Abstract

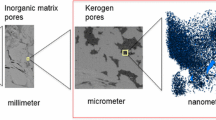

Academic investigations digging into the methane flow mechanisms at the nanoscale, closely related to development of shale gas reservoirs, had attracted tremendous interest in the past decade. At the same time, a good understanding of the complex essence remains challenging, while the broad theoretical scope, as well as application value, possesses great attraction. In this work, with the help of molecular dynamics methods nested in LAMMPS software, a fundamental framework is established to mimic the nanoconfined fluid flow through realistic organic shale matrix. Denoting evident discrepancy with existed contributions, shale matrix in this work is composed of specific number of kerogen molecules, rather than simple carbon-based nanotube. Recently, promotion efforts have been implemented in the academic community with the use of kerogen molecules, however, gas flow simulations are still lacking, and the pore shape in the current papers is always hypothesized as slit pores. The pore-geometry assumption seriously conflicts with the general observation phenomenon according to the advanced laboratory experiments, such as SEM image, AFM technology, that the organic pores tend to have circular pore geometry. In order to fill the knowledge gap, the circular nanopore with desirable pore size surrounded by kerogen molecules is constructed at first. The organic nanopore with various thermal maturity can be obtained by altering the kerogen molecular type, expecting to achieve more physically and theoretically similar to the realistic shale matrix. After that, methane flow simulation is performed by utilization of non-equilibrium molecular dynamics, the methane density as well as velocity distribution under different displacement pressures are depicted. Furthermore, detailed discussion with respect to the simulation results is provided. Results show that (a) displacement pressure acts as a dominant role affecting methane flow velocity and, however, fails to affect methane density distribution, a behavior mainly controlled by molecular–wall interactions; (b) the velocity distribution feature appears to be in line with the parabolic law under high atmosphere pressure, which can be attributed to small Knudsen number; (c) the simulation time will be prolonged with larger displacement pressure imposed on nanoconfined methane. Accordingly, this work can provide profound basis for accurate evaluation of nanoconfined gas flow behavior through shale matrix.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Surprisingly, the successful development of shale gas reservoirs, with the help of hydraulic fracturing technology, changes the overall energy landscape of the world, accounting for the 40% of natural gas production according to the 2016 reports, and it shares potential to further climb up to 45% in 2035 (Cao et al. 2019; Collell et al. 2015; Hughes 2013; Li et al. 2016a, 2016b). Thus, a clear understanding and comprehensive knowledge about the inherent fluid flow mechanisms inside shale reservoirs turns to be more and more urgent and crucial, which however is still a challenging issue and remains to be properly addressed (Sun et al. 2017, 2018a, 2018b; Tang et al. 2018a, 2018b; Whitby et al. 2008; Wu et al. 2019b). In accordance with the well-acknowledged research, shale rock can be classified as organic matter and inorganic matter, both of which possess inherent super heterogeneity feature and therefore are hard to be precisely characterized (Li et al. 2019; Xiong et al. 2019b). Moreover, the pore dimension in the above both matters fall into the typical nanoscale, ranging from several to thousands of nanometers, where the wall–molecule interactions will take the pronounced role affecting fluid flow performance (Feng et al. 2016; Huang et al. 2018a, 2018b). In contrast, the wall–molecule interactions can be overlooked in macroscopic scale; the classic NS equation, designed to capture fluid flow behavior in large scale, has not considered the interaction. Hence, the complexity induced by heterogeneity as well as ultra-small pore scale renders the flow behavior inside realistic shale matrix extremely difficult to be identified (Feng et al. 2020; Ji et al. 2021a, b; Li et al. 2021). Other than that, in light of the broad application scope, lots of research attention have been attracted on this heat research topic. In this paper, the emphasis is the methane flow performance through realistic shale matrix under different displacement pressures, mimicking the gas production from the shale reservoirs. Also, a theoretical framework for realistic shale matrix nanopores, constructed by kerogen molecules, is proposed and shares the obvious advantage for reproducing basic surface wettability, roughness in shale than previous work.

