Abstract

Whether air injection can extract additional oil in high water cut reservoirs is a big question. In this paper, long-core displacement experiment has been carried out to investigate the potential of low oxygen air flooding in high water cut reservoirs. Results indicate that implementing low oxygen air injection has potential to improve oil recovery in high water cut light oil reservoir. The reservoir with higher matrix permeability and or lower reservoir permeability contrast ratio is desirable to achieve higher oil recovery factor. In addition, the oil recovery factor for water/gas alternate injection (WAG) strategy is higher than that of continuous low oxygen air flooding. And the WAG strategy has the ability to delay gas breakthrough compared with the strategy of continuous low oxygen air injection under same experiment condition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Air injection is a good option to enhance oil recovery (EOR) because of its wide availability and low cost, and crude oil can create oxidation reactions to generate flue gas sweep and thermal drive, and the interaction of in situ generated CO2 with crude oil has the potential for IFT reduction, which seems to be a synergic EOR method. In addition, we have proved the evidence of the “bulldozing effect (or pore blocking)” for air injection in light oil reservoirs, which has the potential of redirecting gas flow to improve sweep efficiency (Jia and Sheng 2016). In recent years, low oxygen air injection has been proposed in China in order to replace the conventional air injection from the considerations of the risk reduction and pipeline corrosion. Currently, most oil fields in worldwide use water flooding as the main development strategy after primary depletion stage. Hence, the mature oil field will gradually enter into high water cut production stage, which increases the developing difficulty as well as operation cost to extract residual crude oil. People prefer to adopt polymer and or foam flooding as the tertiary oil recovery method for high water cut reservoir development. However, these technologies are costly and can also bring out groundwater contamination. Besides, chemical additives such as polymer and foaming agent should have favorable adaptability with reservoir conditions (temperature, salinity and pH etc.). With the high demand of crude oil resources, developing high water cut reservoir arouses great attention in the past decades. Whether the low-cost air injection can extract additional oil recovery in high water cut reservoirs is an interesting topic that should be addressed investigation. However, the available literature do not present too much research on the air injection in high water cut reservoirs. The research on oil recovery mechanism of air injection in high water cut reservoir is needed, which can provide a potential EOR method for high water cut reservoir development.

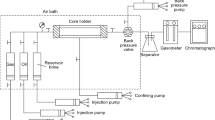

In this study, long-core displacement experiments are conducted to reveal the physical process and recovery mechanism of low oxygen air injection in high water cut reservoir. The variation of system pressure, gas breakthrough time and effluent fluid characteristics are recorded for the analysis on the oil recovery mechanism of low oxygen air injection in high water cut reservoir. To achieve the goal of this study, core flooding apparatus, oil and gas chromatograph (Agilent 7890 B and Agilent 1100 Series, Agilent Technologies, Inc.), gas–liquid separator and Brookfield viscometer DV-III (Brookfield Engineering Laboratories, Inc.) are employed for experimental studies.

Experimental study

Three kinds of synthetic short cores with permeability ranging from 2 to 50 mD and 3.8 cm in diameter, 7.6 cm in length were employed in this study. We use synthetic cores composed by two layers with different permeability to simulate reservoir heterogeneity of different permeability contrast. The permeability contrast is defined as middle-to-low permeability divided by high permeability for the two layers. In this paper, we adopt three permeability contrast value of 1.5, 3.0 and 5.7, respectively. All experimental long core is composed by eleven short cores. The short core sample’s basic parameters are listed in Table 1. Experimental crude oil (Viscosity is 32.6 mPa s at 50 °C, average density at surface condition is around 0.87 g cm−3.) is obtained from Dagang oilfield (Tianjin, China). Lumped hydrocarbon distribution was determined by gas chromatography as shown in Fig. 1. The oxygen mole content of air used in this study had been reduced to 5%. All experiments are conducted under Guan 15–2 reservoir of Dagang oil field condition. The current reservoir temperature is 89.9 °C and average reservoir pressure is close to 20 MPa. Hence, the end piece of core flooding apparatus is set up with backpressure of 20 MPa to simulate reservoir pressure. The viscosity of crude oil was measured by Brookfield viscometer DV-III. And lumped hydrocarbon distribution is determined by oil chromatography. Producing gas was collected and measured by gas meter to calculate GOR (gas oil ratio), and then tested by gas chromatography.

