Abstract

Recently, arsenic-contaminated water has become a big concern. Therefore, the present study aimed to absorb arsenic from the aqueous solution using modified saxaul tree ash. Arsenic adsorption process was performed in vitro by investigating the effect of various parameters such as pH, contact time, arsenic concentrations, temperature and adsorbent dosage on the adsorption efficiency. Isotherms, kinetics and thermodynamic studies were also conducted to better understand the process of adsorption. Maximum level of arsenic adsorption was obtained at a pH of 7, adsorbent dosage of 1.5 g/L, contact time of 60 min, initial arsenic concentration of 250 µg/l and temperature of 323 K. The amount of adsorbed arsenic was increased with increasing initial concentration of arsenic and temperature. Freundlich adsorption isotherm clearly described the arsenic adsorption by modified saxaul ash. Based on the results obtained, it could be concluded that the modified saxaul ash can efficiently remove arsenic from its aqueous solutions.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Contamination of underground water caused by heavy metals is one of the most important hazards to water resources (Asgari et al. 2008). Arsenic is the third element of group V of the periodic table with atomic number of 32 and relative atomic mass of 74.92 (Golami et al. 2009). Arsenic concentrations are in the range of 2–5 ppm (Uddin et al. 2006). Arsenic contaminates the surface and underground water resources within the natural processes such as dissolving minerals, chemical decomposition and corruption, and human activities like animal husbandry, medicine, industry, electronics and metallurgy (Golami et al. 2009; Uddin et al. 2006; Zaw and Emett 2002). Human activities are the main cause of arsenic contamination of surface water and groundwater (Jafari-Mansoorian et al. 2016). Arsenic compounds based on the origin of production are mobile in the environment and could get into the food chain and hydrological cycle by rainfall (Babaakbry Sari et al. 2014). Arsenic is a toxic and accumulative substance and can inhibit SH-group enzymes. Trivalent arsenic (arsenite) is more toxic than arsenic (V) (arsenate) due to its high portability (Tyrovola et al. 2006; Triszcz et al. 2009). Arsenic may cause dysfunction in digestive system, shock leading to death, pulmonary and respiratory failures (Golami et al. 2009; Zaw and Emett 2002; Triszcz et al. 2009). It is also known as a carcinogenic substance and causes testicular, bladder, lung and liver cancers (Golami et al. 2009; Smedley and Kinniburgh. 2002). The resulting complications depend on factors such as duration of exposure, way of entering to body, type and sources of arsenic (Smith et al. 2000).

Numerous arsenic poisoning caused by contaminated drinking water have been reported in Bangladesh, Argentina, Taiwan, America and Malaysia (Ferguson et al. 2007; Smedley et al. 2005). Also in Iran, arsenic level is higher than the standard limit in areas such as Sistan and Baluchestan, Khorasan, East Azerbaijan and Tuyserkan (Rajaei et al. 2012; Mesdaghinia et al. 2005; Feizi et al. 2008; Olyaie et al. 2012). Lately, the International Agency for Research on Cancer (IARC) has classified inorganic compounds of arsenic in drinking water as a group 1 carcinogenic agent for respiratory system (Asgari et al. 2008). Due to the extraordinary toxicity of arsenic, allowable level for arsenic in drinking water has been reported 10 micrograms per liter by the World Health Organization (WHO) and America Environmental Protection Agency (USEPA) (Shih. 2005; Malik et al. 2009; Jiang 2001). According to Iranian standard for drinking water, this level is 0.05 (MCL) milligrams per liter (Mosaferi and Mesdaghinia 2005). In addition, acceptable level recommended by the Food and Agriculture Organization (FAO) is 0.1 mg/l for irrigation water (Golami et al. 2009).

There are different techniques such as coagulation (Kord Mostafapour et al. 2010), chemical oxidation (Gihring et al. 2001), chemical precipitation (Bissen and Frimmel 2003), ion exchange (Kim and Benjamin. 2004), chemical process (Zheng et al. 2011), adsorption and reverse osmosis for reducing concentration of arsenic in aqueous solutions (Sun and Doner 1998). Some of the mentioned techniques require extremely high investment and operation costs and produce high levels of wastes, which in turn makes their treatment and disposal problematic(Junyapoon 2005; Wang et al. 2002). However, the absorption process has an extensive application due to the ease of exploitation, high efficiency and insensitivity to toxic compounds and availability of a wide range of absorbents (Bazrafshan and Kord Mostafapour 2012; Rahdar et al. 2016). Nowadays, simple and cost-effective absorbents such as agricultural residues like rice paddy, sawdust, orange peel, almonds and peanuts peel and wheat bran have been used by different researchers as adsorbents due to proper efficiency of metal adsorption (Mehrasbi 2008). Saxaul tree, Haloxylonpersicun, is abundance in Iran and native to Iran. That is why it is also known as Iranian haloxylon. This tree distributes in the arid and desert-like areas in Zabol, Tabas and Garmsar (Sanchooli Moghaddam et al. 2016). Therefore, the aim of our research is to investigate saxaul ash ability in arsenic removal from aqueous solutions and assess the effects of some parameters including effective temperature, contact time, initial concentration, pH, adsorption isotherms, reaction kinetics and thermodynamic studies on the absorption process.

