Abstract

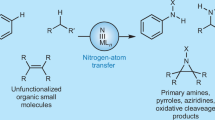

In this article, an overview of the application of selected metal nitrides as ammonia synthesis catalysts is presented. The potential development of some systems into nitrogen transfer reagents is also described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The successful development of the Haber–Bosch Process for the production of ammonia was a paramount achievement of the twentieth Century. Through the provision of an accessible route to synthetic fertiliser, it has been pivotal in sustaining a large proportion of the global population [1]. The process involves the direct combination of pure H2 and N2 reactants over promoted iron catalyst at moderate temperature (typically ca 400 °C) and high pressure (typically 100–200 atmospheres):

The reaction is equilibrium limited and, being exothermic, is thermodynamically favoured at lower reaction temperatures. However, the temperature of operation is dictated by the requirement to achieve acceptable process kinetics. Whilst the Haber–Bosch Process can, to some extent, be viewed as a mature technology, the development of more active (or even more poison tolerant) catalysts which would allow a reduction in the stringent conditions of operation is of significant interest. In this context, it is salient to note that, taken in its entirety, including the provision and purification of reactant feedstreams, on a global scale, the operation of the Haber Process currently consumes 1–2 % of the world’s energy demand, e.g. [2, 3]. Therefore, any improvements can potentially yield massive rewards both in terms of economic and environmental benefits. The identification and application of more active catalysts could lead to lowering of the process temperatures and/or pressures of operation necessary to achieve a desired space time yield of product. Indeed, lowered reaction temperatures result in improved obtainable equilibrium yields offering the tantalising prospect of a possible win–win situation, providing sufficiently favourable kinetics can be achieved. This is, however, a very significant challenge.

Iron is cheap and abundant and, when promoted, very effective under current Haber–Bosch Process conditions. Therefore, any replacement catalyst must afford the opportunity of significantly higher activity leading to lower temperature and/or pressure of application. Indeed, a number alternative systems based upon ruthenium have been identified in the literature, e.g. [4–7]. One such system involving promoted ruthenium supported on carbon is 10–20 times more active than conventional iron systems while operating at lower reaction pressure and forms the basis of an alternative ammonia synthesis process, the Kellogg Advanced Ammonia Process [8, 9].

The focus of this overview is a description of some of the relatively recent literature relating to the activity of metal nitrides as ammonia synthesis catalysts. The potential of nitrides as possible nitrogen transfer reagents will also be considered. In some respects, this relates to historical work on the development of the Haber–Bosch Process where some early studies by Mittasch and co-workers [10] at BASF considered routes to nitrogen fixation involving the formation of nitrides and also demonstrated some nitrides, such as molybdenum nitride, to be intermediates in the stepwise synthesis of ammonia via nitridation of metals with N2 and subsequent reduction by H2.

Metal nitrides as ammonia synthesis catalysts

Binary metal nitrides

In the early studies, Mittasch [10] drew attention to molybdenum metal which was stated to catalyse ammonia synthesis differently from iron in that it formed easily detectable amounts of nitride during catalysis. It was said to resemble tungsten, manganese and uranium in this respect. It is therefore to be expected that nitrides of such metals may be active ammonia synthesis catalysts. However, mention should also be made that under industrial conditions bulk iron nitridation occurs resulting in the distorted structure associated with catalytic activity [11].

A number of binary nitrides have been identified as active ammonia synthesis catalysts in the literature, including those of molybdenum [10, 12–14], uranium [15, 16], vanadium [17, 18], rhenium [19, 20] and cerium [21].

In the case of molybdenum, arguably the most well-studied binary nitride, structure sensitivity has been reported to be operative over γ-Mo2N in studies involving systematic variation of particle size [12]. In these studies, it was proposed that the fraction of active sites decreased with decreasing particle size. However, the effect of morphology was found to be limited in a study comparing plate like γ-Mo2N and nanorod form of γ-Mo2N prepared by the temperature programmed ammonolysis of plate and nanorod MoO3, respectively [14]. Such ammonolysis is known to yield γ-Mo2N which is pseudomorphic with respect to the MoO3 precursor [22]. Comparison of different phases of molybdenum nitride showed β-Mo2N0.78 to possess similar activity to its γ-Mo2N counterpart, whereas δ-MoN was found to be inactive (although potential deleterious effects resulting from residual sulphur left over from the preparation of this phase by ammonolysis of MoS2 could not be excluded) [14]. The β nitride phase can be prepared by reaction of MoO3 with N2/H2 mixtures [23] and the δ phase by ammonolysis of either MoS2 or MoCl5 [24]. Applying 15N labelling to study the mechanism of ammonia synthesis over molybdenum nitride, Aika and Ozaki [25] deduced rate determining N2 activation leading to intermediate N(a). It was argued that a proportion of the 15N was lost into bulk nitride, with the following scheme being presented:

