Abstract

Nowadays, there are increasingly stringent regulations requiring more and more treatment of industrial effluents to generate product waters which could be easily reused or disposed of to the environment without any harmful effects. In the present work, the removal of phenol from aqueous solution across polymer inclusion membrane (PIM), based on mixture of cellulose triacetate and cellulose acetate as support (75/25%), calix[4]resorcinarene derivative as a carrier and 2-nitrophenyl octyl ether (2-NPOE) as plasticizer was investigated. The experimental part of this investigation involved the influence of carrier nature, plasticizer concentration, pH phases, and phenol initial concentration on the removal efficiency of phenol from synthetic wastewater. A PIM containing 0.1 g (of mixture polymer), (0.15 g/g mixture of polymer) of carrier and (0.03 ml/g mixture of polymer) of 2-NPOE provided the highest percentage of phenol removal efficiency over a 6-day transport; the removal was found to be about 95%, indeed the removal was found to be highly dependent of pH phases. The feed solution in these transport experiments was at pH 2, while the stripping solution contained 0.20 M NaOH. This study claims that the PIM with a mixture of cellulose derivatives can be used effectively to remove phenols from wastewaters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Phenols discharged to aqueous systems can produce an unpleasant odor and are harmful to human health. Therefore, phenolic wastewater becomes a great concern in wastewater treatment. There are several techniques have been applied to remove the phenol and its derivatives from wastewater, including the conventional methods of distillation and extraction (Bendini et al. 2003) chemical oxidation (Amiri et al. 2011), biodegradation (Tobajas et al. 2012), and sorption (Hao et al. 2009). Of these methods, membrane separation appears to be a suitable process based on overall separation performance. Studies on membrane separation of small organic molecules from dilute aqueous solutions have included systems based on bulk liquid membranes (Reis et al. 2007), emulsion liquid membranes (Manzak and Tutkun 2004), and supported liquid membranes (Badgujar and Rastogi 2011; Juang and Chen 1997). PIMs have attracted increasing interest due to their potential to reduce the chemical hazards associated with conventional solvent extraction technologies. In PIMs techniques, a complexant agent, the carrier is immobilized in a base polymer with a plasticizer. In recently conducted studies, we have verified the suitability of PIMs with Cyanex 923 as carrier and CTA as a base polymer to extract phenol from its dilute acidic solution and transport it quantitatively into receiving a solution containing at least 0.25 M of NaOH (Pérez-Silva et al. 2013). The PIMs applied in these studies are relatively stable and provide the potential for a safe method for the removal of phenol from dilute aqueous solutions. The polymer inclusion membrane containing polyvinyl chloride (PVC) as the polymer matrix and N, N-di(1-methylheptyl) acetamide (N503) as a specific carrier was prepared by solvent evaporation and investigated in the facilitated transport of phenol from dilute aqueous solutions (Meng et al. 2015). In previous work (Benosmane et al. 2016), we have tested the transport of phenol through polymer inclusion membrane using triacetate cellulose (CTA) only as support and calix[4]resorcinarene as a carrier; in this study, we explored the potential of using polymer inclusion membrane (PIM) with the mixture of cellulose triacetate (CTA) and cellulose acetate (CA) as support and two calix[4]resorcinarenes as a carrier for phenol removal from synthetic wastewater. The removal efficiency characteristics of phenol from aqueous solutions were investigated through a batch study.

Materials and methods

Membrane preparation

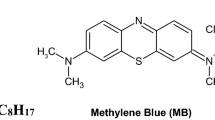

Polymer inclusion membranes were prepared according to the procedure reported by Sugiura et al. (1987); the amount of each constituent was a function of the series of experiments to be performed. Thus, for CTA and CA membrane, 10 ml of a polymer solution (0.1 g of mixture polymer CTA: 75% + CA: 25% in dichloromethane), calix[4]resorcinarene (0–0.06 g/g mixture of polymers) (Fig. 1), and plasticizer (0–0.03 ml of plasticizer/g mixture of polymers) were placed into a Petri dish of 9.0 cm diameter. This solution was allowed to evaporate overnight at room temperature in a hood.

Phenol analyses

The phenol quantification in the transport experiments was carried out using a UV/Vis spectrophotometer Jenway-Serie 6800 at 210 nm.

