Abstract

Phenol and its derivatives are pollutants present in the effluents of major industries such as paper mill, oil refineries and petrochemical plants. Removal of phenol from industrial effluent is extremely important because of its toxicity to the aquatic life and environment. In the present study, an attempt has been made to eradicate the phenol from wastewater using isolated bacteria from chronically contaminated effluent samples of a paper mill industry. The pH value of the effluent has been observed to be 8.2. The presence of high concentration of phenol has been observed in the effluent samples. The total sixteen bacterial isolates as obtained were checked for growth on minimal salt medium amended with different concentrations of phenol by flask culture technique. In the present study, the two isolate species of SP-4 and SP-8 were found to be very tolerant to degrade a phenol concentration up to 1800 mg/L.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the rapid increase in population and hasty industrialization in past few decades, the industries have emerged to be critical for the humans and the environment. The effluents from these industries are proved to be the main source of numerous kinds of pollution in natural water. In India, the paper industry consumes a large amount of water and is considered to be the largest water polluting industry (Trivedy and Raj 1992). It is also reported that almost 75–95% of the water discharged as effluent from various industries contains organic, inorganic pollutants and colouring materials. The produced chemicals as pollutants in various forms effect the soil and growth of plants grown on such soils (Baruah et al. 1996).

Pazarlioglu and Telefoncu (2005) reported that the effluents from pulp and paper, oil refineries, polymeric resins, insecticides, pesticides, steel plants, textile, dyes, coal processing and plastics, and pharmaceutical industries contain phenolic compounds as their major constituents. In all the water pollutants, phenol is amongst the most frequent pollutant. Also, phenol and its derivatives can alter the taste and odour of water and make it highly toxic to aquatic life, animals and human beings (Shazryenna et al. 2015). The phenol is a potential carcinogen as it could be absorbed through skin. Also, upon ingestion of phenol by human beings and animals, it can cause vomiting, paralysis, lung failure and cardiac arrest. It has been reported that phenol concentration of 5–25 mg/L can be poisonous or lethal to fishes (Kumar et al. 2005; Dabhade et al. 2006).

The toxic levels of phenol usually range between the concentrations of 10–24 mg/L for human and the toxicity level for fish between 9 and 25 mg/L. Lethal blood concentration of phenol is around 150 mg/100 mL. Due to the toxic nature of phenol, several regulatory bodies all over the globe like the MOEF, GOI, EPA and USEPA listed phenol and phenolic compounds on the priority pollutants list as well as also have proposed maximum permissible limits of phenol in different categories of water. It is very important to remove phenol from contaminated water before discharge into any natural water because of their toxicity to aquatic organisms. It has severe effect on human being, both short and long term (Sonawane and Koreke 2016).

In the present era of industrial and social growth, developing green and sustainable technology for the treatment of industrial effluents is very prominent research area (Kulkarni and Kaware, 2013). Various researchers used versatile phenol removal methods and techniques such as polymerization, electro-coagulation, extraction, and photocomposition, electro-fenton (EF-Fere) method, advanced oxidation processes, adsorption and ion exchange process. These developments are found to be virtuous but pose certain drawbacks in one way or the other. Thakur (2004) reported that the biological treatment methods are known to be efficient and effective in reducing the organic load and poisonous effects of paper mill effluents. A study being conducted by Park et al. (2007) investigated that the microorganisms treats such effluents generally by the processes including action of enzymes and biosorption. The diverse group of enzymes responsible for the treatment of paper mill effluent are lignin peroxidase, manganese peroxidase and laccase (Malaviya and Rathore 2007). Microorganisms enhancing the production of enzymes are found to be effective in treating the industrial effluents containing phenol and its derivatives (Dubey and Hussain 2014). Considering the above-mentioned facts in view, a study was being planned with the objective of isolation and screening of phenol-degrading bacteria from pulp and paper mill effluent.

