Abstract

Petroleum exploration and production business thrives with in-depth knowledge and understanding of the subsurface. Technological advancement has helped in furnishing the industry with much information about the petroleum reservoir; however, a lot of uncertainties still exist due to the nature of the subsurface. The industry has strived to address this problem in diverse ways; regrettably, the classical methods relied upon have failed to provide a proper guide to management decision in exploiting these reservoirs. In recent times, artificial intelligence techniques, particularly Fuzzy Logic (FL), have been identified as a potential tool to deal with the uncertainties encountered in most exploration and production (E&P) operations. This research provides a review of FL applications in E&P operations under non-deterministic input parameters, possible challenges and solution procedures using FL sensitivity analysis and rule viewers. The focus is on reservoir characterization for reservoir evaluation, drilling/completion operations and stimulation treatment. The study also examines the extent FL could be applied to extract useful information from the large volume of historical oil and gas data already on the shelf and the future gaps to fill. A case study was presented which considered cost optimization in Liquefied Petroleum Gas (LPG) distribution operations using fuzzy logic.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The concept of FL was introduced to model uncertainties (Zadeh 1965, 1996, 1997). Most uncertainties associated with complex systems such as petroleum systems are as a result of imprecision, the failure to carry out the requisite measurements, lack of awareness or fuzziness (Mohaghegh 2000). Human way of reasoning is not crisp. Humans see multitude of possibilities beyond black or white, true or false, ones or zeros computer way of reasoning. Consequently, there is lack of exact correlation between the fuzzy process/vagueness of such human reasoning and the characteristic scientific method of assigning a value of zeros and ones computer approach (Mohaghegh 2000). Fuzzy logic is very distinct in the sense that problems arising from values, ideas, beliefs, judgement, indecision, doubt, uncertainty and probabilities can be effectively solved using fuzzy inference system unlike any other model (Kosko 1993). Some authors are of the opinion that probability is an integral part of fuzzy logic and could serve as a replacement for fuzzy logic (Kosko 1993). There is a clear distinction between fuzzy logic problem and probability problems (Zadeh 2002). The mathematics of fuzzy cannot be described in terms of probability distributions (Klir and Yuan 1995). Studies have shown that the classical probability theory that is based mainly on the concept of randomness is different from fuzzy concept of uncertainty (Chen et al. 1995). Modeling with the application of fuzzy logic is much better and superior to probability modeling because probability modelling is applicable to stochastic-related problems (Kosko 1993). According to Ross (1995), the technique of fuzzy theory is a perfect means of addressing uncertainty associated with information deficit, complexity, inaccuracy of data sets of most problems encountered in the industries. Proper formulation of fuzzy logic rules with the right input variables and rule viewer has eliminated the rigor and hassle of developing mathematical models for solving problems. The conventional rule-based systems have not been able to integrate the human reasoning and computer reasoning in such a manner that computers could assist humans in decision-making when confronted with an infinite number of possibilities. Fuzzy logic has successfully filled this gap. To model uncertainty, fuzzy logic makes use of fuzzy sets. Elements of sets with degrees of membership functions are generally known as fuzzy sets. A membership function allows for the fuzzification of both input and output variables (Popa 2013). With fuzzy rules generated and alpha-cuts taken from membership function, sensitivity analysis of input values is carried out to generate a robust output response.

Merit and demerit of fuzzy logic

Fuzzy logic is more like everyday experience as related to human decision-making. The fuzzy inference system (FIS) logic is very helpful in regulating and managing incomplete information (Bello et al. 2016). Hamdi-Cherif (2010) cited by Zoveidavianpoor et al. (2012) listed merits and demerits of Fuzzy Logic to include the following: (a) Merits: FL mathematical models are veritable means for transforming human reasoning into useful set of rules that could easily be implemented using computer; fuzzy logic models are capable of handling any non-linear problems; FL models are vital techniques in addressing complex stochastic problems that cannot be solved by ordinary mathematical models; fuzzy logic models are robust and find application under information deficit scenarios; fuzzy models are adjudged as appropriate tools in generic decision-making.

(b) Demerits: some of the disadvantages include the fact that experts involved in problem-solving usually have challenges in organizing their thoughts; there may be bias and inconsistencies; another problem with fuzzy logic is the fact that increase in the number of fuzzy subsets per input variable causes exceptionally high increase in the number of rules. This could result in constraint buildup. These disadvantages notwithstanding, fuzzy logic systems have been applied successfully in different areas of research such as manufacturing companies, oil exploration and production operations, transportation problems, chemical industries and so many other areas of human endeavours (Park et al. 2010).

Common applications of fuzzy logic models

Hybrid systems

The limitations of fuzzy logic and other AI techniques led to further research endeavours on how to reduce the impact of these limitations. One major breakthrough was the introduction of hybridization. Hybridization is the concept of combining two or more artificial intelligence techniques. The rationale behind hybridization is to complement the weakness of one technique with the strength of another. In recent times, the popularity of hybrids has increased and has been attributed to extensive success in many real-world complex problems (Giovanni and Vincenzo 2005). Fuzzy logic has been widely applied in hybrid systems. Hybrid systems combining fuzzy logic with other AI techniques such as neural networks, genetic algorithms and support vector machines have been applied in E&P operations. Common examples include neuro-fuzzy systems, support vector machine–fuzzy system, and genetic algorithm–fuzzy logic hybrid.

