Abstract

The overbalance pressure drilling technique is well common and practiced during the drilling operations in the petroleum field. This parameter is very critical and affects the drilled formation characteristics, and therefore, the main objective of the current study is to evaluate the impact of overbalance pressure that is applied during the drilling operation on the rock elastic and strength characteristics by employing integrated lab experimental work. Berea Buff sandstone rock type was utilized to interact with water-based drilling fluid (barite-weighted) under an extended range of overbalance pressure [300 to 1000 psi]. The current research presents extensive lab analyses that cover filtration tests for rock-mud interaction, scratch testing for determining the rock strength profile, sonic data acquisition, elastic properties determination, and spectrometry of scanning electron microscope and nuclear magnetic resonance spectrometry to study the internal pore structure changes. The analysis was performed before the mud interaction for the saturated samples (base case) and after applying different overbalance pressure (pre-mud interaction) to evaluate the rock properties alterations. The obtained results showed the high degree of impact of the overbalance pressure on the sonic wave propagation as the compressional and shear wave velocities increased by 17 and 6%, respectively with increasing the overbalance pressure. Poisson’s ratio showed a stable trend, while Young’s modulus showed an increasing trend by 23% increase with the extended range of the overbalance pressure. The rock strength showed deterioration behavior with increasing the overbalance pressure. The unconfined compression strength decreased by 10% and the tensile strength showed a 9% reduction. The internal pore spectrometry showed the rock structure alterations due to mud solids precipitations and filtrate fluid impact on the rock integrity during the rock-mud interaction. In addition, statistical analysis illustrated the high degree of relationship between the recorded rock characteristics with the overbalance pressure as a controlling factor on the rock and mud interaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1. Introduction

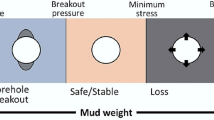

The wellbore stability topic has a significant amount of coverage and discussion from the researchers and experts in the well drilling field practices due to the huge drilling expenditure for this matter and the associated problems (Albukhari et al. 2018; Kang et al. 2009; Moos et al. 2003). During the drilling operation, all technical and economic aspects have to be studied well to mitigate the non-productive time for the drilling rigs to preserve the wellbore in a good condition to drill the hole safely and efficiently. The drilled rock geomechanical characteristics are very critical during the well drilling as the drilling program and drilling parameters are optimized based on the formation characteristics in terms of mineralogical composition (lithology), and strength (rock failure) which are mandatory also for the well development operations as fracturing and acidizing (Gamal et al. 2020b; Larsen et al. 2000; Yale and Jamieson, 1994).

The rock geomechanical properties are classified into main two categories that are failure properties and the second group is elastic rock properties (Fjaer et al. 2011). The rock elastic moduli show specific behavior for the rock deformation under the external stresses and these parameters are key inputs for the rock geomechanical modeling and field stimulation development operations. Among these elastic moduli, Young’s modulus and Poisson’s ratio have a special concern for assessment and determination through lab experiments, developed empirical correlations, and/or machine learning applications (Chang et al. 2006; Xu et al. 2016; Zheng et al. 2020). The formation stiffness is represented by Young’s modulus value for every drilled formation, while the formation deformation is represented by Poisson’s ratio. The rock failure parameters as the unconfined compressive strength and tensile strength represent the maximum stress that can be applied to the rock sample and the rock can bear before break and failure occur under the applied designed stresses and these features are highly affected by the internal pore system, texture, cementing bonds, fluid saturation, and rock internal grain frame (Fjær et al. 2008; Romana and Vasarhelyi, 2007).

The rock’s petrophysical and geomechanical characteristics are specific for each drilled formation and these parameters are highly affected by the drilling fluids’ interaction during the well drilling (Mavko et al. 2009). The drilling mud is commonly utilized during the well drilling for well control by applying mud hydrostatic pressure to overbalance the drilled formation pressure, provide hole cleaning, drill bit and drillstring lubricating, and support the wellbore for good stability conditions (Boyou et al. 2019; Caenn et al. 2011; Caenn and Chillingar, 1996). The composition of the drilling mud is designed carefully to provide efficient rheological properties to achieve the required functions of the mud during the drilling process, in addition, the designed mud composition should be non-damageable to the drilled rock (Boyou et al. 2019; Katende et al. 2019).

1.1 Mud-rock exposure

Due to the drilled formation exposure to the drilling mud, the chemical activity of the mud and the mineralogical composition of the formation will play a critical role in the mud-rock chemical and mechanical interactions, and hence, many changes will arise to the internal pore structure of the drilled formations in terms of pore plugging due to solids precipitations and/or dissolution and pore opening (Cao et al. 2019; Gamal et al. 2020a; Meng et al. 2005). Consequent alterations will be observed in the rock characteristics in terms of porosity, permeability, fluid flow properties, internal rock topography, pore system, elastic properties, and rock strength (Gamal et al. 2020c; Chukwuemeka et al. 2017; Sharma and Wunderlich, 1987).