Materials and methods

Collection and preparation of adsorbent

Saxaul trees were provided from Zabol city, Iran. First, the tree branches were washed to remove possible contaminants and cut to approximately one square centimeter pieces. They were rinsed with deionized water and then placed into the oven at 105 °C for 12 h. In order to modify adsorbent, the tree was immersed in sodium hydroxide solution with 30% volume concentration for 24 h. The mass of the plant was considered relatively twice as sodium hydroxide to investigate the effects of adsorbent modification on the absorption level. Next, the absorbent was placed in the oven to dry again at a temperature of 105 °C for 12 h, and then, it was converted to ash in an electric furnace at a temperature of 650 °C for 3 h. The obtained ashes were made cold in desiccator by standard ASTM sieves with 60 and 200 mesh, and finally kept cold in the desiccant cooling system (Vijayaraghavan and Yun 2008).

Preparation and analysis of arsenic (V) solution

All chemicals used in this study were provided from Merck Co (Germany). In this research, arsenate stock solution was prepared by dissolving arsenate (NaHAsO4·7H2O) in deionized water with 99% of purity, and then, required concentrations were obtained by diluting stock solution. The pH was adjusted by pH meter using 0.1 N sulfuric acid or 0.1 N sodium hydroxide solution. The experiments were performed considering five variables, including initial pH of solution, absorbent dosage, contact time, initial concentration of arsenic and temperature. Arsenic measurements in the solutions were done by silver diethyl dithiocarbamate method (SDDC) using UV–Vis spectrophotometer (GBC, Cintra 202) at 530 nm.

Batch study

The experiments were performed discontinuously in 100-ml flasks on a shaker with a speed of 120 rpm and were carried out considering five variables, including the initial pH of solution (3, 5, 7, 9, 11 and 13), absorbent dosage (0.1 0.5, 1, 1.5, 2, 2.5 and 3 g/L), contact time (5, 10, 30, 60, 90 and 120 min), initial concentration of arsenic (10, 50, 100 and 250 µg/L) and temperature (293, 298, 303, 308, 313 and 323 K).

The amount of absorbed arsenic per unit weight of modified saxaul ash in time t, qt (µg/g) was calculated using the following equation (Ahmadi and Kord Mostafapour 2017a; Balarak et al. 2016a):

where C0 and Ct are, respectively, arsenic concentrations at time zero and t (µg/L), V is volume of the solution (L) and M is the adsorbent mass (g).

Distribution coefficient (Kd), which describes the binding ability of the adsorbate on the adsorbent surface, could be calculated using the following equation (Rahdar and Ahmadi 2017):

where C0 and Ct are, respectively, the initial arsenic concentration and arsenic concentrations in equilibrium (µg/L), V is volume of the solution (L) and M is the adsorbent mass (g).

Results and discussion

Effect of pH

As mentioned in Introduction, in this review one of our aims is to understand effect of pH in removal arsenic and on the adsorption capacities of modified saxaul ash. Experiments were carried out using initial pHs varying from 3 to 13, at constant initial arsenic concentration of 100 µg L−1, adsorbent dose of 1 g L−1 and contact time of 60 min and ambient temperature. The effect of pH on the arsenic removal efficiency and adsorption capacity (qe) is presented in Fig. 1. The adsorption efficiency increased from 50% to 86% as the pH increased from 3 to 7. The rate of arsenic removal was maximum at pH of 7. As shown in Fig. 1, the maximum absorption capacity, 8.6 µg/g, was obtained at the pH = 7 in which the arsenic removal efficiency was 86% but the removal efficiency was only 62%, and absorption capacity was 6.2 µg/g at pH = 13. The results obtained from the present study demonstrated that the arsenic removal efficiency is decreased by increasing pH value that is effective on the contaminant structure and surface charge of absorbent. In addition, binding of metal ions by surface groups depends on the pH level (Rahmani and Amini 2015). The removal efficiency at pH = 7 reaches the maximum level, and then, removal amount decreases in higher pH levels. In the study of Thirunavukkarasu et al. (2003), optimum pH for arsenic removal was determined 7.6 using GFH. The results of the present study are in line with the findings of Askari et al. (2008).