There exist many excellent methods to shed light on the methane flow capacity through shale matrix, which can be generally divided into four major categories, including laboratory experiments, analytical theoretical method, lattice Boltzmann method, as well as molecular dynamics simulations. As for the laboratory experimental method, membrane filled with nanoscale pores, similar to shale matrix featured with nanopores, is utilized to investigate the methane flow flux under various circumstances, including pressure, temperature, pore size distribution. Guo et al., (2015) investigated the nitrogen flow through membranes with diverse pore throat sizes (20, 55, and 100 nm) based on experimental apparatus, and an apparent permeability model is established based on experimental data. Wang et al., (2019) developed a novel experimental method to determine permeability of tight porous media. Although a great deal of experimental efforts has been conducted and related reliable results have been achieved, the experiments for porous media with nanopores are expensive and time-consuming to examine an equilibrium flux at a certain pressure difference (Wu et al. 2013; Majumder et al. 2005; Sun et al. 2019a, 2019b). The fatal deficiency of the experimental method is the limitation of atmosphere pressure, the shale gas reservoirs have fairly high pressure; however, current experimental devices are hard to achieve and remain it. Additionally, the data accuracy measured from experimental investigation heavily depends on apparatus up to date (Qiu et al. 2019; Ji et al. 2021a, b; Zhao et al. 2019; Zhao and Huang 2021) and is still unfavorable, especially for the nanoscale experiments. In contrast, on the basis of relative mature theory and reasonable assumptions, a lot of analytical models have been proposed to capture multiple gas flow mechanisms or fluid storage modes inside both shale organic/inorganic matrix, encompassing gas adsorption, surface diffusion, water distribution features, wall roughness (Sheikholeslami et al., 2020, 2021a, 2021b). Notably, each theoretical model has its own applicable criterions or suitable conditions and may fail to generate desirable results, particularly at nanoscale pores (Bao et al. 2017a, 2017b; Wang et al. 2017). As a result, the analytical models, coupling classic theories and multiple key flow mechanisms, inevitably suffer limitations for practical application toward realistic cases. Recently, lattice Boltzmann method is widely applied to describe the fluid flow capacity through nanopores by modifying the slip boundary of N-S equation (Chen et al. 2015; Zhang et al. 2018a, 2018b, 2018c). However, it is important to highlight that lattice Boltzmann equation is proposed to solve fluid flow issues at mesoscale; therefore, the applicability will be dramatically weakened for nanoconfined fluid flow. Although newly discovered physical equations or phenomenon can be incorporated into the lattice Boltzmann equation, it is still challenging to ensure the reliability and accuracy of the results predicted from this approach. In terms of the aforementioned brief review, it demonstrates that laboratory experiments, analytical models, and lattice Boltzmann equations are difficult to simulate the nanoconfined fluid flow performance. Especially for shale gas reservoirs, featured with nanopores with different surface wettability and complex attributes, applicability of the above methods breaks down (Zafar et al., 2021; Zuo et al. 2020). Thus, it is significantly urgent to seek another sensible pathway to address this issue.

Stemming from the fundamental Newton’s second law and well-developed empirical force field parameters for various atoms, molecular simulation is almost regarded as the most reliable technical tool to investigate fluid interactions and flow behavior at molecular scale and nanoscale (Ho et al., 2019; Kazemi and Takbiri-Borujeni 2016; Tesson and Firoozabadi 2018; Ungerer et al. 2014; Wang et al. 2016; Wu and Firoozabadi, 2019a; Xiong et al. 2019a, Zeng et al. 2018; Sun 2019b). Under the solid theoretical background, molecular simulation data share high credibility; also the reliability of molecular simulations has been verified frequently compared with experimental results across abundant application industries. Molecular dynamics simulation is able to capture molecular interactions at atom scale, which is the key aspect affecting nanoconfined gas flow behavior, and the other methods fail to characterize this point. Currently, the majority of molecular simulation investigations about shale matrix focused on the fluid adsorption characteristics inside kerogen (organic matter) or inorganic matter. In addition, some scholars use the graphene-based nanopore to study the fluid flow feature through shale organic matter, rather than kerogen molecules. The graphene-based nanopore is constructed by smooth carbon nanotube, the surface wettability, chemistry, and roughness considerably differed compared to realistic shale matrix nanopore. It can be attributed to the complexity for constructing a sensible shale matrix with composition of amorphous kerogen molecules. As a result, with the intent of elaborating methane flow behavior through realistic shale organic matrix, the knowledge gap toward the construction of matrix nanopore should be filled at first. A simple while practical method is proposed here, a series of NVT and NPT ensembles for desirable atmosphere conditions, to construct nanopore by compressing kerogen molecules, the nanopore maturity can be adjusted by altering kerogen type. Then, methane flow simulation is performed by utilization of non-equilibrium molecular dynamics (NEMD), methane density and velocity distribution under different displacement pressure presented. Furthermore, nanopore geometry, pore radius, displacement pressure are considered seriously in this simulation study.