and similarities with iron nitride, previously investigated by Logan et al. [26], were drawn. Contrary to this, Hillis et al. [27] had reported the hydrogenation of NH x species to be rate determining and the rate of hydrogenation of bulk nitride to be around 20–50 times slower than ammonia synthesis in this system. Some studies have been undertaken on other binary nitride systems. For example, based upon unusual transient behaviour, the hydrogenation of bulk nitrogen in uranium nitride has been proposed with the suggestion being made of a possible dynamic process between nitrogen species not immediately hydrogenated and loosely bonded subsurface nitrogen species which subsequently diffuse to the surface where they are hydrogenated to form ammonia [15]. This is akin to some oxidation processes which occur by the Mars–van Krevelen process where lattice oxygen species are those active in catalytic oxidation reactions [28]. Phase stability may be a consideration in other systems, for example, in rhenium nitride, the active form of the catalyst is proposed to comprise a mixture of Re3N and Re [19].

Ternary metal nitrides

In recent years, there have been reports that Co3Mo3N-related catalysts have high activity that have attracted interest [29–35]. In particular, it has been reported that when suitably promoted, the activity of this phase can exceed that of conventional iron based Haber–Bosch catalysts. Table 1 presents some activity data taken from a study by Aika and Kojima [29]. Cs+ has been found to be a promoter up to a certain limit, beyond which phase decomposition occurs [29]. Preparation of the phase generally involves ammonolysis of hydrated cobalt molybdate precursor—perhaps surprisingly use of anhydrous cobalt molybdate is less effective. Ammonolysis may present a problem in large-scale application since, for example, heat transfer may be an issue as outlined in the case of the binary molybdenum nitride system [36, 37]. However, straight application of the hydrated molybdate precursor followed by in situ nitriding with 3/1 H2/N2 at 700 °C for 2 h produced a less active catalyst which, although containing some Co3Mo3N, comprised additional phases [38].

The activity of the Co3Mo3N phase has been rationalised in terms of the N2 binding energy by Norskov and co-workers [32] as shown in Fig. 1 which presents a comparison of the calculated turnover frequency for a range of materials as a function of N2 binding energy. The significance of N2 binding energy as an important parameter for a reaction process in which N2 dissociation is generally considered rate limiting has been discussed and justified [39]. In terms of the plot presented in Fig. 1, the high activity of Ru and Fe, the basis for the two major industrial processes, as discussed in the introduction, can be seen. Osmium can also be seen to be a highly active catalyst—a fact recognised in the early work as outlined by Mittasch [10] in which uranium was also highlighted as having high activity. The high activity of Fe, Ru and Os for ammonia synthesis represents an interesting group trend within the d block of the periodic table, although it is seldom, if ever, highlighted as so. In addition, the initial discovery of the activity of Os represents an early example of a currently popular aspect for consideration—scarcity of elements. At that stage, the global reserves of Os were only 100 kg and Os was also susceptible to oxidation to yield OsO4 and so its replacement in the process was of paramount importance, which led to the discovery of the promoted Fe system. In Norskov’s work, the high activity of the Co3Mo3N phase has been explained as an average of the N2 binding energies for Co (which is too weakly binding) and Mo (which is too strongly binding) arriving at an optimum in the Sabatier curve shown in Fig. 1, with the Co3Mo3N catalyst reportedly being developed along this principle. It was argued that both components have to be in close proximity in order to be effective and that the (111) surface plane exhibits mixed Co and Mo sites. N was stated to not participate in the reaction but rather induce the required ordering. Support for this rationalisation was provided in previous microkinetic studies by the authors for which the activation energy was found to be intermediate between Co and Mo [32]. The volcano curve can also be used to rationalise the relatively high ammonia synthesis activity of the Ni2Mo3N phase [29, 33]. Fe3Mo3N, which is iso-structural with Co3Mo3N, is also a high activity ternary nitride for the reaction [29, 33]. A perhaps somewhat related approach to the Sabatier curve are the experimental surface science studies by Attard and King [40] aimed towards the production of hybrid materials combining a component with a marked ability to dissociate N2 with a high sticking probability with a component which bonds weakly to nitrogen in order to produce a nitrogen–metal bond of similar strength to Fe–N. The former component was W, whilst Cu, Ag and Au were examples of the latter component. It was found that N2 would not adsorb at sites consisting of both W and Cu atoms and hence it was predicted that bimetallics of W with Group IB metals would act as poor ammonia synthesis catalysts. However, if N2 could be dissociated by another route, the possibility of copper–tungsten bimetallics functioning as effective ammonia synthesis catalysts was raised.

