Abstract

Graphene Nanoplatelets were fabricated from expandable graphite by rapid microwave exfoliation. Expandable graphite was irradiated in microwave in full power for 3 min, then was soaked in mixed nitric acid and sulphuric acid at volume ratio of 1:1 for 24 h and re-irradiated, thus graphene nanoplatelets (GNPs) were obtained. Extensive characterization techniques showed that GNPs synthesized using this technique are highly pure with traces of oxide groups and without serious unrecoverable oxidation damage. GNPs synthesized by microwave technique have high crystallinity, with variable size and little layer thickness.

Similar content being viewed by others

Introduction

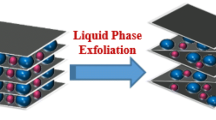

Graphene is one of the allotropes of elemental carbon with a planar monolayer of carbon atoms, arranged into a two-dimensional honey-comb lattice (Novoselov et al. 2004). It has demonstrated a variety of intriguing properties as new material for future applications and composite industry (Zhang et al. 2005; Lee et al. 2008). In particular, the interesting electrical properties candidate the graphene to be an excellent successor to silicon in electronic applications. Since its preparation is rather difficult and complex, graphene nanoplatelets (GNPs) are also intensively studied. GNPs are easier to be obtained, have similar properties and can be used in the same applications (Partoens and Peeters 2006). Graphene like structures, GNPs (quasi 2D) and wrinkled graphene (2D) have been derived from graphite using different routes. GNPs or multi layer graphene can be defined as graphene with more than 10 layers. In comparison graphite has more than 100 layers. GNPs have been produced from crystalline graphite by acid intercalation (Truong et al. 2012), intercalation-exfoliation (Kumar et al. 2014a) and liquid phase exfoliation (Wolf 2014) methods. The aim of the current research is the development of new preparation techniques to obtain GNPs with industrially usable quantities and with a good yield.

Recently, microwave-assisted exfoliation has emerged as an efficient and versatile method to produce graphene sheets, which enjoys obvious advantages, such as energy transfer instead of heat transfer, quick and volumetric heating, eco-friendliness, higher safety and can increase reaction rate by orders of magnitude compared with traditional heating (Menendez et al. 2010; Hu et al. 2011; Wei et al. 2009). In the present study, few-layer grapheme, with high purity and quality, was extracted from expandable graphite sequentially by microwave irradiation, mixed acid soaking and second microwave irradiation, which is facile and energy-saving.

Experimental details

Synthesis of GNPs

Expandable graphite powder was heated by microwave irradiation for 3 min and it displayed the most dramatic volume expansion that resulted in the lightest and most fluffy powders. To further exfoliate this, 0.1 g of this was soaked in 100 ml strong mixed acid [V(H2SO4):V(HNO3) = 1:1] for 24 h, then washed with deionized water till the percolated solution became neutral. Vacuum filtration was conducted and the grayish filter cake was dried at 60 °C in an electric oven. After mixed acid soaking, this was treated with second microwave irradiation for 3 min.

Characterization

Synthesized GNPs were characterized by powder X-ray diffraction (XRD) (Rigaku Japan, Miniflex 600), field emission scanning electron microscope (FESEM) and energy dispersive spectra (EDS) (SUPRA 55 OX-FORD INSTRUMENTS), TEM [Hitachi (H-7500)], Fourier transform infrared spectroscopy (FTIR) (Perkin Elmer–Spectrum RX-IFTIR), UV–Vis absorption spectroscopy (Hitachi-330 spectrophotometer), Micro-Raman spectroscopy was performed on “Renishaw in Via Raman microscope” using Ar+ laser as an excitation source with 514 nm line, X- ray photoelectron spectroscopy (XPS) (kratos axis ultra DLD), Thermogravometric analysis [TGA-DSC-DTA] (Perkin Elmer STA 6000) Photoluminescence (PL) spectroscopy [Spex Fluoromax-3 Spectrofluorometer (Jobin–Yvon, USA)], Time resolved fluorescence spectroscopy using (Edinburgh FL 920 Fluorescence life time spectrometer), Surface area and pore size determination using BET-BJH technique (Nova 2000e Quantachrome) were performed.