The paper content is arranged following the way below. The nanopore construction method with the use of kerogen molecules is introduced at first, laying the physically basis for this work. Then, based on the kerogen nanopore and NEMD, gas flow behavior, mainly the density and velocity distribution feature, through shale organic nanopore is revealed. After that, limitations of this research and prospect in terms of the domain are discussed from our best knowledge. Finally, several key insights are drawn.

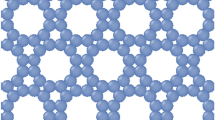

Construction of nanopores inside kerogen matrix

Nanopore construction work is necessary and performed before the molecular simulation at nanoscale. As for the organic matter, little research efforts have devoted to kerogen nanopores; the nanopore surrounded by kerogen molecules, sharing the natural similarity compared to shale rock. With the help of large-scale atomic/molecular massively parallel simulator (LAMMPS), 30 kerogen molecules can be compacted, and the realistic shale matrix can be obtained under several NPT (isothermal–isobaric with a constant molecular number) ensembles. Notably, the molecular structure of Kerogen I-A, able to reach an excellent match with that of experimental data for realistic kerogen molecules, is collected from Ungerer er al (2014). Detailed structure of a single kerogen molecule is provided in Fig. 1 on the left. Total 30 kerogen molecules are inserted into a relatively large simulation box to generate an initial low-density value, as it is shown in Fig. 1 on the right. Multiple tests demonstrate that the initial low density is beneficial for low-energy system, as well as quick stable state (Sun et al. 2020). Simulation box is set as a cubic box with side length of 200 Å, which is larger than that in existed documents and appears to have a positive impact on obtainment of the stable configuration. The initial system density is about 0.03 g/cm3.

Also, boundary condition at the all three directions of the simulation box is set as periodic boundary. Notably, both the methane molecules and kerogen molecules are assigned with CVFF force field by using Molecular Studio software. The force field has been frequently utilized to characterize the molecular behavior of kerogen, which shows pretty good feasibility. The deviation may take place and enlarge if an inappropriate force field is selected; other force field parameters can be utilized to enhance the calculation accuracy. Other than that, the cutoff distance for short-range interactions inside the simulation box is assigned as 9.5 Å. And the long-range interactions are calculated with the utilization of particle–particle/particle-mesh method.

After several cycles of NVT as well as NPT ensembles, the system will approach stable state with the desirable atmosphere temperature and pressure; the duration lasts 12 h in this paper and fluctuates based on the computational power. With the high-pressure value set in NPT ensemble, the entire simulation box will shrink, and overall density will gradually increase. The temperature at the final step of construction process is set as 400 K, a typical shale gas reservoir temperature with depth of 2000 m, and the corresponding pressure will be stable at 200 Bar. The side width of the final simulation box is about 66 Å, and the skeletal density of kerogen is close to 1.06 g/cm3. The skeletal density is a critical indicator to examine the reliability of the constructed nanopore, supposed to be close to realistic shale matrix. Wu et al., (2019a, b) have compacted 60 type-II kerogen molecules, and the final density is 1.03 g/cm3. And the kerogen matrix established by Collell et al., (2015) achieves an average density of 0.96 g/cm3. Thus, the density generated from this research work is close to that from previous scholars, which means that the configuration of kerogen matrix is relatively reasonable. As depicted in Fig. 2 on the left, the matrix has been presented, and a circular nanopore with radius of 1 nm at the center of matrix is shown. Notably, the nanopore inside kerogen matrix is obtained by inserting some dummy atoms at the initial configuration and remaining positions of these atoms unchanged during the above ensembles. Finally, removing dummy atoms leads to the vacant circular space, forming the kerogen nanopore eventually. After that, placing specified numbers of methane molecules during NVT ensemble will lead to a certain atmosphere pressure when the simulation becomes stable, which can also be called as the equilibrium molecular dynamics (EMD). Kerogen molecules will be set as fixed after kerogen nanopore is obtained; only the position or velocity of methane molecules will change based on the specific NVT or NPT ensemble. The molecular configuration at the final step of EMD is provided in Fig. 2 on the right.

