Abstract

Cavitation processing has been proposed as a greener alternative to solvent dilution or heat treatment of bitumen and other heavy oils to reduce viscosity and hence, improve transportability. The effect of acoustic cavitation under different conditions of sonication frequencies (low- to high- frequency range) and power inputs on asphaltene content, rheological changes, and metal content of bitumen was investigated in this study. Ultrasonic treatment resulted in a decrease in asphaltene content in bitumen that lead to lower viscosity and shear stress over a wide range of shear rates. Over the range of sonication frequencies investigated (20 kHz–1.1 MHz), the sonication frequency of 574 kHz with 50 % power input resulted in low asphaltene content and lower viscosity suitable for improved transportability. Further, comparison of different conditions of sonication frequencies and power inputs were carried out to investigate the effect of ultrasound on properties of asphaltene (elemental analysis and metal content). It was observed that the sonication treatment of bitumen under different conditions of frequencies and acoustic power decreased the H/C ratio. These results showed higher content of aromatic hydrogen and lower content of aliphatic hydrogen in bitumen treated under different conditions of sonication frequencies and intensity. Characterization of asphaltene performed using ICP-MS and TXRF, revealed lower metal content (Ni, Fe, and V) in the asphaltene phase of processed (sonicated) bitumen. The lowered metal content can be attributed to the reduced asphaltene formation as a result of sonication treatment of bitumen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bitumen is a complex mixture of hydrocarbons (aromatics, naphthenes, and paraffin among others), oxygen, nitrogen, and sulpfur compounds as well as trace metals. The recovery of bitumen from oil-bearing rocks, including bituminous sand has been recognized as an important Canadian resource (CERI [4] and for energy security of the continent [20]. Bitumen is extremely viscous after the extraction process; therefore, it is essential to reduce its viscosity for enhanced oil recovery and pipeline transportation. The viscosity reduction to increase transportability is commonly attained by heating or dilution with liquid diluents [9]. Such methods of reducing viscosity of bitumen are energy intensive and are performed at high capital and operational costs [2]. As a result, new alternative approaches are sought for reducing viscosity without the use of excess energy or changing the properties of bitumen. Shear technology development, using shear-based approaches such as acoustic cavitation have great potential for shear as well yield stress reduction of bitumen. Sonication processes induces acoustic cavitation into liquid media, involving the generation, expansion, oscillations, splitting, and implosions of numerous tiny gas bubbles called cavitation bubbles. As a result of implosion of cavitation bubbles, extreme temperature and pressure is generated in the centre of the collapsed bubble leading to solute thermolysis as well as the formation of hydroxyl radical and hydrogen peroxide [8]. As a consequence of the cavitation phenomena, the viscosity of bitumen reduces due to the application of energy in the form of higher shear or heat. Acoustic cavitation is applied in research to develop an understanding of the physico-chemical effects of cavitation processing at specific sonication frequencies and intensities.

Furthermore, among many components of bitumen, the asphaltene have been identified as the key in the crude oil viscosity. Challenges due to asphaltene deposition in production, transportation, and refining operations are considered as serious and complicated issues for the petroleum industry that applies a significant effort worldwide into prevention and remediation. Furthermore, several studies have shown that bitumen viscosity is strongly dependent on the volume fraction, chemical structures, and physico-chemical properties of its asphaltenes content, which are the most polar and/or heavy components in bitumen [14, 19]. Mack [13] observed the effect of asphaltene content on viscosity of bitumen and reported that the viscosity of reconstituted bitumen with 20 % of asphaltene was 367 times higher than that of the deasphalted bitumen (i.e., maltenes) at the room temperature. Dealy [6] added 5 % asphaltene into an Athabasca bitumen sample with the original asphaltene content of 16 % and found that the bitumen viscosity increases from 300,000 to 1,000,000 mPa s. Further, a study by Chakma and Berruti [5] reported that viscosity depends not only on asphaltene content but also on the molecular weight of the asphaltene and higher molecular weight asphaltene units have greater tendencies to form aggregates of larger sizes and therefore, provide greater resistance to flow.

