Abstract

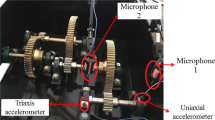

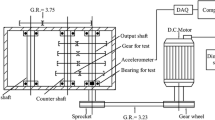

Ball bearing failure are most common failure in rotating machinery, which can be catastrophic. Hence obtaining early failure warning along with precise fault detection technique is at most important. Early detection and timely intervention are the key in condition monitoring for long term endurance of machine components. The early research has used signal processing and spectral analysis extensively for fault detection however data mining with machine learning is most effective in fault diagnosis, the same is presented in this paper. The vibration signals are acquired for an output shaft antifriction bearing in a two-wheeler gearbox operated at various loading conditions with healthy and fault conditions. Data mining is employed for these acquired signals. Statistical, discrete wavelet and empirical mode decomposition are employed for feature extraction process and J48 decision tree for feature selection. Classification is carried out using K*, Random forest and support vector machine algorithm. The classifiers are trained and tested using tenfold cross validation method to diagnose the bearing fault. A comparative study of feature extraction and classifiers are done to evaluate the classification accuracy. The results obtained from K* classifier with wavelet feature yielded better accuracy than rest other classifiers with classification accuracy 92.5% for bearing fault diagnosis.

Similar content being viewed by others

Code availability

A WEKA version 3.6.9 open-source software used for implementing the models.

References

Amarnath M, Praveen Krishna IR (2012) Empirical mode decomposition of acoustic signals for diagnosis of faults in gears and rolling element bearings. IET Sci Meas Technol 6:279. https://doi.org/10.1049/iet-smt.2011.0082

Amarnath M, Sugumaran V, Kumar H (2013) Exploiting sound signals for fault diagnosis of bearings using decision tree. Meas J Int Meas Confed 46:1250–1256. https://doi.org/10.1016/j.measurement.2012.11.011

Aralikatti SS, Ravikumar KN, Kumar H et al (2020) Comparative study on tool fault diagnosis methods using vibration signals and cutting force signals by machine learning technique. SDHM Struct Durab Heal Monit 14:127–145. https://doi.org/10.32604/SDHM.2020.07595

Bordoloi DJ, Tiwari R (2014) Optimum multi-fault classification of gears with integration of evolutionary and SVM algorithms. Mech Mach Theory 73:49–60. https://doi.org/10.1016/j.mechmachtheory.2013.10.006

Bordoloi DJ, Tiwari R (2017) Identification of suction flow blockages and casing cavitations in centrifugal pumps by optimal support vector machine techniques. J Brazilian Soc Mech Sci Eng 39:2957–2968. https://doi.org/10.1007/s40430-017-0714-z

Breiman L (2001) ST4_method_random_forest. Mach Learn 45:5–32. https://doi.org/10.1017/CBO9781107415324.004

Chen Z, Chen X, Li C et al (2017) Vibration-based gearbox fault diagnosis using deep neural networks. J Vibroeng 19:2475–2496. https://doi.org/10.21595/jve.2016.17267

Cleary J (1995) LT-MLP, 1995 U (1995) Cleary95-KStar.pdf. Elsevier 5:1–14

Fei S, wei, (2017) Fault diagnosis of bearing based on wavelet packet transform-phase space reconstruction-singular value decomposition and SVM classifier. Arab J Sci Eng 42:1967–1975. https://doi.org/10.1007/s13369-016-2406-x

Ghaderi H, Kabiri P (2017) Automobile engine condition monitoring using sound emission. Turkish J Electr Eng Comput Sci 25:1807–1826. https://doi.org/10.3906/elk-1605-77

He M, He D, Yoon J et al (2019) Wind turbine planetary gearbox feature extraction and fault diagnosis using a deep-learning-based approach. Proc Inst Mech Eng Part O J Risk Reliab 233:303–316. https://doi.org/10.1177/1748006X18768701

Henriquez P, Alonso JB, Ferrer MA, Travieso CM (2014) Review of automatic fault diagnosis systems using audio and vibration signals. IEEE Trans Syst Man, Cybern Syst 44:642–652. https://doi.org/10.1109/TSMCC.2013.2257752

Hizarci B, Ümütlü RC, Ozturk H, Kıral Z (2019) Vibration region analysis for condition monitoring of gearboxes using image processing and neural networks. Exp Tech 43:739–755. https://doi.org/10.1007/s40799-019-00329-9

Huang W, Sun H, Liu Y, Wang W (2017) Feature extraction for rolling element bearing faults using resonance sparse signal decomposition. Exp Tech 41:251–265. https://doi.org/10.1007/s40799-017-0174-5

Kadry S (2012) Diagnostics and prognostics of engineering systems: Methods and techniques

Kateris D, Moshou D, Pantazi X, et al (2014) A machine learning approach for the condition monitoring of rotating machinery. 28:61–71. Doi: https://doi.org/10.1007/s12206-013-1102-y

Kiral Z, Karagülle H (2006) Vibration analysis of rolling element bearings with various defects under the action of an unbalanced force. Mech Syst Signal Process 20:1967–1991. https://doi.org/10.1016/j.ymssp.2005.05.001

Kumar H, Ranjit Kumar TA, Amarnath M, Sugumaran V (2012) 887. Fault diagnosis of antifriction bearings through sound signals using support vector machine. J Vibroeng 14:1601–1606

