Abstract

In this study, simultaneous removal of Cr(VI) and phenol from binary solution was carried out using Fe-treated tea waste biomass. The effect of process parameters such as adsorbent dose, pH, initial concentration of Cr(VI) (mg/L), and initial concentration of phenol (mg/L) was optimized. The analysis of variance of the quadratic model demonstrates that the experimental results are in good agreement with the predicted values. Based on experimental design at an initial concentration of 55 mg/L of Cr(VI), 27.50 mg/L of phenol, pH 2.0, 15 g/L adsorbent dose, 99.99% removal of Cr(VI), and phenol was achieved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Heavy metals are generally present with phenolic compounds in the environment cause adverse effects on flora and fauna, including human beings (Aksu and Akpinar 2001). Precipitation/coagulation (Wang et al. 2011), chemical oxidation (Dittert et al. 2014), biodegradation (Annadurai et al. 2008), adsorption (Jain et al. 2011), ion exchange (Cavaco et al. 2007), membrane processing (Lin et al. 2014), electrolytic methods (Hamdan and El-Naas 2014), carbon nanomaterial (Salam et al. 2012), etc. are some important methods which have been used to remove the heavy metal ion and phenolic contents together. These components are generally present in the effluents of various industries such as leather tanning, electroplating, and alloying extra (Gladysz-Plaska et al. 2012). Cr(VI) and its copollutants such as phenol, naphthalene, and trichloroethylene discharge from these industries contaminate ground water aquifers, lake, river sediments, and soil (Yen-Hui et al. 2009). Much research has been carried out on the adsorption of a single pollutant nevertheless the fact that organic pollutants also exist with multiple metallic species (Repo et al. 2011; Gupta and Balomajumder 2015); therefore, in the recent year, simultaneous removal of heavy metals and organic compounds has gained a great attention in wastewater treatment processes (Mani et al. 2015). Adsorption of pollutant using commercial granular activated carbon is conventional method, but due to its high cost, this method is not economical (Suresh et al. 2011). Adsorption is proved to be most promising conventional or traditional methods for the simultaneous removal of organic compound and heavy metal ions from wastewater in comparison with other treatment methods such as precipitation, ion exchange, catalytic reaction, etc. (Quintelas et al. 2006; Aksu and Akpinar 2001). Modification of biosorbent by metal impregnation (Talreja et al. 2014) and acid treatment (Garg et al. 2009) improves the percentage removal of pollutants (Kuo and Bembenek 2008; Fonseca-Correa et al. 2013; Owlad et al. 2010; Cronje et al. 2011). Chromium is found in the environment predominantly in two forms Cr(III) and Cr(VI) out of which Cr(VI) is most mutagenic and carcinogenic to the living organism (Acar and Malkoc 2004; Baral et al. 2009). Chromium sulfate [Cr(III)] is used as a tanning agent which can be converted to Cr(VI) and causes severe contamination of ground water (El-Sherif et al. 2013). Phenol is highly toxic and recalcitrant organic compound used as a biocide in the leather tanning process (Srivastava et al. 2007; Hank et al. 2014). According to WHO, the maximum permissible limit of Cr(VI) in drinking water is 0.05 mg/L (Bansal et al. 2009). According to the US environmental protection agency, the maximum permissible limit of discharge of phenol by various process industries is 0.005 mg/L (Banerjee and Ghoshal 2011). The aim of this work is to optimize the process parameters such pH, contact time, adsorbent dose for the simultaneous removal of Cr(VI), and phenol in a multicomponent simulated synthetic wastewater using Box–Behnken design of response surface methodology (RSM). Characterization of Fe-treated tea waste biomass before and after adsorption was also carried out to confirm the simultaneous adsorption of Cr(VI) and phenol using various techniques such as FTIR, FE-SEM, EDX, and BET surface area.

Materials and methodology

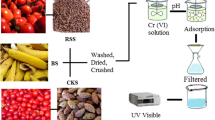

Preparation of biosorbent

Tea waste biomass was collected from local tea stall Roorkee. A soluble sugar and dirt present in tea waste biomass was removed by boiling in distilled water about for 30 min. After boiling, tea waste biomass was washed with distilled water in triplicate and then dried in hot air oven at 50 °C for 12 h. Furthermore, the dried biomass was sieved to the desired particle size 0.5–2 mm (Gupta and Balomajumder 2015).