The neuro-fuzzy system

The combination of fuzzy logic and neural networks is called neuro-fuzzy and combines the advantages of the two (Von Altrock 1995). Neuro-fuzzy system is a hybrid system that combines the self-training abilities of ANN and the unique knowledge representation and inference capabilities of fuzzy logic. The use of neuro-fuzzy hybrid system provides an alternative for pattern recognition, clustering, statistical and mathematical modeling (Jang 1991&1992). It has been applied in different oil and gas operations. For example, Alimonti and Falcone (2004) applied artificial neural networks and fuzzy logic to multiphase-flow metering to provide a real-time monitoring of produced flow rates and stream composition. Okwu and Olufemi (2017) conducted a study by optimizing the cost of distribution of multiple products to multiple destinations using adaptive neuro-fuzzy inference system (ANFIS). Zarei et al. (2008) applied a neuro-fuzzy approach in well-placement optimization. The study showed that the application of neuro-fuzzy technique resulted in time saving in the analysis which was necessary for the success of optimization algorithm. Nikravesh and Aminzadeh (2001) used neuro-fuzzy technique to develop an optimum set of rules for nonlinear mapping between porosity, grain size, clay content, P-wave velocity, P-wave attenuation and permeability. The rules developed from a training set were used to predict permeability in another data set. The prediction performance was very good. The study also showed that the integrated technique discovered clear relationships between P-wave velocity and porosity, and P-wave attenuation and clay content, which were useful to geophysicists. The quest for higher performance accuracy in the prediction of target properties is the main driver for hybrid systems. However, it is important to ensure that the combination is not just for the sake of itself but rather to benefit from the strength offered by the combined technologies and that each hybrid component has a contribution in the solution to the target problem.

Fuzzy c-means

Fuzzy c-means (FCM) is a data clustering technique wherein each data point belongs to a cluster to some degree that is specified by a membership grade. Bezdek (1981) originally introduced the technique as an improvement on earlier clustering methods. The method shows how to group data points that populate some multidimensional space into a specific number of different clusters. Fuzzy c-means is a well-known fuzzy clustering technique that generalizes the classical c-means algorithm and can be used where it is unclear how many clusters there should be for a given set of data (Chiu 1994). Fang and Chen (1997) applied fuzzy rules to predict porosity and permeability from five compositional and textural characteristics of sandstone in the Yacheng Field (South China Sea). The five input attributes were the relative amounts of rigid grains, ductile grains and detrital matrix, grain size and the Trask sorting coefficient. All the porosity and permeability data were first divided into a certain number of clusters by fuzzy c-means. The corresponding sandstone characteristics for each cluster were used to general the fuzzy linguistic rules. Each fuzzy cluster produced one fuzzy if–then rule with five input statements. The formulated rules were then used to make linguistic prediction by combining individual conclusion from each rule. Nikravesh et al. (2000) applied k-clustering, neural networks and fuzzy c-means techniques to characterize a field that produces from Ellenburger Dolomite. They used the techniques to perform clustering of 3D seismic attributes and to establish relationships between the clusters and the production log. The production log was established away from the wellbore. They were able to identify the optimum locations for new wells based on the connectivity, size and shape of the clusters related to the pay zone. IIkachi et al. (2006) used data from three wells of an offshore gas field in Iran to construct fuzzy logic models of the reservoir. They applied fuzzy c-means clustering technique for rock type classification using porosity and permeability data. Permeability was modeled and predicted using Takagi–Sugeno fuzzy inference system. Their results showed that fuzzy logic approach was successful in predicting permeability of rocks in the gas reservoir. Fuzzy c-means is thus a vital technique with the capability of identifying structures in data from the large volume of historical oil and gas data currently residing in E&P companies’ data bases. Pattern recognition and classification will help to achieve a concise representation of a petroleum reservoir’s behaviour which will lead to efficient and cost-effective hydrocarbon recovery.

Application of fuzzy logic in E&P

The application of fuzzy logic cuts across different areas of engineering. Decision-makers solve problems on a daily basis using essentially quantitative information obtained. Solving real-life and industrial problems, therefore, require quantitative information (Tianhua et al. 2012). Fuzzy logic helps to guarantee precision and quality and to avoid inconsistency and uncertainty (Bilgen, 2010). Fuzzy logic applications in E&P operations have been reported in different areas such as engineering design and control (Nikravesh et al. 1997; Sengul and Bekkousha 2002; Mohaghegh et al. 2005; Widarsono et al. 2005; Cao et al. 2006; Taheri 2008; Weiss et al. 2001; Zarei et.al. 2008; Murillo et al. 2009) and also in operations of production facilities, systems and optimal well operations (Rivera and Farabee 1994; Dumans 1995; Xiong et al. 2001; Alimonti and Falcone 2004; Garrouch and Lababidi 2005) and in economic analysis (Zolotukhin 2000; De Salvo; Castro and Fereira Filho 2010; Agbon and Araque 2003; Chang et al. 2006), in scheduling (Seyed 2015) and other engineering fields (Amit and Zhiling 2012; Balendra et al. 2013; Tu-chungchu and Rangnathvarma (2012); Binay 2013; Mohammed and Salman 2014; Vladyslav et al. 2015; Nwoha et al. 2016). Additional areas where fuzzy logic has been used extensively in the literature are reservoir characterization, drilling and completion, and simulation treatment. Fuzzy logic application in distribution operations, which is the major focus of this research, has not been given adequate attention as there exists diminutive information in the open literature.