Furthermore, study on changes in the asphaltene properties during the upgradation of bitumen become an important topic for investigation as asphaltene cause numerous problems and make the process of bitumen upgrading difficult. Characterization techniques that have been widely used to investigate the properties of asphaltene include metal analysis (mainly Ni, V, and Fe), elemental analysis and X-ray diffraction among others. Further, several studies have shown that heavy metals present in bitumen tends to accumulate in asphaltene and form metal porphyrins complexes (or metalloporphyrins) [17, 22, 23]. Extensive studies have been conducted on metalloporphyrins in bitumen, and it has been well established—that bitumen containing large amounts of heavy metals tends to have several adverse effects on refining equipment and processes [10]. Further, Ni and V in bitumen exist as soluble organometallic complexes that characterize as metal porphyrins and non-porphyrin complexes.

Therefore, the present study was carried out under different conditions of sonication frequencies and power inputs with following objectives: (i) effect of acoustic cavitation processes carried out in low- to high-range sonication frequencies such as 20, 40, 378, 574, 860, 992, and 1.1 MHz on rheological profile of bitumen; (ii) to study the effect of different sonication frequencies and power inputs on mass of asphaltene separation from bitumen; and (iii) to investigate the changes in the properties of asphaltene (elemental analysis and metal content) during sonication of bitumen under different frequencies and power inputs.

Materials and methods

Reagents

Bitumen was collected from a facility at Mildred Lake near Fort McMurray, Alberta, Canada. All the chemicals used were of analytical grade. HPLC grade toluene, heptane, methanol (MeOH), dichloromethane (DCM), and acetone used for cleaning and extraction purposes, were purchased from Fisher Scientific (Ontario, Canada). HPLC grade water was prepared in the laboratory using a Milli-Q/Milli-RO Millipore system (Milford, MA, USA). Nitric acid, hydrochloric acid, and hydrogen peroxide were supplied by Fisher scientific (Ontario, Canada).

Sonication experiment

Low frequency (20 and 40 kHz) ultrasonic experiments were carried out using an ultrasonic homogenizer (Autotune 750 W, Cole-Parmer Instruments, Vernon Hills, Illinois, USA). A mid- to high-frequency (378, 574, 860, 992 kHz, and 1.1 MHz) sonochemical processing system was assembled using a broadband transducer (Ultraschalltechnik-Meinhardt GMBH, Germany). The transducer was installed at the bottom of a coolant-jacketed glass column reactor with a diameter of 5 and 100 cm in height. The ultrasound energy was supplied by a power amplifier (HM8001-2) through a function generator (HM 8030-5 and HM 8032). Sonication experiments were carried out at five different frequency conditions using two different broadband transducers with the same effective diameter. The reactor was supplied with different power inputs starting from 16.67 to 83.33 %. The cooling system was operated to maintain a constant temperature. The experiment was carried out with a sample volume of 100 mL held within a jacked glass cooling column.

Rheology study

Viscosity of naphtha diluted bitumen was measured using a rotational viscometer Brookefield DV-II Prime (Brookfield Engineering Laboratories Inc., Stoughton, MA, USA) equipped with Wingather software (for rheological models). Two different spindles, namely, SC-31 (small sample adaptor), and ultralow centipoise adapter were used with a sample cup volume of 18/50 mL (spindle dependent). The calibration and viscosity testing procedure for each spindle was carried out as per instrument manual. The shear rate behavior was determined from 0.5 to 20 s−1.

Extraction of asphaltene

Asphaltenes were extracted from unsonicated and sonicated naphtha diluted bitumen samples as per ASTM-D6560-12. The extraction process was initiated with 4 g of oil sample in a round bottom flask followed by addition of 120 mL of heptane. The mixture was then boiled under reflux for 60 min and store in a dark place for 90–150 min. The resulting solution was filtered through a thimble (Whatman (GE Healthcare Life Sciences, Quebec, Canada) double thickness, 43 mm × 123 mm) and then the thimble was placed into a Soxhlet extraction apparatus and refluxed with heptane for minimum 60 min to separate the wax and resin compounds. Further, the asphaltene was separated under reflux using toluene in the extractor and the content was transferred to a 500 mL round bottom flask weighed previously. After completion of asphaltene separation, the toluene was evaporated in a rotary evaporator completely and the mass of asphaltene was measured.

Characterization of asphaltene samples

Analysis of presence of heavy metals (Ni, Fe, and V) in asphaltene samples was carried out using total reflection X-ray fluorescence (TXRF) and inductively coupled plasma mass spectrometer (ICP-MS) method. TXRF is basically an energy dispersive XRF technique in a special geometry. An incident beam impinges upon a sample at angles below the critical angle of external total reflection for X-rays resulting in reflection of almost 100 % of the excitation beam photons. Due to its unique configuration, the main advantage of TXRF over conventional XRF is reduced measurement background contributions by elimination of sample scattering resulting in increased elemental measurement sensitivity. For TXRF analysis, 10 mg of asphaltene sample was dissolved in 1 mL toluene followed by addition of 10 µL of Gallium as internal standard. Then, the sample was mixed properly in a vortex for 2–5 min. Further, 10 µL of sample was dried in the surface of a polished quartz glass for further analysis by TXRF.