5 g of tea waste biomass was added to 50 mL solution of 2 M FeSO4·7H2O in 500 mL conical flask. It was kept on a magnetic stirring plate at 100 °C for the impregnation of Fe ions onto the surface of tea waste. 0.1 M of NaOH was added dropwise to the conical flask by the help of burette to increase the pH 4–5 for the precipitation of ferrous sulfate. This process was carried out continuously 3–4 h. Upon cooling, the tea waste biomass was covered with a thick layer of orange color iron oxide. Then, tea waste biomass was washed with distilled water to remove extra quantity of precipitate. Finally, this Fe-treated tea waste biomass was dried in an oven at 50 °C for 2 h and then sieved to obtain homogeneous particle size (Nethaji et al. 2013).

Preparation of solutions

All chemicals used for the experimentation purpose including potassium dichromate and phenol were AR grade having more than 99% purity. Stock solutions of Cr(VI) and phenol were prepared by dissolving known quantity of phenol and potassium dichromate in 1 L of Millipore water. To avoid photo-oxidation of phenol, stock solution was stored in brown glass bottle (Chaudhary and Balomajumder 2014). Based on industrial wastewater such as tannery and electroplating, 2:1 ratio of Cr(VI) and phenol were taken for conducting the present experiments, because these components are generally present in the wastewater in this composition (Aksu and Akpinar 2001; Gupta and Balomajumder 2015).

Batch experiments

Batch adsorption studies were carried out in 250 mL round bottom flasks with working volume of 100 mL. The synthetic, simulated binary wastewater was prepared in the laboratory by mixing the necessary amount of K2Cr2O7 and phenol in 2:1 ratio (Anupam et al. 2011). RSM (response surface methodology) using Box–Behnken design was used for the optimization of process parameters. Box–Behnken design does not contain any corner point in the design; therefore, number of experimental run generated is comparatively less than CCD. A range of process parameters was selected as pH (2–8), adsorbent dose (0.5–1.5 g), initial concentration of Cr(VI) (10–100 mg/L), and initial concentration of phenol (5–50 mg/L). The experiments were carried out in an incubator shaker at temperature 30 °C until the equilibrium condition was achieved. The pH of binary solution was controlled by adding 0.1 N HCl and 0.1 N NaOH. When equilibrium was attained, the sample was filtered using the standard Whatman filter paper (Cat No. 1001 125). Thereafter, concentration of Cr(VI) and phenol in the filtrate was analyzed using a UV spectrophotometer.

The percentage removal of phenol and Cr(VI) was calculated by the following equation:

where C i and C t are the initial and final concentrations of the pollutant, respectively.

Analytical method

The residual concentration of Cr(VI) and phenol in the filtrate was analyzed using UV spectrophotometer made of Hach (model no: DR 5500). The residual concentration of Cr(VI) was measured by reacting 10 mL of filtrate with a 200 µL diphenyl carbazide solution and 500 µL H2SO4 and let them stand for 10 min for full color development and its absorbance was noted at 540 nm. For the analysis of phenol, 10 mL of phenol sample was mixed with 0.7 mL of sodium bicarbonate (pH 8), 0.1 mL of 4-amino antipyrine (20.8 mM), and 0.1 mL of potassium ferricyanide (83.4 mM) and let them stand for full color development and its absorbance was noted at 510 nm (Srihari and Das 2008). Both phenol and K2Cr2O7 do not interact with each other as there was no effect on the absorbance of both components and can be measured for the same filtrate in UV spectrophotometer at 510 and 540 nm, respectively.