Transport experiments

A typical laboratory scale device was used for phenol transport experiments through the PIM. It consisted of two compartments made of Teflon with a maximum capacity of 400 ml separated by the PIM and the PIM area exposed to the aqueous phase were 12.56 cm2. One of them contained 10−3 M of phenol as the feed phase, and the other, the stripping phase, contained NaOH in different concentrations. All transport experiments were carried out in triplicate keeping the aforementioned cell at room temperature (25 °C), both phases are agitated. In all figures, the reported error bars represent the standard deviation of the data.

Results and discussion

Effect of contact time

The effect of contact time on the efficiency removal of phenol is presented in Fig. 2. These figures show the removal of phenol increases with increasing contact time attains equilibrium in 4 days. Indeed the larger concentration gradient of phenol is driving force for phenol elimination across the PIM. After this period, the removal of phenol versus time curves are smooth and continue leading to saturation. The higher removal rate at initial period can be attributed to the increase of a number of vacant sites on the carrier in the PIM (Benosmane et al. 2009).

The quantity of phenol eliminated after 6 days of transport (95%) was higher than 5 days (73%) (Benosmane et al. 2016).

Effect of stirring speed

The effect of stirring speed of feed phase and stripping phase in case of phenol elimination using PIM was determined by varying the stirring speed from 200 to 800 rpm (Fig. 3). It was observed that the transport of phenol increases from 200 to 600 rpm, but beyond 600 rpm we revealed a decrease because the aqueous boundary layer thickness decreased continuously with increasing stirring speed up to 600 rpm. The increase of agitation speed beyond 600 rpm leads to turbulence which then causes the release of the carrier out from membranes pores (Benosmane et al. 2015). Hence, the stirring speed of 600 rpm was selected for further experiments.

Effect of stirring speed on removal of phenol. Transport conditions: feed phase: phenol 10−3 M, pH 2. Stripping phase: NaOH 0.20 M. Membrane: 12.60 cm2 of surface area, calix[4]resorcinarene: RC8 (0.15 g/g mixture of polymers), 0.03 ml 2-NPOE/g mixture of polymers values obtained after 6 days of transport

Effect of plasticizer (2-NPOE) contents on the transport of phenol

Plasticizer plays a vital role in the transport of target as well as for membrane softness and flexibility in the PIMs. The influence of the plasticizer 2-NPOE content in the PIM on the removal of phenol was investigated by preparing PIMs at fixed quantity of calix[4]resorcinarene RC8 (0.15 g/g) and plasticizer in varying amounts (0–0.05 ml) (Fig. 4). PIM generated with the different amount of plasticizer was transparent with uniform thickness. Indeed, the transport test through the membrane without plasticizer and in the presence of carrier (RC8) shows a basal flux of phenol. Further variation in the amount of NPOE gives higher transport efficiency up to 0.03 ml of NPOE which might be due to the favorable plasticizer plasticization effect, beyond which a decrease in transport was attributed to intermolecular interaction between target and plasticizer molecule resulting in lower mass transfer (Nghiem et al. 2006).

Effect of plasticizer (2-NPOE) content on the transport of phenol. Transport conditions: feed phase: phenol 10−3 M, pH 2. Stripping phase: NaOH 0.20 M. Membrane: 12.60 cm2 of surface area, calix[4]resorcinarene: RC8 (0.15 g/g mixture of polymers), (0–0.05 ml 2-NPOE/12.56 cm2 mixture of polymers) values obtained after 6 days of transport

Effect of initial concentration of phenol

The effect of initial phenol concentration in feed phase on the transport flux across the PIMs is presented in (Fig. 5). The quantity of target transported increases with increasing initial phenol concentrations in feed phase from 0 to 0.001 M, beyond a decrease in transported quantity was observed due to the formation of a milky layer on the membrane surface. This observation was likely one of the reasons of the flux limit. However, other reasons could be related to the kinetics of the phenol uptake, which could have reached its maximum value, or to a complex of different stoichiometries formed at the highest phenol concentration less soluble in the PIM core.