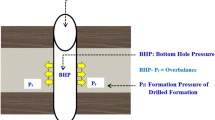

The downhole drilling environment such as overbalance pressure, temperature, exposure time, and the rock mineralogy and drilling fluid composition will determine the degree of interaction between the drilled formation and mud and the consequent alterations to the drilled formation characteristics. As shown in Fig. 1, the drilling mud is pumped through the drillstring using the mud pumps, and the bottomhole pressure overbalances the drilled formation pressure by the value of overbalance pressure or might be named the differential pressure (Jilani et al. 2002; Mondal and Chatterjee, 2019).

Designing the overbalance pressure is very critical during the drilling process as it affects drilling performance as rock drillability rate and pipe differential stuck (Ettehadi and Altun, 2016). Hence, technical aspects have to be considered as well control, depleted zone pressures, and formation integrity (Erivwo and Makis, 2021). By the action of this pressure, the mud solids with the filtrate will invade the pores of the drilled rock and will go for further interaction process with the internal pore system of the rock, and severe changes might occur for the rock structure (Gamal et al. 2020a; Sharma and Wunderlich, 1987; Windarto et al. 2011).

1.2 Rock geomechanics alterations

Many studies in the literature discussed the impact of the drilling fluid exposure on the rock geomechanical properties, especially for the shale rock type due to the rock sensitivity to the fluid and the drilling associated problems during well drilling (Zhang et al. 2021). However, sandstone rock alterations still need more research under the downhole drilling environment (Chukwuemeka et al. 2017; Xu et al. 2018). Sandstone rock contains quartz and different clay types and the quartz-clay frame affects the degree of rock structure alterations after interaction with the drilling fluids (He et al. 2019). The dissolution impact that happens on the sandstone samples is mainly controlled by the fluid pH under the downhole temperature (Knauss and Copenhaver, 1995). The chemical interactions that usually occur in the clay minerals are the main reason for the associated changes to the cohesion bond of the rock grains, rate of clay swelling, and consequent plasticity degree of the rock (Ochieng, 2016). The chemical interactions between the drilling fluids and rock mineralogy will greatly affect the rock petrophysical properties like porosity and permeability that represent the rock fluid storage capacity and fluid flow characteristics (Kassab et al. 2017; Pudlo et al. 2012). Consequent changes to the rock’s internal structure and inter-particle bonding, rock strength, and elastic characteristics (Garia et al. 2019; Hu et al. 2014).

The sandstone-mud exposure was studied under different downhole conditions of exposure time, clay type and content, different mud weighting materials, and mud filtrate impact (Gamal et al. 2021a, c), while the current study presents the role of overbalance pressure on this interaction. The extended exposure time from 30 min to 5 days was found to have significant deterioration to the rock strength as the results showed 18% strength reduction was recorded after five days of mud-rock exposure under 300 psi overbalance pressure and 200°F temperature, in addition, the rock elastic properties showed alterations and the study covered the internal changes to the pore system due to the mud solids precipitations and clay swelling (Gamal et al. 2020a, 2020b). The mud filtrate impact on four sandstone rock samples that show different clay types and content, and the results illustrated that the rock strength decreased with a different trend for each sandstone formation (Berea Buff and Spider, Bandera Brown, and Parker) that shows different behavior due to the clay content, clay type, and quartz-clay frame (Gamal et al. 2021b, 2020a; He et al. 2019). The sonic wave propagation through the rock suffers from such internal pore structure changes and studies showed that the shear wave propagation is mainly controlled by the rock mineralogical composition while the compressional wave propagation is highly affected by the rock saturation by fluid type (Hamada, 2004; Mavko et al. 2009; Motra and Stutz, 2018). The drilling fluid type in terms of water-based mud (WBM) or oil-based mud (OBM) was studied to assess the impact on sandstone and shale rocks and the results showed that OBM is better for maintaining the rock strength from deterioration (Yadav et al. 2016). The sandstone rock hardness for sandstone rock decreased by 10.1% after two hours of interaction with OBM while the reduction reached 22.9% with WBM (Xu et al. 2018).

The overbalance pressure was found to cause severe formation damage even for a short time of drilling with this technique (Ding et al. 2006). The formation damage in terms of mud invasion depth was studied with the overbalance pressure and the results showed that the depth of invasion increases with the overbalance pressure to a certain limit and then it decreases (Jilani et al. 2002). The role of the overbalance pressure on sandstone geomechanics is not covered in many discussions in the literature, hence, the main objective of this research is to assess the sandstone strength and elastic moduli alterations due to the mud-rock interactions under extended overbalance pressure.