Materials and methods

Sample collection and analysis

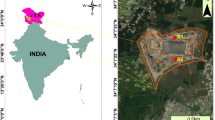

The effluent samples for analysis were collected from a full-scale effluent treatment plant treating paper mill wastewater located at Saharanpur, Uttar Pradesh, India. The samples were collected in screw cap bottles previously cleaned by washing in non-ionic detergent rinsed with tap water and soaked in 10% HNO3 for 24 h prior to final rinsing thoroughly with deionized water. Thereafter, the screw cap bottles were sterilized in autoclave and the collected samples were kept at 4 °C before analysis. The physico-chemical analysis of effluent was carried out as per the methods prescribed in standard methods of APHA (American Public Health Association, 2005). The phenol concentration in wastewater was analyzed using UV–Vis spectrophotometer (Systronics UV–Vis spectrophotometer 118) with 4-aminoantipyrine reagent. All the chemicals used in present study were obtained from Hi-Media Laboratories Pvt. Ltd, Mumbai, India.

For the isolation of pure cultures, serial dilution technique was used for the effluent samples obtained from effluent treatment plant. Pour plating was done from the dilutions 10−6, 10−7 and 10−8 in Petri plates containing minimal salt medium (MSM) at temperature of 37 °C. Thereafter, the appeared single isolated colonies on incubated plates were picked up with the help of sterile nichrome wire and streaked on separate fresh plates of the same medium. These plates were again incubated at 35 ± 2 °C for 24–48 h in incubator to obtain a pure culture.

Media and screening of phenol tolerant bacteria

The strains were screened for phenol tolerance in phenol-amended MSM agar and broth in the presence of 1% glucose (w/v). The medium constituents (g/L) are: Na2HPO4:1.6; KH2PO4:0.4; NH4NO3:0.5; MgSO4.7H2O:0.2; CaCl2:0.025; FeCl3:0.0025; and Agar: 2.0, which was supplemented with varying concentration of phenol (500–2000 mg/L) along with control and with/or without glucose supplementation and pH of the medium was 7.2. Phenol tolerant bacteria were screened from enrichment flask containing MSM with phenol as a sole carbon source. The broth was taken with different concentrations of phenol ranging up to 2000 mg/L. The isolated strains were inoculated into medium with the help of inoculation loop and incubated on a shaking incubator (Biogen) at 125 rpm and 28 ± 2 °C for 48 h in 500-mL conical flasks. Growth of bacterial cells at different phenol concentrations was determined by bacterial turbidity measurement at 610 nm at every 2-h interval up to a 48-h incubation along with control by using UV–Vis Spectrophotometer. The isolates were screened for further studies on the basis of their tolerance to phenol.

The selected isolates were purified by repeated streaking on mineral salt medium containing 100 mg/L of phenol, and the working culture was maintained by culturing in mineral salt medium containing 1000 mg/L of phenol at 2-weeks intervals (Ali et al. 1998).

Result and discussion

Physico-chemical analysis of effluent

The colour of the effluent sample obtained from pulp and paper mill was brown with unpleasant smell. The main problem observed was persistent dark brown colour due to lignin and its derivatives (Madan et al. 2018). Colour derived from lignin indicates the presence of potentially inhibitory compounds, and in addition, it may have direct inhibitory effects on some of the lower organisms in the food chain. Also, odour problem may be due to the presence of high concentration of phenol and its derivatives generally found in pulp and paper mill effluents and are not easily biodegradable. The presence of phenol indicates the high concentration of COD in such type of wastewaters. The physico-chemical parameters of the obtained sample have been determined and are summarized in Table 1. The concentration of total suspended and dissolved solids has been found to be 365 and 2490 mg/L, respectively. This indicates the presence of considerable amount of total suspended solids and total dissolved solids in the pulp and paper mill effluent. These are important parameters for evaluating the suitability of effluent for irrigation purpose as total dissolved solids might clog both the solid pores and component of water distribution system also.

