Abstract

The partial decoupling of electronic and optical properties of organic solar cells allows for realizing solar cells with increased short circuit current and energy conversion efficiency. The proposed device consists of an organic solar cell conformally prepared on the surface of an array of single and double textured pyramids. The device geometry allows for increasing the optical thickness of the organic solar cell, while the electrical thickness is equal to the nominal thickness of the solar cell. By increasing the optical thickness of the solar cell, the short circuit current is distinctly increased. The quantum efficiency and short circuit current are determined using finite-difference time-domain simulations of the 3D solar cell structure. The influence of different solar cell designs on the quantum efficiency and short circuit current is discussed and optimal device dimensions are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Organic materials and organic devices exhibit several electronic and optical properties complementary to conventional inorganic semiconductors. The electronic and optical properties of organic materials can be tailored according to the application needs and the materials can be fabricated at low temperatures on large area and flexible substrates (Gebeyehu et al. 2004; Guo et al. 2013; Peet et al. 2007; Park et al. 2009; Yu et al. 1995). In the last decade, the energy conversion efficiency and stability of organic solar cells have been significantly increased (Gebeyehu et al. 2004; Chamberlain 1983; Wohrle and Meissner 1991; Peumans et al. 2003; Green et al. 2017). Organic single junction solar cells have reached energy conversion efficiencies exceeding 11% (Zhao et al. 2016), which is approx. 30% of the detailed balance limit (Shockley and Queisser 1961). However, the performance of organic solar cell (OSC) is still limited by its electronic properties (Peumans et al. 2003; Savenije 2005). Furthermore, most of the organic semiconductors show high absorption coefficients only over a limited spectral range. For example, the calculated quantum efficiency and total absorption (1-R) of a flat or planar organic solar cell using a blend of zinc-phthalocyanine (ZnPc) and fullerene (C60) (ZnPc/C60 ratio 1:1) with an absorber thickness of 70 nm are shown in Fig. 1 along with the spectral irradiation of the sun under AM 1.5. The maxima of the quantum efficiency occurs in the spectral region ranging from 600 to 750 nm, while the quantum efficiency for shorter and longer wavelengths is distinctly reduced. The thickness of the solar cell is limited by the low carrier diffusion length of the ZnPc/C60 layer. Hence, different optical techniques have been proposed to increase the quantum efficiency and short circuit current of organic solar cells. Geometric light trapping schemes (Niggemann et al. 2004; Roman et al. 2000; Knipp et al. 2017), microlenses (Tvingstedt et al. 2008), V-shaped solar cell arrangements (Kim et al. 2013), and anti-reflection coatings (Forberich et al. 2008) have been proposed and investigated.

In the current study, we try to decouple the electrical and optical properties of the solar cell using a 3D solar cell architecture. The solar cell is formed on an array of single or double textured pyramids. It is assumed that the films are formed conformally on the surface of the pyramids, while the dimensions of the pyramid are distinctly larger than the thickness of the organic solar cell. Due to the conformal growth of the films, the electrical thickness of the solar cell remains unchanged. The electrical thickness defines the distance between the electrical contacts of the solar cell. Hence, the electrical thickness represents the maximal charge transport distance of the photogenerated charges. Furthermore, the 3D geometry leads to a distinctly increased optical thickness of the solar cell. The optical thickness of the solar cell is defined as the thickness of the organic film calculated at each point of the substrate and averaged over the area of the substrate. The optical thickness of the solar cell on a planar or flat substrate is equal to the nominal thickness, while the optical thickness of the organic layers on a 3D surface is increased if conformal deposition is assumed. In this study, the organic solar cell is placed on conductive TiO2 pyramids. The finite-difference time-domain optical simulation method was utilized to study the wave propagation, electric field distribution, and determine the optical parameters for the organic solar cell stack placed on single and double textured pyramids. The influence of the dimensions of the pyramids on the quantum efficiency and short circuit current is investigated and optimal device dimensions are proposed.