Characterization of biosorbent

FTIR of tea waste biomass before and after adsorption

The FTIR spectrum is an important tool used for the identification of characteristic functional groups responsible for the adsorption of Cr(VI) and phenol onto the surface of Fe-treated tea waste biomass. The FTIR spectrum of tea waste biomass before surface modification, after surface modification, and after simultaneous adsorption of Cr(VI) and phenol is shown in Fig. 1a–c, respectively. FTIR study suggested that functional groups such as N–H, O–H, C=O, and C–O were present onto the surface of tea waste biomass (Golbaz et al. 2014). The FTIR spectrum of tea waste biomass before adsorption (Fig. 1a) indicates the strong band of O–H functional groups at 3612.29 cm−1 wavelength (Kamsonlian et al. 2011; Srivastava et al. 2015). Adsorption band at around 1989–1654.67 cm−1 indicates the C=O group (Moussavi and Barikbin 2010). Furthermore, peaks at 1396.67 and 1095.67 cm−1 were significance of C–O and N–H stretching (Mohan et al. 2006). After surface modification of tea waste biomass shown in Fig. 1b, there is a change in the vibration of the O–H functional group at 3443.04 cm−1 which became broad after simultaneous adsorption of Cr(VI) and phenol, as shown in Fig. 1c. A peak of the C–H functional group at 2923.82 cm−1 was observed after surface modification of tea waste biomass (Quintelas et al. 2009). Furthermore, the shift in the functional groups such as C=O, C–O, and N–H was observed after surface modification and after simultaneous adsorption of Cr(VI) and phenol, as shown in Fig. 1b, c, respectively. Changes in the peak of functional group after surface modification shown in Fig. 1b depict that the surface of tea waste biomass was modified as iron was impregnated. Furthermore, the changes in the peak of functional group shown in Fig. 1c confirm the simultaneous adsorption of Cr(VI) and phenol onto the surface of Fe-treated tea waste biomass.

SEM and EDX analysis

FE-SEM shows the morphology of tea waste biomass before surface modification, after surface modification, and after simultaneous adsorption of Cr(VI) and phenol onto the surface of Fe-treated tea waste biomass, as shown in Fig. 2a–c, respectively. The composition of various elements present onto the surface of tea waste biomass was obtained by EDX analysis. It is clear from SEM analysis that (Fig. 2a), before the surface modification, surface was highly porous and homogeneous as large number of pores was observed. The surface morphology of tea waste biomass after surface modification was different from before surface modification. After surface modification, it was covered with a layer of Fe ions. After simultaneous adsorption of Cr(VI) and phenol onto the surface of Fe-treated tea waste biomass, the surface became rough and bulky, which was due to the fact that all the active pores were filled with Cr(VI) and phenol anion. The adsorption of Cr(VI) and phenol anions was due to strong electrostatic force between negatively charged Cr(VI) and phenol anions and positively charged tea waste biomass surface (Zuo and Balasubramanian 2013). The EDX of tea waste biomass before surface modification, after surface modification, and after simultaneous adsorption of Cr(VI) and phenol is shown in Fig. 3a–c, respectively. The results of the EDX analysis showed a sharp peak of elements such as C, O, and Ca before surface modification, but after surface modification, a peak of Fe in K and L shell of tea waste biomass was observed which confirms that iron was impregnated onto the surface of tea waste biomass. After simultaneous adsorption of Cr(VI) and phenol, a peak of Cr in K and L shell was observed which confirms the adsorption of Cr(VI). The changes in the peaks of carbon and oxygen in the EDX spectrum before and after adsorption confirm the adsorption of phenol. The weight % of elements present onto the surface of tea waste biomass before surface modification, after surface modification, and after simultaneous adsorption of Cr(VI) and phenol is given in Tables 1, 2, and 3, respectively. From Tables 1, 2, and 3, it is clear that after surface modification with FeSO4·7H2O, the weight % of C was decreased, while weight % of O was increased. After simultaneous adsorption of Cr(VI) and phenol, a peak of 4.87 weight % of Cr and changes in the weight % of C and O were observed in the EDX spectra which confirm the simultaneous adsorption of Cr(VI) and phenol (Kumar et al. 2012).

BET surface area analysis

BET surface area and total pore volume of the tea waste biomass before and after surface modification, and after simultaneous adsorption of Cr(VI) and phenol are given in Table 4. The surface area of tea waste biomass was calculated using surface area analyzer ASAP 2010 Micrometrics, USA). The surface area of tea waste biomass was (23.658 m2/g). After surface modification, the surface area was slightly decreased (20.196 m2/g), because iron was impregnated onto the surface of tea waste biomass. After simultaneous adsorption of Cr(VI) and phenol, the surface area was reduced (2.456 m2/g), because all the pores were filled by Cr(VI) and phenol anions.