Results and discusion

XRD pattern of microwave assisted synthesized GNPs is shown in Fig. 1. The XRD patterns show the most prominent peak after acid soaking at 26.406° and after re-radiation at 26.491°, and the corresponding inter-planar distance of d 002 3.3725 Å and d 002 3.3619 Å These data are a little higher than that of those of typical graphite (d 002 = 3.354 Å). Thus, the mixed acid soaking and microwave treatment slightly increase the distance between graphene ab planes, and the specimens retain high crystallographic quality. Average crystallite size can be calculated from the line broadening of the diffractogram peaks using Scherrer formula

where, D is the average crystallite size, λ is incident X-ray wavelength, β is the full width half maximum (FWHM) of diffraction peak expressed in radians and θ is peak position in X-ray diffract gram. Average crystalline size and after acid treatment is 18.6 nm and after re-radiation i.e. for synthesized GNPs the same is 16.02 nm and the structure is hexagonal wurzite structure.

Figure 2 is FESEM micrographs of microwave synthesized GNPs at various resolution. It seems from FESEM micrographs that though graphite is a good microwave absorbent, the energy absorbed from microwave irradiation is not strong enough to break numerous chemical bond interactions that exist between graphite layers. The results show that expandable graphite with loose, porous and worm-like morphology forms instantaneously in microwave irradiation with crackling sound and sparkles, which manifests physical exfoliation of graphene sheets.

Figure 3 is HRTEM micrographs of synthesized GNPs. TEM micrograph reveals that few-layer graphene sheets with a dozen or more layers and thickness of few nm are obtained eventually after sequential treatment of microwave irradiation, mixed acid soaking and second microwave irradiation. The as-prepared few-layer graphene still has high crystallinity and high purity with traces of oxide groups and without serious unrecoverable oxidation damage.

Figure 4 reveals the texture property of microwave synthesized GNPs. The surface area and total pore volume, as measured by the BET method (calculated by N2 gas adsorption on the surface of the materials) for GNPs, is 8.251 m2/g. Total pore volume is 3.023 e− 02 cc/g for GNPs with pores smaller than 723.3 Å (Radius) at P/P o = 0.98655 where as analyzed pore radius is 2.84847e + 02 Å for microwave synthesized GNPs.

X-ray energy dispersive microanalysis of the GNPs in Fig. 5 shows that the sample was essentially pure carbon and content of oxygen is very small as compared to carbon. The result shows that the surface of GNPs was clean. Recorded spectra indicates that carbon content is 96.22 wt% where oxygen content is 3.4 wt% and S is 0.38 wt%

FTIR spectrum of synthesized GNPs is shown in Fig. 6. which illustrates O–H stretching vibration at 3,444 cm−1, carbonyl group and skeletal ring vibrations at 1,637 cm−1, and C–O–C groups at 1,064 cm−1. The O–H peak is relatively sharp, which contradicts the feature for –COOH and may come from absorbed water. Apparently, Fig. 6 shows weak oxygen functional groups and proves the formation of graphene nanoplatelets with high quality, which is consistent with XPS results.

Raman spectroscopy is widely performed to examine carbon derivatives. Figure 7 shows D (1,350 cm−1), G (1,582 cm−1) and 2D (2,700 cm−1) bands of microwave synthesized GNPs. Band G corresponds to E 2g phonon in Brillouin zone center (Reina et al. 2009) where as sharpness in G band means that carbon atoms mainly bond in sp2 hybridization to form a dense-hexagonal structure. Generally speaking, band D is associated with breath vibration mode of sp2 atoms in carbon rings, and implies the reduction in strong sp2 covalent bonds induced by defects, newly emerged edges and sp3 hybridization atoms. I D/I G ratio was used to evaluate the average size of sp2 domain and the degree of disorder and in present case the same is 0.14 which indicates high order and low degree of structural defects as a result of efficient deoxygenation of carboxyl, epoxy and other oxygen functional groups. The position, shape and full width half maximum (FWHM) of the second-order 2D band are sensitive to the number of layers in grapheme nanoplatelets (Ni et al. 2007; Ferrari and Robertson 2000; Ni et al. 2008), which may be triggered by double-resonant effect, in other words, may be caused by changes in electronic and vibrational properties (Thomson and Reich 2000)