Optical simulation modeling

The optical wave propagation is investigated by utilizing three-dimensional (3D) Finite-difference Time-domain (FDTD) simulations. The complex refractive indices of the used organic materials are adapted from the literature and included in the supplementary material (Fig. S1) (Maennig et al. 2004; Fritz et al. 1989; Hoppe et al. 2002; Davis et al. 2015). Based on the simulated electric field distributions, the time-averaged power loss is calculated by

where E(x, y, z) is the electric field distribution, α is the absorption coefficient (α = 4πΚ/λ) with Κ being the imaginary part of the complex refractive index, n is the real part of the complex refractive index, ε0 is the permittivity of free space, and c is the speed of light (Dewan et al. 2009; Jovanov et al. 2013). Based on the time-averaged power loss distribution, the absorption for each layer of the solar cell is calculated by

where Popt is the power of the incident wave and Vm is the volume of the m-th layer of the solar cell. By assuming the collection efficiency of the ZnPc:C60 absorber layer as 100%, the upper limit of quantum efficiency is calculated by

In general, the quantum efficiency is defined as the ratio of photon absorbed by the ZnPc:C60 (1:1) layer to the total photon incident on the unit cell. The short circuit current density of the solar is calculated by

where q is the elementary charge, h is the Planck’s constant, S(λ) represents spectral irradiance of the sun (AM 1.5), and λ is the wavelength. The simulations are carried out for an incident wave with an amplitude of 1 V/m and a spectral range from 300 to 900 nm.

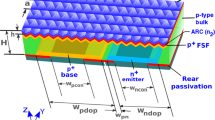

Device structure of small molecule organic solar cells

In this study, small molecule-based organic solar cells in substrate configuration are investigated. Cross-sections of the investigated solar cells are shown in Figs. 2a, 3a, 4a, 7a. The solar cells are formed on an aluminum back contact. The organic solar cell consists of a 70 nm thick ZnPc:C60 (1:1) absorber, a 20 nm thick wide band-gap MeO-TPD hole transport layer, and a 25 nm thick C60 electron transport layer. The thickness of the ZnPc:C60 absorber layer is determined by the electronic properties of the material. Increasing the thickness of the ZnPc:C60 absorber layer leads to an increased short circuit current and a reduced fill factor and open circuit voltage, so that the resulting energy conversion efficiency drops. A 130 nm thick ITO layer acts as front contact of the solar cell. The used layer sequence is in agreement with organic solar cells described in literature (Maennig et al. 2004; Schünemann et al. 2012; Lüssem et al. 2013; Kwanghee et al. 2006). Prior to forming the organic solar cell on the aluminum reflector, a conductive TiO2 layer is inserted between the organic solar cell and the back reflector. In the case of the planar or flat solar cell (Fig. 2a), a smooth TiO2 spacer layer is introduced, which acts as an optical spacer. In the case of the textured solar cells, a pyramidal textured TiO2 layer is introduced (Figs. 3a, 4a, 7a).

Small molecule organic solar cells on smooth surface

The calculated power loss profile of a solar cell on flat substrate is shown in Fig. 2. The solar cell on the flat substrate is used as reference solar cell. The corresponding quantum efficiency and absorption are shown in Fig. 1. For short wavelengths, a significant fraction of the incident light is absorbed by the C60 electron transporting layer as shown in Fig. 2b. Furthermore, approx. 30% of the incident light is absorbed by the photoactive ZnPc:C60 absorber (Figs. 1, 2b). In the spectral range from 550 to 750 nm, most of the light is absorbed by the ZnPc:C60 layer. This is confirmed by the power loss profile for a wavelength of 640 nm as shown in Fig. 2c. The quantum efficiency reaches a maximum of approx. 85% as depicted in Fig. 1. The short circuit current of the solar cell was maximized by tuning the thickness of the conductive TiO2 layer. The TiO2 layer acts as an optical spacer (Kwanghee et al. 2006). The TiO2 spacer has the function of introducing an optical phase change. The thickness of the ZnPc:C60 absorber is smaller than half of the wavelength of the incident light, so that the maxima of the standing wave formed in the solar cell due to the constructive and destructive interference of the forward and backward (reflected) electromagnetic wave has to be matched to the position of the ZnPc:C60 absorber in the solar cell. The thickness of the TiO2 spacer was varied until a maxima of the short-circuit current of 13.8 mA/cm2 was obtained for a TiO2 spacer thickness of 10 nm.