Effect of adsorbent dosage

The effect of adsorbent dose on the removal of arsenic and adsorption capacity (qe) was studied (Fig. 2). The effect of arsenic dosage (0.1–3 g/L) on the removal efficiency of arsenic was investigated at the reaction time of 60 min, temperature 298 K and optimum pH of 7. As shown in Fig. 2, the amount of absorbed arsenic per adsorbent mass (qe) is rapidly decreased by increasing the adsorbent dosage from 0.1 to 1.5 g/L, but is dropped with lower slope from adsorbent dosages of 1.5–3 g/L. Maximum capacity of arsenic adsorption using ash (14.833 µg/g) was observed at the dosage of 0.1 g/L adsorbent. However, the highest efficiency was reported as 89% at a dosage of 1.5 g/L of adsorbent. The distribution coefficient for arsenic adsorption on saxaul ash is also given in Fig. 2 showing decreased distribution coefficient by increasing adsorbent dosage. Removal rate is improved by increasing adsorbent dosage, its optimum dosage was 1.5 g/L, and the number of active adsorption sites on the adsorbent surface, available for arsenic ions, is increased in high dosages of absorbent (Abbad et al. 2012). Due to the increasing adsorption sites during the adsorption process, the number of active sites of adsorbent remains unsaturated (Rahmani and Amini 2015). These findings are consistent with the findings of Rahmani and colleagues (Rahmani et al. 2010; Lackovic 2000; Rahmini et al. 2009).

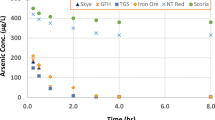

Effect of contact time and initial concentration of arsenic

The effect of contact time and initial concentration on arsenic removal using saxaul ash was investigated in the range of 5–120 min and 10–250 µg/L, respectively. As shown in Fig. 3, the arsenic removal is enhanced with increasing contact time in all initial concentrations of arsenic. In the beginning until 30 min, absorption occurred sharply and the amount of arsenic absorbed per unit mass of adsorbent reached 0.25 µg/g and 36.91 µg/g, respectively, for initial concentrations of arsenic of 10 and 250 µg/L. Then, the elevation in qe goes ahead at a slower rate with increasing contact time and finally reaches equilibrium within contact time of 60 min. Absorption rate was fast in the first 30 min and reached equilibrium in 60 min, and no changes were observed in the time needed for equilibrium by changing the initial arsenic concentration. The monolayer and rapid absorption was due to physically passive absorption or ion exchange at the surface of absorbent. Since there are a specified number of adsorption sites on the absorbent surface, the metal absorption on the absorbent is firstly fast, but over time the number of available active sites reduces and competition of remaining metal ions decreases absorption rate because of reduced binding sites (Abdel-Ghani et al. 2007). The findings of the present study are in agreement with the results of Mosaferi and Mesdaghinia (2005) and Nourozi and Azizian (2014).

Initial absorbed arsenic per unit mass of adsorbent improves by increasing initial concentration of arsenic. Therefore, capacity of arsenic adsorption by modified saxaul ash strongly depends on initial concentration of arsenic.

Effect of temperature

The effect of temperature on arsenic adsorption was investigated at the temperature range of 293–323 K. As shown in Fig. 4, arsenic removal efficiency is increased for all of initial concentrations increasing temperature from 293 to 323 K. For example, removal efficiency in initial arsenic concentration of 100 µg/L was reached from 71% to 87.24% by increasing the temperature from 293 to 323 K. Absorption capacity of adsorbent was elevated for modified saxaul ash by increasing temperature. (Respective data are not given.) Regarding the effect of temperature on the arsenic adsorption (using modified saxaul ash), when the temperature increases from 293 to 323 K, arsenic removal efficiency is increased for all initial concentrations. The viscosity in aqueous solutions is decreased by increasing temperature. In addition, the release of adsorbent molecules is increased across the external boundary layer and in the pores of adsorbent particles, hereby resulting in increased removal efficiency. Moreover, the changes in temperature also increased the adsorption capacity of adsorbent (Ananta et al. 2015; Al-Qodah and Lafi 2003).

Isotherm study

Adsorption isotherms show the models on distribution status of adsorbate molecules in the liquid and solid phases in equilibrium. The most important adsorption models include linear Langmuir, Freundlich and the Temkin adsorption isotherm models.

Langmuir isotherm model is based on scientific assumptions; the most important of these assumptions is that the adsorbates (atoms, molecules or ions) are bound to certain and identical sites on the surface of adsorbent as monolayer adsorption (Bazrafshan et al. 2015a; Ahmadi and Igwegbe 2018), which can be presented by the following equation (Bazrafshan et al. 2015b; Nur-E-Alam et al. 2018):

where qe (µg/g) is the amount of fluoride adsorbed per specific amount of adsorbent, Ce is equilibrium concentration of the arsenic solution (µg/L), KL (L/µg) is Langmuir constant and qm (µg/g) is the maximum amount of arsenic required to form a monolayer. The Langmuir equation can be rearranged to linear form for the convenience of plotting and determining KL and qm with drawing the curve 1/qe versus 1/Ce (Ahmadi and Kord Mostafapour 2017b; Azarpira et al.2016):