Application of fuzzy logic in reservoir characterization

Reservoir characterization is a process for quantitatively assigning petroleum reservoir properties such as porosity, permeability, fluid contacts and many other properties needed to understand hydrocarbon reservoirs (Mohaghegh et al. 1996). It also involves recognizing geologic information uncertainties and spatial variability. Good reservoir characterization is vital to hydrocarbon production optimization. The industry has various means of evaluating a given reservoir, but taking a core sample from a formation is one of the best options and always recommended. The information gathered from core analysis include porosity, fluid content and saturation, permeability, relative permeability, mineral composition, particle size distribution and rock strength. While many of these properties aid in evaluating the ability of the reservoir to store and produce hydrocarbons, others such as mineral composition and rock strength help to achieve successful drilling and production operations. Hu et al. (2017) classified minerals in petroleum reservoirs as water-sensitive minerals, salinity-sensitive minerals, acid-sensitive minerals, alkaline-sensitive minerals and minerals sensitive to flow velocity. For instance, knowledge of mineral composition, particularly clay type and distribution of the formation of interest will aid in the design of non-damaging drilling fluids and also help to plan a successful treatment for either acidizing or hydraulic fracturing jobs. Also information about the rock strength will assist in planning the correct drilling fluid density, wellbore stability issues and sand control techniques. Thus information from core analysis will not only evaluate a given reservoir but will also help to optimize well operations. Till date, it is impossible to core every well because coring is time consuming and expensive. This presents a problem when an accurate 3D static model of a field is required because the availability of cores is limited compared to the number of wells in the field. Reservoir characterization is oftentimes challenging and complicated due to the nonlinear and heterogeneous physical properties of the petroleum reservoir rock. These issues can easily be addressed accurately and efficiently by the use of computer-based artificial intelligence methods such as neural networks, fuzzy logic and genetic algorithm. Artificial neural network or genetic algorithm, however, cannot effectively handle uncertainties that exist whenever there is insufficient information, inability to perform adequate measurements or imprecision (Moghghegh 2000). In recent times, however, fuzzy logic has presented the industry with a new interpretation technique that fully accounts for uncertainty to predict reservoir parameters such as permeability and lithofacies in uncored but logged wells (Cuddy 2000; Hambalek and Gonzalez 2003; Taghavi 2005; Shokir 2006; Abudulraheem et al. 2007). Saggaf and Nebrija (2003) listed the advantages of fuzzy logic in categorizing rock types from wireline logs. Their study showed that fuzzy logic can predict rock types from wells that do not have any core samples with acceptable accuracy compared to the conventional statistical methods. This is a cost-saving technique for the industry and should act as a catalyst for future research in the area of FL applications in E&P companies. Cuddy (2000) reported a study where fuzzy logic technique was successfully used to derive information about lithofacies and permeabilities in 30 uncored wells by applying knowledge gained from only 10 cored wells. When compared with neural network models, fuzzy logic gave much better predictions. The FL-predicted model yielded robust results. The applications of fuzzy logic could be extended to core refinement interpretations where the subjective nature of the measurement gives rooms for errors (Cuddy 2000). Fuzzy logic technique has also been useful in describing different rock types (Hamidi et al. 2010). They stated that the existing methods of classifying rocks were based on sharp transitions which may not exist in all cases. In contrast, fuzzy logic does not require any such simplifying conditions and has proved to be a better option in differentiating between rock types. Fuzzy logic regression approach has been found to be superior to conventional regression analysis especially where there is uncertainty in the available data (Chen et al. 1995). They applied a fuzzy regression approach to determine the parameters of an Archie equation when the differences between the observed and simulated values were traceable to many causes such as measurement errors and vagueness of variables in the model. Another area where fuzzy logic has been applied in reservoir characterization is to classify reservoir properties with directional dependency or anisotropic in nature. Zhangguli et al. (1998) combined fuzzy logic and geo-statistics to characterize the anisotropy and quantify the spatial correlations that exist among the reservoir properties. The result was then used to predict the permeability distribution in a reservoir. The advantage of fuzzy logic over other techniques in reservoir characterization is the fact that it is not affected by data deficit which is a serious challenge at the early stages of reservoir exploitation. Fuzzy logic does not require any prior assumption about physical or experimental considerations of reservoir complexities to build a true model from a set measured data (Shokir 2006). As far as reservoir characterization is concerned, fuzzy logic is a vital tool that has the capacity to integrate a large number of input logs and could be applied in fields containing hundreds of wells in a very short time with minimal user intervention because the need for making cross-plots has been eliminated (Cuddy 2000). Reservoir characterization is a good means of understanding our petroleum reservoir so as to be better positioned to get maximum benefit during its productive life. Achieving maximum benefit entails a consideration of inherent error associated with any physical measurement, recognition of uncertainties arising from the complex nature of petroleum reservoirs as well as the ability to tackle information gap/deficit. Fuzzy logic has done exceedingly well in this regard. However, future researches should be focused on the use of hybrid systems to complement the deficiencies of fuzzy logic with the strength of other AI methods such as ANN and GA. Although some hybrid systems have been built, their potentials in extracting useful relationships between reservoir data types and performing reliable extrapolation away from the wellbores have not been fully explored. Given the amount of relevant data the E&P industry has accumulated over the years, research on how to adapt these data to present and future uses using AI hybrid systems that incorporate fuzzy logic will decrease risk and provide better insight for improved reservoir characterization for both green and brown fields.