The current research provides a comprehensive study to evaluate the role of the overbalanced pressure drilling technique on the drilled rock geomechanics by providing an integrated experimental work for assessing the rock strength and elastic moduli changes. The study utilized laboratory analysis of rock mineralogical composition as X-ray diffractions (XRD), spectrometry of scanning electron microscopes (SEM) and nuclear magnetic resonance (NMR) to study the internal pore structure alterations, sonic data acquisition, and scratch testing to determine the rock strength alterations. A modified aging cell was employed to accommodate the rock samples for the mud-rock interaction under the pressure, temperature, and time environment to simulate the downhole conditions for mud-rock interaction during the drilling operation.

2. Experimental work and materials

The current research employed sandstone rock samples (Berea Buff) to represent the drilled formation with an exposure to the drilling fluid WBM that is weighted with barite weighting material under the same conditions of temperature and time; while extending the overbalance pressure factor. The overbalance pressure was extended from 300, 700, and 1000 psi to assess the role of overbalance pressure as a factor for sandstone geomechanics alterations after the mud-rock interaction process, and the filtration test is conducted under the same temperature (200°F) and time that is extended for 30 min of filtration as per the standard procedures (American Petroleum Institute (API), 2009)) to record the filtrate volume and filter cake thickness for each level of overbalance. The aforementioned ranges for the downhole temperature and overbalance pressure ranges were designed to simulate the downhole conditions during real field drilling operations besides showing the overbalance pressure extent on the rock characteristics alterations for a kind of comparison.

2.1 Experimental design

Figure 2 illustrates the experimental design layout to achieve the proposed objective of studying the role of overbalance pressure on the mud-rock exposure under the downhole drilling environment of pressure, temperature, and exposure time. The rock samples (Berea Buff) were prepared and cut into cylindrical shapes (2 inches in length by 1.5 inches in diameter) and saturated with 3 wt% potassium chloride (KCl) to provide clay stability and inhibit the clay swelling (Koteeswaran et al. 2018). An integrated rock characterization was performed for the rock samples as a mineralogical composition by X-ray diffractions analysis, scanning electron microscopes, sonic measurements, and rock scratch testing. This phase was followed by the filtration test where the mud and rock samples were accommodated in the modified cell for the filtration test as shown in Fig. 3. During the filtration test, the mud-rock interaction starts and mimics the way of the downhole real drilling operation mechanism for mud-rock exposure. During the test, the filtration properties were determined in terms of filtrated volume during the test and the formatted filter cake thickness that was recorded after the filtration test period. The mud-rock interaction was executed under the designed environment of temperature (200°F), time (30 min), and different scenarios of overbalanced pressure (300, 700, and 1000 psi). The rock samples’ geomechanics in terms of rock failure property (unconfined compression strength and tensile strength), and elastic moduli (Young’s modulus, and Poisson’s ratio) were evaluated after the mud-rock exposure to compare with the initial condition saturated samples (base case).

The mineralogical composition for the sandstone rack samples was determined using XRD and showed that quartz shared 91 and 4 wt% microcline, in addition, clay content of 5 wt% that contains kaolinite, smectite, and muscovite with 3, 1, and 1 wt%, respectively. The quartz clay frame is very critical to the mud interaction besides the clay content and type (Lange et al. 2021; Ombaka, 2016).

The current study utilized the same WBM drilling fluid formulation and Berea Buff sandstone samples for the research scope as listed in Table 1 (Gamal et al. 2020b, 2020c) to assess every parameter separately on the mud-rock interaction. The formulation contains water as the base fluid for the WBM drilling fluid, polymer (XC) and bentonite as mud viscosity control, starch was added to control the fluid loss, calcium carbonates with a size of 50 microns (D50) as a bridging agent, and barite was used to control the mud weight. The mud rheological properties for the formulation were measured at 80 ˚F temperature as the normal procedure on the rig site and the recorded values were listed in Table 2 as the mud weight is 12.25 ppg, and pH of 9.5 which is considered a good range for the mud pH that will greatly enhance the mud filtration properties (Gamal et al. 2019). The mud viscosity was 13 cP, while yield point, initial, and 10-min gel strength showed 63, 11, and 21 lb/100 ft2, respectively.

2.2 Geomechanical properties determination

The scratch testing machine was used to evaluate the changes in the rock geomechanics, as the tool has a cutter for rock scratching for specific cutting depths that is designed by the tool software. The normal and shear forces were recorded during the rock scratching, and then, the unconfined compression strength (UCS) was determined using a database that is relating these forces with the rock specific energy for different formation types. The scratch test is a common technique for geomechanics research for petroleum rock samples (Richard et al. 2012; Schei et al. 2000).