Calculated turnover frequencies for ammonia synthesis as a function of the adsorption energy of nitrogen. The synthesis conditions are 400 °C, 50 bar, gas composition H2/N2 3/1 containing 5 % NH3. Reproduced with permission from [32]. Copyright (2001) American Chemical Society

In the context of high ammonia synthesis activity, it is interesting to draw attention to the reported high activity of cobalt–rhenium phases [19, 41]. Whilst these do not seem to have achieved the prominence of the Co3Mo3N related systems, literature studies have indicated that the activity exceeds that of them. A Co/Re material ratio of 1/4 prepared by ammonolysis at 700 °C was found to be particularly effective and it was proposed that catalytic activity may relate to the presence of some form of rhenium nitride phase. However, the scarcity of rhenium and its relative cost may be a consideration in large-scale application, although it should be acknowledged that Pt–Re reforming catalysts are applied on an industrial scale and also that Co–Re catalysts for Fischer–Tropsch synthesis have been a focus of interest, e.g. [42]. Whilst many formulations were screened by Mittasch and colleagues [10] in the early development of ammonia synthesis catalysts, it is an interesting thought to note that rhenium as such would not have formed part of the matrix, since its discovery was not documented until 1925. Indeed, in these studies Co was even documented as a promoter of Mo which is fascinating in the context of the development of the Co3Mo3N catalytic system at a very much later stage and illustrative of the wide ranging nature of the early work conducted at BASF.

Whilst it was stated that the lattice N of the Co3Mo3N catalyst did not participate in the NH3 synthesis reaction, a nitrogen isotopic exchange reaction undertaken by Hunter et al. has shown it to be exchangeable [43]. Figure 2 presents the homomolecular isotopic exchange profile in which a mixture of 14N2 and 15N2 is scrambled over Co3Mo3N at 450 °C. Most pertinent is the observation that the atomic fraction of 15N in the gas phase decreases over the course of the reaction which is a clear indication of the operation of the heterolytic exchange pathway in which exchange of gas-phase species with the lattice N (which is, of course, predominantly 14N reflecting the natural distribution of nitrogen isotopes) occurs and that the dissociative activation of N2 does not occur. Isotope exchange studies of the materials with 15N2(g) only were undertaken at higher reaction temperature and the results and the reaction and pre-treatment conditions are presented in Table 2. From this data, a clear influence of the nature of pre-treatment upon the exchangeability of lattice nitrogen is observed—in these studies, the influence of adsorbed N species was discounted and it was found that ca. 25 % of lattice N species could be exchanged at 600 °C following N2 pre-treatment at 700 °C as compared to 6 % for the corresponding pre-treatment in Ar. Whilst these reaction temperatures are significantly above that for ammonia synthesis, the presence of H2 in that case could accentuate the lattice N reactivity. These results were taken to demonstrate the possibility that the lattice nitrogen may indeed be reactive under reaction conditions and hence that a Mars–van Krevelen type mechanism, in which NH3 formation occurs by direct hydrogenation of lattice species which are then replenished from gas-phase N2, could be operative and the significant effects of pre-treatment upon the extent of exchange demonstrate the sensitivity of the system, possibly involving surface restructuring effects.