Applications of fuzzy logic in drilling and completion

Fuzzy logic is mostly applied to partially depleted or depleted reservoir intervals. After some reservoirs have been depleted, we often discover that there are still large volumes of recoverable oil left. The choice of drilling method to adopt in such situations does not always come easy although experience has shown that underbalanced drilling works best in depleted or low-pressure reservoirs as well as in reservoirs that are prone to formation damage. In some situations, the applicability of underbalanced drilling is not as clear-cut such as low-pressure reservoirs with fractures, very high permeability reservoirs and extremely high-pressure formations. In such situations, fuzzy logic becomes a veritable tool. Garrouch and Labbabidi (2003) applied fuzzy logic in selecting underbalanced drilling (UBD) candidates, underbalanced drilling technique and fluid type. They obtained good results in the two case studies reported; one a highly depleted and damaged reservoir interval while the other is a low-pressure fractured and vuggy limestone reservoir. In partially depleted reservoirs, fuzzy logic has been applied in infill drilling applications. Infill drilling helps in the recovery of bypassed reserves and could be optimized if the inherent uncertainties in reservoir properties/geology are incorporated using fuzzy logic. Popa (2013) presented a case where they applied fuzzy logic model to horizontal well identification using a complex 3D full field earth model developed with data from more than 21,000 wells. He reported that the application of fuzzy logic for horizontal well identification maximized production outcome of the field. This was attributed to its ability to focus on high potential areas, flexibility as well as being more realistic. Garrouch and Lababidi (2005) applied a fuzzy expert system to some heavy-oil-producing formations which were exploited with multilateral wells. FL was used to plan the wellbore geometry and completion strategies of the multilateral wells. They stated that in situations where operational conditions were constrained, the fuzzy expert system could help drilling engineers in decision-making on the best drilling options to adopt.

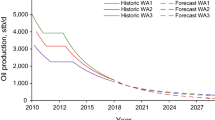

Drilling operations often encounter some drilling problems such as differential pipe sticking. Avoidance of such problems could minimize drilling cost and optimize drilling operations. Murillo et al. (2009) combined discriminant function analysis, neural network and fuzzy logic to evaluate the risk of stuck pipe during the well planning process and the actual drilling operation in real time. Wu et al. (1997) compared statistical recovery forecast models and fuzzy-logic recovery forecast models for primary, initial waterflooding and infill drilling ultimate oil recovery. They concluded that fuzzy-logic recovery forecast models developed using variables identified from statistical approach provided the best results.

Fuzzy logic applications in the area of drilling/completion by virtue of addressing uncertainties in reservoir quality, heterogeneity, identification of areas of high potentials, avoidance of drilling problems have greatly improved infill drilling projects for maximum benefits. However, fuzzy logic applications in drilling operations have not been fully exploited. The various aspects of drilling operations such as well planning, drilling optimization, well integrity, operational troubleshooting, drilling problem detection and decision-making all have some measure of uncertainties. Fuzzy logic and/or hybrids of other artificial intelligence with fuzzy logic should be considered as a means of improving performance.

Applications of fuzzy logic in stimulation treatment

Well stimulation is a very important technique in crude oil production, especially for damaged and/or very tight reservoirs. Achieving success in well stimulation requires proper candidate well selection and treatment design. Conventional method of candidate well selection for hydraulic fracturing is complex and does not have a well-defined globally accepted approach (Zoveidvianpoor et al. 2012). Fuzzy logic technique has filled that gap. Researchers have demonstrated that fuzzy logic could be applied successfully in stimulation candidate well selection (Xiong and Holditch 1995; Yang 2009; Yin and Wu 2009; Zoveidvianpoor et al. 2012). In 1995, Xiong and Holditch designed well stimulation treatment with the aid of fuzzy logic model. They developed eight fuzzy evaluators that were able to select wells that are candidates for stimulation, select optimal type of stimulation treatment, diagnose the type of damage affecting the formation, evaluate rock layers that could be barriers to fracture propagation and also select appropriate treatment fluids and additives. Yang (2009) established a fuzzy model for selecting wells and oil layers to be fractured. His fuzzy mathematical model was used to choose target well and formation for hydraulic fracturing from a set of fuzzy variables. The proposed system performed better than the current imprecise approaches. Yin and Wu (2009) established fuzzy mathematical model for selecting fracturing candidate wells based on quantitative analysis of the main factors of influencing the fracturing effects and parameters. Rivera et al. (1994) designed a fuzzy logic system to control the pressure during fracturing stimulation. The main aim was to solve the problem of controlling fluids at the throttling valve. Zoveidavianpoor et al. (2012) trained a Mamdani fuzzy system model which they applied in candidate well selection for hydraulic fracturing (HF) in a fractured carbonate reservoir. They reported that this system could assist in selecting and ranking the high-priority well for HF treatment. In all these studies, the researchers demonstrated that fuzzy logic is one artificial intelligent technique that could be utilized to obtain more value addition in the area of well stimulation of oil and gas reservoirs. Suitably designed well stimulation process has three main objectives: design of the stimulation treatment, selection of the specific treatment and selection of candidate wells. Although fuzzy logic techniques have been applied successfully in the selection of specific treatment and candidate well selection, little information is available in the literature on the design of stimulation treatment using fuzzy logic. Future research pathways for fuzzy logic applications in well stimulation should consider the design aspect where there are a lot of uncertainties which are better handled using fuzzy logic models.