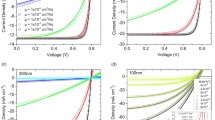

Organic solar cells on pyramidal textured substrates

In the following section of the manuscript, the optics of organic solar cells on single and double textured substrates is investigated. It is assumed that the organic films of the solar cells are conformally deposited on a 3D textured back contact. An array of conductive TiO2 single or double textured pyramids on an aluminum reflector is used as a substrate. The surface morphology of each layer of the textured organic solar cells was simulated using a 3D morphological algorithm. The 3D morphological algorithm allows for describing the growth of films on 3D surfaces (Jovanov et al. 2013; Wiesendanger et al. 2014; Topič et al. 2015). In the current study, it is assumed that the organic films grow in the direction of the local surface normal. The input parameters of the growth model are the substrate morphology and nominal thickness of the films. To obtain the surface morphology of the deposited film, the growth algorithm determines the local surface normal for each position on the substrate. More details on the film formation and the growth model can be found in the literature (Jovanov et al. 2013; Wiesendanger et al. 2014; Topič et al. 2015). The period and height of the surface texture were varied from 0 to 600 nm and from 0 to 1500 nm. The cross-section of a pyramid textured small molecule organic solar cell with a period of 600 nm and height of 1500 nm is shown in Fig. 3a. The total thickness of the organic diode layer stack, 115 nm, is distinctly smaller than half of the period of the surface texture. Hence, a good coverage of the pyramids by the organic layer stack is observed. And the electrical thickness of the solar cell, which is determined by the thickness of the ZnPc:C60 absorber, remains unaffected for most part of the solar cell. The power loss maps for a pyramid height of 1500 nm are shown in Fig. 3b, c. The corresponding quantum efficiency is shown in Fig. 5a. In comparison to a solar cell on a flat substrate, a distinct gain of the quantum efficiency is obtained by the textured solar cells for short wavelengths. This is confirmed by the power loss map in Fig. 3b. For high pyramids (h = 1000 and 1500 nm), the ZnPc:C60 absorber exhibits a higher absorption in comparison to the solar cell on a flat substrate (Fig. 2b). For long wavelengths (640 nm), most of the light is absorbed by the ZnPc:C60 absorber. Introducing the pyramid texture leads to the reduction of the reflection losses and a gain of the quantum efficiency [Fig. 5a for short (400–550 nm) and long (750–900 nm) wavelengths]. For pyramid heights of only 500 nm, a drop of the quantum efficiency is observed in the wavelength region from 600 to 750 nm in comparison to the solar cell on a smooth surface as shown in Fig. 5a. The power loss for a period and height of 600 nm and 500 nm is provided in the supplementary material (Fig. S3). The quantum efficiency in Fig. 5a shows that the quantum efficiency increases up to a height of the pyramid of approx. 1000 nm. Increasing the height of the pyramid to 1500 nm does not lead to an additional gain of the quantum efficiency and short circuit current.