Evolution of the nitrogen isotopomer partial pressures and the gas-phase 15N atomic fraction during homomolecular isotopic nitrogen exchange at 450 °C over Co3Mo3N. Reproduced with permission from [43]. Copyright (2013) American Chemical Society

Potential of nitrides as nitrogen transfer reagents

The possible existence of Mars–van Krevelen type reaction mechanisms in both the binary and ternary nitride systems raises the interesting possibility of the development of nitrides as reagents for novel nitrogen transfer pathways. The prospect of such a “mechanism” leads to the idea of a “process”.

The mechanism implies two concurrent general stages to ammonia synthesis:

-

(i)

the hydrogenation of lattice N species to yield NH3, and

-

(ii)

the replenishment of lattice N vacancies from gas-phase N2

In terms of a “process” stages (i) and (ii) could be conducted under different conditions (e.g. at different temperatures) leading to potential kinetic and/or thermodynamic advantages. In oxidation catalysis there is a precedent for the distinction between “mechanism” and “process” as illustrated by the example of butane oxidation catalysed by vanadium phosphate. On the basis that this reaction occurred by a Mars–van Krevelen mechanism it has proved possible to separate the butane oxidation and catalyst re-oxidation steps into separate stages [44, 45]. In this way, the desired partial oxidation product, maleic anhydride, does not come into direct contact with O2 in the presence of the catalyst.

Applying this general concept, it may prove possible to develop new nitrogen transfer reagents by-passing the use of NH3 as a nitrogen transfer reagent. The potential value of this idea can be illustrated by consideration of the large-scale production of aniline via the selective reduction of nitrobenzene. Considering this process from the viewpoint of N2 as the initial source of nitrogen, the process steps can be considered as:

As detailed above, the production of ammonia by Haber–Bosch Process is extremely energy intensive. Having applied this energy to form intermediate ammonia, the second equation (a simplified representation of the Ostwald Process) involves oxidation of some of the hydrogen atoms bonded to each ammonia molecule added in the previous process step. Taken together, these initial two stages represent an indirect way of oxidising hydrogen to yield water! The nitric acid product is then used to form the nitronium cation in corrosive mixture of concentrated acids. Having obtained the nitronium cation benzene is nitrated and the nitrobenzene product selectively reduced to yield aniline—in another stage indirectly involving the reaction between oxygen and hydrogen to yield water!

It might be imagined that the direct amination of benzene:

is a potential alternative route, but it is thermodynamically limited and approaches to overcome this limitation by use of a cataloreactant [46] or coupled hydrogen consuming reactions [47] have proved unsuccessful.

If the lattice nitrogen of a nitride could be used in an alternative aniline forming two-stage process such as:

and

(where MN represents a metal nitride, M the corresponding metal and “N” a nitridation agent such as NH3 or, ideally, N2) although a formidable challenge, the potential interest in the development of such a route is readily apparent. Indeed the nitrogen transfer and renitridation stages could be conducted under different reaction conditions. However, non-selective reduction could be a major potential issue. Aniline production is just one of a number of major “nitrogen incorporation” processes for which a similar potential approach may be imagined.

Whilst not widespread, reports of the reactivity of lattice N are not without precedent, some of which were already mentioned in the section relating to binary nitride catalysts applied to ammonia synthesis. In 1948, Goodeve and Jack [48] published an investigation relating to the denitridation of iron nitride. In this study, hydrogen was shown to enhance the loss of lattice nitrogen leading to its complete conversion to ammonia in the 250–450 °C range. Interestingly, when CO was used, 25 % of the nitrogen lost formed cyanogen with isomorphous substitution of lattice N by C. Lattice nitrogen reactivity has also been implicated in NH3 decomposition over zirconium oxynitride [49] and the ammoxidation of propane over VAlON [50].