The pH value of effluent has been observed to be 8.2, thus indicating the alkaline range. The discharge of waste water into water bodies may cause a drop or increase in their pH values due to the size and activities of microbial population. The concentration of biochemical oxygen demand and chemical oxygen demand in the effluent as shown in Table 1 has been found to be 1186 and 2748 mg/L, respectively. It indicates the presence of high concentration of organic matter in the effluent sample. The results of sample analysis revealed that thorough treatment of the effluent is required before discharging. Biological method of utilizing specific class of microorganisms is the only choice to treat that type of effluent. This is because the biological system proves to be beneficial for treatment and removal of hazardous substances from the ecosystem (Marihal and Jagadeesh 2013).

Isolation and culture of bacteria from paper mill effluent

The effluent samples in the present study were measured in terms of viable counts per mL of sample. It has been found to be 2 × 104 cells per mL of effluent. The colony forming unit (2 × 104 cells per mL) of the effluent sample has been found to be 2 × 104 cells per mL as extremely low indicating the loss of useful microflora. Haritash and Kaushik (2009) observed that the phenol-degrading enzymes are broadly distributed in different microorganisms that play an important role in the degradation of phenol. Marihal and Jagadeesh (2013) reported the loss of very important microbes due to addition of untreated chemicals and other contaminants.

The enrichment method for isolation has been used in the present study in order to obtain specific bacteria amongst diverse natural population. However, a total of 16 different types of bacterial strains were isolated from the collected effluent sample. For enumeration of bacteria, nutrient agar medium was used. To obtain pure culture, the cultures were repeatedly streaked on nutrient agar medium and incubated at 37 °C for 24 h. Pure culture of all total sixteen bacterial isolates was developed and categorized serially as SP-1, SP-2, SP-3, SP-4, SP-5, SP-6, SP-7, SP-8, SP-9, SP-10, SP-11, SP-12, SP-13, SP-14, SP-15 and SP-16 (Fig. 1).

These isolates were further checked for growth on MSM broth medium amended with different concentrations of phenol. Growth has been found to be negligible on applying higher concentration of phenol (2000 mg/L). This may be due to the sensitivity of these bacteria towards higher concentration of phenol, or they may require acclimatization on phenol prior to its degradation (Abd-El-Haleem et al. 2002). It has also been observed that with respect to time and acclimatization, the growth of bacteria appears in the phenol medium, indicating that the bacteria gradually adapt themselves to the compound. A large number of phenol tolerant bacterial and fungal species have been isolated from phenol contaminated sites (Bhushan et al. 2000; Sun et al. 2012). Arutchelvan et al. (2005) reported isolation of competent bacterial cells from the wastewater of industry manufacturing phenol–formaldehyde resins.

Screening by growth studies

Phenol and its derivatives have shown surprising capability in phenol elimination with bacteria having fast reproduction after acclimatization. So with isolation, purification and growth of species, which has high capability of phenol removal, can be utilized in areas with wastewaters containing high phenol concentrations. However, logically it can be inferred that the increase in the phenolic concentration causes the selection and utilization of the phenol-degrading microorganisms with less diversity. On the other hand, selecting groups can be more effective which can withstand more tolerance of phenol concentration when compared with the non-degrading microorganisms. Hussain et al. (2008, 2009, 2010) conducted a study using membrane bioreactor in treatment of phenolic wastewater. The study revealed the various significant features regarding diversity, physiology and function of pseudomonas population that is found in industrial phenol-degrading bioreactors. However, a significant physiological heterogeneity in the tolerance limit of bacterial isolates has been observed in treatment of phenolic wastewater (Whiteley et al. 2001; Whiteley and Mark 2000).