Effect of initial concentration of phenol. Transport conditions: feed phase: phenol (0–0.0025 M), pH 2. Stripping phase: NaOH 0.20 M. Membrane: 12.60 cm2 of surface area, calix[4]resorcinarene: RC8 (0.15 g/g mixture of polymers), (0.03 ml 2-NPOE/12.56 cm2 mixture of polymers) values obtained after 6 days of transport

Effect of calix[4]resorcinarene nature

Some of the calix[4]resorcinarene have the ability to form a complex with phenolic compounds. In the present study, two different types of calix[4]resorcinarene such as RC8 and RCph were used as a carrier in polymer inclusion membrane (PIM). The phenol concentration was kept at 10−3 M. The membrane without calix[4]resorcinarene did not transport the phenol to the stripping phase. The percentage of phenol removal are presented in Table 1, which indicates that the RC8 shows higher mass transfer as compared to RCph; which is dependent on the intermolecular interactions between the phenol and calix[4]resorcinarene; this complex can form by hydrogen bonding and or intermolecular interactions, when the complex formed is more stable and the phenol can be easily eliminated.

Effect of pH solution of feed phase on the removal efficiency of phenol

It can be observed in Table 2. When the feed solution pH is equal to 2, the removal efficiency of phenol reaches the maximum 95%; this result is in agreement with those obtained by Pérez-Silva et al. (2013) and Benosmane et al. (2016). The phenol-calix[4]resorcinarene complex was formed by hydrogen bond, in addition the degree of ionization of phenol was comparatively stronger at the higher pH (pH 3) which decreases the complexation rate between calix[4]resorcinarene and phenol. The formation rate of phenol-calix[4]resorcinarene complex was influenced strongly by pH of feed phase. Regarding the influence of pH on the surface of the membrane when in contact with the environment medium, the surface of the membrane consists of cellulose acetate polymer chains and calix[4]resorcinarene macromolecules; in fact, the acid medium will not affect the surface by which this type of polymer is stable to pH acid and even see basic. We have verified with Infra-Red spectroscopy technique (FTIR) that the membranes after contact with the acidic medium we conclude no modification on the surface weres observed.

Effect of NaOH concentration in stripping phase on the transport of phenol

Figure 6 shows the effect of NaOH concentration in strip phase on the elimination efficiency of phenol with keeping the pH of feed phase constant at pH 2. We have observed that the removal of phenol increased with increasing the concentration of NaOH from 0 to 0.20 M but with CTA used only as support, NaOH concentration was 0.25 M (Benosmane et al. 2016); possible explanation was the change of character of surface in the case of the mixture of CTA and CA. At acidic medium, the mass transfer of target is less due to the presence of protons ions, which can prevent the complex formation between phenol and carrier. Moreover, the presence of OH− with high quantity can affect the formation of the complex.

Effect of NaOH concentration in stripping phase on the removal efficiency of phenol. Transport conditions: feed phase: phenol 10−3 M, pH 2. Stripping phase: NaOH 0–0.30 M. Membrane: 12.60 cm2 of surface area, calix[4]resorcinarene: RC8 (0.15 g/g mixture of polymers), 0.03 ml 2-NPOE/g polymers. Values obtained after 6 days of transport

Effect of plasticizer content on membrane stability

The stability of PIMs for a different quantity of plasticizer 2-NPOE (0.01–0.03 ml) in PIMs preparation under the same conditions was evaluated. The feed and strip phases were renewed every 6 days (one cycle) without changing the membrane (Fig. 7.) A gradual decrease of the phenol removal efficiency was observed with increasing the number of cycles. We observed that in the case of the PIM with 0.01 ml of plasticizer after 4 days of use the decrease was important with 47%, but with 0.02 ml of plasticizer the decrease appears to be linear and the percentage of diminution was 21%; then with 0.03 ml of NPOE, the decrease was reached 27%.

Suggested mechanism

Transport of phenol by the calix[4]resorcinarene RC8 obeys a facilitated co-transport (Fig. 8). As it is shown in Fig. 8, the phenol forms a neutral complex at the interface feed phase/membrane and after forming a hydrophobic pair complex, the resulting complex diffuses through the membrane phase to the membrane/strip phase interface. Then the free carrier diffuses back across the polymer inclusion membrane and the cycle starts again. The net result is the mass transfer of phenol forms source phase to the receiving phase through a PIM system.