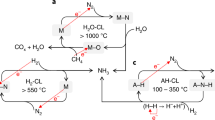

With the Mars–van Krevelen process concept in mind, the reactivity of a number of metal nitrides towards H2 has been investigated [14, 38, 51, 52]. Co3Mo3N proved a particularly interesting case in this regard—at 700 °C the previously unprecedented Co6Mo6N phase was formed through loss of 50 % of the lattice nitrogen [51, 52]. Despite the fact that the majority of N eliminated was in the form of N2, with NH3 being a minor co-product, H2 was necessary to drive the process. In Co3Mo3N all the lattice nitrogen is crystallographically equivalent and it might be imagined that it would be totally lost upon reaction with H2. However, the residual 50 % relocates to a different crystallographic site (migration from the 16c to the 8a Wyckoff site) as confirmed by powder neutron diffraction [52]. Restoration of the Co3Mo3N phase, which would be a necessary step for its application as a nitrogen transfer reagent, was found to be relatively facile when using a N2/H2 mix and achievable at higher temperature when using N2 alone [53]. It was demonstrated that the Co3Mo3N/Co6Mo6N system can be cycled back and forth. It has tentatively been postulated that the H2 necessary to accomplish the Co3Mo3N to Co6Mo6N phase change may function by inducing a phase change through reduction of surface stoichiometry—in terms of diffraction analysis, the transformation occurs between the two end members with no intermediate stoichiometries being formed. Isotopic nitrogen exchange over the Co6Mo6N phase has demonstrated that simultaneously, along with renitridation occurring leading to regeneration of the Co3Mo3N phase, a degree of exchange occurs with both processes ceasing simultaneously [43]. A schematic of the entire Co3Mo3N–Co6Mo6N interconversion and isotopic exchange processes is presented in Fig. 3.

Schematic of the phase transformations and isotopic exchange pathways over the Co3Mo3N–Co6Mo6N system. Reproduced with permission from [43]. Copyright (2013) American Chemical Society

Whilst Fe3Mo3N is iso-structural with Co3Mo3N, its lattice nitrogen is much less reactive. In terms of Co3Mo3N, the elevated temperature necessary to conduct the loss of 50 % of the lattice nitrogen would lead to carbidation upon contact with hydrocarbon reactants and so it is necessary to either find a means for enhancement of the lattice nitrogen reactivity or to develop different systems of enhanced reactivity. This could involve experimental based studies or, perhaps more excitingly, computational modelling techniques could be applied to design systems with desired lattice nitrogen reactivity. In the Co3Mo3N–Co6Mo6N system, it is probable that the renitridation step is enhanced by the maintenance of 50 % of the original nitrogen in the system. In other nitrides, such as Cu3N, where N loss occurs at temperatures of greater potential interest for nitrogen transfer avoiding carbidation, the total loss of nitrogen which is difficult to suppress and the concomitant structural transformation have rendered renitridation extremely difficult [54].

In principle, routes to nitrogen-containing organic products such as amines could be envisaged based upon the application of carbonitrides as reagents involving hydrogenation. This could open up the exciting prospect of indirect routes from N2 and CH4 in three stage procedures involving nitridation, carbidation and reduction separately. In practice, each step could be conducted under different reaction conditions and the sequence of nitridation and carbidation could be reversed. This prospect is a significant challenge but arguably any demonstration of the indirect reaction of methane and nitrogen to yield any organic nitrogen-containing product, and even HCN, would be of major interest. To this end, preliminary investigations of the reduction molybdenum carbonitride systems prepared from single source routes have been undertaken [55]. In these studies, the preferential reactivity of lattice N over lattice C has been observed, indicating that it would be necessary to develop materials with more closely matched reactivity of the lattice N and C components. Again, computational modelling in which target phases are identified could play a significant role in this regard.

Related alternative strategies for ammonia synthesis

The observations outlined above indicate that it could be possible to apply Co3Mo3N as a material for the two-stage synthesis of ammonia in which hydrogenation of the lattice nitrogen and its subsequent replenishment from N2 are conducted in separate stages. However, the temperatures involved in this would be high. Also, the mass fraction of N in the system is very low—an issue compounded when it is considered that only 50 % of the lattice nitrogen is “active”—and only a relatively fraction of it is hydrogenated to yield NH3 with the major proportion being lost in the form of N2.

The design of new, improved systems with greater efficiency of N utilisation and enhanced reactivity of N based along these lines represents an exciting opportunity for combined computational modelling and experimental studies. Cyclic operation of ammonia synthesis has been proposed previously in the literature by Amariglio and co-workers as a means of overcoming the inhibition of reaction rate by H2 for Ru [56] and Os [57] systems. It was suggested that reaction rates of possible commercial interest could be achieved at atmospheric pressure using such an approach in these systems. For example, by applying the cyclic two-step procedure—saturation under pure N2, followed by hydrogenation under pure H2—extrapolation indicated that rates comparable to the industrial performance of iron catalysts could be obtained over Ru at 300 °C and atmospheric pressure.

