Abstract

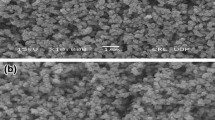

Zirconia-supported palladium (Pd/ZrO2) and Zirconia-supported platinum (Pt/ZrO2) nanoparticles (NPs) are synthesized from their precursors via impregnation technique. The Pd/ZrO2 and Pt/ZrO2 NPs were analyzed via SEM and EDX, while the study of indigo disulfonate dye degradation was carried out by UV/VIS spectrophotometer. The SEM micrographs illustrated that the Pd and Pt NPs were well placed on ZrO2 surface. The Pd/ZrO2 and Pt/ZrO2 NPs were also employed as photocatalysts for the photodegradation of indigo disulfonate in an aqueous medium under UV-light irradiation. The photodegradation study presented that Pd/ZrO2 and Pt/ZrO2 NPs degraded 96 and 94% of indigo disulfonate in 14 h, respectively. The effect of pH of medium and catalyst dosage and efficiency of recovered Pd/ZrO2 and Pt/ZrO2 NPs on the photocatalytic degradation were also studied. It was also found that the maximum degradation of dye was found at pH 10 (95–97%) and at 0.02 g weight (40.28%).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Industries are considered not only as a backbone for country development but also responsible as the major source for discarding toxic wastes into aquatic systems (Shah et al. 2016). Their growth has increased the generation and accumulation of waste by-products (Mital and Manoj 2011). These industries discharge their effluents containing water pollutants such as dyes and pigments (Saeed et al. 2015). Synthetic dyes have been increasingly used in textiles, plastic, rubber, cosmetics, foods, and pharmaceutical industries (Sharma and Sharma 2013). About 10–15% of all dyes are directly lost to waste water during the dyeing process (Tolia et al. 2012). Synthetic dyes significantly cause an environmental pollution because of stability and toxicity and result in severe health risk (Reza et al. 2015). Most of these dyes are non-biodegradable, toxic, and carcinogenic because of complex structures and large size (Xu et al. 2008). Various chemical, biological, and physical techniques are used for its elimination like adsorption, precipitation, ozonization, membrane separation, ultrafiltration, and flocculation. Most of these treatment techniques are non-destructive and convert them into other products which are considered as secondary pollutants that need further treatment (Saeed et al. 2015). Recently, semiconductor photocatalysis has attracted much attention for waste water treatment due to its potential of scavengering large range of toxic pollutants (organic and inorganic) at ambient pressure and temperature with no harmful by-products (Saeed et al. 2015). This technology provides a simple route for conversion of solar energy into chemical energy used for water splitting and other purposes (Ayodhya et al. 2016). In photocatalysis, semiconductors are used as photocatalysts (Kumar et al. 2008). Photocatalysts are semiconducting materials that are activated via adsorbing high-energy photon and have the ability of accelerate photodegradation reaction without being consumed (Saeed et al. 2016; Fox 1988). Various photocatalysts are reported for the photodegradation of organic pollutants such as Zn2+–Ni2+–Fe3+–CO32− LDHs for methyl orange (Dang et al. 2017), PAN/CNT–TiO2 for methylene blue and indigo carmine (Mohamed et al. 2016), Ag/OM-PAN nanofiber for methyl orange (Saeed et al. 2015), graphene-supported Sn-Pt bimetallic nanoparticles Basic Green 5 (Saeed et al. 2016), TiO2 nanoparticles for methyl orange (Su et al. 2013), Mg doped TiO2 for methyl orange (Avasarala et al. 2016), TiO2/Pt and TiO2/Pd photocatalysts for methyl violet dye (Saeed et al. 2017), and chitosan conjugated magnetic nanoparticles used for of bromophenol blue (Khan et al. 2016).

In the present study, Pd- and Pt-deposited zirconia nanoparticles were synthesized by impregnation technique and were used as photocatalysts for photodegradation of indigo disulfonate in aqueous medium. ZrO2 is the main material of ceramics industry and is currently used as heterogeneous photocatalyst because of its n-type semiconductor nature (Botta et al. 1999). In this work, we use ZrO2 as a support for the better dispersion of Pt and Pd nanoparticles. The Pd and Pt were selected because they have high melting point, less toxicity, efficiently recycled, and highly catalytic ability (Emsley 2011; Golunski 2007). However, the indigo is selected because it is an oldest and most importantly used dye. Its production is 3% of the total dye production. The major industrial application of indigo is the dyeing of clothes (blue jeans) and other blue denim products. Its melting point is 390–392 °C and has very poor solubility because of the existence of strong intermolecular hydrogen bond (Vautier et al. 2001). The morphological and elemental compositions of the prepared photocatalysts were studied. The photodegradation study was carried out by UV/VIS spectrophotometer. The recycle abilities of Pd/ZrO2 and Pt/ZrO2 photocatalysts were also investigated.