Experimental procedures

① All experimental long cores are first saturated crude oil at original oil saturation; ② and then pumping water with injection rate of 0.125 mL/min to simulate water flooding until water cut approaching to 98%; ③ After setting up all long cores at high water cut, switching to continuous low oxygen air injection with flow rate of 0.125 ml/min at reservoir condition, and the injecting mode of WAG’s water/gas slug is controlled around 0.1 PV (pore volume). ④ Recording all the required data during experimental stages. Experimental flow chart is shown in Fig. 2.

Results and discussion

Effect of reservoir permeability

Analysis of low oxygen air injection performance

The fitted curves display the variation of GOR and pressure difference between inlet and outlet at different injection PV as shown in Fig. 3. The variation trend of the curves significantly reflects the flooding mechanism under different long cores with permeability of 2, 20 and 50 mD. It exhibits that the pressure difference between inlet and outlet initially increasing due to the gas tamponade of pores medium. It is then followed by a sudden decrease caused by gas breaking through. The initial and maximum value of pressure difference between inlet and outlet is increased with the decreasing of long-core permeability. Besides, the reduction rate of pressure difference after gas breakthrough is declined with the decreasing of permeability in above curves. This is because of the naturally bigger throat in higher permeability cores that helps gas flowing. The variation of GOR and pressure difference can help us identify the exact time when gas channeling taken place. In this study, we estimate the first detection of gas at outlet point as the time of gas breakthrough and the sudden sharply increasing of GOR as the time of gas channeling. The injection PV corresponding to gas breakthrough and channeling is listed in Table 2. It is obviously that injection PV of gas breakthrough for the permeability of 2, 20 and 50 mD is 0.25, 0.23 and 0.21 PV, respectively. Likewise, the injection PV of gas channeling for them is 0.58, 0.50 and 0.41 PV. It indicates that, for high water cut reservoir, the lower permeability of the porous media is, the later of gas breakthrough occur is. This is caused by smaller percolation channel of lower permeability cores which obstacle gas streaming in high water cut reservoir. Figure 4 shows the typical long-core photography after experiment. The left of the long core represents inlet, and the right is the outlet. Based on the gradually change of color between two points, gas breakthrough shows negative effect on oil displacement with large quantity of oil sticking in outlet point in later stage of experiment. Hence, the present work can help us further understand of low oxygen air injection process in high water cut reservoirs.

Analysis of oxygen consumption and effluent gas and crude oil

The effluent gas has been analyzed, and the results are listed in Table 2. The effluent CO and CO2 verifies the existence of LTO reactions during low oxygen air flooding in high water cut reservoir as the available literature indicates that CO2 and CO are significant component evidence for bond scission and heat release process (Zhao et al. 2012; Jia et al. 2014; Montes et al. 2010). The maximum value of effluent CO2 for long-core permeability of 2, 20 and 50 mD is 0.45, 0.83 and 1.21%, respectively. And the effluent CO concentration for each test is 0.38, 0.51 and 0.58%. The generation of flue gas is increased with the increasing of core permeability. Higher extent of LTO reaction in higher permeability long cores is responsible for this difference. However, the limit consumption of oxygen reflects the poor oxidation ability of the selecting crude oil in the high water cut condition. Lacking of contacting area for crude oil and gas and or serious heat loss in high water cut reservoir contributes to this weakness.