Conclusion

In the present study, two different types of calix[4]resorcinarene such as RC8 and RCph were used as a carrier in polymer inclusion membrane (PIM). RC8 shows higher mass transfer as compared to RCph; which is dependent on the intermolecular interactions between the phenol and calix[4]resorcinarene, this complex can be formed by hydrogen bonding and/or intermolecular interactions. It can be observed when the feed solution pH is equal to 2, the removal efficiency of phenol reaches the maximum 95%, since the larger concentration gradient of phenol is the factor driving phenol across the PIM. This work has demonstrated the developed PIM on the removal of phenol from synthetic wastewater. The method was simple, easy and also rapidly applied for wastewater sample. The results show that the PIM with the mixture of CTA and CA has the high analytical potential for removing phenol from water samples.

References

Amiri H, Jaafarzadeh N, Ahmadi M, Martinez SS (2011) Application of LECA modified with Fenton in arsenite and arsenate removal as an adsorbent. Desalination 272:212–217

Badgujar V, Rastogi NK (2011) Extraction of phenol from aqueous effluent using triglycerides in supported liquid membrane. Desalination Water Treat 36:187–196

Bendini A, Cerretani Bonoli M, Biguzzi L, Lercker B, Toschi TG (2003) Liquid-liquid and solid-phase extraction of phenols from virgin olive oil and their separation by chromatographic and electrophoretic methods. J Chromatogr A 985:425–433

Benosmane N, Boutemeur B, Hamdi M, Hamdi SM (2009) Selective transport of metal ions across polymer inclusion membranes (PIMs) containing calix[4]resorcinarenes. Sep Purif Technol 65:211–219

Benosmane N, Boutemeur B, Hamdi M, Hamdi SM (2015) Application of cellulose acetate membranes for removal of toxic metal ions from aqueous solution. Fresenius Environ Bull 24:2296–2309

Benosmane N, Boutemeur B, Hamdi SM, Hamdi M (2016) The removal of phenol from synthetic wastewater using calix[4]resorcinarene derivative based polymer inclusion membrane. Algerian J Environ Sci Technol 2(2):26–33

Hao X, Pritzker M, Feng X (2009) Use of pervaporation for the separation of phenol from dilute aqueous solutions. J Membr Sci 335(1):96–102

Juang RS, Chen LJ (1997) Transport rate of citric acid across a supported liquid membrane containing salts of a tertiary amine. J Membr Sci 123:81–87

Manzak A, Tutkun O (2004) Extraction of citric acid through an emulsion liquid membrane containing aliquat 336 as a carrier. Sep Sci Technol 39:2497–2512

Meng X, Gao CG, Wang L, Wang X, Tang W, Chen H (2015) Transport of phenol through polymer inclusion membrane with N, N-di (1-methylheptyl) acetamide as carriers from aqueous solution. J Membr Sci 493:615–621

Nghiem LD, Morname P, Potter JM, Perera Cattrall RW, Kolev SD (2006) Extraction and transport of metal ions and small organic compounds using polymer inclusion membranes (PIMs). J Membr Sci 218:7–41

Pérez-Silva I, Galán-Vidal CA, Ramírez-Silva MT, Rodríguez JA, Álvarez-Romero GA, Páez-Hernández ME (2013) Phenol removal process development from synthetic wastewater solutions using a polymer inclusion membrane. Ind Eng Chem Res 52:4919–4923

Reis MTA, Ondina MF, Rosinda M, Ismael C, Jorge M, Carvalho R (2007) Recovery of phenol from aqueous solution using liquid membranes with Cyanex 923. J Membr Sci 305:313–324

Sugiura M, Kawa MK, Urita S (1987) Effect of plasticizer on the carrier-mediated transport of zinc ion through cellulose triacetate membranes. Sep Sci Technol 22:2263

Tobajas M, Mohedano AF, Rodriguez JJ (2012) Enhancement of cometabolic biodegradation of 4-chlorophenol induced with phenol and glucose as carbon sources. J Environ Manag 95:116–121

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Benosmane, N., Boutemeur, B., Hamdi, S.M. et al. Removal of phenol from aqueous solution using polymer inclusion membrane based on mixture of CTA and CA. Appl Water Sci 8, 17 (2018). https://doi.org/10.1007/s13201-018-0643-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0643-8