In the present study, two bacterial isolates SP-4 and SP-8 showed luxuriant growth on phenol-amended minimal salt medium (MSM) in the presence of 1% glucose (w/v), whereas no growth has been observed in the absence of glucose. Both the strains showed fast and luxuriant growth at phenol concentration of 0–1000 mg/L as shown in Fig. 2. The results obtained from present study pertaining to growth studies indicate that SP-4 is capable to tolerate the phenol up to a phenol concentration of 1600 mg/L. Also, the bacterial isolate SP-8 can tolerate the phenol up to a phenol concentration of 1800 mg/L. However, no growth has been observed in both the bacterial isolates at phenol concentration of 2000 mg/L (Figs. 2, 3).

Similar study being conducted by Yang and Lee (2007) reported that phenol has a potentially inhibitory effect on cell growth based on the fact that the high phenol concentration of 2000 mg/L causes substrate inhibition. It is also reported that the subsequent exposure to the increasing phenol concentration from 0 to 2000 mg/L on isolated microorganisms can degrade it effectively and efficiently. It is a common technique used in the enrichment process also. However, Rigo and Alegre (2004) observed that isolated Candida parapsilosis can degrade phenol concentration of 1000 mg/L after screening. Therefore, from present study it can be inferred that the wastewater containing phenol concentration of 1800 mg/L can be effectively treated, and thus, phenol can be removed by using bacterial isolation method.

Conclusion

The removal of phenol in industrial effluents is very crucial due to its persistent and toxic effects. In the present study, two bacterial strains SP-4 and SP-8 have been isolated from the pulp and paper mill effluent and screened out for phenol degradation. The obtained bacterial stains SP-4 and SP-8 are capable of tolerating phenol up to a concentration of 1600 and 1800 mg/L, respectively. The obtained strains were found to be efficient amongst the sixteen strains established by checking their capability of phenol tolerance with respect to the incubation time. The present study can be utilized in real-scale systems as identification of phylogenetically closely related species for phenol degradation is an important aspect. This will help in treatment of industrial wastes, and the utilization of such isolated microorganisms proves to be more economical and feasible. This will reduce the environmental burden with the development of technology as an effective and economical method.

References

Abd-El-Haleem D, Moawad H, Zaki EA, Zaki S (2002) Molecular characterization of phenol-degrading bacteria isolated from different Egyptian ecosystems. Micro Ecol 43:217–224

Ali S, Lafuente RF, Cowan DA (1998) Meta-pathway degradation of phenolics by Thermophilic Bacilli. Enz Microb Technol 23:462–468

APHA (2005) Standard methods for the examination of water and wastewater, (20th ed), Washington, New York

Arutchelvan V, Kanakasabai S, Nagarajan S, Muralikrishnan V (2005) Isolation and identification of novel high strength phenol degrading bacterial strains from phenol formaldehyde resin manufacturing industrial wastewater. J Hazard Mater 127:238–243

Baruah BK, Baruah D, Das M (1996) Sources and characteristics of paper mill effluent. Environ Ecol 14:686–689

Bhusan B, Chauhan A, Samanta SS, Jain RK (2000) Kinetics of biodegradation of p-nitrophenol. Biochem Biophy Res Commun 274:626–630

CPCB (1975) Scheme for zoning and classification of Indian rivers, estuaries and coastal waters, ADSORBS/3. Central Pollution Control Board, New Delhi, pp 78–79

Dabhade MA, Saidutta MB, Murthy DVR (2006) Three phase spouted bed bioreactor for phenol biodegradation, proceedings of national conference on environmental conservation (NCEC), BITS Pilani, India, pp 341–348

Dubey SK, Hussain A (2014) Phenol biodegradation: a review. Int J Environ Eng 1(2):151–157

Haritash A, Kaushik C (2009) Biodegradation aspects of polycyclic aromatic hydrocarbons (PAHs): a review. J Hazard Mater 169:1–15

Hussain A, Kumar P, Mehrotra I (2008) Treatment of phenolic wastewater in UASB reactor: effect of Nitrogen and Phosphorous. Biores Technol 99:8497–8503