We observe that the component of effluent crude oil at different period changes rapidly. This is because of the different oil/gas contact time at varying position in long cores. In this study, we divide the hydrocarbon of crude oil into four parts, followed by C1–C6, C7–C16, C 17–C35 and C35+. It can be seen that the hydrocarbon distribution of C1–C16 component content is decreased in all experiments. The medium composition (C7–C16) of 50 mD long core exhibits greater cracking extend. And heavy component is increased. It is deduced that oxygenation reaction products of ketone, aldehyde, acid and other substance in medium component would combine together through the chelation. As we know the effect of chelation can result in carbon chain growth. And we find that the range ability of light composition content is increased with the increasing of core permeability. While, heavy component content displays inverse. This can be an evident for higher extent of oxidation in higher permeability long cores. The variation maximum value of each component is also listed in Table 2.

Analysis of air flooding efficiency

The oil recovery factor for long-core permeability of 50, 20 and 2 mD is 11.74, 10.86 and 6.86%, respectively. The oil recovery factor is increased with the increasing of core permeability, as shown in Fig. 5. As we have discussed above that the oxidation reaction extent in higher permeability cores is higher which is favorable to heat release and generate more flue gas to participate in oil displacement. Although higher extent of oxidation reaction would result in increasing of heavy component, it can plug larger pore throat effectively and low oxygen air has access to flow to fine porosity and improve sweeping efficiency. The increasing of heavy component would lead to “pore blocking.” Some people tend to use “bulldozing effect” to describe the hypothesis. As Jia and Sheng (2016) have verified that temporary pore blocking can redirect gas flow, which can improve volumetric sweep efficiency. Moreover, it has the potential of delaying gas breakthrough due to this gas moving frontal ‘‘self-adjustment.” Therefore, EOR method of low oxygen air injection obtains better performance in higher permeability reservoir.

Effect of heterogeneity and displacement mode

Analysis of consecutive low oxygen air injection displacement

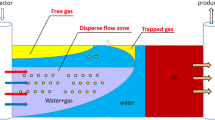

The two mode flooding processes of low oxygen air under different permeability contrast porous media are exhibited in Figs. 6 and 7. The results show that the pressure difference between inlet and outlet performs similar variation trend. With the pressure difference is increased before gas breakthrough is occurred, after which it is sharply decreased. Meanwhile, GOR is increased slightly. And then it is increased rapidly as the gas channeling happens. Injection PV corresponding to the time of gas breakthrough and gas channeling for each test in this section are also summarized in Table 2. In terms of the consecutive low oxygen air injection mode, the injection PV for long cores with permeability contrast of 5.7, 3.0 and 1.5 is 0.23, 0.21 and 0.2 PV, respectively. Although heterogeneity is more serious in pores media with higher permeability contrast, it has immeasurable ability to delay gas breakthrough. Generally, the existent of heterogeneity in porous medium can result in gas flowing to bigger pore throat which has bad effect on its sweeping efficiency and would cause earlier gas breakthrough. The phenomenon found in this work gives a new insight of low oxygen air flooding mechanism in heterogeneity reservoir with high water cut situation. While, whether this hypothesis is reasonable or not need a further investigation. Altering flooding mode to WAG does not change variation trend in terms of injection PV of gas breakthrough discussed above. However, WAG can effectively delay gas breakthrough which is favorable for low oxygen air flooding EOR method (Fig. 8).

Analysis of oil recovery factor

According to Figs. 9 and 10, for continuous flooding mode, the oil recovery factor for the core permeability contrast of 5.7, 3.0 and 1.5 is 6.35, 14.62 and 15.94%, respectively. The oil recovery is sharply increased from 6.35% to almost 16% between permeability contrast of 1.5 and 5.7, which is a nonlinear increasing. The homogeneity long core that discussed in previous chapter whose the water-related permeability is similar to the permeability contrast of 1.5 in this section is around 50 mD. Hence, we compare the oil recovery performance of the two typical experiments. An interesting phenomenon is found that the long core with heterogeneity performs better. This discovery can verify the hypothesis we submit in above section that light existence of heterogeneity is favorable to low oxygen air flooding. Akkutlu and Yortsos (2005) stated that for layered heterogeneous porous media, if the permeability–thickness contrast exceeds the threshold, thermal coupling occurs and the fronts in the different layers travel coherently (with the same speed), which would improve the sweep efficiency and recovery. And Awoleke (2007) also indicated that the ISC can be successfully implemented in reservoir with small-scale heterogeneities (a few inches) and may be challenged by much larger scales (feet). When the flooding mode changed to WAG, the oil recovery factor exhibits slight rises compared with the injection mode of consecutive at same permeability contrast as shown in Fig. 10.