In addition, the rock tensile strength (TS) that represents the rock failure limit under tensile stress can be determined through the existing correlations for relating the TS with UCS values (Nazir et al. 2013). One of the most common correlations has a high degree of correlation coefficient (0.9) for TS-UCS relationship determination that was developed for 143 samples for many types of formations is presented in Eq. 1 (Altindag and Guney, 2010):

where UCS and TS are in MPa.

The machine is equipped with probes for measuring the sonic wave velocities which are compressional wave velocity (Vp) and shear wave velocity (Vs) and these sonic data are employed to determine the elastic moduli as per the standards of American society for testing and materials (ASTM, 2005):

where; \({\mathrm{E}}_{\mathrm{d}}\) is the dynamic Young’s modulus in Giga Pascal, \({PR}_{d}\) is the dynamic Poisson’s ratio in fraction, \(\uprho\) is the density of rock sample in grams per cubic centimeters, Vs in kilometers per second, Vp in kilometers per second.

2.3 Rock internal pore structure

The rock samples were scanned using the spectrometry analysis of scanning electron microscopes and nuclear magnetic resonance to assess the degree of alterations that happened to the internal pore structure (rock integrity and the cementing degree) over the extended overbalance pressure (Byrne et al. 2000; Ge et al. 2018). Studying the internal structure of the rock samples will help to reveal the driving mechanism for the strength and elastic moduli alterations. The spectrometry was performed for the core samples pre-mud exposure and post-mud interactions to represent the overbalance impact on the mud-rock interaction during the drilling operation.

3. Results and discussion

This section presents the obtained results from the experimental work through the filtration test results, sonic data acquisition and analysis, rock strength and elastic moduli results, and discussion of the analysis of the obtained result and relating the rock geomechanics alterations to the rock pore structure changes with the extended overbalance pressure for the rock and mud interaction.

3.1 Filtration test

The collected filtrate volume and formatted filter cake thickness were recorded after every filtration test experiment to evaluate the overbalance pressure on the filtration properties. As shown in Fig. 4, there is an increase in the filtration properties (filter cake thickness and filtrate volume) with increasing the overbalance pressure as the filtrate volume increased from 5.5 to 6.5 to 7.5 cm3 by increasing the overbalance pressure from 300 to 700 to 1000 psi, while the filter cake thickness increased from 1.51 to 2.29 to 3.18 mm with the overbalance pressure steps, respectively. These results revealed the strong role of the overbalance pressure increase for enforcing the drilling fluids to invade the drilled rock pores during the drilling operation that will affect consequently the formation damage.

3.2 Sonic data measurement

The sonic data measurements showed that the velocities of compressional and shear waves increased with increasing the overbalance pressure ranges as shown in Fig. 5 where Vp increased from 2.11 to reach 2.47 km/s while Vs increased from 1.14 to 1.21 km/s with extending the overbalance pressure from 300 to 1000 psi. The role of overbalance affected the rock-mud interaction process and caused more driving pressure to motivate the mud to invade the rock samples pore system, and consequently, the wave propagation behavior changed due to the post-mud rock structure that suffered from mud solids precipitations and filtrate accumulations within the rock pores.

3.3 Rock elastic properties

The rock elastic properties were evaluated after each overbalance pressure experiment and the results are plotted in Fig. 6 which shows that Poisson’s ratio increased from 0.30 to 0.34 after applying 300 psi overbalance and stabilized with no more changes with increasing the overbalance pressure up to 1000 psi, while Young’s modulus showed an increasing trend with increasing the overbalance pressure value as it increased from 6.8 to 8.4 GPa by increasing the overbalance pressure to 1000 psi. The behavior of the Poisson’s ratio trend for the first increase from 0.3 to 0.34 by 300 psi overbalance experiment is attributed to the replacement of the filtrate fluid and mud solids with the initial saturating fluid that affects the wave propagation characteristics within the rock structure, while the following stabilization behavior for Poisson’s ratio at 0.34 even with increasing the overbalance pressure is mainly due to the theoretical relationship with Vp/Vs values that were recorded for the overbalance pressure experiments.

3.4 Rock strength

The rock strength was evaluated for the saturated core samples before mud interaction (base case) and after every overbalance pressure increase stop for study and comparison. The rock strength was presented in terms of unconfined compression strength (UCS) which is directly determined from the scratch testing and tensile strength (TS) which is determined from the UCS-TS correlation. The results showed the UCS decrease trend with increasing the overbalance pressure as UCS was 50.9 MPa for the base case (pre-mud interaction saturated rock sample) and decreased to 45.8 MPa with 5% strength reduction for 300 psi overbalance pressure experiment, and UCS recorded 47.1 MPa with 8% reduction under 700 psi overbalance pressure, and the strength reduction reached 10% for 1000 psi overbalance pressure to have UCS of 46 MPa as shown in Fig. 7.