The influence of the period of the pyramid on the quantum efficiency for periods ranging from 0 (flat) to 400 nm (height 1500 nm) is provided in the supplementary material (Fig. S2). With increasing period, the quantum efficiency converges towards the solar cell on a flat substrate. The highest short circuit current is observed for a period of 200 nm. Figure 4 exhibits the cross-section and power loss maps of a solar cell with a period of 200 nm. The total thickness of the organic layer stack, 115 nm, is larger than half of the period of the surface texture and the valley between two neighboring pyramids is completely filled by organic material. Hence, the electrical thickness of the organic ZnPc:C60 absorber layer is increased and photo generated charges can not be efficiently extracted. Nevertheless, we will discus the optics of the structure to study the influence of the device geometry on the quantum efficiency and short circuit current. The power loss maps for such solar cell are depicted in Fig. 4b, c for the wavelengths of 400 and 640 nm. Most of the light is absorbed within the first 500 nm of the solar cell. The corresponding quantum efficiency is shown in Fig. 5b. The quantum efficiency is distinctly increased for short and long wavelengths. Additionally, the quantum efficiency increases continuously with increasing height of the pyramid. The enhancement is mainly caused by the increased optical thickness of the organic layer stack. The optical thickness of the ZnPc:C60 layer is calculated by the ratio of ZnPc:C60 layer volume within a unit cell to the area of the unit cell (Jovanov et al. 2013). The optical thickness increases with decreasing period and increasing height of the pyramid.

The influence of the pyramid dimensions on the short circuit current is summarized in Fig. 6. The short-circuit current density of the flat reference solar cell is 13.8 mA/cm2, which is increased to 21.4 mA/cm2 using a period of 200 nm and a height of 1500 nm. The enhancement of the short circuit current density is mainly obtained due to the enhanced optical thickness of the solar cell. However, for the combination of a small period and a large height pyramid, poor charge extraction can be expected, which limits the short circuit current and energy conversion efficiency.

To achieve high short circuit currents while at the same time allowing for efficient charge extraction, we have modified the design of the pyramid texture. Small pyramids were added on the large pyramids allowing for the realization of a double textured pyramid. The increased surface area allows for increasing the optical thickness of the solar cell, while at the same time good charge extraction can be maintained. The power loss profile of an organic solar cell on a pyramidal double texture for incident wavelengths of 400 and 640 nm is depicted in Fig. 7b, c, respectively.

The corresponding quantum efficiency of the solar cell is shown in Fig. 8. Furthermore, the QE of a solar cell on a smooth substrate and single textured was added. By moving from a single to a double texture, the short circuit current is increased from 17.7 to 20.1 mA/cm2. Again, the enhancement is mainly caused by an increased optical thickness. Compared to the flat solar cell, a short circuit current gain of 29 and 46% is achieved for the single pyramid textured (p = 600 nm, h = 1500 nm) and double pyramid textured (large pyramid: p = 600 nm and h = 1500 nm, small pyramid: p = 120 nm and h = 500 nm), respectively. A detailed comparison of the absorption of the individual layers of the flat, single textured, and double textured small molecule organic solar cells is given in the supplementary material (Table S1). The short circuit current of the double texture is approaching the short circuit current of single texture with a small period. However, the double texture allows for efficient extraction of charges, while the single texture with small period does not allow for such an efficient extraction. Hence, double textured substrates represent a promising alternative to solar cells with single texture.

In next step, organic solar cells have to be realized on such single and double textured substrates. Excellent conformity of inorganic thin films on textured surfaces has been demonstrated for atomic layer deposition (ALD) (Ritala and Leskela 2001) and chemical vapor deposition (CVD) (Kuang et al. 2011; Adachi et al. 2013). The successful experimental realization of thin film solar cells on double or multiscale textured substrates has been demonstrated for amorphous silicon (Tamang et al. 2014), microcrystalline silicon (Hongsingthong et al. 2013; Tamang et al. 2016), and multijunction silicon solar cells (Tan et al. 2015). So far few studies have been published on the conformal deposition of organic films on 3D textured substrates. However, promising initial results have been demonstrated for the deposition of organic films by chemical vapor deposition (Loscutoff et al. 2010), molecular deposition techniques (Mullings et al. 2010; Räupke et al. 2013), and vapor phase deposition (OVPD) (Yang and Forrest 2006; Yang et al. 2005).