Experimental design and procedure

The Box–Behnken design matrix has been applied for the simultaneous adsorption of Cr(VI) and phenol using the design expert software 6.0.8. The interactive effects of four most important operating variables, pH (X 1), adsorbent dose (X 2), initial concentration of Cr(VI) (X 3), and initial concentration of phenol (X 4), were determined onto the percentage removal of Cr(VI) and phenol. A total of 29 experiments was carried out in the present study as suggested by Box–Behnken design for the construction of quadratic equation model for the two responses Y 1 [percentage removal of Cr(VI)] and Y 2 (percentage removal of phenol). An orthogonal 24 Box–Behnken design (BBD) with five replicates at the center point was used to optimize the selected key variables (X 1, X 2, X 3, and X 4) (Singh et al. 2013). The coded values of the process parameters were determined by the following equation (Rajasimman et al. 2009; Satapathy and Das 2014; De Sales et al. 2013):

where x i is the coded value of the ith variable, X i is the uncoded value of the ith test variable, and X o is the uncoded value of the ith test variable at center point. The range and level of individual variables selected are given in Table 5. The Box–Behnken experiment design for the simultaneous adsorption of Cr(VI) and phenol onto the Fe-treated tea waste biomass is given in Table 6 which shows that the experimental data are close to the predicted value (Park et al. 2011).

Model and statistical analysis

The experimental data were analyzed using ANOVA (Analysis of variance) and validated for two responses of interest percentage removal of Cr(VI) (Y 1) and percentage removal of phenol (Y 2). A second-order polynomial equation was developed to study the interactive effect of four process parameters (X 1, X 2, X 3, and X 4) onto the percentage removal of Cr(VI) (Y 1) and Y 2 (percentage removal of phenol) (Chaudhary and Balomajumder 2014; Abigail et al. 2015).

where Y i is the predicted value of the response of interest, α o is intercept coefficient, α i is linear coefficient, α ii is quadratic regression coefficient, and α ij is regression coefficients of interaction. Some insignificant terms of the above model can be neglected based on the statistical analysis for the accurate prediction of response (Cao et al. 2014).

Results and discussion

The effect of process variable on response of interest was investigated by conducting a total of 29 experiments suggested by the Box–Behnken design of design expert software (Ferreira et al. 2007). Batch experiments were conducted for visualizing the effects of independent variables on responses of interest. Multiple regression analysis using response surface methodology was carried out to generate the following regression equation for the two responses of interest Y 1 and Y 2 (Xu et al. 2013):

The regression equation coefficients were calculated and the data fitted to a second-order polynomial equation for simultaneous removal of Cr(VI) and phenol. The results of ANOVA for the response Y 1 [percentage removal of Cr(VI)] and Y 2 (percentage removal of phenol) are given in Tables 7 and 8, respectively. The significance of the second-order quadratic equation developed depends upon the coefficient of determination (R 2) and F test (Gonen and Aksu 2009). Values of “P > F” less than 0.05 indicate that model terms are significant for the simultaneous removal of Cr(VI) and phenol (Pavlovic et al. 2014). The value of the mean squares is calculated by dividing the sum of squares of each variable by their respective degree of freedom. The F (Fishers’ variance ratio) value is calculated by taking the ratio of the mean square owing to regression and the mean square owing to error. F values show the variation in the experimental and predicted values of the variables about the mean. Here, the ANOVA of the regression model for response Y 1 [percentage removal of Cr(VI)] and response Y 2 (percentage removal of phenol) shows that the model is highly significant which is confirmed by the calculated F value for response Y 1 (79.53) and response Y 2 (50.11) and a very low probability value (P ≤ 0.0001) was obtained for both responses Y 1 and Y 2 (Cao et al. 2014). The lack of fit F value for response Y 1 (147.32) and Y 2 (185.22) depicts that the lack of fit is significant. There is only a 0.01% chance of “Lack of Fit F value” (Kumar et al. 2009). The predicted R 2 for response Y 1 (0.9285) is in reasonable agreement with the adjusted R 2 of 0.9752. Similarly, for response Y 2, the predicted R 2 (0.8873) is in good agreement with adjusted R 2 (0.9606) (Sahu et al. 2009). “Adequate Precision” measures the signal-to-noise ratio, and a ratio greater than 4 is desirable (Gonen and Aksu 2009). Here, the ratio of 31.253 for response Y 1 and 26.376 for response Y 2 indicates an adequate signal.