Routes applying solar energy towards nitrogen fixation and the production of ammonia have been described recently by Pfromm and co-workers [58–60]. In these routes, metal nitrides are prepared by various means from N2 and NH3 is generated in a subsequent hydrolysis step. The necessary high temperatures are attained via a solar furnace. The use of a solar furnace as an environmentally friendly means to attain high temperatures for application to nitrogen fixation is an interesting concept. Historically, in the cyanamide process which immediately pre-dated the Haber–Bosch Process, nitrogen fixation was achieved by direct reaction of N2 with calcium dicarbide producing calcium cyanamide (CaCN2). Although this process required high temperatures, it was exothermic and self-sustaining once initiated [61]. However, the production of calcium carbide from CaO and C necessary for the process did involve the application of very high temperatures. CaCN2 could be directly applied as a fertiliser itself or hydrolysed to liberate ammonia.

Conclusion

In this overview, selected examples of the applications of metal nitrides as catalysts for the synthesis of ammonia have been described. The potential of this class of material for the development of novel nitrogen transfer reagents has also been outlined. It can be anticipated that advances in nitride synthesis coupled with the application of more complex materials, such as quaternary systems, may result in exciting developments in these areas. It is clear that nitride materials represent an interesting opportunity. They are of increasing interest in other areas of heterogeneous catalysis.

References

Smil V (2002) Nitrogen and food production: proteins for human diets. AMBIO J Hum Env 31:126–131

Tanabe Y, Nishibayashi Y (2012) Developing more sustainable processes for ammonia synthesis. Coord Chem Rev 257:2551–2564

Bielawa H, Hinrichsen O, Birkner A, Muhler M (2001) The ammonia synthesis catalyst of the next generation: barium promoted oxide supported ruthenium. Angew Chemie Int Edn 40:1061

Jacobsen CJH (2001) A novel support for ruthenium-based ammonia synthesis catalysts. J Catal 200:1–3

Urabe K, Aika K, Ozaki A (1976) Activation of nitrogen by alkali metal promoted transition metal. 6. Hydrogen effect on isotopic equilibration of nitrogen and rate-determining step of ammonia-synthesis on potassium promoted ruthenium catalysts. J Catal 42:197–204

Rao KSR, Masthan SK, Prasad PSS, Rao PK (1991) Effect of barium addition on the ammonia synthesis activity of a cesium promoted ruthenium catalyst supported on carbon covered alumina (CAA). Appl Catal 73:L1–L5

Honkala K, Hellman A, Remediakis IN, Logadottir A, Carlosson A, Dahl S, Christensen CH, Norskov JK (2005) Ammonia synthesis from first principles calculations. Science 307:555–558

Rhodes AK (1996) New ammonia process, catalyst proven in Canadian plant. Oil Gas J 94(47):37–41

Liu H (2012) Ammonia synthesis catalysts—innovation and practice. World Scientific Press. ISBN: 978-981-4355-77-3

Mittasch A (1950) Early studies of multicomponent catalysts. In: Frankenburg WG, Rideal EK, Komorewsky VI (eds) Advances in catalysis, vol II. Academic Press, New York, pp 81–104

Schlogl R (2003) Catalytic synthesis of ammonia—a “never ending story?” Angew Chemie Int Edn 42:2004–2008

Volpe L, Boudart M (1986) Ammonia synthesis on molybdenum nitride. J Phys Chem 90:4874–4877

Kojima R, Aika K (2001) Molybdenum nitride and carbide catalysts for ammonia synthesis. Appl Catal A Gen 219:141–147

Mckay D, Hargreaves JSJ, Rico JL, Rivera JL, Sun XL (2008) The influence of phase and morphology of molybdenum nitrides on ammonia synthesis activity and reduction characteristics. J Solid State Chem 161:325–333

Segal N, Sebba F (1967) Ammonia synthesis catalyzed by uranium nitride. 1. Reaction mechanism. J Catal 8:105–112

Segal N, Sebba F (1967) Ammonia synthesis catalyzed by uranium nitride. 2. Transient behaviour. J Catal 8:113–119

King DA, Sebba F (1965) Catalytic synthesis of ammonia over vanadium nitride containing oxygen. 1. Reaction mechanism. J Catal 4:253–259

King DA, Sebba F (1965) Catalytic synthesis of ammonia over vanadium nitride containing oxygen. 2. Order-disorder transition revealed by catalytic behavior. J Catal 4:430–439