Summary

The short circuit current and energy conversion efficiency of organic solar cells can be increased by a partial decoupling of the electrical and optical properties. In this study, organic solar cells on 3D textured surfaces were studied. Forming conformal organic solar cells on textured arrays of single or double textured pyramids allow for increasing the optical thickness of the solar cell, while the electrical thickness is equal to the nominal thickness. By increasing the optical thickness, the quantum efficiency and short circuit current are increased. In the case of a single pyramid surface texture, the short circuit current is increased by 29%, while in the case of double or multiscale texture the short circuit current is increased by 46%. The conformal deposition of organic solar cells on multiscale textured might allow for the realization of high efficiency organic solar cells.

References

Adachi MM, Anantram MP, Karim KS (2013) Core-shell silicon nanowire solar cells. Sci Rep 3:1546

Chamberlain GAA (1983) Organic solar cells: a review. Sol Cells 8:47–83. https://doi.org/10.1016/0379-6787(83)90039-X

Davis KO, Jiang K, Habermann D, Schoenfeld WV (2015) Tailoring the optical properties of APCVD titanium oxide films for all-oxide multilayer antireflection coatings. IEEE J Photovolt 5:1265–1270. https://doi.org/10.1109/JPHOTOV.2015.2437272

Dewan R, Marinkovic M, Noriega R, Phadke S, Salleo A, Knipp D (2009) Light trapping in thin-film silicon solar cells with submicron surface texture. Opt Express 17:23058. https://doi.org/10.1364/OE.17.023058

Forberich K, Dennler G, Scharber MC, Hingerl K, Fromherz T, Brabec CJ (2008) Performance improvement of organic solar cells with moth eye anti-reflection coating. Thin Solid Films 516:7167–7170. https://doi.org/10.1016/j.tsf.2007.12.088

Fritz T, Hahn J, Böttcher H (1989) Determination of the optical constants of evaporated dye layers. Thin Solid Films 170:249–257. https://doi.org/10.1016/0040-6090(89)90731-1

Gebeyehu D, Pfeiffer M, Maennig B, Drechsel J, Werner A, Leo K (2004) Highly efficient p-i-n type organic photovoltaic devices. In: Thin solid films, pp 29–32. https://doi.org/10.1016/j.tsf.2003.10.087

Green MA, Emery K, Hishikawa Y, Warta W, Dunlop ED, Levi DH, Ho-Baillie AWY (2017) Solar cell efficiency tables (version 49). Prog Photovoltaics Res Appl 25:3–13. https://doi.org/10.1002/pip.2855

Guo X, Zhou N, Lou SJ, Smith J, Tice DB, Hennek JW, Ortiz RP, Navarrete JTL, Li S, Strzalka J, Chen LX, Chang RPH, Facchetti A, Marks TJ (2013) Polymer solar cells with enhanced fill factors. Nat Photonics 7:825–833. https://doi.org/10.1038/nphoton.2013.207

Hongsingthong A, Krajangsang T, Limmanee A, Sriprapha K, Sritharathikhun J, Konagai M (2013) Development of textured ZnO-coated low-cost glass substrate with very high haze ratio for silicon-based thin film solar cells. Thin Solid Films 537:291–295

Hoppe H, Sariciftci NS, Meissner D (2002) Optical constants of conjugated polymer/fullerene based bulk-heterojunction organic solar cells. Sol Cells 385:233–240. https://doi.org/10.1080/10587250290113268

Jovanov V, Palanchoke U, Magnus P, Stiebig H, Hupkes J, Sichanugrist P, Konagai M, Wiesendanger S, Rockstuhl C, Knipp D (2013a) Light trapping in periodically textured amorphous silicon thin film solar cells using realistic interface morphologies. Opt Express 21:A595–A606. https://doi.org/10.1364/Oe.21.00a595