Application of fuzzy logic in petroleum distribution operations

Distribution of petroleum products also requires creative algorithm for effective delivery. Not too many researchers have looked in this direction though a lot have been done using fuzzy logic in product allocation and cost optimization of fast-moving consumer goods, bottling companies and other manufacturing industries. A display of the application of fuzzy logic in effective product distribution in Liquefied Petroleum Gas (LPG) operations is demonstrated in this article.

Application of fuzzy logic in LPG distribution operations

Fuzzy set distribution model

The study applies fuzzy set to trans-shipment model using data from three LPG plants. The Mamdani model was used with input parameters defined and membership functions were created with well-defined rules simulated in the fuzzy logic system. Standard membership function was applied in the fuzzy set to describe the factors in the overall trans-shipment, demand at the trans-shipment point (TP), anticipated products available at the three plants and the unit cost of distribution from plants to TP.

Experiments and discussion

The case scenario presented is a three source (LPG plants) located in Warri, Delta State, Nigeria. To expand the system, it became necessary to create two trans-shipment points (TP) within the conurbation to enable customers at strategic locations have access to available products at favorable cost. Products can flow from any of the three sources to the two TP. Fuzzy logic rule is suggested for effective facility design. Table 1 shows a clear illustration of products available at the source and demand at all trans-shipment points within the period of investigation.

Parameters

Production facility: 3.

Total TP = 2.

Demand at TP1: 1710 items per week.

Demand at TP2: 1290 items per week.

Periodic availability of item at Plant 1 = 1290.

Periodic availability of item at Plant 2 = 780.

Periodic availability of item at Plant 3 = 930.

\({C_{ij}}\) is the unit cost of transporting available product from source i to TP j.

X is the decision variable representing the amount of product transported from source i to TP j.

The unit cost of distributing items from plant or source to TP 1 and TP2 is shown in Table 2.

Procedure for using fuzzy logic to address distribution problems with non-deterministic inputs

In effective design and simulation of fuzzy logic system, the input and output variables were defined, membership function was created, fuzzy rules were defined and results generated.

The architecture of the input output system was developed as shown in Fig. 1. Rules were perfectly created and defined using the rule editor. With the graphical user interface as simulink input, an initial fuzzy model was derived to trigger the modelling process. The model is required for the selection of appropriate input variable, input space partitioning and choosing the number and type of membership function (MF). The membership function used is the Gaussian MF. The unit cost of distribution of products to each depot and the demand at different depots represent the input variables. The solution was mapped out into FIS model explained in linguistic term of “WHAT IF” rule. The architecture of the Mamdani model is suitable for effective facility design using FIS as demonstrated in Fig. 1. Membership function associated with the fuzzy inference system and variables are stated clearly in Figs. 2, 3.

Analysis and result

The developed fuzzy model is highly efficient and creative, it involves a creative algorithm capable of fine-tuning parameters using dataset provided by taking alphacuts from membership functions based on linguistic terminologies with good adjustments and robust solutions. The control surface plot in Fig. 4 graphically represents all possible inputs and outputs in terms of cost, demand and supply. It is a three-dimensional case scenario since there are two input variables (cost and demand) and one output signal (supply). For example, graph (a) shows that when C14 is low and C35 is low, then product flow to TP1 is high. For graph (b), when C15 is high and C35 is high then product flow to TP1 is high. For graph (c), at very low cost, C34 and high cost, C35, product flow to TP1 is low. For graph (f), at high cost, C34 and very low cost C35, product flow to TP2 is very high. The results obtained from the sensitivity rule viewer of Fig. 5 are presented in Fig. 6a, b. All the products needed at trans-shipment point 1 were supplied from sources 2 and 3. Source 1 supplied products to trans-shipment point 2. Source 2 supplied 7800 products to trans-shipment point 1 at a total cost of ₦7800. Source 3 supplied 930 products to the same trans-shipment point 1, at a total cost of ₦12,090. Also all the products needed at transshipment point 2 were supplied from source 1 at a total cost of ₦12,900. The overall cost of supply from sources 1, 2 and 3 is ₦32,790.