Kojima R, Aika K (2001) Rhenium containing binary catalysts for ammonia synthesis. Appl Catal A Gen 209:317–325

Kojima R, Enomoto H, Muhler M, Aika K (2003) Cesium promoted rhenium catalysts supported on alumina for ammonia synthesis. Appl Catal A Gen 245:311–322

Panov GI, Kharitonov AS (1985) Catalytic properties of nitrides in ammonia synthesis. React Kinet Catal Lett 29:267–274

Volpe L, Boudart M (1985) Compounds of molybdenum and tungsten with high surface area. 1. Nitrides. J Solid State Chem 59:332–347

Gong SW, Chen HK, Li W, Li BQ (2005) Synthesis of beta-Mo2N0.78 hydrodesulfurization catalyst in mixtures of nitrogen and hydrogen. Appl Catal A Gen 279:257–261

Ganin AY, Kienle L, Vajenine GV (2006) Synthesis and characterisation of hexagonal molybdenum nitrides. J Solid State Chem 179:2339–2348

Aika KI, Ozaki A (1969) Mechanism and isotope effect in ammonia synthesis over molybdenum nitride. J Catal 14:311–321

Logan SR, Moss RL, Kemball KC (1958) The catalytic decomposition of ammonia over evaporated iron films. Trans Faraday Soc 54:922–930

Hillis MR, Kemball C, Roberts MW (1966) Synthesis of ammonia and related processes on reduced molybdenum dioxide. Trans Faraday Soc 62:3570–3585

Doornkamp C, Ponec V (2000) The universal character of the Mars and van Krevelen mechanism. J Mol Chem A Chem 162:19–32

Kojima R, Aika K (2001) Cobalt molybdenum bimetallic nitride catalysts for ammonia synthesis—Part 1. Preparation and characterization. Appl Catal A Gen 215:149–160

Kojima R, Aika K (2001) Cobalt molybdenum bimetallic nitride catalysts for ammonia synthesis—Part 2. Kinetic study. Appl Catal A Gen 218:121–128

Kojima R, Aika K (2001) Cobalt molybdenum bimetallic catalysts for ammonia synthesis—Part 3. Reactant gas treatment. Appl Catal A Gen 219:157–170

Jacobsen CJH, Dahl S, Clausen BS, Bahn S, Logadottir A, Norskov JK (2001) Catalyst design by interpolation in the periodic table: bimetallic ammonia synthesis catalysts. J Am Chem Soc 123:8404–8405

Jacobsen CJH (2000) Novel class of ammonia synthesis catalysts. Chem Commun 12:1057–1058

Boisen A, Dahl S, Jacobsen CJH (2002) Promotion of binary nitride catalysts: isothermal N2 adsorption, microkinetic model, and catalytic ammonia synthesis activity. J Catal 208:180–186

Kojima R, Aika K (2000) Cobalt molybdenum bimetallic catalysts for ammonia synthesis. Chem Lett 514–515

Wise RS, Markel EJ (1994) Catalytic NH3 decomposition by topotactic molybdenum oxides and nitrides—effect on temperature programmed gamma-Mo2N synthesis. J Catal 145:335–343

Wise RS, Markel EJ (1994) Synthesis of high surface area molybdenum nitride in mixtures of nitrogen and hydrogen. J Catal 145:344–355

Hargreaves JSJ, Mckay D (2009) A comparison of the reactivity of lattice nitrogen in Co3Mo3N and Ni2Mo3N catalysts. J Mol Catal A Chem 305:125–129

Dahl S, Logadottir A, Jacobsen CJH, Norskov J (2001) Electronic factors in catalysis: the volcano curve and the effect of promotion in catalytic ammonia synthesis. Appl Catal A Gen 222:19–29

Attard GA, King DA (1990) Co-adsorption of nitrogen with Cu, Ag and Au on W(100)—the role of metal adatoms in controlling surface reactivity. J Chem Soc Faraday Trans 86:2735–2741

Alexander A-M, Hargreaves JSJ, Mitchell C (2013) The denitridation of nitrides of iron, cobalt and rhenium under hydrogen. Top Catal 56:1963–1969