Experimental work

Materials

The NaOH and HNO3 were purchased from Scharlau chemicals and Sigma Aldrich. Zirconium oxide dichloride octahydrate (ZrOCl2·8H2O), PtCl4, and PdCl2 are supplied by BDH. Indigo disulfonate was purchased from Merck.

Preparation of Pd/ZrO2 and Pt/ZrO2 photocatalysts

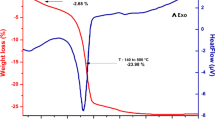

First of all, monoclinic zirconia was prepared from their precursors ZrOCl2·8H2O by ammonolysis and then calcined at 750 °C in the furnace at a heat ramp of 5 °C/min for 3 h. Pd/ZrO2 and Pt/ZrO2 were prepared separately by the impregnation method by addition of 0.01% solution of PdCl2 and PtCl4, respectively. The paste of the prepared samples was dried overnight in an oven at 110 °C. Pd/ZrO2 and Pt/ZrO2 were thus obtained after calcination at 750 °C at a rate of 3 °C/min for 3 h.

Photodegradation of indigo disulfonate

10 mL of indigo disulfonate (100 ppm) and 0.02 g of Pd/ZrO2 and Pt/ZrO2 were separately taken in vials and placed in UV-light (254 nm, 15 W) with constant stirring. The catalyst from each vial is separated by centrifugation (1200 rpm) after specific irradiation time, while the indigo disulfonate degradation was calculated by UV–VIS spectrophotometry ((UV-1800, Shimadzu, Japan). The following equation was used for the calculation of %degradation of indigo disulfonate in aqueous medium (Saeed et al. 2015).

where C0 is the initial dye concentration, C is the dye concentration after UV irradiation, A0 shows the initial absorbance, and A shows the dye absorbance after UV irradiation.

Results and discussion

SEM and EDX study

Figure 1a and b shows the SEM micrographs of Pd/ZrO2 and Pt/ZrO2, respectively. The micrographs presented that Pd and Pt NPs are formed on the surface of ZrO2. Micrographs show that at some points Pd and Pt form agglomerates, while also appear in dispersed form at some points. The images also presented that the size of NPs was below 100 nm, while the size of agglomerates is in the range of 100–700 nm. The formation of Pd and Pt was also confirmed by EDX analyses (Fig. 2a, b for Pd/ZrO2 and Pt/ZrO2, respectively). The figures illustrated that about 0.04 and 0.16 %weights of Pd and Pt NPs are deposited on ZrO2. The presence of oxygen also confirms that the TiO2 has been prepared from their precursor.

Photodegradation study of indigo disulfonate

The photocatalytic activities of Pd/ZrO2 and Pt/ZrO2 were examined against indigo disulfonate under UV-light irradiation. Figure 3a and b shows the UV–Visible spectra of indigo disulfonate dye before and after UV-light irradiation photodegraded by Pd/ZrO2 and Pt/ZrO2, respectively, in aqueous medium. The photodegradation of indigo disulfonate dye was obtained from its relative intensity of UV/VIS spectra which give the maximum absorbance peak at 611 nm. The comparison of %degradation of dye in the presence of Pd/ZrO2 and Pt/ZrO2 is shown in Fig. 3c. Figure 3a–c shows that dye degradation increased by increasing the irradiation time to their optimum. Figure also shows that Pd/ZrO2 is more active in dye degradation as compared to Pt/ZrO2 under the same experimental conditions. The result data revealed that Pd/ZrO2 degraded about 10.26% of dye within 30 min, and the degradation increased up to 96.61% by increasing UV-light irradiation time up to 14 h. Similarly, the Pt/ZrO2 degraded about 6.04% of dye within 30 min, and the degradation increased up to 94.46% by increasing UV-light irradiation time up to 14 h. The effect of recycle catalyst was also investigated by washing and using it again as photocatalysts under the same experimental conditions. The recycle catalysts were also active against dye degradation. However, the recycle catalysts show less activity as compared to the originals, which might be due to photosensitive hydroxide deposition on the photocatalysts surface, and that might block active site of the catalyst (Saeed et al. 2016).