The following symbolizations were implemented in graphical fuzzy model.

SP= Supply point

TP1=Trans-shipment Point 1

TP2=Trans-shipment Point 2

C1=Unit cost from SP to TP1

STP1= Total supply to TP1

STP2= Total supply to TP2

Total cost of Supply from SP to TP 1 = ₦19890

Total cost of Supply from SP to TP 2 = ₦12,900

Total cost of supply from sources to trans-shipment points Z_pi

Total cost of supply from sources to transshipment points Zpi

Conclusions

In this paper, key issues related to fuzzy logic applications in E&P operations have been discussed. It is important to note that fuzzy logic applications hold potentials in E&P operations. Most significant is the application of fuzzy logic in reservoir characterization, drilling and completion, simulation treatment, distribution operation under non-deterministic or stochastic environment. The uncertainties arise from difficulties of obtaining data, errors in measurement, imprecision or vagueness. In summary, this paper demonstrates the need for a paradigm shift from conventional methods and rule of thumb allocation in distribution operations to global techniques of solving problems in the industry, especially the oil and gas sector. A case study was presented in this paper considering cost optimization in LPG distribution operations using fuzzy logic. However, using fuzzy logic as a creative and intelligent technique has helped in effective product allocation and cost optimization of LPG products. FL is highly recommended for addressing problems in a system with uncertainties.

References

Abdulraheem A, Sabakhi E, Ahmed M (2007) Estimation of permeability from wireline logs in a middle eastern carbonate reservoir using fuzzy logic. SPE 105350 presented 15th SPE Middle East Oil and Gas Show

Agbon IS, Araque JC (2003) Predicting oil and gas spot prices using chaos time series analysis and fuzzy neural network model. Paper SPE 82014 presented at the SPE Hydrocarbon Economics and Evaluation Symposium, Dallas. https://doi.org/10.2118/82014-MS

Alimonti C, Falcone G (2004) Integration of multiphase flow-metering, neural networks and fuzzy logic in field performance monitoring. SPE Prod 19(1):25–32

Amit k, Zhiling G (2012).Applied fuzzy logic approach to intergraded qualitative survey data into Traditional MCDM. Hawaii International conference on System Sciences.7

Balendra B, Anil SY, Rammohan SB (2013) Transportation system of coal distribution: a fuzzy logic approach using MATLAB. Corona J Sci Technol ISSN(2):2319–6327 20–30.

Bello O, Teodoru C, Yaqoob T, Oppelt J, Holzmann J, Obiwanne A (2016) Application of artificial intelligence technique in drilling system design and operations: a state of the art review and future research pathways. SPE paper 184320-MS presented at SPE Nigeria Annual International Conference and Exhibition held in Lagos, Nigeria

Bezdek JC (1981) pattern recognition with fuzzy objective function algorithms. Plenum Press, New York

Binay A (2013) Modeling The Impact of transportation on public health using Fuzzy Logic, Mastersdegree research presented at the University of Texas at Arlington

Cao D, Ni Y, Yao F, Weng D, Fu G (2006) Application and realization of fuzzy method for selecting welss and formations in fracturing in putaohua oilfield: productions and operations: diagnostic and evaluation. Paper SPE 106355 presented at the SPE Technical Symposium of Saudi Arabia Section, Dhahran, Saudi Arabia. https://doi.org/10.2118/106355-MS

Cao et al (2010a) Developed a stochastic chance constrained mixed-integer nonlinear programming models to solve the refinery short-term crude oil scheduling problem. Zandhessami et al. (2011) proposed a hybrid ANP and fuzzy goal programming to select the best supplier

Cao C, Gu X, Xin Z (2010b) Stochastic chance constrained mixed-integer nonlinear programming models and the solution approaches for refinery short-term crude oil scheduling problem. Applied Mathematical Modeling

Chang Y, Dou H, Chen C, Wang X, Liu K (2006) An innovative method: risk assessment for exploration and development of oil and gas. Paper SPE 104458 presented at the SPE regional Meeting, Canton, Ohio, 11–13 October. https://doi.org/10.2118/104458-MS

Chen HC, Fang JH, Kortright ME, Chen DS (1995) Novel approaches to the determination of archie parameters II: fuzzy regression analysis” SPE paper 28287, SPE Advanced Technology Series, Vol 3, No 1 pp 44–52

Chiu S (1994) “Fuzzy Model Identification Based on Cluster Estimation” Journal of Intelligent and Fuzzy Systems, Vol. 2 (3)

Cuddy SJ (2000) Litho- Facies and Permeability Prediction from Electrical Logs using Fuzzy Logic. SPE Reservoir Eval&Eng 3(4):319–324

De Castro AO, Fereira Filho VJM (2010) The use of fuzzy mathematics of finance: risk evaluation in petroleum development. Paper SPE 69556 presented at the SPE Latin American and Caribbean Petroleum Engineering Conference, Buenos Aires. https://doi.org/10.2118/69556-MS

Dumans CFF (1995) quantification of the effect of uncertainties on the reliability of wellbore stability model predictions. PhD thesis, University of Tulsa, Tulsa