Freundlich is merely an empirical equation representing heterogeneous and multilayer adsorption on the surface of adsorbent. The Freundlich model is an empirical relation between qe and Ce. It is obtained by assuming a heterogeneous surface with nonuniform distribution of the adsorption sites on the adsorbent surface and can be expressed by the following equation (Fu et al. 2011):

where Kf and 1/n are the Freundlich constants related to adsorption capacity and adsorption intensity, respectively. The Freundlich constants can be obtained by drawing the Logqe versus Log Ce based on experimental data in light to linear equation (Khoshnamvand et al. 2017; Akbari et al.2018):

Temkin model corrects the adsorption theory by considering adsorbate–adsorbate and adsorbate–adsorbent interactions. The adsorption heat of all molecules in absorption layer is decreased linearly with the amount of coverage. In Temkin model, the surface absorption theory was corrected considering possible reactions between adsorbent–adsorbent and adsorbent–adsorbate. This model can be expressed by the following equation (Ahmadi et al. 2017):

A (l/g) plot of qe versus ln Ce (µg/l) enables the determination of the constants A and B (J/mol). B is corresponding to the heat of sorption, and A is the equilibrium binding constant.

The constants and correlation coefficients of three adsorption isotherms of Langmuir, Freundlich and Temkin are calculated and presented in Table 1. According to this table, the correlation coefficient for Freundlich (R2 = 0.99) model is higher than the other models; this demonstrates that Freundlich model is more appropriate to describe the equilibrium adsorption of arsenic on modified saxaul ash. In the Langmuir isotherm model, monolayer of dissolved molecules is absorbed on absorbent, the energy level of absorption is the same in whole surface of absorbent, and absorbed links are assumed to be reversible. In Freundlich model, absorbent surface areas are not uniform and have different absorption force (Gulnaz et al. 2011). The correlation coefficient of Freundlich model was higher than the other models. This shows that Freundlich model is more suitable to describe the adsorption equilibrium of arsenic on modified saxaul ash. Also, the intensity of adsorption, n (2.1–2.27), lies within the range of 1–10 (1 < n < 10) which suggests that the adsorption of arsenic on modified saxaul ash is favorable.

Kinetic study

Adsorption kinetics are used to determine the mechanisms of controlling adsorption processes and for describing the behavior of transfer of adsorbate molecules per unit of time or for investigating the variables affecting the reaction rate (Mohammadnia and Naghizadeh 2016).

The pseudo-second-order, pseudo-first-order and intraparticle diffusion models were applied in this study to examine the mechanism behind the adsorption of arsenic on modified saxaul ash at pH 7, modified saxaul ash dosage of 1.5 g/L and arsenic concentration of 10-250 µg/L at temperature of 323 K. In first-order kinetic model, it is assumed that the rate of changes in withdrawal of the solute over time is directly proportional to variations in the saturation concentration and the amount of adsorbent withdrawal with time. The pseudo-first-order rate equation is defined as Eq. (8) (Agarwal et al. 2016; Rahdar et al. 2018):

where qt and qe are the amounts of arsenic adsorbed at time t and at equilibrium (µg/g) and k1 is the pseudo-first-order rate constant for the adsorption process (g/µg/min).

In second-order kinetic model, it is assumed that adsorption process can be controlled by chemical adsorption (Bayramoglu et al. 2009; Ruixia et al. 2002). The pseudo-second-order model can be represented as Eq. (9) (Ahmadi and Kord Mostafapour 2017c):

where K2 is the pseudo-second-order rate constant (g/µg/min) and qe and qt are the amounts of arsenic adsorbed on the modified saxaul ash (µg g/g) at equilibrium and at time t, respectively.

The intraparticle diffusion plot is generally used to identify the mechanism involved in an adsorption process (Bazarafshan and Ahmadi 2017). The intraparticle diffusion model according to Weber Morris is given by Eq. (10) (Ahmadi et al. 2018; Rahdar et al. 2019):

where c is a constant that provides the information about the thickness of the boundary layer, kpi is the intraparticle diffusion rate constant (µg/g min0.5) and qt is the amount of arsenic adsorbed (µg g/g) at time t (min.).

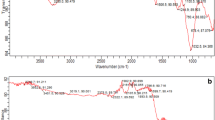

Parameters of the three models are listed in Table 2. The goodness of fit of the models was expressed by the coefficients of determination (R2), and a relatively high R2 value indicated that the model successfully described the kinetics of arsenic sorption by modified saxaul ash. It was not appropriate to use the pseudo-first-order model to predict the sorption kinetics of arsenic onto modified saxaul ash for the entire arsenic concentration range. The results showed the intraparticle diffusion model could not fit well with the kinetic data due to the lower R2 values (0.817–0.907) (Table 2), suggesting that the intraparticle diffusion was not the rate-controlling step for the sorption of arsenic onto modified saxaul ash. Finally, pseudo-second-order model has the best fit for adsorption kinetics of various initial concentrations of arsenic, indicating that the adsorption of arsenic onto modified saxaul ash was a chemical adsorption process. Figure 5 shows the linear fitting lines of pseudo-second-order model.