Similar strength reduction behavior was recorded for the tensile strength as shown in Fig. 8 that TS decreased from 3.8 to 3.6 MPa from the base case condition to 300 psi overbalance pressure experiment with 4% reduction and still showing decreasing behavior till reached 3.4 MPa with 9% reduction percentage under 1000 psi overbalance pressure case.

The rock strength deterioration is attributed to the rock structure integrity that is affected by the role of mud filtrate on the rock mineralogy as the clay minerals are highly sensitive and active to the filtrate chemical interactions. These changes are strongly affecting the rock cementing bonds and the rock structure integrity that consequently affect the rock strength by the recorded deterioration behavior.

3.5 Internal pore structure

The internal pore structure for the sandstone rock samples was evaluated using the spectrum of SEM and NMR to study the overbalance pressure impact on the rock pore structure alterations after the mud interaction and compare it with the initial base case (Pre-mud interaction). Fig. 9 illustrates the SEM analysis for the core samples pore structure changes from the base case to different level experiments for the overbalance pressure as more mud solids precipitated with increasing the level of overbalance from 300 to 700 to 1000 psi and the pore plugging impact is shown clearly recorded. The NMR analysis confirmed the SEM results as the total porosity of the rock samples showed a reduction with increasing the overbalance pressure as the porosity decreased from 21.6 to 17.6% with 300 psi overbalance pressure, while it recorded 17.6% with 700 psi overbalance pressure, and still decreased till recorded 14.2% under 1000 psi overbalance pressure. This porosity reduction behavior is mainly attributed to the mud solids precipitations during the mud-rock interaction during the filtration test and this solids invasion is increasing with increasing the driving force by the overbalance pressure increase. This conclusion is well known and reported during the field drilling practice for the overbalance pressure drilling technique.

3.6 Statistical analysis

The obtained results were studied from a statistical view to evaluate the overbalance pressure as a factor for changing the sonic data acquisition, Young’s modulus, and strength reduction. The analysis showed that Vp, Vs, and Young’s modulus have a direct linear relationship with the overbalance pressure increase for the studied range of overbalance pressure during the experimental work as illustrated in Figs. 10 and 11.

The sandstone rock strength, in addition, was found to be highly impacted with a high degree of relationship (polynomial of order 2 type) with the overbalance pressure as shown in Fig. 12.

The following correlations show the correlations recorded from the overbalance pressure relationship with sonic, Young’s modulus, and rock strength and the determination coefficient (R2):

where ΔP is the overbalance pressure in psi.

It is worth mentioning that these correlations are limited to the tested range of the overbalance pressure of 300 to 1000 psi and for the specific rock type (sandstone Barea Buff) and water-based mud drilling fluid, in addition to the temperature level during the filtration test (200°F).

4. Conclusions

The overbalance pressure was evaluated in this research for assessing the impact on the sandstone rock interaction with WBM during an extended level of overbalance pressure. The experimental work was designed to assess the changes in the rock elastic and failure characteristics, in addition to the sonic data acquisition after the rock-mud interaction. The following outcomes are concluded from the study results:

-

The sonic data in terms of Vp and Vs showed an increasing trend with increasing the overbalance pressure from 300 to 1000 psi as Vp increased by 17% while Vs by 6%.

-

Poisson’s ratio showed no change during the overbalance pressure increase while Young’s modulus increased from 6.8 to 8.4 GPa with increasing the overbalance pressure value from 300 to 1000 psi.

-

The rock strength showed deterioration behavior with increasing the overbalance pressure as UCS decreased from 50.9 to 46 MPa and TS decreased from 3.8 to 3.4 MPa with 10 and 9% reduction percentages for UCS and TS, respectively.

-

The statistical analysis revealed the high impact of the overbalance pressure on the sonic data propagation, Young’s modulus, and strength deterioration over the tested range of overbalance pressure [300 to 1000 psi].

-

The spectrometry analysis illustrated the internal pore structure changes with increasing the overbalance pressure due to mud solids precipitations and pore plugging impact.

The limitations of the current study are considered the designed formulations of WBM and Barea Buff sandstone rock samples, besides the designed range of the operational parameters for the mud-rock interaction process. The study recommended evaluating the impact of different mud formulations and a wide range of rock types to evaluate the impact on the rock-mud interaction and rock characteristics alterations.