The proposed mechanism is that when UV-light falls upon the NPs, the valence electrons (e−) get excited toward the conduction band and result in the formation of positive hole (h+) in the valence band. The e− and h+ play important role in the generation of reactive radicals. For example, the h+ and e− react with water and O2 molecules, which results in hydroxyl radicals (·OH) and superoxide radical ion (·O2−), respectively. These reactive radicals are responsible for the photodegradation of dye. The major reaction mechanism under sunlight irradiation is summarized in the following equations:

Effect of photocatalysts dosage

The effect of photocatalyst amount was also tested on the photodegradation of dye by applying different amounts (0.010, 0.015, 0.020, 0.025, and 0.030 g) of photocatalysts under constant experimental conditions (time = 6 h). Figure 4a and b shows the UV/Visible spectra of indigo disulfonate dye before and after UV-light irradiation in the presence of different amounts of Pd/ZrO2 and Pt/ZrO2, respectively. Figure 4c shows the comparison of % degradation of indigo disulfonate dye photodegraded by Pd/ZrO2 and Pt/ZrO2. Figure 4a–c shows that as catalyst amount increases photocatalytic degradation of dye also increases. The result revealed that 0.01 g of Pd/ZrO2 photocatalyst degraded 19.11% dye which gradually increased to 48.1% with the increasing catalyst amount to 0.02 g and any addition beyond 0.02 g of catalyst dosage causes decrease in degradation of dye. The 0.03 g of photocatalyst degraded 16.14% of dye which is very low as compared to degradation of 0.02 g of Pd/ZrO2 photocatalyst. Similarly, 0.01 g of Pt/ZrO2 catalyst degraded 25.36% of dye which is gradually increased with the increasing amount of catalyst, and 0.02 g of catalyst degraded about 40.28% of dye, and then increasing Pt/ZrO2 catalyst dosage further decreases degradation of dye. The 0.03 g of photocatalyst degraded 16.14% of dye which is very low as compared to degradation of 0.02 g of the Pt/ZrO2 photocatalyst. The result indicates that 0.02 g is the optimal dosage for both photocatalysts for dye degradation, and the increasing catalyst causes decrease in dye degradation. This decrease in dye degradation might be due to the interception of light by suspension and agglomeration of catalyst particles due to which surface for photon absorption becomes unavailable due to the increased catalyst dosage beyond optimal limit (Akpan and Hameed 2009).

Effect of pH on indigo disulfonate degradation

pH is an important parameters in photodegradation as it plays a vital role in the release of proton and hydroxyl radicals’ production. The mechanism of pollutant (dyes) degradation involves the attack of hydroxyl radical, direct reduction by electron in the conduction band, and direct oxidation by the positive holes (Saeed et al. 2016). Different industries such as dyes, textile, and surface coating release their effluents to water reservoirs at various levels. Hence, it is important to evaluate the function of pH on photodegradation of pollutants (Saeed et al. 2015). The effect of pH on the rate of photodegradation of indigo disulfonate is shown in Fig. 5. Figure 5a and b shows UV–Visible spectra of indigo disulfonate before and after UV-light irradiation photodegraded at various pH values in the presence of Pd/ZrO2 and Pt/ZrO2. Figure 5c shows the comparison of % degradation of indigo disulfonate photodegraded by Pd/ZrO2 and Pt/ZrO2. The results illustrated that the photodegradation of dye increased as by increasing the pH of medium. The maximum degradation is achieved in the basic medium, which might be due to the highest formation of hydroxyl radicals (Saeed et al. 2015). Results show that at pH 3 Pd/ZrO2 degraded 40.86% dye which decreased to 16.92% at pH 7, while by adjusting pH to 10, the maximum degradation of 97.03% was achieved. Similarly, Pt/ZrO2 catalyst degraded about 47.47% dye at pH 3 and then degradation decreased to 16.04% by adjusting pH to 7. The photodegradation increased in basic medium and the maximum degradation of 95.93% was achieved at pH 10.

Conclusion

Both Pd/ZrO2 and Pt/ZrO2 NPs are effective for photodegradation of indigo disulfonate dye in aqueous medium. The Pd/ZrO2 NPs were more efficient than Pt/ZrO2 NPs. It was concluded that indigo disulfonate degradation rate increased as catalyst dosage and irradiation time increased. Both the recovered catalysts also significantly degraded indigo disulfonate dye in aqueous medium but present lower activity than unused catalyst. It was also reported that basic medium is favorable for photodegradation of indigo disulfonate in aqueous medium and Pd/ZrO2 degraded 97% and Pt/ZrO2 95% within 2 h at pH 10.