Fang JH, Chen HC (1997) Fuzzy modelling and the prediction of porosity and permeability from the compositional and textural attributes of sandstone. J Pet Geol 20:185–204

Garrouch AA, Lababidi HMS (2003) Using fuzzy logic for UBD candidate selection. IADC/SPE Underbalanced Technology Conference and Exhibition, Houston Texas, 23–26 March

Garrouch AA, Lababidi HMS (2005) Implementation of a fuzzy expert system for multilateral well completion case studies. SPE 93930 presented at SPE Europe/EAGE Annual Conference held in Maldrid, Spain

Giovanni A, Vincenzo L (2005) Using FML and fuzzy technology in adaptive ambient intelligence environments. Int J Comput Intell Res 1:171–182

Gulrajani SN, Nolte KG (2000) Fracture evaluation using pressure diagnostics. Prentice Hall PTR, Upper Saddle River

Hambalek N, Gonzalez R (2003) Fuzzy logic applied to litho-facies and permeability forecasting, case study: sandstone of naricual formation, El Furrial Field, Eastern Venezuela Basin. Paper SPE 81078 presented at SPE Latin American and Carribean Petroleum Engineering Conference held in Port-of-Spain Trindad, West Indies

Hamdi C (2010) Type 2 fuzzy control for bioinformatics—a system approach. Int J Comput Sci Netw Secur 10(7):69–75

Hamidi K, Shahriar J, Rezai B, Bejari H (2010) Application of fuzzy set theory to rock engineering classification systems. An illustration of the rock mass excavability index. Rock Mech Rock Eng 43:335–350

Hu X, Jin HS, F. and Huang S (2017) Physics of petroleum reservoirs http://www.Springer.com/

IIkachi AK, Rezaee M, Moallemi SA (2006) A fuzzy logic approach for estimation of permeability and rock type from conventional well log data: an example from the kangan reservoir in the iran offshore gas field. J Geophys Eng 3:356–369

Jang JSR (1991) Fuzzy modeling using generalized neural networks and kalman filter algorithm. Proc. Ninth Natl. Conf. Artif. Intell. Pp 762–767

Jang JSR (1992) Self-learning fuzzy controllers based on temporal backpropagation IEEE Trans. Neural Networks 3 (5)

Klir GJ, Yuan B (1995) Fuzzy sets and fuzzy logic: theory and applications. Prentice Hall P R T, Upper Saddle River

Kosko B (1993) Fuzzy thinking: the new science of fuzzy logic. Hyperion, New York

Mohaghegh SD (2000) Virtual-intelligence applications in petroleum engineering: part 3- fuzzy logic. SPE 62415, Distinguished Authors Series

Mohaghegh SD, Arefi R, Ameri S, Hefner MH (1996) A methodological approach for reservoir heterogeneity characterization using artificial neural networks. J Petrol Sci Eng 10 (1996):263–274

Mohaghegh SD, Gaskari R, Jalali J (2005) A new method for production data analysis to identify new opportunities in mature Field: method and application. Paper SPE 98010 presented at the SPE Eastern Regional Meeting, Morgantown, West Virginia. https://doi.org/10.2118/98010-MS

Mohammed A, Salman JA (2014) Weighting suppliers using fuzzy inference system and gradual covering in a supply chain network. International Conference on Industrial Engineering and Operations ManagementBali, Indonesia, 2437–2444

Murillo A, Neuman J, Samuel R (2009) Pipe sticking prediction and avoidance using adaptive fuzzy and nueral network modeling. SPE 120128 presented at SPE Production and Operation Symposium held in Oklahoma

Nikravesh M, Aminzadeh F (2001) Mining and fusion of petroleum data with fuzzy logic and neural network agents. J Petrol Sci Eng 29:221–238

Nikravesh M, Dobie CA, Patzek TW (1997) Field-wise waterflood management in low permeability, fractured oil reservoirs: neuro-fuzzy approach. Paper SPE 37523 presented at the International Thermal Operations and Heavy Oil Symposium, Bakersfield, California. https://doi.org/10.2118/37523-MS

Nikravesh M, Adams RD, Levey RA, Ekart DD (2000) Soft computing: tools for intelligent reservoir characterization (IRESC) and Optimum Well Placement (OWP). Internat Mgt Soc Expl Geophys 977–980

Nwoha TC, Ombor. G, Okwu MO (2016) A combined algorithm to fuel consumption rate analysis and prediction to fuel consumption rate analysis and prediction of sea worthy diesel engine powered marine vessel. International Journal of Engineering for the Marine Environment, SAGE, UK, pp 1–131

Okwu MO, Olufemi A (2018) A comparative study of artificial neural network (ANN) and adaptive neuro-fuzzy inference system (ANFIS) model in distribution system with non-deterministic inputs. Int J Eng Bus Manag SAGE 10:1–17

Park H, Lim J, Kang JM, Min H (2010) Production system optimization of gas fields using hybrid fuzzy genetic approach, pp 417–425

Popa AS (2013) Identification of horizontal well placement using fuzzy logic. SPE 166313 presented at SPE Annual Technical Conference and Exhibition, held in New Orleans Louisiana, USA