Gas flow simulations

After the above EMD simulation, the organic nanopore, kerogen nanopore in this paper, in shale is constructed. Then, NEMD starts by adding a body force at a specific direction on the methane molecules inside the circular nanopore space. Notably, attracted by the surrounding kerogen molecules, several methane molecules may enter into kerogen matrix during EMD simulation. And these methane molecules will hardly return to the circular nanopore and will not be assigned with the additional force during NEMD simulation. In this work, two sets of force are set, including 0.0005 kcal/mol/Å and 0.001 kcal/mol/Å, which is referred as small and large force, respectively, in the following technical context. The NEMD is mimicked at a constant temperature controlled by a thermostat. Special attention should be arisen that velocity in the flow direction is excluded for the computation of system temperature. Moreover, during NEMD simulation process, the kerogen matrix is remained as stationary, meaning the kerogen matrix is set as a rigid body with zero velocity. All the methane molecules are free to move, adsorption/desorption within the entire system. Generally speaking, NEMD will take longer time to reach an equilibrium than that of the EMD simulation, because the stream velocity is not easy to form with the interference of thermal velocity, especially when the small additional force is imposed. Based on the statistics, the equilibrium time for large force in this paper is about 5 ns and that for small force is about 7 ns. Anyway, both the two cases with different forces are simulated with 10 ns, ensuring the whole system reaches the equilibrium and the results can make sense. More importantly, associated flow behavior data of the final 2 ns are collected for further analysis. In addition, methane velocity and density contours are extracted, which are shown in the following part.

Results and discussion

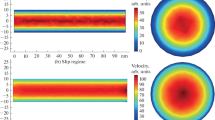

First of all, methane flow behavior under large displacement force is presented; the corresponding velocity and density contour from NEMD are depicted in Fig. 3. Observing the technical content in velocity contour in Fig. 3 on the left, it can be demonstrated that high velocity value will tend to take place at the center of the nanopore, and the methane velocity at the vicinity of kerogen surface will close to zero. Basically, the methane adsorption will happen near the kerogen surface, its thickness approaches several methane molecular diameters, and the adsorption methane is believed to lose mobility. One feature should be highlighted that the system pressure at this paper is about 65 MPa, the high-pressure atmosphere for shale gas reservoirs. And the pore radius of the circular nanopore is about 1 nm. As for the velocity contour, it can be further demonstrated that the actual flow region is smaller than the pore cross section, which means that methane velocity is zero with a distance away from the pore surface, about 5 Å in this research, instead of the nanopore boundary. Analyzing the velocity contour in Fig. 3, it can be further concluded that the methane flow in nanopores has the similarity with that of continuum flow to some extents, which seems to obey the parabolic principle. The phenomenon may be the results from the high pressure, which will lead to low Knudsen number, defined as a ratio of molecular mean free path to nanopore size, for methane flow in nanopores. The fluid flow will be dominated by continuum flow when Knudsen number falls into the range lower than 0.001. In the meanwhile, from the density contour shown in Fig. 3 on the right, it can be found that position where density peak occurs is near the pore surface, which can be considered as the adsorption phenomenon induced by interactions between nanopore surface molecules and methane. Combining the two figures in Fig. 3, an interesting conclusion can be drawn that the velocity of adsorption gas, i.e., density peak, is nearly zero, failing to contribute to the overall confined methane flow capacity. Thus, under relatively high pressure, the velocity distribution in nanopores will be like parabolic. In addition, adsorption methane molecules fail to flow like that in the center of the nanopore. However, surface diffusion mechanism, a special interface phenomenon that adsorption molecules may hop and move at the direction of displacement pressure, has been reported. It provides the possibility that adsorption methane can contribute to flow behavior based on surface diffusion; however, this research has not captured this point. More importantly, it can be easily found from Fig. 3 that strong heterogeneous characteristics regarding methane density takes place, different from homogeneous feature generated from the graphene-like material. From analysis, the heterogeneous features are originated from the heterogeneous nature of kerogens, which is exactly the characteristics of realistic shale matrix, i.e., the well-acknowledged fact that highly heterogeneity exists. And the research content in this paper can present the characteristics directly, sharing the advantage over other existed literatures to be more suitable tool to evaluate the fluid flow behavior through actual shale matrix.