For ICP-MS analysis, 0.2 g of asphaltene was weighed into a microwave digesting vessel followed by addition of 10 ml of nitric acid and 1 mL of hydrochloric acid. Further, 2 mL of 30 % H2O2 was added to the acid mixtures and the acid-peroxide mixture was transferred for the microwave digestion system. The digestion process was performed using a Multiwave-microwave sample preparation system (Anton Parr, Ashland, VA) with infrared temperature control and hydraulic pressure control with feedback function capable of reducing microwave power near the limit of operating pressure. The microwave digestion process was conducted at microwave power of 1400 W, operating pressure of 60 bar and temperature 180 ± 1 °C for 1 h. Further, the digestate was dried in a hot block (Environmental Express, MA) at 106 °C until complete dryness followed by addition of 25 mL of 1 M HCl for analysis in ICP-MS.

Elemental analysis of asphaltene samples was performed to determine the carbon, hydrogen, nitrogen and sulfur content. The analysis was carried out using a Vario MICRO CUBE analyzer (Elementar, Hanau, Germany).

Statistical analysis

All data presented in Tables 3, 4, and Figs. 1, 2 are representative of at least three independent experiments with all samples measured in triplicates within each experiment. Repetition of statistical results was carried out using Statistical 6.0 software for Windows by employing the Student’s t test.

Results and discussion

Effect of sonication frequency and power input on asphaltene content of bitumen

This study focused on evaluating the effect of sonication frequency on asphaltene metal content during sonochemical upgrading of bitumen. For this study, low (20 and 40 kHz), mid (378 and 574 kHz,), and high- (860, 992 kHz and 1.1 MHz) sonication frequencies over a range of input acoustic intensities were applied in a sonochemical reactor. The asphaltene yield at each condition is shown in Table 1. No changes in asphaltene yield waere observed in post processed bitumen sonicated under low sonication frequencies such as 20 and 40 kHz as compared to unsonicated bitumen and hence, the data not reported. Higher asphaltene yield was found to be extracted in unsonicated bitumen as compared to post processed bitumen sonicated under mid- to high-sonication frequencies. However, under the sonication frequency of 1.1 MHz with 33.33 % power input, no changes in asphaltene yield was observed as compared to unsonicated samples. Lower mass of asphaltene observed in post processed bitumen in a sonochemical reactor as compared to unsonicated samples can be attributed to the dissolution and disintegration of asphaltene in bitumen during sonication treatment. During sonication treatment, two mechanisms are hypothesized to be active in bitumen/heavy oil systems. These mechanisms are molecules disintegration into free radicals and hydrocarbons with shorter chain length, and integration of free radicals. Further, these mechanisms cause formation of free radicals resulting in change the composition of bitumen. Free radicals formed during these processes subtract hydrogen from asphaltene which enhances the formation of double bonds and eventually the aromatization of naphthenes leading to decrease in asphaltene content. Najafi and Amani [15] studied the effect of ultrasound treatment (low to mid-range frequency level) on asphaltene content of bitumen and observed that ultrasonic wave radiation results in asphaltene flocculation inhibition and solubilisation leading to lower mass separation. They observed 11 and 27 % reduction in mass of asphaltene from two different samples after a specific time of ultrasonic irradiation of bitumen. Furthermore, Sawarkar et al. [18] reported that the reduction in asphaltene content of bitumen after ultrasonic treatment was due to the conversion of refinery residues to lighter hydrocarbons in the boiling range of gasoil fractions.

Furthermore, among all the mid to high-sonication frequencies tested at different power inputs, lower mass of asphaltene was extracted from bitumen in sonication frequency of 574 kHz with power input of 83.33 %. The results showed that sonication frequency of 574 kHz generate maximum cavitation in the medium resulting higher rate of disintegration as compared to other frequencies tested. It was observed that mid-frequency levels (378 and 574 kHz) showed higher efficiency on decreasing the asphaltene content of bitumen as compared to higher frequency levels (860, 992 kHz and 1.1 MHz). There are other studies also showed that at mid-frequency level, there is significant rise in the number of cavities formed resulting higher formation of hydroxyl radicals and consequent disintegration of molecules [11]. Kirpalani and McQuinn [11] compared mid to high-range sonication frequencies for the oxidation of iodide to iodine and reported that cavitation yield increases in mid-range frequency levels as compared to high-frequency range.