Comparison with other adsorbents for arsenic removal

Table 3 shows the adsorption capacities obtained for the removal of arsenic on various adsorbents. From the table, it can be seen that the modified saxaul ash can be used efficiently for the removal of arsenic from aqueous environments.

Thermodynamic assessments

Thermodynamic results determine the possibility and spontaneous process, endothermic or exothermic reaction, and the entropy changes during adsorption or changes in Gibbs free energy (ΔG°) and basic excitation criteria. If the ΔG° is minus, absorption process will be spontaneous. Thermodynamic parameters including ΔG°, changes in enthalpy (ΔH°) and changes in entropy (ΔS°) for the absorption processes are calculated using the following equations (Balarak et al. 2016b):

where R is universal gas constant (314.8 J/mol/k), T is the temperature in degrees Kelvin and Ka is the thermodynamic equilibrium constant.

The enthalpy and entropy changes of the process adsorption can be determined from the slope and intercept of line obtained by plotting KL vs 1/T (Bazrafshan et al. 2015a, b; Dursun 2006; Pimentel et al. 2008). ΔH° is 14.05 kJ/mol and ΔS° is 20.6 kJ/mol K−1 (2).

The results of thermodynamic assessment for arsenic adsorption on modified saxaul ash are given in Table 4. Positive value of ΔG0 for the arsenic represents an increase in randomness of the adsorption process. Table 4 clearly shows that the value of change of the standard enthalpy (ΔH°) is positive for the adsorption of arsenic by modified saxaul ash considered as adsorbents are endothermic and the removal efficiency of arsenic increases with the increase in temperature T (Bazrafshan et al. 2015b; Twarakavi and Jagath 2006).

Conclusion

Absorption capacity and efficiency of modified saxaul ash were studied in the removal of arsenic from aquatic solutions. The results showed that the efficiency of the process depends on various factors such as contact time, temperature, arsenic concentrations, initial concentration of absorbent and pH of the solution. The highest absorption was obtained at pH = 7. Increasing initial concentration of arsenic, adsorption capacity of absorbent was increased due to elevated mass transfer force, and high removal rate was observed with increasing temperature for all concentrations. The maximum arsenic removal (94.62%) was obtained at the concentration of 250 µg/l, temperatures of 323 K, pH of 7 and adsorbent dosage of 1.5 g/l. Laboratory data of arsenic absorption are in accordance with the Freundlich model. Because of the saxaul ash benefits such as high absorption capacity, effective removal efficiency, cost-effectiveness and availability, the use of this natural absorbent can be considered for the removal of arsenic from the aqueous solution.

References

Abbad B, Lounis A, Djilali T (2012) Adsorption of methylene blue from aqueous solution on the surface of Znapso-34 nanoporous material. In: Proceedings of world academy of science, engineering and technology, vol 71, p 1664

Abdel-Ghani NT, Hefny M, El-Chaghaby GA (2007) Removal of lead from aqueous solution using low cost abundantly available adsorbents. Int J Gen Eng Technol 4(1):67–73

Agarwal S, Tyagi I, Gupta VK, Asif M (2016) Rapid removal of noxious nickel (II) using novel γ-alumina nanoparticles and multiwalled carbon nanotubes: kinetic and isotherm studies. J Mol Liq 224:618–623

Ahmadi S, Igwegbe CA (2018) Adsorptive removal of phenol and aniline by modified bentonite: adsorption isotherm and kinetics study. Appl Water Sci 8(6):170

Ahmadi S, Kord Mostafapour F (2017a) Adsorptive removal of aniline from aqueous solutions by Pistacia Atlantica (Baneh) shells: isotherm and kinetic studies. J Sci Technol Environ Inf 5:327–335. https://doi.org/10.18801/jstei.050117.35

Ahmadi S, Kord Mostafapour F (2017b) Adsorptive removal of bisphenol A from aqueous solutions by Pistacia Atlantica: isotherm and kinetic studies. Pharm Chem J 4:1–8

Ahmadi S, Kord Mostafapour S (2017c) Tea waste as a low cost adsorbent for the removal of COD from landfill leachate: kinetic study. J Sci Eng Res 4(6):103–108

Ahmadi S, Banach A, Mostafapour FK, Balarak D (2017) Study survey of cupric oxide nanoparticles in removal efficiency of ciprofloxacin antibiotic from aqueous solution: adsorption isotherm study. Desalin Water Treat 89:297–303. https://doi.org/10.5004/dwt.2017.21362

