Abstract

In this study, preformed particle gel was prepared from a hydrogel crosslinking of an aqueous solution containing chromium acetate (III) and the co-polymer of 2-acrylamido-2-methyl-propanesulfonic-acid sodium salt (AMPS) and acrylamide (PAMPS). The effects of CaCl2 concentration and pH were investigated on swelling behavior. To determine the significant factors that affect the equilibrium swelling ratio (ESR) and also to develop the quadratic mathematical models, central composite design, the most popular form of response surface methodology, was applied. Therefore, the main purpose was to establish functional relationship between the two factors and the ESR using a statistical technique. The results of analysis of variance of the developed models illustrated that the fitted models were significant with a 99 % confidence limit. The results were also shown that the ESRs depended more on CaCl2 concentration than pH and in the range of 22,500–30,000 ppm concentration of CaCl2 there was also an interaction between these two factors. The optimum ESRs with the purpose of maximizing it based on the model prediction with respect to the selected factors were presented in the absence of CaCl2 concentration and the presence of pH in the range of 5–8.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water production in oil-producing wells becomes a more serious problem as the wells mature. Remediation techniques for controlling water production, generally referred to as conformance control, are selected on the basis of the water source and the method of entry into the wellbore (Reddy et al. 2002). Water shut-off methods can be classified in two different types: mechanical and chemical methods. The mechanical methods are limited to the application of specific completion tools (Vega et al. 2010). On the other hand, the chemical methods, extensively used in the last decade (Sydansk and Southwell 2000; Seright et al. 2003), consist namely of chemical products that are pumped into producer or injector wells. Most of these systems are based on polymer solutions that after a given time from low-viscosity liquids turn to strong or weak gels depending on their formulations, which are the basis of most water shut-off treatments. Several authors have reported the characteristics of gel polymers (hydrogels) utilized for other purposes in detail (Ganji and Vasheghani-Farahani 2009; Rudzinski et al. 2002; Huang et al. 2006). To control water cut and improve the oil recovery of oil fields, many technologies, such as polymer flooding, surfactant flooding, foam flooding, etc. have been widely applied (Liu et al. 2005; Welton et al. 2007; Simjoo et al. 2009). Several authors have also recommended the preformed gel to control conformance in mature oil fields because of their overcoming ability in some distinct drawbacks inherent in in-situ gelation systems (Bai et al. 2007a, b). Preformed particle gels (PPG)—a kind of preformed gel—is an improved super absorbent polymer and primarily used as an absorbent for water and aqueous solutions. PPGs have developed for the conformance control purposed with some suitable properties such as adjustable sizes, swelling ability in formation water, salt resistance, thermal stability, adjustable strength and slightly controlled swelling rate. PPG treatments have been selected because of its some suitable reasons, its unique properties, overcoming some distinct disadvantages and so on (Bai et al. 2008). PPG was developed by some authors (Bai et al. 2007a, b) and also has been applied to control conformance in most of the mature oil fields in China. Moreover, most of the PPG applications have shown positive results (Liu et al. 2006). Feng et al. (2003) demonstrated the microgels as good candidates for water shutoff and profile-control operations while they could be injected easily in porous media without any plugging. Bai et al. (2007a, b) studied the effects of gel compositions and reservoir conditions on PPG properties by evaluating the swollen PPG strength and PPG swelling capacity. They found that although PPG is not sensitive to reservoir minerals and formation-water salinity and also stable over a long period of time, it is strength and size-controlled. Zhang and Bai (2010) studied the quantification of PPG propagation during extrusion through a transport open fracture. They showed that high-concentration brine in preparation of swollen PPG has higher reduction in water permeability than the low-concentration brine. Selection of a polymer gel system for a given well treatment strongly depends on the reservoir conditions such as temperature, salinity, hardness and the pH of the water used for preparation of the gelant; and some other parameters include salinity of the formation water, permeability of the target zone, and the lithology of the formation (Sydansk 1988; Vossoughi 2000; Sydansk 1987; Seright and Martin 1993). Aalaie et al. (2008) investigated the gelation process and effects of clay content and ionic strength and influence of nanoclay content and salt concentration on swelling behavior. They indicated that the swelling ratio of nanocomposite gels in tap-water decreased as the concentration of the clay increased.