Effect of sonication frequency and power input on rheology of bitumen

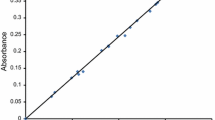

The rheogram and shear rate behavior of post processed bitumen in a sonochemical reactor system was studied over a wide range of shear rates. The measurement was conducted in varying speed mode condition and the values of shear rate and shear stress were obtained. Figures 1 and 2 illustrate rheogram and shear rate behavior of bitumen sonicated under different frequencies and power inputs. The results showed that the viscosity for a given shear rate decreased in bitumen sonicated under different frequencies and power inputs. The decrease in viscosity during sonication treatment of bitumen can be attributed to higher disintegration of asphaltene flocs. There are studies reported the dependency of viscosity of bitumen upon its asphaltene content [12, 14, 15]. Hence, during the sonication treatment of bitumen, the dissolution of asphaltenic components occurs resulting in breakdown of asphaltene molecules to lighter molecules leading to decrease in viscosity in the medium. Argillier et al. [2] conducted a rheological study of several heavy oils and concluded that the asphaltene content was a controlling factor for viscosity. Hence, sonication treatment of bitumen under different sonication frequencies and power inputs decrease the asphaltene content of bitumen leading to higher viscosity change.

Further, lower shear stress value with shear rate (Fig. 2) was also observed in bitumen sonicated under different frequencies and power inputs. The decreased viscosity and shear stress in bitumen sonicated under different conditions of sonication frequencies and power inputs indicated shear-thinning (pseudo-plastic) behavior of bitumen under sonolysis. However, in between the three sonication frequencies of interest in this study, 378, 574, and 992 kHz with power input of 50 and 83.33 %, property changes such as lower viscosity and shear stress with respect to shear rate were observed in frequency condition of 574 kHz with 50 % power input, showing higher shear-thinning behavior of bitumen. The lower viscosity and shear stress with respect to shear rate observed in frequency condition of 574 kHz with 50 % power input was due to higher formation of hydroxyl radicals and disintegration of asphaltene flocs.

Effect of sonication frequency and power input on properties of asphaltene

Elemental analysis

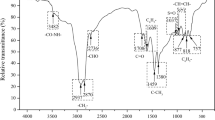

The elemental analysis data of asphaltene samples extracted from bitumen sonicated under five different sonication frequency conditions such as 378, 574, 860, 992 kHz, and 1.1 MHz with different power inputs starting from 16.67 to 83.33 % is presented in Table 2. The elemental analysis results showed an increase in carbon content of bitumen sonicated under different sonication frequencies and power input conditions. The carbon content of unsonicated bitumen was observed as 75.2 % and an increased value of 80.44, 80.16, 109.64, 79.98, and 77.93 % in bitumen sonicated under five different sonication frequency conditions such as 378, 574, 860, 992 kHz and 1.1 MHz, respectively. However, no uniformity was observed in hydrogen content of post processed bitumen as compared to unsonicated samples (in some treatment conditions reduction in hydrogen content was observed). Further, it was observed that the sonication treatment of bitumen under different conditions of frequency and power inputs decreased the H/C ratio in bitumen (Table 2). These results showed higher content of aromatic hydrogen and lower content of aliphatic hydrogen in bitumen treated under different conditions of sonication frequencies and power inputs. The increase in aromaticity in sonicated bitumen was due to the dissolution and disintegration of asphaltene leading to breakage of side alkyl chains [7, 15]. Ultrasonic energy is exerted in a micro-environment via cavitation, in which high-temperature and pressure is applied to the location instantaneously. Under cavitation condition thermal scission of the bonds of the heavy fraction and generation of free radicals occurs leading to hydrocarbon conversion processes such as cracking, dehydrogenation (reforming), dehydrocyclization, and isomerization [16].

