013). “Fatigue behavior oforthotropic steel deck with both side fillet welds betweendeck and trough ribs.” Proc. 68th JSCE Annual Meeting, pp. I-572 (in Japanese).

Radaj, D. (1996). “Review of strength assessment ofnonwelded and welded structures based on localparameters.” International Journal of Fatigue, 18, pp.153–170.

Schijve, J. (2012). “Fatigue prediction of welded joints andthe effective notch stress concepts.” International Journalof Fatigue, 45,pp. 31–38.

Sim, H. B., Uang, C. M., and Sikorsky, C. (2009). “Effect offabrication procedures on fatigue resistance of weldedjoints in steel orthotropic decks.” Journal of BridgeEngineering, 14(5), pp. 366–373.

Sim, H. B. and Uang, C. M. (2012). “Stress analyses andparametric study on full-scale fatigue tests of rib-to-deckwelded joints in steel orthotropic decks.” Journal ofBridge Engineering, 17(5), pp. 765–733.

Kusumoto, T., Sakano, M., Tabata, A., Sugiyama, Y., Maeda, T., Arimochi, K., and Honda, N. (2012). “Influence ofpenetration depth in the longitudinal weld between deckand trough ribs on fatigue behavior of orthotropic steeldeck.” Proc. 67th JSCE Annual Meeting, pp. I-297 (inJapanese).

FHWA (2012). Manual for design, construction, andmaintenance of orthotropic steel deck bridges. PublicationNo. FHWA-IF-12-027, US Department of Transportation,Federal Highway Administration.

Ya, S., Yamada, K., and Ishikawa, T. (2011). “Fatigueevaluation of rib-to-deck welded joints of orthotropicsteel bridge deck.” Journal of Bridge Engineering,ASCE, 16(4), pp. 492–499.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dung, C.V., Sasaki, E., Tajima, K. et al. Investigations on the effect of weld penetration on fatigue strength of rib-to-deck welded joints in orthotropic steel decks. Int J Steel Struct 15, 299–310 (2015). https://doi.org/10.1007/s13296-014-1103-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-014-1103-4