Determination of the effect of such parameters as salinity and pH on swelling ratio of PPG is highly significant because of the reservoirs condition. Consequently, in this research, the parameters influencing the equilibrium swelling ratio (ESR) were investigated with the central idea of conducting the least number of experiments. To present the general result, for the range of both of the experimental variables of the studied factors, response surface methodology (RSM) was used to obtain the interactions of CaCl2 concentration and pH. RSM is a collection of useful statistical and mathematical techniques for modeling and analysis of the experiment of our interest with a multi-variable method, optimization toolbox. Central composite design (CCD), as the most popular form of RSM used in the process of optimization studies, is used extensively in building the second-order response surface models (NIST/SEMATECH 2003). Finally, the main purpose of this research was to establish a functional relationship of the ESR in terms of pH and CaCl2 concentration factors via the experimental design matrix proposed by the CCD approach. The significant factors that affect the ESR were presented with the development of a quadratic mathematical model. The optimized model with respect to the selected factors were predicted the maximum ESR for a particular CaCl2 concentration and pH condition.

Experimental measurement remarks

Materials

In this research, the tests were conducted by the use of a co-polymer of 2-acrylamido-2-methyl-propanesulfonic-acid sodium salt (AMPS) and acrylamide (AcA), with an average molecular weight of 8,000,000, sulfonation degree of 25 % and water content of <10 wt %, provided by SNF Co. (France). It is also called sulfonated polyacrylamide (PAMPS), under the trade name of AN125, in powder form. Chromium triacetate, as a metallic crosslinker, purchased from Carlo Erba Co. (Italy), was used in powder (pure) form. CaCl2 of analytical grade, HCl (0.01 M) and NaOH (0.01 M) from Merck Co. (Germany) were used for the preparation of acidic or basic water, respectively.

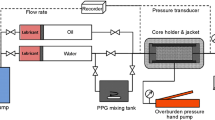

Experimental procedures

To prepare the samples, based on the designed plan, each factor was varied in five levels while the other operational parameters affecting the ESR were kept constant (Table 1). The preformed particle gels were prepared as follows.

At first, the polymer gel was prepared by mixing the PAMPS solution and second solution to obtain a gelant solution. The PAMPS solution was obtained at the concentration of 2 %, by mixing the co-polymer powder and distilled water for the period of 2 h. Shortly before the commencement of the experiment, the PAMPS solutions were diluted to the required concentrations and the mixtures were stirred for 5 min. The second solution was obtained by mixing the Cr(III)-acetate (as crosslinker) and NaCl with acidic or basic water at room temperature, using a heater magnetic stirrer (Stuart CB162, UK) for 5 min.

After the polymer gel formed at 90 °C (because of the temperature of the most of the south Iranian reservoirs which is around 90 °C), gel was dried in the oven. Then the dried gel was pulverized, since the sieve size of the particle gels were screened with the mesh of 80 (Tyler measurement, opening size: 0.177 mm). Moreover, because of the high amount of calcium ion, in contrast with other divalent ions, in formation water of Iranian reservoirs, it was selected to examine its effect on the swelling of the gel.

Swelling of the gel

To measure the ESR, tea bags (i.e., a 100 mesh nylon screen) containing 2 g of the prepared particle gel were immersed entirely in the solution of the acidic or basic water and CaCl2 (according to the experimental design composition presented in Table 2) and allowed to soak for 2, 15, 30, 40 and 50 days to make sure of the equilibrium state. The equilibrated swollen gels were allowed to drain by removing the tea bags from the water and the excess surface water was removed by filter paper. The ESR was measured using the following equation (Aalaie et al. 2008):

where W0 and Ws are the weights of the dry and the swollen gel, respectively.