Interaction effects of independent variables (X 1, X 2, X 3, and X 4 on responses Y 1 and Y 2)

RSM is a statistical method for the analysis of interactive effects of operating variables onto the response of interest. The effects of independent process variables were evaluated by 3D plots shown in Fig. 4a, b for response Y 1 [percentage removal of Cr(VI)] and Fig. 5a, b for response Y 2 (percentage removal of phenol). For response Y 1, the linear effects of the process variables X 1 (pH), X 2 (adsorbent dose), X 3 (initial concentration of Cr(VI) are highly significant, given in Table 5, which is confirmed by high F values and low P value (P < 0.0001) (Fereidouni et al. 2009; Singh et al. 2013), but the effect of X 4 (initial concentration of phenol) was not highly significant as the P values obtained were P > 0.005. Similarly, the linear effects of process variables (X 1, X 2, X 3, and X 4) were examined onto the percentage removal of phenol (response Y 2) given in Table 6 which shows that effect of pH (X 1), adsorbent dose (X 2), and initial concentration of phenol (X 4) was highly significant. The effect of process variable X 3 [initial concentration of Cr(VI)] onto the percentage removal of phenol was not highly significant. Therefore, the percentage removal of Cr(VI) and phenol in the binary mixture using Fe-treated tea waste biomass was not affected by the presence of each other. It can be concluded that Cr(VI) and phenol can be easily removed from binary mixture using Fe-treated tea waste biomass. The effects of X 21 , X 22 , X 23 , and X 24 onto the responses Y 1 and Y 2 were also appreciated. The combined effects of adsorbent dose and pH (X 1 X 2), initial concentration of Cr(VI), and initial concentration of phenol (X 3 X 4) onto the responses Y 1 and Y 2 were also observed. Based on the response surface design, it is evident that at an initial concentration of 55 mg/L of Cr(VI), 27.50 mg/L of phenol, pH 2.0, adsorbent dose 15 g/L, and 99.99% removal of both Cr(VI) and phenol was obtained. The response surface curves were plotted, as shown in Fig. 4a, b which depicts the effect of independent variables onto the percentage removal of Cr(VI). Figure 5a, b shows the effects of independent variables onto the percentage removal of phenol. The circular nature of the contour signifies that the effect of initial concentration of phenol onto the percentage removal of Cr(VI) and initial concentration of Cr(VI) onto the percentage removal of phenol was not significant, as shown in Figs. 4b and 5b, respectively. The percentage removal of Cr(VI) decreases with the increase in the initial concentration of Cr(VI) and percentage removal of phenol decreases with the increase in the initial concentration of phenol. The effects of adsorbent dose, pH, and initial concentration of Cr(VI) onto the percentage removal of Cr(VI) were found significant. Similar effects of these independent variables onto the percentage removal of phenol were observed. The percentage removal of Cr(VI) and phenol was decreased with increasing pH and increases with increase in adsorbent dose. The possible reason of these phenomena is given below.

Effect of pH onto the percentage removal of Cr(VI) and phenol

pH is an important parameter for the simultaneous removal of Cr(VI) and phenol. At low pH value, the percentage removal of Cr(VI) and phenol was maximum, because at low pH value, the surface of Fe-treated tea waste biomass becomes more protonated. At low pH, Cr(VI) was in the form of Cr2O7 2− and HCrO4 −, while phenol was present in the form of C6H5O− (Chaudhary and Balomajumder 2014). Therefore, there is a strong electrostatic interaction between negatively charge chromate, dichromate, and phenolate anions to the positively charged surface of Fe-treated tea waste biomass. At high pH value, after pH 6, a rapid decrease in the percentage removal of Cr(VI) and phenol was observed, because at this pH, the surface of biosorbent becomes negatively charged which repel the Cr(VI) and phenol anions. Favorable adsorption occurs between pH (2–5). There was also a competition between negatively charged phenolate and chromate anions for adsorption to the vacant positively charged active sites. When all the vacant active sites are filled, equilibrium was established between negatively charged chromate and phenolate anions present in the synthetic binary solution and positively charged surface.

Effects of adsorbent dose onto the percentage removal of Cr(VI) and phenol

Fe-treated tea waste biomass is used as a adsorbent for the simultaneous adsorption of Cr(VI) and phenol. The simultaneous adsorption of both Cr(VI) and phenol from a binary mixture increases with the increase in adsorbent dose (mg/g) due to increase in possible active sites and surface area for adsorption. After reaching optimum adsorbent dose, simultaneous removal of both Cr(VI) and phenol becomes constant and then decreases. The decrease in percentage removal after reaching the optimum dose was due to all the vacant seats which were filled (Garg et al. 2004).