When the additional force assigned on the methane molecules becomes small, i.e., small displacement pressure, it is attractive to present the velocity and density contour again. Comparing the output results from large force with that from small force, the effect of pressure difference on nanoconfined methane flow will be clarified. As we all know, at the macroscale where the classic Darcy equation still holds, the velocity profile has a linear positive relationship with pressure difference. Thus, a critical question raised up and required to be properly answered that the relationship will still hold or not. As illustrated in Fig. 4 on the left, the velocity contour feature is overall flat, indicating that pressure difference indeed has a direct positive impact on methane flow velocity. However, it should point out that the linear relationship will break down. Because only the methane molecules inside the nanopore are free to move, the velocity of atoms surrounding the methane in Fig. 4 is zero and stays stationary as the matrix system. From the observations, methane molecules fail to move efficiently under the small displacement pressure; velocity of the entire molecules is close to zero. This phenomenon may be correlated to the minimum displacement pressure, a critical value that fluid flow behavior starts once pressure difference exceeds it, or remains still. The minimum displacement pressure should be mainly affected by pore size, climbing with decline of pore size. As for the nanopores, where surface–molecule interactions are crucial, the surface chemistry, wettability, and roughness may also affect the minimum displacement pressure. The phenomenon requires extensive investigations in the future.

Collecting the methane velocity data of a cross section of the nanopore, the velocity distribution under different displacement pressure can be depicted in Fig. 5. With the large driven force, the velocity profile tends to have a parabolic feature with the fitting coefficient of 0.7489, while the velocity profile under the small driven force fails to capture the parabolic feature, indicating a relatively low fitting coefficient of 0.0387. At the same time, consistent with the above analysis, it can be demonstrated that displacement pressure always acts as a positive factor affecting the overall velocity value. Notably, the positive factor is different from that in classic Darcy equation. Also, it should be noted that the location of 100 Å is the center of the circular nanopore. And the pore radius is about 1 nm, i.e., 10 Å. The occurrence of velocity of methane outside of the nanopores can be observed in Fig. 5. This phenomenon can be attributed to the attraction of kerogen molecules toward methane during the NEMD simulation process. Finally, for Fig. 6, representing the density distribution in the nanopore with different driven forces. It can be observed that the two lines nearly coincide with each other, manifesting the density distribution will not be affected by pressure difference. The deviation between the both two lines is calculated and depicted in Fig. 6 as the pink line; the deviation is always close to zero. It suggests that pressure difference has little influence on the density distribution of methane molecules inside the nanopore. It further reflects that the dominant role played by surface–molecule interactions on fluid molecular distribution features.

Limitations and prospects

The investigation of nanoconfined gas flow behavior in shale matrix is meaningful, especially with nanopores constructed by kerogen molecules, rather than regular carbon-based material. This research provides a general technical framework to shed light on fluid behavior, including phase behavior, original distribution, and flow performance, in realistic shale matrix or coal matrix. However, several limitations should be highlighted here and researchers with interests should pay uttermost attention. At first, although the kerogen nanopore shares the evident advantage over carbon-based nanopore, the concrete difference between kerogen nanopore and realistic organic pore is still unclear and requires quantification. Actually, a certain amount of asphalt exists in shale organic matter, while the paper content fails to cover this point. After that, the pore geometry in the paper is considered as circle; actually many kinds of geometry are discovered for organic pores, like triangle, ellipse. Notably, kerogen nanopore with various pore geometry can be achieved by the proposed method by altering the geometry of the inserted dummy atoms in Section Construction of nanopores inside Kerogen matrix. Finally, shale matrix is composed by a lot of kerogen nanopores; the flow behavior through single nanopore is hard to represent that in shale matrix. Basically, changing the way inserting dummy atoms at the initial simulation system, shale matrix with complex spatially distribution can be obtained. As the research provides a pathway to construct porous media more similar to shale organic matter, the upcoming research can use the kerogen-based nanopore or nanoporous media to investigate interesting nanoconfined fluid behavior.

Summary and conclusions

-

A circular nanopore with radius of 1 nm surrounding with 30 type I kerogen molecules is constructed in this paper. Then the methane flow simulation is conducted with the utilization of NEMD nested in LAMMPS. Compared with the graphene-like material, the nanopore surrounded with several kerogen molecules is similar to the realistic shale organic pores regarding surface chemistry, which can provide more accurate evaluation about nanoconfined methane flow performance;

-

Skeleton density of the obtained shale matrix is nearly 1.06 g/cm3 at a normal atmosphere condition, clarifying its reliability by agreements with previous contributions. Two sets of force are added on the methane molecules inside the circular nanopore, i.e., 0.0005 kcal/mol/Å referred as small force and 0.001 kcal/mol/Å referred as large force. NEMD will take longer time to reach an equilibrium state than that of the EMD simulation, because the stream velocity is not easy to form with the interference of thermal velocity;

-

Under large driven force, the velocity distribution appears to obey the parabolic law, which can be attributed to low Knudsen number at the high atmosphere pressure, close to 65 MPa. It suggests that pressure difference acts as a dominant role affecting methane flow velocity; methane mobility is almost lost under small displacement pressure. Also, pressure difference fails to influence the density distribution, which is considered to be mainly controlled by the molecular–surface interactions.