Jovanov V, Xu X, Shrestha S, Schulte M, Hüpkes J, Knipp D (2013b) Predicting the interface morphologies of silicon films on arbitrary substrates: application in solar cells. ACS Appl Mater Interfaces 5:7109–7116. https://doi.org/10.1021/am401434y

Kim SJ, Margulis GY, Rim S-B, Brongersma ML, McGehee MD, Peumans P (2013) Geometric light trapping with a V-trap for efficient organic solar cells. Opt Express 21:A306. https://doi.org/10.1364/OE.21.00A305

Knipp D, Jovanov V, Tamang A, Wagner V, Salleo A (2017) Towards 3D organic solar cells. Nano Energy 31:582–589. https://doi.org/10.1016/j.nanoen.2016.11.059

Kuang Y, van der Werf KHM, Houweling ZS, Schropp REI (2011) Nanorod solar cell with an ultrathin a-Si: H absorber layer. Appl Phys Lett 98:113111

Kwanghee L, Jin Young K, Heeger AJ (2006) New architecture for high-efficiency polymer photovoltaic cells using solution-based titanium oxide layer. Proc SPIE Int Soc Opt Eng 6117:1–8. https://doi.org/10.1117/12.640666

Loscutoff PW, Lee HBR, Bent SF (2010) Deposition of ultra-thin polythiourea films by molecular layer deposition. Chem Mater 22:5563–5569

Lüssem B, Riede M, Leo K (2013) Doping of organic semiconductors TL-210. Phys Status Solidi 210:9–43. https://doi.org/10.1002/pssa.201228310

Maennig B, Drechse J, Gebeyehu D, Simon P, Kozlowski F, Werner A, Li F, Grundmann S, Sonntag S, Koch M, Leo K, Pfeiffer M, Hoppe H, Meissner D, Sariciftci NS, Riedel I, Dyakonov V, Parisi J (2004) Organic p-i-n solar cells. Appl Phys A 79:1–14. https://doi.org/10.1007/s00339-003-2494-9

Mullings MN, Lee H-B-R, Marchack N, Jiang X, Chen Z, Gorlin Y, Lin KP, Bent SF (2010) Area selective atomic layer deposition by microcontact printing with a water-soluble polymer. J Electrochem Soc 157:D600–D604

Niggemann M, Glatthaar M, Gombert A, Hinsch A, Wittwer V (2004) Diffraction gratings and buried nano-electrodes—architectures for organic solar cells. In: Thin solid films, pp 619–623. https://doi.org/10.1016/j.tsf.2003.11.028

Park SH, Roy A, Beaupré S, Cho S, Coates N, Moon JS, Moses D, Leclerc M, Lee K, Heeger AJ (2009) Bulk heterojunction solar cells with internal quantum efficiency approaching 100%. Nat Photonics 3:297–302. https://doi.org/10.1038/nphoton.2009.69

Peet J, Kim JY, Coates NE, Ma WL, Moses D, Heeger AJ, Bazan GC (2007) Efficiency enhancement in low-bandgap polymer solar cells by processing with alkane dithiols. Nat Mater 6:497–500. https://doi.org/10.1038/nmat1928

Peumans P, Yakimov A, Forrest SR (2003) Small molecular weight organic thin-film photodetectors and solar cells. J Appl Phys 93:3693–3723. https://doi.org/10.1063/1.1534621

Räupke A, Albrecht F, Maibach J, Behrendt A, Polywka A, Heiderhoff R, Helzel J, Rabe T, Johannes HH, Kowalsky W, Mankel E (2013) Conformal and highly luminescent monolayers of Alq3 prepared by gas-phase molecular layer deposition. ACS Appl Mater Interfaces 6:1193–1199

Ritala M, Leskela M (2001) Atomic layer deposition. Handb Thin Film Mater 1:103–159

Roman LS, Inganäs O, Granlund T, Nyberg T, Svensson M, Andersson MR, Hummelen JC (2000) Trapping light in polymer photodiodes with soft embossed gratings. Adv Mater 12:189–195. https://doi.org/10.1002/(sici)1521-4095(200002)12:3<189::aid-adma189>3.0.co;2-2