Further, it was observed that the differences in nitrogen content of bitumen sonicated under different frequencies and power inputs as compared to unsonicated bitumen are minor. The results showed the difficulty of nitrogen removal from bitumen because of its position in the aromatic rings of the asphaltene molecule within stable metal complexes [1]. Further, minimal changes in sulfur content in bitumen treated under different conditions of frequencies and power inputs was observed as compared to unsonicated bitumen. The results may be due to the presence of sulpfur compound in the polyaromatic ring of asphaltene leading to lower effect of treatment. Further, the reduction and increased of H/S ratio in bitumen treated under different sonication frequencies and power input conditions were observed as compared to unsonicated samples. This results indicate that sulfur present in asphaltene possess a disulfide nature and also present as thiophenols or HS groups.

Metal content

A number of heavy metals such as nickel, iron, and vanadium among others can be effectively bound in large organic molecules characteristics, of those found in the asphaltene fraction. The study of metals presence in asphaltene is of particular importance as they play an important role in the technological difficulties which appear in the treatment of bitumen as well as inclusion of these metals during the diagenesis and maturation process of petroleum formation. For this study, the effect of mid to high-sonication frequencies (378, 574, 860, 992 kHz, and 1.1 MHz) over a range of input acoustic intensities in a sonochemical reactor system on heavy metal content of bitumen was observed. Experiments were carried out to determine the concentration of Ni, Fe, and V in asphaltene separated from bitumen treated under different conditions of sonication frequencies and power inputs. Further, metal analysis in asphaltene samples were carried out by TXRF and ICP-MS method. Tables 3 and 4 presents the concentration of heavy metals in bitumen sonicated under different conditions of sonication frequencies and power input observed by TXRF and ICP-MS methods, respectively. It was observed that the results obtained for three target heavy metals such as Fe, Ni, and V, by TXRF and ICP-MS methods were different. Ni and V content in asphaltenes were comparable between TXRF and ICP-MS methods. However, Fe content was not found to be similar. As TXRF is a new technology for analysis of heavy metals, this study focused more on results obtained by ICP-MS methods for discussions to compare the effect of different sonication frequencies and power inputs on heavy metal concentration in bitumen.

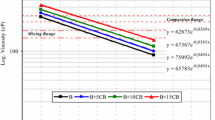

It was observed that metal extraction in the asphaltene phase is dependent on the sonication frequency and power input as shown in Figs. 3 and 4. The decrease in metal content in post processed bitumen in a sonochemical reactor was due to disintegration of large asphaltene molecules to smaller molecules as metals such as V and Ni are mainly located in the core of the cluster sheets (porphyrin).

Bitumen is a complex mixture of heavy molecules including asphaltene which is the most polar and heaviest molecule and bears the most heteroatom and organometallic compounds (i.e., hybrid organic radicals that are attached to the metal atom). It has been reported that asphaltene components aggregate to form clusters or nanoparticles over a wide range of concentration and also formed coordination complexes of metals such as vanadium [3, 21]. Therefore, during sonication treatment, disintegration of asphaltene flocs occurs leading to the formation of smaller asphaltene chains with lower metal content. The metal content can, thus be used as an indirect measure of the size of asphaltene molecule to evaluate process operation.

Further, this study focused on evaluating the effect of mid to high-sonication frequencies (378, 574, 860, 992 kHz, and 1.1 MHz) over a range of input acoustic intensities in a sonochemical reactor system on asphaltene metal content of bitumen. Lower concentration of Ni, Fe, and V was observed in asphaltene extracted from bitumen sonicated at sonication frequency of 574 and 860 kHz with power input of 50 and 83.33 % as compared to other frequencies tested. Sonication frequency of 574 and 860 kHz with power input of 50 and 83.33 % resulted in smaller asphaltene molecules in the medium leading to lower metal content.

Conclusions

In this study, low to high-sonication frequencies (20, 40, 378, 574, 860, 992 kHz, and 1.1 MHz) over a range of input acoustic intensities were applied in a sonochemical reactor system for the bitumen upgrading. The effect of sonication frequency and input acoustic intensities on bitumen upgrading was carried out on the basis of asphaltene separation, change in rheology, and heavy metal removal. Sonication treatment results in decrease the mass of asphaltene extracted from bitumen due to the disintegration and solubilisation of asphaltene flocs in the medium. Further, it was observed that sonication treatment of bitumen results in decrease in viscosity and shear stress with shear rate and highest change was observed with sonication frequency of 574 kHz with power input of 50 %. Asphaltene content in bitumen plays a dominant role on its viscosity and ultrasound treatment of bitumen leading to decrease in strong attractive interaction among the asphaltene particles resulting decrease in viscosity and shear stress indicating shear-thinning behavior. However, low sonication frequency levels such as 20 and 40 kHz showed no effect on asphaltene content of bitumen.