References

Bao A, Gildin E (2017a) Data-driven model reduction based on sparsity-promoting methods for multiphase flow in porous media. In SPE Latin America and Caribbean petroleum engineering conference. Society of Petroleum Engineers.

Bao A, Hazlett RD, Babu DK (2017b) A discrete, arbitrarily oriented 3D plane-source analytical solution to the diffusivity equation for modeling reservoir fluid flow. SPE J 22(05):1–609

CaoJ, Liang Y, Masuda Y, Koga H, Tanaka H, Tamura K, Takagi S, Matsuoka T (2019) Molecular simulation of methane adsorption behavior in Kerogen nanopores for shale gas resource assessment. In: International petroleum technology conference. International Petroleum Technology Conference.

Chen L, Zhang L, Kang Q, Viswanathan HS, Yao J, Tao W (2015) Nanoscale simulation of shale transport properties using the lattice Boltzmann method: permeability and diffusivity. Sci Rep 5:8089

Collell J, Galliero G, Vermorel R, Ungerer P, Yiannourakou M, Montel F, Pujol M (2015) Transport of multicomponent hydrocarbon mixtures in shale organic matter by molecular simulations. J Phys Chem C 119(39):22587–22595

Feng D, Li X, Li J, Zhang K, Miao Y, Shi J, Sun Z, Zhang T, Li P, Liu D (2016) Investigation of gas-water distribution characteristics in Kerogen pores: a view of intermolecular surface force. In: Unconventional resources technology conference, San Antonio, Texas, 1–3 August 2016 (pp 2580–2596). Society of Exploration Geophysicists, American Association of Petroleum Geologists, Society of Petroleum Engineers.

Feng P, Chang H, Liu X, Ye S, Shu X, Ran Q (2020) The significance of dispersion of nano-SiO2 on early age hydration of cement pastes. Mater Des 186:108320. Doi: https://doi.org/10.1016/j.matdes.2019.108320

Guo C, Xu J, Wu K, Wei M, Liu S (2015) Study on gas flow through nano pores of shale gas reservoirs. Fuel 143:107–117

Ho TA, Wang Y (2019) Enhancement of oil flow in shale nanopores by manipulating friction and viscosity. Phys Chem Chem Phys

Huang L, Ning Z, Wang K, Wang Q, Sun Z, Sun F(2018a) Geochemistry and microstructure characterization of Kerogen in Chinese cambrian shale: a combined experimental and molecular simulation study. In: AAPG ACE.

Huang L, Ning Z, Wang Q, Ye H, Wang Z, Sun Z, Qin H (2018b) Microstructure and adsorption properties of organic matter in Chinese Cambrian gas shale: experimental characterization, molecular modeling and molecular simulation. Int J Coal Geol 198:14–28

Hughes JD (2013) Energy: a reality check on the shale revolution. Nature 494(7437):307

Ji X, Cheng Y, Tian J et al (2021) Structural characterization of polysaccharide from jujube (Ziziphus jujuba Mill.) fruit. Chem Biol Technol Agric 8:54. Doi: https://doi.org/10.1186/s40538-021-00255-2

Kazemi M, Takbiri-Borujeni A (2016) Flow of gases in organic nanoscale channels: a boundary-driven molecular simulation study. Energy Fuels 30(10):8156–8163

Li J, Li X, Wang X, Li Y, Wu K, Shi J, Yang L, Feng D, Zhang T, Yu P (2016a) Water distribution characteristic and effect on methane adsorption capacity in shale clay. Int J Coal Geol 159:135–154

Li J, Li X, Wu K, Wang X, Shi J, Yang L, Zhang H, Sun Z, Wang R, Feng D (2016b) Water sorption and distribution characteristics in clay and shale: effect of surface force. Energy Fuels 30(11):8863–8874

Li J, Wu K, Chen Z, Wang W, Yang B, Wang K, Luo J, Yu R (2019) Effects of energetic heterogeneity on gas adsorption and gas storage in geologic shale systems. Appl Energy 251:113368.