Abbreviations

- OBM:

-

Oil-based mud.

- WBM:

-

Water-based mud.

- XRD:

-

X-ray diffractions.

- SEM:

-

Spectrometry of scanning electron microscopes.

- NMR:

-

Nuclear magnetic resonance.

- UCS:

-

Unconfined compression strength.

- TS:

-

Tensile strength.

- Vp:

-

Compressional wave velocity.

- Vs:

-

Shear wave velocity.

References

Albukhari TM, Beshish GK, Abouzbeda MM, Madi A (2018) Geomechanical wellbore stability analysis for the reservoir section in J-NC186 oil field. 1st international conference on advances in rock mechanics, TuniRock 2018 179–193

Altindag R, Guney A (2010) Predicting the relationships between brittleness and mechanical properties (UCS, TS and SH) of rocks. Sci Res Essays 5:2107–2118. https://doi.org/10.5897/SRE.9000753

American Petroleum Institute (API), (2009) API RP 13B-1 - recommended practice for field testing water-based drilling fluids. American petroleum institute, Washington, DC, USA

ASTM, S.D.-05 (2005). Standard test method for laboratory determination of pulse velocities and ultrasonic elastic constants of rock. Astm i, 5–11

Boyou NV, Ismail I, Wan Sulaiman WR, Sharifi Haddad A, Husein N, Hui HT, Nadaraja K (2019) Experimental investigation of hole cleaning in directional drilling by using nano-enhanced water-based drilling fluids. J Petrol Sci Eng 176:220–231. https://doi.org/10.1016/J.PETROL.2019.01.063

Byrne MT, Spark ISC, Patey ITM, Twynam AJ (2000) A laboratory drilling mud overbalance formation damage study utilising cryogenic sem techniques. Proceedings - SPE international symposium on formation damage control 295–303. Doi: https://doi.org/10.2118/58738-MS

Caenn R, Chillingar Gv (1996) Drilling fluids: state of the art. J Pet Sci Eng 14:221–230. https://doi.org/10.1016/0920-4105(95)00051-8

Caenn R, Darley HCH, Gray GR (2011) Composition and properties of drilling and completion fluids, composition and properties of drilling and completion fluids. Gulf professional publishing, Houston. https://doi.org/10.1016/C2009-0-64504-9

Cao H, Zhang Z, Bao T, Sun P, Wang T, Gao Q (2019) Experimental investigation of the effects of drilling fluid activity on the hydration behavior of shale reservoirs in Northwestern Hunan, China. Energies 12:3151. https://doi.org/10.3390/EN12163151

Chang C, Zoback MD, Khaksar A (2006) Empirical relations between rock strength and physical properties in sedimentary rocks. J Pet Sci Eng 51:223–237. https://doi.org/10.1016/J.PETROL.2006.01.003

Ding Y, Herzhaft B, Renard G (2006) Near-wellbore formation damage effects on well performance: A comparison between underbalanced and overbalanced drilling. SPE Prod Oper 21:51–57. https://doi.org/10.2118/86558-pa

Erivwo O, Makis V (2021) Improved abnormal formation pressure detection from drilling performance data in a partially observable setting. J Pet Sci Eng 206:108947. https://doi.org/10.1016/J.PETROL.2021.108947

Ettehadi A, Altun G (2016) Thermal effects on differential pressure pipe sticking tendency. J Pet Sci Eng 146:50–60. https://doi.org/10.1016/J.PETROL.2016.03.018

Fjaer E, Holt RM, Horsrud P, Raaen AM, Risnes R (2011) Petroleum related rock mechanics, Marine Environmental Research

Fjær E, Holt RM, Horsrud P, Raaen AM, Risnes R (2008) Geological aspects of petroleum related rock mechanics. Dev Pet Sci 53:103–133. https://doi.org/10.1016/S0376-7361(07)53003-7

Gamal H, Bageri BS, Elkatatny S, Patil S (2021a) Investigating the alteration of sandstone pore system and rock features by role of weighting materials. ACS Omega Acsomega. https://doi.org/10.1021/acsomega.0c06256

Gamal H, Elkatatny S, Abdulraheem A (2020a) Effect of the filtrate fluid of water-based mud on sandstone rock strength and elastic moduli. ACS Omega. https://doi.org/10.1021/acsomega.0c05067

Gamal H, Elkatatny S, Abdulraheem A, Al Majed A (2020b) Exposure time impact on the geomechanical characteristics of sandstone formation during horizontal drilling. Molecules. https://doi.org/10.3390/molecules25112480

Gamal H, Elkatatny S, Adebayo A (2021b) Influence of mud filtrate on the pore system of different sandstone rocks. J Petrol Sci Eng 202:108595. https://doi.org/10.1016/j.petrol.2021.108595