Rivera VP, Farabee LM (1994) Fuzzy logic controls pressure in fracturing fluid characterization facility. SPE 28239, SPE Petroleum Computer Conference, Dallas, USA

Saggaf M, Nebrija L (2003) A fuzzy Approach for the Estimation of Facies from Wire-line Logs. AAPG Bull 87:1233–1240

Sengul M, Bekkousha MA (2002) Applied production optimization:i-field. Paper SPE77608 presented at the SPE Annual Technical Conference and Exhibition, San Anthonio, Texas. https://doi.org/10.2118/77608

Seyed MH (2015) A fuzzy genetic algorithm for scheduling of handling/storage equipment in automated container terminal. Int J Eng Technol 7(6)

Shokir EM (2004) A novel model for permeability prediction in uncored wells SPE Res Eval&Eng 9(3) 266–273. https://doi.org/10.2118/78038-PA

Taghavi AA (2005) Improved permeability estimation through use of fuzzy logic in carbonate reservoir from Southwest Iran. SPE 93269 presented at the 14th SPE Middle East Oil and Gas Show and Conference held in Bahrain International Exhibition Centre, 12–15 March

Taheri SR (2008) Remote sensing, fuzzy logic and GIS in petroleum exploration. Paper SPE 120199 presented as part of the student paper contest associated with the SPE Annual Technical Conference and Exhibition, Denver

Tianhua W, Mingtian F, Pingyang W, Zongbin Y, Ruili G (2012) Application of Fuzzy logic and transshipment model to spatial load forecasting. Electric Power Research Institute, Qinghe, Beijing, China

Vladyslav S, Oleg N, Valentina F (2015) Application of adaptive neuro-fuzzy regulators in the controlled system by the vehicle suspensioninternational. J Automation Control Intell Syst 1:66–72

Von Altrock C (1995) Fuzzy logic and neurofuzzy application explained. Prentice Hall PRT

Weiss WW, Wo S, Weiss JW, Weber J (2001) Data mining at a regulatory agency to forecast waterflood recovery. Paper SPE 71057 presented at the SPE Rocky Mountain Petroleum Technology Conference, Keystone, Colorado. https://doi.org/10.2118/71057-MS

Widarsono B, Atmoko H, Robinson WIV, Yuwono IP, Tunggal FS, Ridwan T (2005) Application of fuzzy logic for determining production in commingled production wells. SPE 93275 presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta. https://doi.org/10.2118/93275-MS

Wu CH, Lu GF, Yen J (1997) Statistical and fuzzy infill drilling recovery models for carbonate reservoirs. SPE 37728 SPE 16th Middle East Oil Show and Conference

Xiong H, Holditch SA (1995) An investigation into the application of fuzzy logic to well stimulation treatment design. SPE 27672, SPE Computer Applications

Xiong H, Robinson BM, Foh S (2001) Using an expert system to diagnose formation damage mechanisms and design stimualtion treatments for gas storage wells. Paper SPE presented at the SPE Eastern Regional Meeting, Canton, Ohio. https://doi.org/10.2118/72374-MS

Yang E (2009) Selection of target wells and layers for fracturing with fuzzy mathematics method. Papers presented at the Sixth International on Fuzzy Systems and Knowledge Discovery, 366–369

Yin D, Wu T(2009) Optimizing well for fracturing by. Paper presented at the 1st International Conference on Information Science and Engineering (ICISE) 286–369

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Zadeh L (1996) Fuzzy logic equals computing with words. IEEE Trans Fuzzy Syst 4(2):103–111

Zadeh L (1997) Toward a theory of fuzzy information granulation and its centrality in human reasoning and fuzzy logic. Fuzzy Sets Syst 90(2):111–127

Zadeh LA (2002) Toward a perception-based theory of probabilistic reasoning with imprecise probabilities. J Stat Plan Inference 105(1):233–264

ZandHesami H, Afshari M, Ayazi S (2011) A hybrid analytical network process and fuzzy goal programming for supplier selection: A case study of auto part maker. Manag Sci Lett 1(4):583–594

Zarei F, Daliri A, Alizadeh N (2008) The use of neuro-fuzzy proxy in well placement optimization. Paper presented at SPE intelligent energy conference and exhibition held in Amsterdam, Netherlands. https://doi.org/10.2118/112214-MS

Zhanggui L (1998) Integration of fuzzy methods into geostatistics for petrophysical property distribution, SPE 49964, SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia

Zolotukhin HJ (2000) A novel approach to resources and reserves determination. Paper SPE 63199 presented at the SPE Annual Technical Conference and Exhibition, Dallas, 1–4 October. https://doi.org/10.2118/63199-MS

Zoveidavianpoor M, Samsuri A, Shadizadeh SR (2012) Development of a fuzzy system model for candidate-well selection for hydraulic fracturing in a carbonate reservoir. SPE 153200 presented at the SPE Oil and Gas India Conference and Exhibition held in Mumbai, India 28–30

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Okwu, M.O., Nwachukwu, A.N. A review of fuzzy logic applications in petroleum exploration, production and distribution operations. J Petrol Explor Prod Technol 9, 1555–1568 (2019). https://doi.org/10.1007/s13202-018-0560-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-018-0560-2