Sonication treatment of bitumen under different sonication frequencies and power inputs showed the change in metal content (Ni, V, and Fe) of asphaltene samples. Mid-frequency levels (378 and 574 kHz) showed higher efficiency on decreasing the asphaltene content of bitumen leading to lower metal content.

References

Ancheyta J, Centeno G, Trejo F, Marroquin G (2003) Changes in asphaltene properties during hydrotreating of heavy crudes. Energy Fuels 17:1233–1238

Argillier JF, Barre L, Brucy F, Douranaux JL, Henaut I, Bouchard R (2001) Influence of asphaltene content and dilution on heavy oil rheology. In: SPE conference, Porlamar, SPE 69711

Aske N, Kallevik H, Sjöblom J (2002) Water-in-crude oil emulsion stability studied by critical electric field measurements Correlation to physico-chemical parameters and near-infrared spectroscopy. J Pet Sci Eng 36:1–17

Canadian Energy Research Institute (2012) Pacific access: part 1—linking oil sands supply to new and existing markets

Chakma A, Berruti F (1993) The effects of ultrasonic treatment on the viscosity of Athabasca bitumen and bitumen-solvent mixtures. J Can Pet Technol 32:48–51

Dealy JM (1979) Rheological properties of oil sands bitumen. Can J Chem Eng 57:677–683

Dunn K, Yen TF (2001) A plausible reaction pathway of asphaltene under ultrasound. Fuel Process Technol 73:59–71

Entezari MH, Kruus P (1996) Effect of frequency on sonochemical reactions II. Temperature and intensity effects. Ultrason Sonochem 3:19–24

Gateau P, Hénaut I, Barré L, Argillier JF (2004) Heavy oil dilution. Oil Gas Sci Technol 59:503–509

Gould KA (1980) Oxidative demetallization of petroleum asphaltene and residua. Fuel 59:733–736

Kirpalani DM, McQuinn KJ (2006) Experimental quantification of cavitation yield revisited: focus on high frequency ultrasound reactors. Ultrason Sonochem 13:1–5

Luo P, Gu Y (2007) Effects of asphaltene content on the heavy oil viscosity at different temperature. Fuel 86:1069–1078

Mack C (1932) Colloid chemistry of asphalts. J Phys Chem 36:2901–2914

Mohammadreza MS, Ahmad R, Iman N, Mohammad DS (2012) Effect of ultrasonic irradiation on rheological properties of asphaltenic crude oils. Pet Sci 9:82–88

Najafi I, Amani M (2011) Asphaltene flocculation inhibition with ultrasonic wave radiation: a detailed experimental study of the governing mechanisms. Adv Pet Explor Dev 2:32–36

Olah GA, Molnar A (1995) Hydrocarbon chemistry. Wiley, New York, pp 1–53

Rocha LC, Ferreira MS, Silava Ramos AC (2006) Inhibition of asphaltene precipitation in Brazilian crude oils using new oil soluble amphiphiles. J Pet Sci Eng 51:26–36

Sawarkar AN, Aniruddha BP, Shriniwas DS, Jyeshtharaj BJ (2009) Use of ultrasound in petroleum residue upgradation. Can J Chem Eng 87:329–342

Sheu EY, Mullins OC (1995) Asphaltenes fundamentals and applications. Plenum Press, New York

Speight JG (2007) The chemistry and technology of petroleum, 4th edn. CRC Press-Taylor & Francis Group, Boca Raton

Tanaka R, Sato S, Takanohashi T, Hunt JE, Winans RE (2004) Analysis of the molecular weight distribution of petroleum asphaltenes using laser desorption-mass spectrometry. Energy Fuels 18:1405–1413

Verdier S, Duong D, Andersen SI (2005) Experimental determination of solubility parameters of oils as function of pressure. Energy Fuel 19:1225–1229

Yin CX, Stryker JM, Gray MR (2009) Separation of petroporphyrins from asphaltenes by chemical modification and selective affinity chromatography. Energy Fuels 23:2600–2605

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mohapatra, D.P., Kirpalani, D.M. Bitumen heavy oil upgrading by cavitation processing: effect on asphaltene separation, rheology, and metal content. Appl Petrochem Res 6, 107–115 (2016). https://doi.org/10.1007/s13203-016-0146-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-016-0146-1