Ahmadi S, Rahdar S, Igwegbe CA, Rahdar A (2018) Data on the removal of fluoride from aqueous solutions using synthesized P/γ-Fe2O3 nanoparticles: a novel adsorbent. MethodsX 6:98–106

Akbari H, Jorfi S, Mahvi AH, Yousefi M, Balarake D (2018) Adsorption of fluoride on chitosan in aqueous solutions: determination of adsorption kinetics. Fluoride 51(4):319–327

Al-Qodah Z, Lafi W (2003) Adsorption of reactive dyes using shale oil ash in fixed beds. J Water Supply Res Technol-AQUA 52(3):189–198

Ananta S, Saumen B, Vijay V (2015) Adsorption isotherm, thermodynamic and kinetic study of arsenic (III) on iron oxide coated granular activated charcoal. Int Res J Environ Sci 1(4):64–77

Asgari R, Mahvi AH, Vaezi F, Khalili FA (2008) Study of the efficiency of arsenic removal from drinking water by granular ferric hydroxide (GFH). Majallah-i Dānishgāh-i Ulūm-i Pizishkī-i Qum. 2(1):53–63

Ayanda OS, Malomo D, Oketayo OO, Nelana SM, Naidoo EB (2017) Removal of arsenic (III) from aqueous solutions by adsorption onto fly ash. Asian J Chem 29:10

Azarpira H, Mahdavi Y Y, Balarake D (2016) Removal of Cd(II) by adsorption on agricultural waste biomass. Der Pharma Chem 8(12):61–67

Babaakbry Sari M, Farabakhsh M, Savaghebi N, Najafi N (2014) Arsenic concentrations in some calcareous soils Qorveh and its absorption by corn, wheat and rapeseed in a natural contaminated soil. Knowl Soil Water 23(4):1–6

Balarak D, Azarpira H, Mostafapour FK (2016a) Thermodynamics of removal of cadmium by adsorption on Barley husk biomass. Der Pharma Chem 8(10):243–247

Balarak D, Mahdavi Y, Bazrafshan E, Mahvi AH (2016b) Kinetic, isotherms and thermodynamic modeling for adsorption of acid blue 92 from aqueous solution by modified azolla filicoloides. Fresenius Environ Bull 25(5):1321–1330

Bayramoglu G, Gursel I, Tunali Y, Arica MY (2009) Biosorption of phenol and 2-chlorophenol by Funaliatrogii pellets. Bioresource technol 100(10):2685–2691

Bazarafshan E, Ahmadi S (2017) Efficiency of combined processes of coagulation and modified activated bentonite with sodium hydroxide as a biosorbent in the final treatment of leachate: kinetics and thermodynamics. J Health Res Community 3(3):58–69

Bazrafshan E, Kord Mostafapour F (2012) Evaluation of color removal of Methylene blue from aqueous solutions using plant stem ash of Persica. J North Khorasan Univ Med Sci 4:523–532

Bazrafshan E, Kord Mostafapour F, Rahdar S, Mahvi AH (2015a) Equilibrium and thermodynamics studies for decolorization of Reactive Black 5 (RB5) by adsorption onto MWCNTs. Desalin Water Treat 54(8):2241–2251

Bazrafshan E, Rahdar S, Balarak D, Mostafapour FK, Zazouli MA (2015b) Equilibrium and thermodynamics studies for decolorization of reactive black 5 by adsorption onto acid modified banana leaf ash. Iran J Health Sci 3(3):15–28

Bissen M, Frimmel FH (2003) Arsenic—a review. Part II: oxidation of arsenic and its removal in water treatment. Acta Hydrochim Hydrobiol 31(2):97–107

Dursun AY (2006) A comparative study on determination of the equilibrium, kinetic and thermodynamic parameters of biosorption of copper (II) and lead (II) ions onto pretreated Aspergillus niger. J Biochem Eng 28(2):187–195

Feizi H, Mosaferi M, Dastgiri S, Zolali S, Pouladi N, Azarfam P (2008) Contamination of drinking water with arsenic and its various health effects in the Village of Ghopuz. Iranian J Epidemiology 3(3):21–27

Ferguson MA, Fernandez DP, Hering JG (2007) Lowering the detection limit for arsenic: implications for a future practical quantitation limit. J Am Water Works Assoc 99(8):92–98

Fu J, Song R, Mao WJ, Wang Q, An SQ, Zeng QF, Zhu HL (2011) Adsorption of disperse 18 blue 2BLN by microwave activated red mud. Environ Prog Sustain 30:558–566

Gihring TM, Druschel GK, McCleskey RB, Hamers RJ, Banfield JF (2001) Rapid arsenite oxidation by Thermus aquaticus and Thermus thermophilus: field and laboratory investigations. Environ Sci Technol 35(19):3857–3862