Conclusion

In this study, Fe-treated tea waste biomass was used for the simultaneous removal of Cr(VI) and phenol from binary mixture using Fe-treated tea waste biomass. Impregnation of Fe ions onto the surface of tea waste biomass improves the morphology of adsorbent and thus the percentage removal of Cr(VI) and phenol. Response surface methodology (RSM) using Box–Behnken design was used for the determination of optimum conditions for adsorption of Cr(VI) and phenol from binary mixture. The experimental and predicted values were in good agreement for both responses Y 1 [percentage removal of Cr(VI)] and Y 2 (percentage removal of phenol). A second-order quadratic equation was developed to predict the effects of independent variables onto the percentage removal of Cr(VI) and phenol from binary mixture. The application of statistical design using RSM for the adsorption of Cr(VI) and phenol from a binary mixture reduces the time and overall cost, and improved the efficiency of the process.

References

Abigail EA, Samuel MS, Chidambaram R (2015) Hexavalent chromium biosorption studies using Penicillium griseofulvum MSR1 a novel isolate from tannery effluent site: Box-Behnken optimization, equilibrium, kinetics and thermodynamic studies. J Taiwan Inst Chem Eng 49:156–164

Acar F, Malkoc NE (2004) The removal of chromium(VI) from aqueous solutions by Fagus orientalis L. Bioresour Technol 94:13–15

Aksu Z, Akpinar D (2001) Competitive biosorption of phenol and chromium (VI) from binary mixtures onto dried anaerobic activated sludge. Biochem Eng J 7:183–193

Annadurai G, Ling LY, Lee JF (2008) Statistical optimization of medium components and growth conditions by response surface methodology to enhance phenol degradation by Pseudomonas putida. J Hazard Mater 151:171–178

Anupam K, Dutta S, Bhattacharjee C, Datta S (2011) Adsorptive removal of chromium (VI) from aqueous solution over powdered activated carbon: optimisation through response surface methodology. Chem Eng J 173:135–143

Banerjee A, Ghoshal AK (2011) Phenol degradation performance by isolated Bacillus cereus immobilized in alginate. Int J Biodeterior Biodegrad 65:1052–1060

Bansal M, Singh D, Garg VK (2009) A comparative study for the removal of hexavalent chromium from aqueous solution by agriculture wastes’ carbons. J Hazard Mater 171:83–92

Baral SS, Das N, Chaudhury GR, Das SN (2009) A preliminary study on the adsorptive removal of Cr(VI) using seaweed, Hydrilla verticillata. J Hazard Mater 171:358–369

Cao J, Wu J, Jin Y, Yilihan P, Huang W (2014) Response surface methodology approach for optimization of the removal of chromium(VI) by NH2-MCM-41. J Taiwan Inst Chem Eng 45:860–868

Cavaco SA, Fernandes S, Quina MM, Ferreira LM (2007) Removal of chromium from electroplating industry effluents by ion exchange resins. J Hazard Mater 144:634–638

Chaudhary N, Balomajumder C (2014) Optimization study of adsorption parameters for removal of phenol on aluminum impregnated fly ash using response surface methodology. J Taiwan Inst Chem Eng 45:852–859

Cronje KJ, Chetty K, Carsky M, Sahu JN, Meikap BC (2011) Optimization of chromium(VI) sorption potential using developed activated carbon from sugarcane bagasse with chemical activation by zinc chloride. Desalination 275:276–284

De Sales PF, Magriotis ZM, Rossi MALS, Resende RF, Nunes CA (2013) Optimization by response surface methodology of the adsorption of Coomassie Blue dye on natural and acid-treated clays. J Environ Manag 130:417–428

Dittert IM, Brandao HDL, Pina F, da Silva EAB, de Souza SMAGU, de Souza AAU, Botelho CMS, Boaventura RAR, Vilar VJP (2014) Integrated reduction/oxidation reactions and sorption processes for Cr(VI) removal from aqueous solutions using Laminaria digitata macro-algae. Chem Eng J 237:443–454

El-Sherif IY, Tolani S, Ofosu K, Mohamed OA, Wanekaya AK (2013) Polymeric nanofibers for the removal of Cr(III) from tannery wastewater. J Environ Manag 129:410–413

Fereidouni M, Daneshi A, Younesi H (2009) Biosorption equilibria of binary Cd(II) and Ni(II) systems onto Saccharomyces cerevisiae and Ralstonia eutropha cells: application of response surface methodology. J Hazard Mater 168:1437–1448

Ferreira SLC, Bruns Ferreira HS, Matos GD, David JM, Brandao GC, da Silva EGP, Portugal LA, dos Reis PS, Souza AS, dos Santos WNL (2007) Box-Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597:179–186

Fonseca-Correa R, Giraldo L, Moreno-Pirajan JC (2013) Trivalent chromium removal from aqueous solution with physically and chemically modified corncob waste. J Anal Appl Pyrol 101:132–141