Iida H, Sakamoto K, Takeuchi M, Igarashi A (2013) Fischer–Tropsch synthesis over Co/SiO2 and Co-M (M:Ru, Re)/SiO2 catalysts prepared by a high temperature supercritical drying method. Appl Catal A Gen 466:256–263

Hunter SM, Gregory DH, Hargreaves JSJ, Richard M, Duprez D, Bion N (2013) A study of 15N/14N isotopic exchange over cobalt molybdenum nitrides. ACS Catal 3:1719–1725

Contractor RM (1999) Dupont’s CBT technology for maleic anhydride. Chem Eng Sci 54:5627–5632

Bordes E, Contractor RM (1996) Adaptation of the microscopic properties of redox catalysts to the type of gas-solid reactor. Top Catal 3:365–375

Desrosiers P, Guan SH, Hagemeyer A, Lowe DM, Lugmair C, Poojary DM, Turner H, Weinberg H, Zhou XP, Armbrust R, Fengler G, Notheis U (2003) Application of combinatorial catalysis for the direct amination of benzene to aniline. Catal Today 81:319–328

Becker J, Holderich WF (1998) Amination of benzene in the presence of ammonia using a Group VIII metal supported on a carrier as catalyst. Catal Lett 54:125–128

Goodeve C, Jack KH (1948) Kinetics of nitrogen evolution from an iron-nitrogen interstitial alloy. Disc Faraday Soc 4:82–91

Soerijanto H, Rodel C, Wild U, Lerch M, Schomaker R, Schlogly R, Ressler T (2007) The impact of nitrogen mobility of zirconium oxynitride catalysts for ammonia decomposition. J Catal 250:19–24

Olea M, Florea M, Sack I, Silvy PR, Gaigneaux EM, Marin GB, Grange P (2005) Evidence for the participation of lattice nitrogen from vanadium aluminium oxynitrides in propane ammoxidation. J Catal 232:152–160

Mckay D, Gregory DH, Hargreaves JSJ, Hunter SM, Sun XL (2007) Towards nitrogen transfer catalysis: reactive lattice nitrogen in cobalt molybdenum nitride. Chem Commun 29:3051–3053

Hunter SM, Mckay D, Smith RI, Hargreaves JSJ, Gregory DH (2010) Topotactic nitrogen transfer: structural transformation in cobalt molybdenum nitrides. Chem Mater 22:2898–2907

Gregory DH, Hargreaves JSJ, Hunter SM (2011) On the regeneration of Co3Mo3N from Co6Mo6N and N2. Catal Lett 141:22–26

Alexander A-M, Hargreaves JSJ, Mitchell C (2012) The reduction of various nitrides under hydrogen: Ni3N, Cu3N, Zn3N2 and Ta3N5. Top Catal 55:1046–1053

AlShalwi M, Hargreaves JSJ, Liggat JJ, Todd D (2012) The reactivity of lattice nitrogen species in molybdenum (oxy)carbonitrides prepared by single-source routes. Mater Res Bull 47:1251–1256

Rambeau G, Amariglio H (1981) Improvement of the catalytic performance of a ruthenium powder in ammonia synthesis by use of a cyclic procedure. Appl Catal 1:291–302

Rambeau G, Jorti A, Amariglio H (1982) Improvement of the catalytic performance of an osmium powder in ammonia synthesis by the use of a cyclic procedure. Appl Catal 3:273–282

Michalsky R, Pfromm PH (2011) Chromium as reactant for solar thermochemical synthesis of ammonia from steam, nitrogen and biomass at atmospheric pressure. Sol Energy 85:2642–2654

Michalksy R, Parman BJ, Amanor-Boadu V, Pfromm PH (2012) Solar thermochemical production of ammonia from water, air and sunlight: thermodynamic and economic analyses. Energy 42:251–260

Michalsky R, Pfromm PH (2012) An ionicity rationale to design solid phase metal nitride reactants for solar ammonia production. J Phys Chem C 116:23243–23251

Topham SA (1985) The history of the catalytic synthesis of ammonia. In: Anderson JR, Boudart M (eds) Catalysis science and technology, vol. 7, Chapter 1. Springer, Berlin

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Hargreaves, J.S.J. Nitrides as ammonia synthesis catalysts and as potential nitrogen transfer reagents. Appl Petrochem Res 4, 3–10 (2014). https://doi.org/10.1007/s13203-014-0049-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-014-0049-y