XPS scan was adopted to confirm remnant amount of oxygen functional groups that may impair the conductive network and electrochemically active surfaces for supercapacitor applications. The survey scan plotted in Fig. 8a shows C 1 s peak at about 284.78 eV and weak O 1 s peak at about 533.3 eV, which indicates lower oxygen content and the same has been confirmed by Fig. 8b and c. C1 s core peak in Fig. 8b at 284.78 eV (C–C and C=C bond), a minor peak at 285.78 eV (C–O bond) and 286.98 eV (O–C=O bond). It is clear that high quality graphene nanoplatelets with low oxygen content (3.2 %) are prepared.

Figure 9 reveals high thermal stability of GNPs in air flow. There were two main weight loss steps for microwave synthesized GNPs, one of which, at around 200–400 °C, and the other, at around 450–800 °C, was from the thermal decomposition of the GNPs structure The weight loss was slow initially (nearly 20 %) in first step and then as the temperature increased loss in weight was fast and the corresponding exothermic peaks are observed through DSC analysis. DTG analysis indicate that no amorphous carbon is present in the sample.

Figure 10 shows the recorded UV–Vis. absorption spectra of microwave synthesized GNPs exist as aggregates and bundles in suspension, no exceptional features are seen in the absorption spectra.

Room temperature PL studies in Fig. 11 of microwave synthesized GNPs shows multi-modal peaks tunable with excitation wavelength. Excitation wavelengths have been changed through the broad spectral width ranging from 230 to 270 nm to check the excitation tunability of GNPs. Recorded PL spectra reveals that the microwave synthesized GNPs show emission tunability almost over the whole visible region of electromagnetic spectrum with variation in excitation wavelength. This study shows the potential of GNPs for fabrication of different colored LED’s.

The intensity ‘I’ of the luminescent radiation at any time, t, is given by following equation

where I 0 is the intensity of radiation at cut-off position and the constant p = 1/τ is the transition probability of the corresponding radiative transition and τ is excited state lifetime, From the slope of the ln(I) vs. t, one can easily calculate transition probability. Figure 12 show time resolved decay curves recorded for microwave synthesized GNPs. Method of Kumar et al. 2014b, c was used to peel off the decay curves into three exponential components (τ 1, τ 2, τ 3). Trap-depth values ‘E’ had been calculated using Boltzmann equation. Distribution of traps within the phosphor bandgap can be explained with the help of decay constant values. All these values are listed in Table 1.

where, p is transition probability; S, escape frequency factor (~109 s−1); k, Boltzmann’s constant and T, the absolute temperature. The decay constant value ‘b’ has been calculated using the equation

Such types of decay curves due to superposition of number of exponential decays are popularly known as hyperbolic decay curves or multi-exponential decay curves. If the value of b is unity, one can say that the distribution of trapping states is uniform, otherwise, it is non-uniform. In terms of lifetime values so calculated, one can calculate the oscillator strengths and dipole moments of the radiative transitions using above well known equations. The oscillator strength ‘f’ of a transition is a dimensionless quantity that is useful for comparing different radiative transitions. Classically, oscillator strength is used as a statistical weight indicating the relative number of oscillators bound at each resonant frequency. The life time values may also be used to calculate Einstein’s spontaneous (A), stimulated emission (B) coefficients and dipole moment µ of the radiative transtion. Moreover the oscillator strength, along with absorption coefficients, is often used as a method for calculating the concentration of impurities in a host. The oscillator strength, the integrated cross section of the transition, the corresponding dipole moment and Einstein’s stimulated coefficient has been calculated using well known relations. (Kumar et al. 2014d, e, f)

‘n’ is the index of refraction of the material which is 1.42 in case of microwave assisted synthesized GNPs, λ is emission wavelength (482 nm)

From Table 1 it is evident that excited state life times for microwave synthesized GNPs is 1.85–14.80 ns

Conclusions

GNPs were fabricated by first microwave irradiation for 3 min, and then strong mixed acid soaking for 24 h and second microwave irradiation for 3 min. This is an eco-friendly approach to synthesize graphene nanoplatelets. GNPs synthesized by this method are highly pure and have high aspect ratio. GNPs have enhanced PL properties and faster decay time.