Gamal H, Elkatatny S, Adebayo A, Bageri B (2020c) Effect of exposure time on the compressive strength and formation damage of sandstone while drilling horizontal wells. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2020.107590

Gamal H, Elkatatny S, Basfar S, Al-Majed A (2019) Effect of pH on rheological and filtration properties of water-based drilling fluid based on bentonite. Sustainability 11:6714. https://doi.org/10.3390/su11236714

Gamal H, Suleymanov V, Elkatatny S, Adebayo A, Bageri B (2021c) The impact of weighting materials on carbonate pore system and rock characteristics. Can J Chem Eng. https://doi.org/10.1002/cjce.24092

Garia S, Pal AK, Ravi K, Nair AM (2019) A comprehensive analysis on the relationships between elastic wave velocities and petrophysical properties of sedimentary rocks based on laboratory measurements. J Pet Explor Prod Technol 9:1869–1881. https://doi.org/10.1007/S13202-019-0675-0/FIGURES/8

Ge X, Liu J, Fan Y, Xing D, Deng S, Cai J (2018) Laboratory investigation into the formation and dissociation process of gas hydrate by low-field NMR technique. J Geophys Res Solid Earth 123:3339–3346. https://doi.org/10.1029/2017JB014705

Hamada GM (2004) Identification de fluides de réservoir par le rapport Vp/Vs. Oil Gas Sci Technol 59:649–654. https://doi.org/10.2516/ogst:2004046

He W, Chen K, Hayatdavoudi A, Sawant K, Lomas M (2019) Effects of clay content, cement and mineral composition characteristics on sandstone rock strength and deformability behaviors. J Pet Sci Eng 176:962–969. https://doi.org/10.1016/J.PETROL.2019.02.016

Hu R, Liu HH, Chen Y, Zhou C, Gallipoli D (2014) A constitutive model for unsaturated soils with consideration of inter-particle bonding. Comput Geotech 59:127–144. https://doi.org/10.1016/J.COMPGEO.2014.03.007

Jilani SZ, Menouar H, Al-Majed AA, Khan MA (2002) Effect of overbalance pressure on formation damage. J Pet Sci Eng 36:97–109. https://doi.org/10.1016/S0920-4105(02)00268-1

Kang Y, Yu M, Miska S, Takach NE (2009) Wellbore stability: a critical review and introduction to DEM.In: proceedings - spe annual technical conference and exhibition 4, 2689–2712. Doi: https://doi.org/10.2118/124669-ms

Kassab MA, Abu Hashish MF, Nabawy BS, Elnaggar OM (2017) Effect of kaolinite as a key factor controlling the petrophysical properties of the Nubia sandstone in central Eastern Desert Egypt. J African Earth Sci 125:103–117. https://doi.org/10.1016/J.JAFREARSCI.2016.11.003

Katende A, Boyou NV, Ismail I, Chung DZ, Sagala F, Hussein N, Ismail MS (2019) Improving the performance of oil based mud and water based mud in a high temperature hole using nanosilica nanoparticles. Coll Surf Physicochem Eng Asp 577:645–673. https://doi.org/10.1016/j.colsurfa.2019.05.088

Knauss KG, Copenhaver SA (1995) The effect of malonate on the dissolution kinetics of albite, quartz, and microcline as a function of pH at 70 °C. Appl Geochem 1:17–33

Koteeswaran S, Habibpour M, Puckette J, Pashin JC, Clark PE (2018) Characterization of shale–fluid interaction through a series of immersion tests and rheological studies. J Pet Explor Prod Technol 8:1273–1286. https://doi.org/10.1007/s13202-018-0444-5

Lange I, Toro M, Arvidson RS, Kurganskaya I, Luttge A (2021) The role of crystal heterogeneity in alkali feldspar dissolution kinetics. Geochim Cosmochim Acta 309:329–351. https://doi.org/10.1016/J.GCA.2021.06.032

Larsen I, Fjær E, Renlie L (2000) Static and dynamic poisson’s ratio of weak sandstones. Balkema

Mavko G, Mukerji T, Dvorkin J (2009) The rock physics handbook, the rock physics handbook. Cambridge University Press, Cambridge, United Kingdom. https://doi.org/10.1017/cbo9780511626753

Meng Z, Yi W, Tiedemann J (2005) Analysis of mechanical properties of sedimentary rocks of coal measures and their influencing factors. In: Paper presented at the Alaska Rocks 2005, The 40th U.S. Symposium on Rock Mechanics (USRMS). Anchorage, Alaska