Analysis of oxygen consumption and effluent fluid

The results show that oxygen consumption of experiments in this section is less than 0.65% as listed in Table 2. Compared with tests in last chapter this consumption is also very low. It has further proved that oxidizability of selecting crude oil in high water cut and low oxygen air condition is weak. However, the detection of flue gas demonstrates that LTO reactions are occurred in heterogeneity high water cut reservoir under low oxygen air situation. The generation of flue gas is benefit for EOR performance. Likewise, the analysis of effluent crude oil shows that the content of C1–C16 is decreased. On the contrary, C17+ is increased. Bond session in light components and chelation after oil oxidation in medium components are responsible for this variation. The variation has two benefits as we discussed in previous chapter. First, the increasing of heavy components can delay gas breakthrough; second, it can improve sweeping efficiency. In this work, we find that the variation value is increased with the decreasing of core permeability contrast as shown in Table 2. The variation of effluent gas content shows that experiments of WAG mode have higher extent of oxygen addition and bond scission reaction compared with the experimental results of continuous injection mode.

Conclusions

In this paper, we find that low oxygen air injection displacement efficiency ranges from 6.86 to 11.74% for homogeneous porous medium which is impressive in high water cut reservoir. The pilot crude oil in this research mainly shows oxygen addition reaction with low oxygen consumption is less than 1.2%. The reservoir with higher matrix permeability and or lower reservoir permeability contrast ratio is desirable to achieve higher oil recovery factor. The oil viscosity increased after oxidation which was helpful to prevent gas breakthrough. The existence of heterogeneity is sometimes favorable for oil recovery during low oxygen air injection in high water cut reservoir. The influence of permeability is greater than heterogeneous on oil recovery for low oxygen air injection in high water cut reservoir. Injection mode of WAG has better performance than that of consecutive low oxygen air flooding. WAG could prevent gas breakthrough due to the creative of water/gas slug and results in higher extent of oxidation reaction in high water cut reservoir.

References

Akkutlu IY, Yortsos YC (2005) The effect of heterogeneity on in-situ combustion: propagation of combustion fronts in layered porous media. In: SPE 75128 paper presented at the SPE/DOE symposium on improved oil recovery, Tulsa, Oklahoma, 13–17 April

Awoleke OG (2007) An experimental investigation of in-situ combustion in heterogonous media, In: M.Sc. Thesis, Stanford University, Stanford

Jia H, Sheng JJ (2016) Numerical modeling on air injection in a light oil reservoir: recovery mechanism and scheme optimization. Fuel 172:70–80

Jia H, Ni J, Pu W, Yue P, Jiang H, Yang J (2014) New view on the oxidation mechanisms of crude oil through combined thermal analysis methods. J Therm Anal Calorim 118:1707–1714

Montes AR, Gutierrez D, Moore RG et al (2010) Is high-pressure air injection (HPAI) simply a flue-gas flood? J Can Pet Technol 49(2):56–63

Zhao JZ, Hu J, Pu WF, Wang LL, Peng H (2012) Sensitivity studies on the oxidation behavior of crude oil in porous media. Energy Fuels 26(11):6815–6823

Acknowledgements

This paper is supported by NSFC (No. 51404202) and Sichuan Youth Science and Technology Fund (No. 2015JQ0038).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Jia, H., Yin, SP. & Ma, XP. Enhanced oil recovery mechanism of low oxygen air injection in high water cut reservoir. J Petrol Explor Prod Technol 8, 917–923 (2018). https://doi.org/10.1007/s13202-017-0389-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-017-0389-0