CCD approach

Central composite design is an efficient, practical method for design and study of an experiment space. It is used to design experiments with a minimum computational expense. CCD was used as the response surface method used for the design of experiments (NIST/SEMATECH 2003). According to the CCD, the total number of experimental combinations is \( 2^{k} + 2k + n_{0} \), where k is the number of independent variables and n0 is the number of repetitions of the experiments at the centre point. For statistical calculation, the experimental variables X i have been coded as x i according to the following transformation equation:

where x i is the dimensionless coded value of the variable X i , X0 is the value of x i at the center point, and \( \delta X \)is the step change. This design consists of the following parts: (1) a full factorial or fractional factorial design; (2) an additional design, often a star design in which experimental points are at the distance from its center (±α); The value of star points can be obtained as well; \( \alpha = 2^{k/4} \), since two factors were used in this study, the value of α was 1.41; (3) a central point. This design consisted of thirteen experimental runs given in Table 2. Enough information could be generated to fit a second-order polynomial called “quadratic”, using these many levels. Standard statistical software can compute the actual fitting of the model. Coded factors can be presented in five levels (\( - \alpha \), −1, 0, +1, \( + \alpha \)). The optimum ESR condition having satisfactory performance can be achieved with minimum number of experiments without any need of studying all possible combinations experimentally (Bezera et al. 2008).

Results and discussion

The selected control factors, CaCl2 concentration (A) and pH (B) are illustrated in Table 1. A wide range of CaCl2 concentration (0–30,000 ppm) was selected to determine its effect on the ESR. Because the acidic and basic pH has different effects on the ESR, we selected a wide range of pH, from low pH (3) to high pH (11).

Modeling process remarks

Thirteen experiments were designed applying the CCD method. Table 2 shows the experimental conditions and their responses. The ESRs were presented after 2, 15 and 30 days, so that the gel-swelling procedure could be studied during this time. It must be mentioned that the results were presented until 30 days, because the ESR stayed constant even after 40 and 50 days (Fig. 1).

To find the mathematical model fitted fine to the results, the results were inserted in “Design Expert (DX)” software (State-Ease, version 7.1.3, USA). Among several possible models, a quadratic model was found to be adequate for the prediction of the ESR which was given by the following equations:

Equilibrium swelling ratio equation | After 2 days | \( {\text{ESR after 2 days }} = \, 0.49 - 0.069A - 2.092 \times 10^{ - 3} B + 2.944 \times 10^{ - 3} AB \) | (3) |

After 15 days | \( {\text{ESR after 15 days }} = 0.65 - 0.12A - 0.018B - 3.55 \times 10^{ - 3} AB \) | (4) | |

After 30 days | \( {\text{ESR after 30 days }} = 0.7 - 0.14A - 0.014B + 3.404 \times 10^{ - 3} AB \) | (5) |

In these models, all variables are indicated through the coded values, where A is CaCl2 concentration and B is pH, and hence, AB is considered as the interaction of the main factors. As can be seen in presented equations, the interaction between variables had significant effects on the responses; so here, the results are preferably presented and discussed in terms of interactions. The statistical significance of Eqs. (3–5) is shown in Table 3, where the mean square, sum of squares and model degree of freedom (DOF) terms are, respectively, defined as the estimation of the model variance, total of the sum of squares for the terms in the model and the number of model terms. DOF shows the total number of model terms, including intercept minus one while mean square estimates the model variance, calculated by the model sum of squares divided by model degrees of freedom.

It is evident that the models are highly significant, as suggested by the model F value and a low probability value (P value). Figure 2 presents the predicted values of the obtained model versus actual values of the experiment’s results of the ESR. The high value of R2, for the developed quadratic models given in Table 3, indicates that the quadratic polynomial was capable of representing the system for the given experimental domain. As presented in Eqs. (3–5) the coefficient of factor A (CaCl2 concentration) was higher than the pH coefficient, so that the effect of CaCl2 concentration was greater than the pH. This result was due to the difference of ionic osmotic pressure between the ionic gel network and the external ionic media of the gels in contrast to the nonionic media of the gel (distilled water), which results in loss of swelling (Aalaie et al. 2008; Vasheghani-Farahani et al. 1990; Aalaie and Rahmatpour 2008).