References

Akpan UG, Hameed BH (2009) Parameters affecting the photocatalytic degradation of dyes using TiO2-based photocatalysts: a review. J Hazard Mater 170:520–529

Avasarala BK, Tirukkovalluri SR, Bojja S (2016) Magnesium doped titania for photocatalytic degradation of dyes in visible light. J Environ Anal Toxicol. https://doi.org/10.4172/2161-0525.1000358

Ayodhya D, Venkatesham M, Kumari AS, Reddy GB, Ramakrishna D, Veerabhadram G (2016) Photocatalytic degradation of dye pollutants under solar, visible and UV lights using green synthesised CuS nanoparticles. J Exp Nanosci 11:418–432

Botta SG, Navio JA, Hidalgo MC, Restrepo GM, Litter MI (1999) Photocatalytic properties of ZrO2 and Fe/ZrO2 semiconductors prepared by a sol–gel technique. J Photochem Photobiol A 129:89–99

Dang R, Ma X, Liu J, Yan L, Gao W, Li J, Chen B (2017) Preparation of Zn2+–Ni2+–Fe3+–CO3 2− LDHs and study of photocatalytic activities for decomposition of Methyl Orange solution. Compos Interfaces 24:1–11

Emsley J (2011) Nature’s building blocks: an A-Z guide to the elements. Oxford University Press, Oxford, p 384, 387

Fox M (1988) Photocatalytic oxidation of organic substances. In: Schiavello M (ed) Photocatalysis and environment: trends and applications. Kluwer Academic Publishers, New York, pp 445–467

Golunski S (2007) Why use platinum in catalytic converters. Platin Metals Rev 51:162

Khan H, Khalil AK, Khan A, Saeed K, Ali N (2016) Photocatalytic degradation of bromophenol blue in aqueous medium using chitosan conjugated magnetic nanoparticles. Korean J Chem Eng 33:2802–2807

Kumar PSS, Sivakumar R, Anandan S, Madhavan J, Maruthamuthu P, Ashokkumar M (2008) Photocatalytic degradation of Acid Red 88 using Au–TiO2 nanoparticles in aqueous solutions. Water Res 42:4878–4884

Mohamed A, El-Sayed R, Osman TA, Toprak MS, Muhammed M, Uheida A (2016) Composite nanofibers for highly efficient photocatalytic degradation of organic dyes from contaminated water. Environ Res 145:18–25

Mital GS, Manoj T (2011) A review of TiO2 nanoparticles. Chin Sci Bull 56:1639–1657

Reza KM, Kurny ASW, Gulshan F (2015) Parameters affecting the photocatalytic degradation of dyes using TiO2: a review. Appl Water Sci. https://doi.org/10.1007/s13201-015-0367-y

Saeed K, Khan I, Shah T, Park SY (2015) Synthesis, characterization and photocatalytic activity of silver nanoparticles/amidoxime-modified polyacrylonitrile nanofibers. Fiber Polym 16:1870–1875

Saeed K, Khan I, Sadiq M (2016) Synthesis of graphene-supported bimetallic nanoparticles for the sunlight photodegradation of Basic Green 5 dye in aqueous medium. Sep Sci Technol 51:1421–1426

Saeed K, Khan I, Gul T, Sadiq M (2017) Efficient photodegradation of methyl violet dye using TiO2/Pt and TiO2/Pd photocatalysts. Appl Water Sci 7:3841–3848

Shah A, Shahzad S, Munir A, Nadagouda MN, Khan GS, Shams DF, Dionysiou DD, Rana UA (2016) Micelles as soil and water decontamination agents. Chem Rev 116:6042–6074

Sharma O, Sharma MK (2013) Copper hexacyanoferrate(II) as photocatalyst: decolorisation of neutral red dye. Int J ChemTech Res 5:2706–2716

Su Y, Yang Y, Zhang H, Xie Y, Wu Z, Jiang Y, Fukata N, Bando Y, Wang ZL (2013) Enhanced photodegradation of methyl orange with TiO2 nanoparticles using a triboelectric nanogenerator. Nanotechnology. https://doi.org/10.1088/0957-4484/24/29/295401

Tolia JV, Chakraborty M, Murthy ZVP (2012) Photocatalytic degradation of malachite green dye using doped and undoped ZnS nanoparticles. Pol J Chem Technol 14:16–21

Vautier M, Guillard C, Herrmann JM (2001) Photocatalytic degradation of dyes in water: case study of indigo and of indigo Carmine. J Catal 201:46–59

Xu L, Zhu Y, He X, Han G, Tian X (2008) Evaluation of a new fungus Ceriporia lacerate strain P2—its ability to decolorize alizarin red and methyl orange. World J Microbiol Biotechnol 24:3097–3104

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Saeed, K., Sadiq, M., Khan, I. et al. Synthesis, characterization, and photocatalytic application of Pd/ZrO2 and Pt/ZrO2. Appl Water Sci 8, 60 (2018). https://doi.org/10.1007/s13201-018-0709-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0709-7