Garg VK, Gupta R, Kumar R, Gupta RK (2004) Adsorption of chromium from aqueous solution on treated sawdust. Bioresour Technol 92:79–81

Garg UK, Kaur MP, Sud D, Garg VK (2009) Removal of hexavalent chromium from aqueous solution by adsorption on treated sugarcane bagasse using response surface methodological approach. Desalination 249:475–479

Gladysz-Plaska A, Majdan M, Pikus S, Sternik D (2012) Simultaneous adsorption of chromium(VI) and phenol on natural red clay modified by HDTMA. Chem Eng J 179:140–150

Golbaz S, Jonidijafari A, Raffie M, Kalantry RR (2014) Separate and simultaneous removal of phenol, chromium and cyanide from aqueous solution by coagulation/precipitation: mechanisms and theory. Chem Eng J 253:251–257

Gonen F, Aksu Z (2009) Single and binary dye and heavy metal bioaccumulation properties of Candida tropicalis: use of response surface methodology (RSM) for the estimation of removal yields. J Hazard Mater 172:1512–1519

Gupta A, Balomajumder C (2015) Simultaneous removal of Cr(VI) and phenol from binary solution using Bacillus sp. immobilized tea waste biomass. J Water Process Eng 6:1–10

Hamdan SS, El-Naas MH (2014) Characterization of the removal of Chromium (VI) from groundwater by electrocoagulation. J Ind Eng Chem 20:2775–2781

Hank D, Azi Z, Hocine SA, Chaalal O, Hellal A (2014) Optimization of phenol adsorption onto bentonite by factorial design methodology. J Ind Eng Chem 20:2256–2263

Jain M, Garg VK, Kadirvelu K (2011) Investigation of Cr(VI) adsorption onto chemically treated Helianthus annuus: optimization using response surface methodology. Bioresour Technol 102:600–605

Kamsonlian S, Balomajumder C, Chand S, Suresh S (2011) Biosorption of Cd (II) and As (III) ions from aqueous solution by tea waste biomass. Afr J Environ Sci Technol 5:1–7

Kumar R, Singh R, Kumar N, Bishnoi K, Bishnoi NR (2009) Response surface methodology approach for optimization of biosorption process for removal of Cr(VI), Ni (II) and Zn(II) ions by immobilized bacterial biomass Bacillus Brevis. Chem Eng J 146:401–407

Kumar ASK, Gupta T, Kakan SS, Kalidhasan S, Mansi Rajesh V, Rajesh N (2012) Effective adsorption of hexavalent chromium through a three center (3c) co-operative interaction with an ionic liquid and biopolymer. J Hazard Mater 239:213–224

Kuo S, Bembenek R (2008) Sorption and desorption of chromate by wood shavings impregnated with iron or aluminum oxide. Bioresour Technol 99:5617–5625

Lin L, Xu X, Papelis C, Cath TY, Xu P (2014) Sorption of metals and metalloids from reverse osmosis concentrate on drinking water treatment solids. Sep Purif Technol 134:37–45

Mani AD, Reddy PMK, Srinivaas M, Ghosal P, Xanthopoulos N, Subrahmanyama C (2015) Facile synthesis of efficient visible active C-doped TiO2 nanomaterials with high surface area for the simultaneous removal of phenol and Cr(VI). Mater Res Bull 61:391–399

Mohan D, Singh KP, Singh VK (2006) Trivalent chromium removal from wastewater using low cost activated carbon derived from agricultural waste material and activated carbon fabric cloth. J Hazard Mater B135:280–295

Moussavi G, Barikbin B (2010) Biosorption of chromium(VI) from industrial wastewater onto pistachio hull waste biomass. Chem Eng J 162:893–900

Nethaji S, Sivasamy A, Mandal AB (2013) Preparation and characterization of corn cob activated carbon coated with nano-sized magnetite particles for the removal of Cr(VI). Bioresour Technol 134:94–100

Owlad M, Aroua MK, Daud WMAW (2010) Hexavalent chromium adsorption on impregnated palm shell activated carbon with polyethyleneimine. Bioresour Technol 101:5098–5103

Park D, Yun YS, Lee D, Park JM (2011) Optimum condition for the removal of Cr(VI) or total Cr using dried leaves of Pinus densiflora. Desal 271:309–314