Figure 3 showed a contour plot and response surface plot of CaCl2 concentration and pH effect on ESR; at a constant pH, the ESR decreased highly by increasing of CaCl2 concentration and gets fairly constant at high concentration of CaCl2.

According to the results trend of ESR versus two factors, CaCl2 concentration has the main effect on ESR of preformed particle gels where the effect of pH is negligible. Figure 3 shows that there was an interaction between these two factors in the range of 22,500–30,000 ppm concentration of CaCl2. The increase in the slope of the response surface plots of Fig. 3b for the CaCl2 concentration in contrast to the pH also confirmed the above results.

Optimization

Finding a desirable location in the design space is the purpose of optimizing the response surface which can be maximum, minimum, or an area where the response is stable over a range of factors. In this research, a simultaneous optimization technique was used (using the DX7 software) for the response optimization. The surfaces generated by linear models can be used to indicate the direction in which the original design must be displaced to obtain the optimal conditions. However, if the experimental region could not be displaced due to physical or instrumental reasons, the researcher must find the best operational condition inside the studied experimental condition by visual inspection.

For quadratic models, the critical point can be characterized as a maximum, minimum, or saddle. Calculating the coordinates of the critical point through the first derivative of the mathematical function is possible which describes the response surface and equates it to zero (Myers and Montgomery 1995). The quadratic function obtained for two variables (x1 and x2), as described below, is used to illustrate the example:

In Eqs. (3–5), a model was presented based on the factors. In Eq. 6, y represented ESR, and x1 and x2 represented CaCl2 concentration and pH consequently. According to the purpose of optimization which was the maximum value for ESR, the three equations (6) for our all three responses simultaneously were solved by the DX7 software with the purpose of maximizing ESR. Finally the extremum values of pH and CaCl2 concentration was presented in Table 4 to show the optimum conditions.

Conclusions

The ESR of preformed particle gels of the PAMPS/Cr(III)-acetate hydrogels was measured as a function of pH and CaCl2 concentration, and their interaction, using the CCD method of RSM. Therefore, a functional relationship between the two factors and the ESR was established using the statistical technique. The results of analysis of variance (ANOVA) of the quadratic model illustrated that the fitted model was significant with a 99 % confidence limit. To indicate the equilibrium time of swelling of the gel, the samples were studied in various times of 2, 15, 30, 40 and 50 days which showed a constant results after 30 days. The results were also shown that CaCl2 concentration has the main effect on ESR of preformed particle gels where the effect of pH is negligible. There was also an interaction between these two factors in the range of 22,500–30,000 ppm concentration of CaCl2. The optimum ESRs of particular CaCl2 concentration and pH condition with the purpose of maximizing ESR were presented based on the model prediction with respect to the selected factors in the absence of CaCl2 concentration and the presence of pH in the range of 5–8.

References

Aalaie J, Rahmatpour A (2008) Preparation and swelling behavior of partially hydrolyzed polyacrylamide nanocomposite hydrogels in electrolyte solutions. J Macromol Sci Part B 47(1):98–108

Aalaie J, Vasheghani-Farahani E, Rahmatpour A, Semsarzadeh MA (2008) Effect of montmorillonite on gelation and swelling behavior of sulfonated polyacrylamide nanocomposite hydrogels in electrolyte solutions. Eur Polymer J 44:2024–2031

Bai B, Li L et al (2007a) Preformed particle gel for conformance control: factors affecting its properties and applications. SPE Reservoir Eval Eng 89389:415–422

Bai B, Liu Y, Coste JP, Li L (2007b) Preformed particle gel for conformance control: transport mechanism through porous media. SPE Reservoir Eval Eng 89468:176–184

Bai B, Huang F, Liu Y, Seright RS, Wang Y (2008) Case study on preformed particle gel for in-depth fluid diversion. In: SPE/DOE improved oil recovery symposium, Tulsa, Oklahoma, USA. 113997