Laala W, Guedidi A, Guettaf A (2020) Bearing faults classification based on wavelet transform and artificial neural network. Int J Syst Assur Eng Manag. https://doi.org/10.1007/s13198-020-01039-x

Lambert M, Engroff A, Dyer M, Byer B (2020) EMD. https://www.clear.rice.edu/elec301/Projects02/empiricalMode/app.html

Lauro CH, Brandão LC, Baldo D et al (2014) Monitoring and processing signal applied in machining processes-a review. Meas J Int Meas Confed 58:73–86. https://doi.org/10.1016/j.measurement.2014.08.035

Liaw A, Wiener M (2002) Classification and regression by randomForest. R News 2:18–22

Lu C, Hu J, Liu H, Wang J (2013) Rolling bearing fault diagnosis based on EMD-TEO and Mahalanobis distance. In: Vibroengineering Procedia. pp 59–64

Luo W, Qiao B, Shen Z et al (2021) Investigation on the influence of spalling defects on the dynamic performance of planetary gear sets with sliding friction. Tribol Int. https://doi.org/10.1016/j.triboint.2020.106639

Madhusudana CK, Kumar H, Narendranath S (2017) Face milling tool condition monitoring using sound signal. Int J Syst Assur Eng Manag 8:1643–1653. https://doi.org/10.1007/s13198-017-0637-1

Madhusudana CK, Gangadhar N, Kumar H, Narendranath S (2018) Use of discrete wavelet features and support vector machine for fault diagnosis of face milling tool. SDHM Struct Durab Heal Monit 12:97–113. https://doi.org/10.3970/sdhm.2018.01262

Mayadevi N, Mini VP, Hari Kumar R, Prins S (2020) Fuzzy-based intelligent algorithm for diagnosis of drive faults in induction motor drive system. Arab J Sci Eng 45:1385–1395. https://doi.org/10.1007/s13369-019-03935-2

Moosavian A, Ahmadi H, Tabatabaeefar A, Khazaee M (2013) Comparison of two classifiers; k-nearest neighbor and artificial neural network, for fault diagnosis on a main engine journal-bearing. Shock Vib 20:263–272. https://doi.org/10.3233/SAV-2012-00742

Pal M (2005) Random forest classifier for remote sensing classification. Int J Remote Sens 26:217–222. https://doi.org/10.1080/01431160412331269698

Purarjomandlangrudi A, Ghapanchi AH, Esmalifalak M (2014) A data mining approach for fault diagnosis: an application of anomaly detection algorithm. Meas J Int Meas Confed 55:343–352. https://doi.org/10.1016/j.measurement.2014.05.029

Ravikumar KN, Kumar H, Gangadharan KV (2020) Application of vibration analysis and data mining techniques for bearing fault diagnosis in two stroke IC engine gearbox. AIP Conf Proc. https://doi.org/10.1063/5.0003811

Ravikumar KN, Madhusudan CK, Kumar H, Gangadharan KV (2021) Engineering science and technology, an international journal classification of gear faults in IC engine gearbox using discrete wavelet features and K star. Eng Sci Technol an Int J. https://doi.org/10.1016/j.jestch.2021.08.005

Saimurugan M, Praveenkumar T, Sabhrish B et al (2016) On-road testing of a vehicle for gearbox fault detection using vibration signals. Indian J Sci Technol. https://doi.org/10.17485/ijst/2016/v9i34/100957

Shi L, Wen J, Pan B et al (2020) Dynamic characteristics of a gear system with double-teeth spalling fault and its fault feature analysis. Appl Sci 10:1–23. https://doi.org/10.3390/app10207058

Sugumaran V, Ramachandran KI (2011) Effect of number of features on classification of roller bearing faults using SVM and PSVM. Expert Syst Appl 38:4088–4096. https://doi.org/10.1016/j.eswa.2010.09.072

Vernekar K, Kumar H, Gangadharan KV (2017) Engine gearbox fault diagnosis using empirical mode decomposition method and Naïve Bayes algorithm. Sadhana-Acad Proc Eng Sci 42:1143–1153. https://doi.org/10.1007/s12046-017-0678-9

Wang H, Li R, Tang G et al (2014) A compound fault diagnosis for rolling bearings method based on blind source separation and ensemble empirical mode decomposition. PLoS ONE. https://doi.org/10.1371/journal.pone.0109166

Wang W, Liu H, Zhu C et al (2020) Evaluation of contact fatigue risk of a carburized gear considering gradients of mechanical properties. Friction 8:1039–1050. https://doi.org/10.1007/s40544-019-0317-z

Zhang M, Li X, Wang R (2021) Incipient fault diagnosis of batch process based on deep time series feature extraction. Arab J Sci Eng. https://doi.org/10.1007/s13369-021-05388-y

Acknowledgements

The authors acknowledge the support from SOLVE: The Virtual Lab @ NITK and experimental facility provided by Centre for System Design (CSD): A Centre of excellence (http://csd.nitk.ac.in/) at National Institute of Technology Karnataka, India. The authors also acknowledge the help rendered by Dr. Sugumaran V, Professor, VIT University, Chennai.

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The Authors declare that there is no conflict of interest in publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ravikumar, K.N., Aralikatti, S.S., Kumar, H. et al. Fault diagnosis of antifriction bearing in internal combustion engine gearbox using data mining techniques. Int J Syst Assur Eng Manag 13, 1121–1134 (2022). https://doi.org/10.1007/s13198-021-01407-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01407-1