Golami M, Mohammadi HA, Mokhtari SA (2009) Application of reverse osmosis technology for arsenic removal from drinking water. ZUMS J 17(68):9–20

Gulnaz O, Sahmurova A, Kama S (2011) Removal of reactive red 198 from aqueous solution by Potamogeton crispus. J Chem Eng 174(2):579–585

Jafari-Mansoorian H, Farzadkia M, Ansari M, Ahmadi E, Majidi G, Amraie A, Joghataie A (2016) Evaluating the activated carbon prepared from walnut in removal of arsenic from aqueous solution. Saf Promot Inj Prev 3(4):287–294

Jiang JQ (2001) Removing arsenic from groundwater for the developing world—a review. Water Sci Technol 44(6):89–98

Junyapoon S (2005) Use of zero-valent iron for wastewater treatment. KMITL Sci Technol J 5(3):587–595

Khoshnamvand N, Ahmadi S, Mostafapour FK (2017) Kinetic and isotherm studies on ciprofloxacin adsorption using magnesium oxide nanoparticles. J Appl Pharm Sci 7:079–083. https://doi.org/10.7324/JAPS.2017.71112

Kim J, Benjamin MM (2004) Modeling a novel ion exchange process for arsenic and nitrate removal. Water Res 38(8):2053–2062

Kord Mostafapour F, Bazrafshan E, Kamani H (2010) Survey of arsenic removal from water by coagulation and dissolved air floatation method. Iran J Health Environ 3(3):309–318

Lackovic JA, Nikolaidis NP, Dobbs GM (2000) Inorganic arsenic removal by zero-valent iron. Environ Eng Sci 17(1):29–39

Malik AH, Khan ZM, Mahmood Q, Nasreen S, Bhatti ZA (2009) Perspectives of low cost arsenic remediation of drinking water in Pakistan and other countries. J Hazard Mater 168(1):1–2

Mehrasbi MR (2008) Heavy metal removal from aqueous solution by adsorption on modified banana shell. Iran J Health Environ 1(1):57–66

Mesdaghinia AR, Mosaferi M, Yunesian M, Nasseri S, Mahvi AH (2005) Measurement of arsenic concentration in drinking water of a polluted area using a field and SDDC methods accompanied by assessment of precision and accuracy of each method. Hakim Res J 8(1):43–51

Mohammadnia M, Naghizadeh A (2016) Surveying of kinetics, thermodynamic, and isotherm processes of fluoride removal from aqueous solutions using graphene oxide nano particles. J Birjand Univ Med Sci 23(1):29–43

Mosaferi M, Mesdaghinia AR (2005) Removal of arsenic from drinking water using modified activated alumina. J Water Wastewater 55:2–14

Narooie MR, Afsharnia M, Rahdar S, Baneshi MM, Ahamadabadi M, Saeidi M, Salimi A, Khaksefidi R (2017) Arsenic removal from aqueous solutions by raw and incinerated pine bark. J Glob Pharma Technol 9:29–34

Nourozi R, Azizian S (2014) Arsenic (V) removal from aqueous solution by produced iron and detect isoterms and kinetic adsorption. J Environ Health Eng 1(2):146–156

Nur-E-Alam M, Mia MA, Ahmad F, Rahman MM (2018) Adsorption of chromium (Cr) from tannery wastewater using low-cost spent tea leaves adsorbent. Appl Water Sci 8(5):129

Olyaie E, Banejad H, Rahmani AR, Afkhami A, Khodaveisi J (2012) Feasibility study of using calcium peroxide nanoparticles in arsenic removal from polluted water in agriculture and it’s effect on the irrigation quality parameters. Iran J Health Environ 5(3):319–330

Pimentel PM, Melo MA, Melo DM, Assuncao AL, Henrique DM, Silva CN, González G (2008) Kinetics and thermodynamics of Cu (II) adsorption on oil shale wastes. Fuel Process Technol 89(1):62–67

Rahdar S, Ahmadi S (2017) Removal of phenol and aniline from aqueous solutions by using adsorption on to pistacia terebinthus: study of adsorption isotherm and kinetics. J Health Res Community. Winter 2(4):35–45

Rahdar S, Ahmadabadi M, Bazrafshan E, Taghavi M, Amrollahi M (2016) Evaluation of methylene blue removal from aqueous solution using peanut shell powder. TB 15(1):36–50

Rahdar S, Igwegbe CA, Rahdar A, Ahmadi S (2018) Efficiency of sono-nano-catalytic process of magnesium oxide nano particle in removal of penicillin G from aqueous solution. Desalin Water Treat 106:330–335

Rahdar S, Rahdar A, Igwegbe CA, Moghaddam F, Ahmadi S (2019) Synthesis and physical characterization of nickel oxide nanoparticles and its application study in the removal of ciprofloxacin from contaminated water by adsorption. Equilib Kinet Stud 141:386–393