Li X, Yang H, Zhang J, Qian G, Yu H Cai J (2021) Time-domain analysis of tamper displacement during dynamic compaction based on automatic control. Coatings, 11(9). Doi: https://doi.org/10.3390/coatings11091092

Sheikholeslami M, Jafaryar M (2020) Nanoparticles for improving the efficiency of heat recovery unit involving entropy generation analysis. J Taiwan Inst Chem Eng 115:96–107. https://doi.org/10.1016/j.jtice.2020.09.033

SheikholeslamiM, Jafaryar M, Said Z, Alsabery AI, Babazadeh H, Shafee A (2021a) Modification for helical turbulator to augment heat transfer behavior of nanomaterial via numerical approach. Appl Thermal Eng 182:115935. Doi: https://doi.org/10.1016/j.applthermaleng.2020.115935

Sheikholeslami M, Farshad SA (2021b) Numerical simulation of effect of non-uniform solar irradiation on nanofluid turbulent flow. Int Commun Heat Mass Transf, p 105648. Doi: https://doi.org/10.1016/j.icheatmasstransfer.2021.105648

Majumder M, Chopra N, Andrews R, Hinds BJ (2005) Nanoscale hydrodynamics: enhanced flow in carbon nanotubes. Nature 438(7064):44

Qiu X, Tan SP, Dejam M, Adidharma H (2019) Experimental study on the criticality of a methane/ethane mixture confined in nanoporous media. Langmuir 35(36):11635–11642

Sun Z, Li X, Liu W, Zhang T, He M, Nasrabadi H (2020) Molecular dynamics of methane flow behavior through realistic organic nanopores under geologic shale condition: pore size and kerogen types. Chem Eng J 398:124341

Sun Z, Li X, Shi J, Zhang T, Sun F (2017) Apparent permeability model for real gas transport through shale gas reservoirs considering water distribution characteristic. Int J Heat Mass Transf 115:1008–1019

Sun Z, Shi J, Wu K, Li X (2018a) Gas flow behavior through inorganic nanopores in shale considering confinement effect and moisture content. Ind Eng Chem Res 57(9):3430–3440

Sun Z, Shi J, Wu K, Xu B, Zhang T, Chang Y, Li X (2018b) Transport capacity of gas confined in nanoporous ultra-tight gas reservoirs with real gas effect and water storage mechanisms coupling. Int J Heat Mass Transf 126:1007–1018

Sun Z, Shi J, Wu K, Zhang T, Feng D, Huang L, Shi Y, Ramachandran H, Li X (2019a) An analytical model for gas transport through elliptical nanopores. Chem Eng Sci 199:199–209

Sun Z, Wu K, Shi J, Zhang T, Feng D, Wang S, Liu W, Mao S Li X, (2019b) Effect of pore geometry on nanoconfined water transport behavior. AIChE Journal.

Tang J, Wu K, Li Y, Hu X, Liu Q, Ehlig-Economides C (2018a) Numerical investigation of the interactions between hydraulic fracture and bedding planes with non-orthogonal approach angle. Eng Fract Mech 200:1–16

Tang J, Wu K, Zeng B, Huang H, Hu X, Guo X, Zuo L (2018b) Investigate effects of weak bedding interfaces on fracture geometry in unconventional reservoirs. J Petrol Sci Eng 165:992–1009

Tesson S, Firoozabadi A (2018) Methane adsorption and self-diffusion in shale kerogen and slit nanopores by molecular simulations. J Phys Chem C 122(41):23528–23542

Ungerer P, Collell J, Yiannourakou M (2014) Molecular modeling of the volumetric and thermodynamic properties of kerogen: Influence of organic type and maturity. Energy Fuels 29(1):91–105

Wang J, Yu L, Yuan Q (2019) Experimental study on permeability in tight porous media considering gas adsorption and slippage effect. Fuel 253:561–570

Wang S, Javadpour F, Feng Q (2016) Fast mass transport of oil and supercritical carbon dioxide through organic nanopores in shale. Fuel 181:741–758

Wang S, Shi J, Wang K, Sun Z, Zhao Z (2017) New coupled apparent permeability models for gas transport in inorganic nanopores of shale reservoirs considering multiple effects. Energy Fuels 31(12):13545–13557

Whitby M, Cagnon L, Thanou M, Quirke N (2008) Enhanced fluid flow through nanoscale carbon pipes. Nano Lett 8(9):2632–2637