Mondal S, Chatterjee R (2019) Quantitative risk assessment for optimum mud weight window design: a case study. J Pet Sci Eng 176:800–810. https://doi.org/10.1016/j.petrol.2019.01.101

Moos D, Peska P, Finkbeiner T, Zoback M (2003) Comprehensive wellbore stability analysis utilizing quantitative risk assessment. J Pet Sci Eng 38:97–109. https://doi.org/10.1016/S0920-4105(03)00024-X

Motra HB, Stutz HH (2018) geomechanical rock properties using pressure and temperature dependence of elastic P- and S-wave velocities. Geotech Geol Eng 36:3751–3766. https://doi.org/10.1007/s10706-018-0569-9

Nazir R, Momeni E, Armaghani DJ, Amin MFM (2013) Correlation between unconfined compressive strength and indirect tensile strength of limestone rock samples. Electron J Geotech Eng 18:1737–1746

Ochieng O (2016) Characterization and classification of clay minerals for potential applications in Rugi Ward, Kenya. Afr J Environ Sci Technol 10:415–431. https://doi.org/10.5897/AJEST2016.2184

Chukwuemeka AO, Amede G, Alfazazi U (2017) A review of wellbore instability during well construction: types, causes, prevention and control. Pet Coal 59(5):590–610

Ombaka O (2016) Characterization and classification of clay minerals for potential applications in Rugi Ward, Kenya. Afr J Environ Sci Technol 10:415–431. https://doi.org/10.5897/AJEST2016.2184

Pudlo D, Reitenbach V, Albrecht D, Ganzer L, Gernert U, Wienand J, Kohlhepp B, Gaupp R (2012) The impact of diagenetic fluid–rock reactions on rotliegend sandstone composition and petrophysical properties (Altmark area, central Germany). Undefined 67:369–384. https://doi.org/10.1007/S12665-012-1723-Y

Richard T, Dagrain F, Poyol E, Detournay E (2012) Rock strength determination from scratch tests. Eng Geol 147–148:91–100. https://doi.org/10.1016/J.ENGGEO.2012.07.011

Romana M, Vasarhelyi B (2007) A Discussion On the Decrease of unconfined compressive strength between saturated and dry rock samples. In: Paper presented at the 11th ISRM Congress. Lisbon, Portugal

Schei G, Fjær E, Detournay E, Kenter CJ, Fuh GF, Zausa F (2000) The Scratch test: an attractive technique for determining strength and elastic properties of sedimentary rocks. All Days. https://doi.org/10.2118/63255-MS

Sharma MM, Wunderlich RW (1987) The alteration of rock properties due to interactions with drilling-fluid components. J Pet Sci Eng 1:127–143. https://doi.org/10.1016/0920-4105(87)90004-0

Windarto GAY, Sukarno P, Soewono E (2011) Modeling of mud filtrate invasion and damage zone formation. J Pet Sci Eng vol.77,pp. 359–364. Doi: https://doi.org/10.1016/j.petrol.2011.04.011

Xu F, Yan Z, Wang L, Guo Y, Yang C (2018) Effect of the drilling fluid on hardness characteristics of tight sandstone.

Xu H, Zhou W, Xie R, Da L, Xiao C, Shan Y, Zhang H (2016) Characterization of rock mechanical properties using lab tests and numerical interpretation model of well logs. Math Probl Eng. https://doi.org/10.1155/2016/5967159

Yadav PK, Ali SS, Al Tawat NA, Al Dhamen AA, Jin G (2016). Effect of drilling fluid on rock mechanical properties at near-drilling conditions: an implication of fluid design on wellbore stability. In: offshore technology conference asia 2016, OTCA 2016 1399–1407. https://doi.org/10.4043/26460-MS

Yale DP, Jamieson WH (1994) Static and dynamic mechanical properties of carbonates. 1st North American Rock Mechanics Symposium, NARMS 1994 463–471

Zhang F, Liu HB, Cui S, Meng YF, Wang JJ (2021) Influence of the weakening effect of drilling fluid on wellbore stability in anisotropic shale formation. Front Phys 9:541. https://doi.org/10.3389/FPHY.2021.745075/BIBTEX

Zheng M, Tang H, Li H, Zheng J, Jing C (2020) Geomechanical analysis for deep shale gas exploration wells in the ndnr blocks, sichuan basin, southwest China. Energies 13:1117. https://doi.org/10.3390/EN13051117

Acknowledgements

The authors wish to acknowledge King Fahd University of Petroleum & Minerals for providing the research facilities and permitting the publication of this work.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gamal, H., Elkatatny, S. The impact of overbalance pressure on the alteration of sandstone geomechanical properties. J Petrol Explor Prod Technol 13, 123–133 (2023). https://doi.org/10.1007/s13202-022-01540-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01540-y