Rahmani A, Amini S (2015) Remove arsenic from aqueous solutions by sawdust modified and unmodified oak tree. J Water Wastewater 26(6):42–49

Rahmini A, Samadi, MT, Gheyamli M, Motaghipour H, Mirzaei S (2009) Comparison of performance of three type of sawdust in Hamadan city of a low cost adsorbent for arsenic and syanid removal from wastewater. In: 12th conference of environmenal health, Isfahan University of Medical Sciences, Isfahan

Rahmani AR, Ghaffari HR, Samadi MT (2010) Removal of arsenic (III) from contaminated water by synthetic nano size zerovalent iron. World Acad Sci Eng Technol 62:1116–1119

Rajaei Q, Jahantigh H, Mir A, Hesari Motlagh S, Hasanpour M (2012) Evaluation of concentration of heavy metals in Chahnimeh water reservoirs of Sistan-va-Baloochestan Province in 2010. J Mazandaran Univ Med Sci 22(90):105–112

Ruixia L, Jinlong G, Hongxiao T (2002) Adsorption of fluoride, phosphate, and arsenate ions on a new type of ion exchange fiber. J Colloid Interface Sci 248(2):268–274

Sanchooli Moghaddam M, Rahdar S, Taghavi M (2016) Cadmium removal from aqueous solutions using saxaul tree ash. Iran J Chem Eng 35(3):45–52

Shih MC (2005) An overview of arsenic removal by pressure-driven membrane processes. Desalination 172(1):85–97

Smedley PL, Kinniburgh DG (2002) A review of the source, behaviour and distribution of arsenic in natural waters. Appl Geochem 17(5):517–568

Smedley PL, Kinniburgh DG, Macdonald DM, Nicolli HB, Barros AJ, Tullio JO, Pearce JM, Alonso MS (2005) Arsenic associations in sediments from the loess aquifer of La Pampa, Argentina. Appl Geochem 20(5):989–1016

Smith AH, Arroyo AP, Mazumder DN, Kosnett MJ, Hernandez AL, Beeris M, Smith MM, Moore LE (2000) Arsenic-induced skin lesions among Atacameno people in Northern Chile despite good nutrition and centuries of exposure. Environ Health Perspect 108(7):617

Sun X, Doner HE (1998) Adsorption and oxidation of arsenite on goethite. Soil Sci 163(4):278–287

Thirunavukkarasu OS, Viraraghavan T, Subramanian KS (2003) Arsenic removal from drinking water using granular ferric hydroxide. Water Sa 29(2):161–170

Triszcz JM, Porta A, Einschlag FS (2009) Effect of operating conditions on iron corrosion rates in zero-valent iron systems for arsenic removal. J Chem Eng 150(2–3):431–439

Twarakavi NKC, Jagath JK (2006) Arsenic in the shallow ground waters of conterminous united states: assessment, health risks, and costs for mcl compliance. J Am Water Resour Assoc 42:275–294

Tyrovola K, Nikolaidis NP, Veranis N, Kallithrakas-Kontos N, Koulouridakis PE (2006) Arsenic removal from geothermal waters with zero-valent iron—effect of temperature, phosphate and nitrate. Water Res 40(12):2375–2386

Uddin MM, Harun-Ar-Rashid AK, Hossain SM, Hafiz MA, Nahar K, Mubin SH (2006) Slow arsenic poisoning of the contaminated groundwater users. Int J Environ Sci Technol 3(4):447–453

Vijayaraghavan K, Yun YS (2008) Biosorption of CI Reactive Black 5 from aqueous solution using acid-treated biomass of brown seaweed Laminaria sp. Dyes Pigments 76(3):726–732

Wang L, Chen AS, Sorg TJ, Fields KA (2002) Field evaluation of As removal by IX and AA. J Am Water Works Assoc 94(4):161–173

Yao S, Liu Z, Shi Z (2014) Arsenic removal from aqueous solutions by adsorption onto iron oxide/activated carbon magnetic composite. J Environ Health Sci Eng 12(1):58

Zaw M, Emett MT (2002) Arsenic removal from water using advanced oxidation processes. Toxicol Lett 133(1):113–118

Zheng YM, Zou SW, Nanayakkara KN, Matsuura T, Chen JP (2011) Adsorptive removal of arsenic from aqueous solution by a PVDF/zirconia blend flat sheet membrane. J Membr Sci 374(1):1–1

Acknowledgements

We would like to thank environmental chemistry laboratory of Zahedan University of Medical Sciences for financial support of this research project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Rahdar, S., Taghavi, M., Khaksefidi, R. et al. Adsorption of arsenic (V) from aqueous solution using modified saxaul ash: isotherm and thermodynamic study. Appl Water Sci 9, 87 (2019). https://doi.org/10.1007/s13201-019-0974-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-019-0974-0