Savenije TJ (2005) Organic solar cells. In: Exciton solar cells, chap 8. Delft Chem Tech, Faculty of Applied Sciences, Delft University of Technology

Schünemann C, Wynands D, Wilde L, Hein MP, Pfützner S, Elschner C, Eichhorn KJ, Leo K, Riede M (2012) Phase separation analysis of bulk heterojunctions in small-molecule organic solar cells using zinc-phthalocyanine and C 60. Phys Rev B Condens Matter Mater Phys 85. https://doi.org/10.1103/physrevb.85.245314

Shockley W, Queisser HJ (1961) Detailed balance limit of the efficiency of p-n junction solar cells. J Appl Phys 32:510

Tamang A, Hongsingthong A, Sichanugrist P, Jovanov V, Konagai M, Knipp D (2014) Light-trapping and interface morphologies of amorphous silicon solar cells on multiscale surface textured substrates. IEEE J Photovolt 99:1–6

Tamang A, Hongsingthong A, Jovanov V, Sichanugrist P, Khan BA, Dewan R, Konagai M, Knipp D (2016) Enhanced photon management in silicon thin film solar cells with different front and back interface texture. Sci Rep 6:29639

Tan H, Moulin E, Si FT, Schüttauf J-W, Stuckelberger M, Isabella O, Haug F-J, Ballif C, Zeman M, Smets AHM (2015) Highly transparent modulated surface textured front electrodes for hig-efficiency multijunction thin-film silicon solar cells. Prog Photovolt Res Appl 23:949–963

Topič M, Sever M, Lipovšek B, Čampa A, Krč J (2015) Approaches and challenges in optical modelling and simulation of thin-film solar cells. Sol Energy Mater Sol Cells 135:57–66. https://doi.org/10.1016/j.solmat.2014.09.026

Tvingstedt K, Dal Zilio S, Inganäs O, Tormen M (2008) Trapping light with micro lenses in thin film organic photovoltaic cells. Opt Express 16:21608. https://doi.org/10.1364/OE.16.021608

Wiesendanger S, Bischoff T, Jovanov V, Knipp D, Burger S, Lederer F, Rockstuhl C (2014) Effects of film growth modes on light trapping in silicon thin film solar cells. Appl Phys Lett 104. https://doi.org/10.1063/1.4882997

Wohrle D, Meissner D (1991) Organic solar cells. Sol Energy Mater Sol Cells 3:129–138. https://doi.org/10.1002/adma.19910030303

Yang F, Forrest SR (2006) Organic solar cells using transparent SnO2: F anodes. Adv Mater 18:2018–2022

Yang F, Shtein M, Forrest SR (2005) Controlled growth of a molecular bulk heterojunction photovoltaic cell. Nat Mater 4:37–41

Yu G, Gao J, Hummelen JC, Wudl F, Heeger AJ (1995) Polymer photovoltaic cells—enhanced efficiencies via a network of internal donor-acceptor heterojunctions. Science 270:1789–1791. https://doi.org/10.1126/science.270.5243.1789

Zhao J, Li Y, Yang G, Jiang K, Lin H, Ade H, Ma W, Yan H (2016) Efficient organic solar cells processed from hydrocarbon solvents. Nat Energy 1:15027. https://doi.org/10.1038/nenergy.2015.27

Acknowledgements

The work is partly supported by the Research Grants Council of Hong Kong, China (Project Number: GRF 152109/16E PolyU B-Q52T) and the Hong Kong Polytechnic University (Project Number: G-YBFR, G-UA7N).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Qarony, W., Hossain, M.I., Jovanov, V. et al. Maximizing the short circuit current of organic solar cells by partial decoupling of electrical and optical properties. Appl Nanosci 8, 339–346 (2018). https://doi.org/10.1007/s13204-018-0713-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-018-0713-0