Pavlovic MD, Buntic AV, Mihajlovski KR, Marinkovic SSS, Antonovic DG, Radovanovic Z, Brankovic SID (2014) Rapid cationic dye adsorption on polyphenol-extracted coffee grounds—a response surface methodology approach. J Taiwan Inst Chem Eng 45:1691–1699

Quintelas C, Sousa E, Silva F, Neto S, Tavares T (2006) Competitive biosorption of ortho-cresol, phenol, chlorophenol and Chromium(VI) from aqueous solution by a bacterial biofilm supported on granular activated carbon. Process Biochem 41:2087–2091

Quintelas C, Rocha Z, Silva B, Fonseca B, Figueiredo H, Tavares T (2009) Removal of Cd(II), Cr(VI), Fe(III) and Ni(II) from aqueous solutions by an Escherichia coli biofilm supported on kaolin. Chem Eng J 149:319–324

Rajasimman M, Sangeetha R, Karthik P (2009) Statistical optimization of process parameters for the extraction of chromium(VI) from pharmaceutical wastewater by emulsion liquid membrane. Chem Eng J 150:275–279

Repo E, Petrus R, Sillanpa M, Warchol JK (2011) Equilibrium studies on the adsorption of Co(II) and Ni(II) by modified silica gels: one-component and binary systems. Chem Eng J 172:376–385

Sahu JN, Acharya J, Meikap BC (2009) Response surface modeling and optimization of chromium(VI) removal from aqueous solution using Tamarind wood activated carbon in batch process. J Hazard Mater 172:818–825

Salam MA, Al-Zhrani G, Kosa SA (2012) Simultaneous removal of copper(II), lead(II), zinc(II) and cadmium(II) from aqueous solutions by multi-walled carbon nanotubes. CR Chim 15:398–408

Satapathy MK, Das P (2014) Optimization of crystal violet dye removal using novel soil-silver nanocomposite as nano adsorbent using response surface methodology. Environ Chem Eng J 2:2708–2714

Singh R, Narsi Bishnoi R, Kirrolia A (2013) Evaluation of Pseudomonas aeruginosa an innovative bioremediation tool in multi metals ions from simulated system using multi response methodology. Bioresour Technol 138:222–234

Srihari V, Das A (2008) The kinetic and thermodynamic studies of phenol-sorption onto three agro-based carbons. J Desalin 225:220–234

Srivastava S, Ahmad AH, Thakur IS (2007) Removal of chromium and pentachlorophenol from tannery effluents. Bioresour Technol 98:1128–1132

Srivastava V, Sharma YC, Sillanpa M (2015) Response surface methodological approach for the optimization of adsorption process in the removal of Cr(VI) ions by Cu2(OH)2CO3 nanoparticles. Appl Surf Sci 326:257–270

Suresh S, Srivastava VC, Mishra IM (2011) Adsorptive removal of phenol from binary aqueous solution with aniline and 4-nitrophenol by granular activated carbon. Chem Eng J 171:997–1003

Talreja N, Kumar D, Verma N (2014) Removal of hexavalent chromium from water using Fe-grown carbon nanofibers containing porous carbon microbeads. J Water Process Eng 3:34–45

Wang JP, Chen YZ, Wang Y, Yuan SJ, Yu HQ (2011) Optimization of the coagulation-flocculation process for pulp mill wastewater treatment using a combination of uniform design and response surface methodology. Water Res 45:5633–5640

Xu Z, Lu B, Wu J, Zhou L, Lan Y (2013) Reduction of Cr(VI) facilitated by biogenetic jarosite and analysis of its influencing factors with response surface methodology. Mater Sci Eng C33:3723–3729

Yen-Hui L, Wu CL, Hsu CH, Li HL (2009) Biodegradation of phenol with chromium (VI) reduction in an anaerobic fixed-biofilm process—kinetic model and reactor performance. J Hazard Mater 172:1394–1401

Zuo XJ, Balasubramanian R (2013) Evaluation of a novel chitosan polymer based adsorbent for the removal of chromium(III) in aqueous solutions. Carbohydr Polym 92:2181–2186

Acknowledgements

The author is thankful to Chemical Engineering department IIT Roorkee for the facility provided for research work and MHRD INDIA for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gupta, A., Balomajumder, C. Statistical optimization of process parameters for the simultaneous adsorption of Cr(VI) and phenol onto Fe-treated tea waste biomass. Appl Water Sci 7, 4361–4374 (2017). https://doi.org/10.1007/s13201-017-0582-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-017-0582-9