Wu Q, Ok JT, Sun Y, Retterer ST, Neeves KB, Yin X, Bai B, Ma Y (2013) Optic imaging of single and two-phase pressure-driven flows in nano-scale channels. Lab Chip 13(6):1165–1171

Wu T, Firoozabadi A (2019) Effect of microstructural flexibility on methane flow in Kerogen matrix by molecular dynamics simulations. J Phys Chem C 123(17):10874–10880

Wu Y, Cheng L, Huang S, Bai Y, Jia P, Wang S, Xu B, Chen L (2019a) An approximate semianalytical method for two-phase flow analysis of liquid-rich shale gas and tight light-oil wells. J Petrol Sci Eng 176:562–572

Wu Y, Cheng L, Huang S, Fang S, Jia P, Rao X (2019b) An analytical model for analyzing the impact of fracturing fluid-induced formation damage on rate transient behavior in tight formations. J Petrol Sci Eng 179:513–525

Ji X, Peng B, Ding H, Cui B, Nie H, Yan Y (2021) Purification, structure and biological activity of pumpkin polysaccharides: a review. Food Rev Int. Doi: https://doi.org/10.1080/87559129.2021.1904973

Xiong H, Devegowda D, Huang L (2019a) EOR solvent-oil interaction in clay-hosted pores: Insights from molecular dynamics simulations. Fuel 249:233–251

Xiong H, Huang S, Devegowda D, Liu H, Li H, Padgett Z (2019b) Influence of pressure difference between reservoir and production well on steam-chamber propagation and reservoir-production performance. SPE Journal.

Zafar Said L, Sundar S, Tiwari AK, Muhammad Ali H, Sheikholeslami M, Bellos E, Babar H (2021) Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys Rep. Doi: https://doi.org/10.1016/j.physrep.2021.07.002

Zeng K, Jiang P, Lun Z, Xu R (2018) Molecular simulation of carbon dioxide and methane adsorption in shale organic nanopores. Energy Fuels 33(3):1785–1796

Zhang T, Li X, Li J, Feng D, Wu K, Shi J, Sun Z, Han S (2018a) A fractal model for gas–water relative permeability in inorganic shale with nanoscale pores. Transp Porous Media 122(2):305–331

Zhang T, Li X, Shi J, Sun Z, Yin Y, Wu K, Li J, Feng D (2018b) An apparent liquid permeability model of dual-wettability nanoporous media: A case study of shale. Chem Eng Sci 187:280–291

Zhang T, Li X, Wang X, Li J, Sun Z, Feng D, Huang L, Yao T, Zhao W (2018c) A discrete model for apparent gas permeability in nanoporous shale coupling initial water distribution. J Natural Gas Sci Eng 59:80–96

Zhao X, Huang B, Xu J (2019) Experimental investigation on the characteristics of fractures initiation and propagation for gas fracturing by using air as fracturing fluid under true triaxial stresses. Fuel 236:1496–1504

Zhao X, Huang B (2021) Distribution relationship of pore pressure and matrix stress during hydraulic fracturing. ACS Omega. https://doi.org/10.1021/acsomega.1c04268

Zuo Y, Jiang S, Wu S, Xu W, Zhang J, Feng, R.,... Santosh, M. (2020) Terrestrial heat flow and lithospheric thermal structure in the Chagan Depression of the Yingen-Ejinaqi Basin, north central China. Basin Res 32(6):1328–1346. https://doi.org/10.1111/bre.12430

Acknowledgements

Thanks for the conference lecture (SPE-198230). This is an improvement, and the full copyright of presentation has been reverted to the original owner. We also acknowledge China University of Mining & Technology for the permission to publish this work.

Funding

The research was supported by National Natural Science Foundation Projects of China (No. 52104099) and Natural Science Foundation Projects of Jiangsu Province (No. BK20210508). The first author also acknowledges the Fundamental Research Funds for Central Universities (No. 2021QN1059) to support part of this work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

None is declared.

Ethical statement

On behalf of all the co-authors, the corresponding author states that there are no ethical statements contained in the manuscripts.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sun, Z., Huang, B., Li, Y. et al. Nanoconfined methane flow behavior through realistic organic shale matrix under displacement pressure: a molecular simulation investigation. J Petrol Explor Prod Technol 12, 1193–1201 (2022). https://doi.org/10.1007/s13202-021-01382-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-021-01382-0