Hussain A, Parveen T, Kumar P, Mehrotra I (2009) Phenolic wastewater: effect of F/M on anaerobic degradation. Desalination Water Treat 2:254–259

Hussain A, Kumar P, Mehrotra I (2010) Anaerobic treatment of phenolic wastewater: effect of phosphorous limitation. Desalination Water Treat 20:189–196

Kulkarni SJ, Kaware JP (2013) Review on research for removal of phenol from wastewater. Int J Sci Res Publ 3(4):1–5

Kumar A, Kumar S, Kumar S (2005) Biodegradation Kinetics of phenol and catechol using Pseudomonas putida MTCC 1194. Biochem Eng J 22:151–159

Madan S, Sachan P, Singh U (2018) A review on Bioremediation of Pulp and Paper mill effluent: an alternative to conventional remedial technologies. J Appl Nat Sci 10(1):367–374

Malaviya P, Rathore VS (2007) Bioremediation of pulp and paper mill effluent by a novel fungal consortium isolated from polluted soil. Biores Technol 98:3647–3651

Marihal AK, Jagadeesh KS (2013) Plant-microbe interaction: a potential tool for enhanced bioremediation. In: Arora NK (ed) Plant microbe symbiosis: fundamentals and advances. Springer, India, pp 395–410

Park C, Lee M, Lee B, Kim SW, Chase HA, Lee J, Kim S (2007) Biodegradation and biosorption for decolorization of synthetic dyes by Funalia trogii. Biochem Eng J 36:59–65

Pazarlioglu NK, Telefoncu A (2005) Bio degradation of phenol by Pseudomonas putida immobilized on activated pumice particles. Proc Biochem 40:1807–1814

Rigo H, Alegre RM (2004) Isolation and selection of phenol degrading microorganisms from industrial wastewaters and kinetics of the biodegradation. Folia Microbial (Praha) 49:41–45

Shazryenna D, Ruzanna R, Jessica MS, Piakong MT (2015) Phenol biodegradation by free and immobilized Candida tropicalis RETL-Cr1 on coconut husk and Loofah packed in Biofilter Column. IOP Conf Ser Mater Sci Eng 78:1–8

Sonawane BK, Korake SR (2016) Review on removal of phenol from wastewater using low cost adsorbent. Int J Sci Eng Tech Res 5(6):2249–2253

Sun JQ, Xu L, Tang YQ, Chen FM, Wu XL (2012) Simultaneous degradation of phenol and n-hexadecane by Acinetobacter strains. Biores Tech 123:664–668

Thakur IS (2004) Screening and identification of microbial strains for removal of colour and absorbable organic halogens in pulp and paper mill effluent. Process Biochem 39:1693–1699

Trivedy PK, Raj G (1992) Encyclopaedia of environmental sciences: environmental industrial pollution control, vol 9. Akashdeep Publishing House, New Delhi

Whiteley A, Mark J (2000) Bacterial Community structure and physiological state within an industrial phenol bioremediation system. Appl Environ Microbiol 66:2401–2407

Whiteley AS, Wiles S, Lilley K, Philip J, Babailey MJ (2001) Ecological and physiological analyses of Pseudomonad species within a phenol remediation system. J Microbiol Methods 44:79–88

Yadav S, Yadav N (2014) Physicochemical study of paper mill effluent: to asses pollutant release to environment. Int J Environ Sci 4(5):1053–1057

Yang CF, Lee CM (2007) Enrichment, isolation and characterization of phenol-degrading Pseudomonas resinovorans strain P-1 and Brevibacillus sp. strain P-6. Int Biodeterior Biodegrad 59:206–210

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sachan, P., Madan, S. & Hussain, A. Isolation and screening of phenol-degrading bacteria from pulp and paper mill effluent. Appl Water Sci 9, 100 (2019). https://doi.org/10.1007/s13201-019-0994-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-019-0994-9