Bezera MA, Santelli RE et al (2008) Review response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76:965

Feng Y, Tabary R et al (2003) Characteristics of microgels designed for water shutoff and profile control. In: SPE international symposium on oilfield chemistry, Houston. 80203

Ganji F, Vasheghani-Farahani E (2009) Hydrogels in controlled drug delivery systems. Iran Polym J 18:63–68

Huang J, Wang XI, Yu XH (2006) Solute permeation through the polyurethane-NIPAAm hydrogel membranes with various crosslinking densities. Desalination 192:125–131

Liu H, Wang J, Yang Y, Wang F (2005) A new method for profile control with compound ion gel before polymer flooding. In: SPE Middle East oil and gas show and conference, Bahrain. 93359

Liu Y, Bai B, Shuler PL (2006) Application and development of chemical-based conformance control treatments in china oil fields. In: SPE/DOE symposium on improved oil recovery, Tulsa. 99641

Myers R, Montgomery D (1995) Response surface methodology: process and product optimization using designed experiments. Wiley, New York

NIST/SEMATECH (2003) Engineering statistics handbook. National Institute of Standards and Technology and the International SEMATECH, USA

Reddy BR, Eoff L, Dalrymple ED, Black K, Brown D, Rietjens M (2002) A natural polymer-based crosslinker system for conformance gel systems. In: SPE/DOE improved oil recovery symposium, Tulsa, Oklahoma, USA. 75163

Rudzinski WE, Dave AM et al (2002) Hydrogels as controlled release devices in agriculture. Design Mon Polym 5:39–65

Seright RS, Martin FD (1993) Impact of gelation ph, rock permeability, and lithology on the performance of a monomer-based gel. SPE Reservoir Eng 8(1):43–50

Seright RS, Lane RH, Sydansk RD (2003) A strategy for attacking excess water production. SPEPF 70067:158–169

Simjoo M, Nick MM, Farajzadeh R, Mirhaj SA, Zitha PLJ (2009) A CT scan study of foam flooding in porous media, international petroleum conference and exhibition, Shiraz, Iran

Sydansk R (1987) Conformance improvement in a subterranean hydrocarbon-bearing formation using a polymer gel. US Patent No. 4683949

Sydansk RD (1988) A new conformance improvement treatment chromium (III) gel technology. In: SPE enhanced oil recovery symposium, Tulsa, Oklahoma. 17329

Sydansk RD, Southwell GP (2000) More than 12 years experience with a successful conformance control polymer gel technology. SPEPF 15(4):270–278

Vasheghani-Farahani E, Vera JH, Cooper DG, Weber ME (1990) Swelling of ionic gels in electrolyte solutions. Ind Eng Chem Res J 29:554–560

Vega I, Morris W, Robles J, Peacock H, Marin A (2010) Water shut-off polymer systems: design and efficiency evaluation based on experimental studies. In: SPE improved oil recovery symposium, Tulsa, Oklahoma, USA. 129940

Vossoughi S (2000) Profile modification using in situ gelation technology: a review. J Petrol Sci Eng 26:199–209

Welton TD, Bryant J, Funkhouser GP (2007) Anionic surfactant gel treatment fluid. In: SPE international symposium on oilfield chemistry, Texas. 105815

Zhang H, Bai B (2010) Preformed particle gel transport through open fractures and its effect on water flow. In: SPE improved oil recovery symposium, Tulsa, Oklahoma, USA. 129908

Acknowledgments

The authors wish to acknowledge the contribution of the Petroleum Engineering and Development Company (National Iranian Oil Co., NIOC) for the financial support of the research. We also thank Dr. Mehdi Sheykhan for interpretation of results in this work.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Mousavi Moghadam, A., Vafaie Sefti, M., Baghban Salehi, M. et al. Preformed particle gel: evaluation and optimization of salinity and pH on equilibrium swelling ratio. J Petrol Explor Prod Technol 2, 85–91 (2012). https://doi.org/10.1007/s13202-012-0024-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-012-0024-z