References

Ferrari AC, Robertson J (2000) Resonant Raman spectroscopy of disordered, amorphous and diamondlike carbon. Phys Rev B 61:14095

Hu H, Wang X, Wang J, Liu F, Zhang M, Xu C (2011) Microwave assisted covalent modification of grapheme nanosheets with chitosan and its electrorheological characteristics. Appl Sci Surf 257:2637–2642

Kumar D, Singh K, Verma V, Bhatti HS (2014a) Synthesis and characterization of pristine and functionalized graphene nanoplatelets. Adv Sci Eng Med 6:1143–1151

Kumar D, Kavita Singh K, Verma V, Bhatti HS (2014b) Investigation of pristine and functionalized single walled carbon nanohorns for phosphor applications. Dig J Nanomater Bios 9:1713–1727

Kumar D, Singh K, Verma V, Bhatti HS (2014c) Synthesis, structural and optical characterization of grapheme oxide and reduced grapheme oxide. J Nanoelectron Optoelectron 9:458–467

Kumar D, Singh K, Verma V, Bhatti HS (2014d) Investigation of optical properties of pristine and functionalized single-walled carbon nanotubes J Mater Sci Mater Electron. doi:10.1007/s10854-014-2656-x

Kumar D, Kavita, Singh K, Verma V, Bhatti HS (2014e) Microwave assisted synthesis and characterization of silver nanowires by polyol process Appl Nanosci. doi:10.1007/s13204-014-0386-2,

Kumar D, Singh K, Verma V, Bhatti HS (2014f) Synthesis and characterization of carbon quantum dots from orange juice. J Bionanosci 8:274–279

Lee C, Wei XD, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Menendez JA, Arenillas A, Fidalgo B, Fernandez Y, Zubizarreta L, Calvo EG, Bermudez JM (2010) Review: microwave heating processes involving carbon materials. Fuel Process Technol 91:1–8

Ni ZH, Wang HM, Kasim J, Fan HM, Yu T, Wu YH, Feng YP, Shen ZX (2007) Graphene thickness determination using reflection and contrast spectroscopy. Nano Lett 7:2758–2763

Ni ZH, Yu T, Lu YH, Wang YY, Feng YP, Shen ZX (2008) Uniaxial strain on grapheme: raman spectroscopy study and band gap opening. ACS Nano 2:2301–2305

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Partoens B, Peeters FM (2006) From graphene to graphite: electronic structure around the K point. Phys Rev B 74:075404

Reina A, Jia X, Ho J, Nezich D, Son HB, Bulovic V, Dresselhaus MS, Kong J (2009) Large area-few layer graphene films on arbitrary substrates by chemical vapour deposition. Nanoletters 9:30–35

Thomson C, Reich S (2000) Double resonant Raman scattering in graphite. Phys Rev Lett 85:5214–5217

Truong QT, Pokharel P, Song GS, Lee DS (2012) Preparation and characterization of graphene nanoplatelets from natural graphite via intercalation and exfoliation with tetraalkylammoniumbromide. J Nanosci Nanotechnol 12:4305–4308

Wei T, Fan Z, Luo G, Zheng C, Xie D (2009) A rapid and efficient method to prepare exfoliated graphite by microwave irradiations. Carbon 47:337–339

Wolf EL (2014) Applications of graphene Springerbriefs in materials. doi:10.1007/978-3-319-03946-6_2

Zhang Y, Tan YW, Stormer HL, Kim P (2005) Experimental observations of quantum Hall effect and Berry’s phase in graphene. Nature 438:201–204

Acknowledgments

The authors are thankful to Dr. Sushil Kumar Kansal, Associate Professor, Dr. S S Bhatnagar University Institute of Chemical Engineering and Technology, Panjab University, Chandigarh for guiding and providing necessary facilities to bring this work to the present form.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Kumar, D., Singh, K., Verma, V. et al. Microwave assisted synthesis and characterization of graphene nanoplatelets. Appl Nanosci 6, 97–103 (2016). https://doi.org/10.1007/s13204-015-0415-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-015-0415-9