Abstract

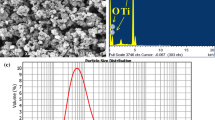

Cu-Zn-Al particles reinforced 6061Al composites were fabricated by friction stir processing (FSP). The microstructure and mechanical properties of the composites under the FSP and T6 heat treatment were investigated. Microstructure observation showed that Cu-Zn-Al particles were homogeneously distributed in the Al matrix. FSP resulted in grain refinement and the reduction of the number of β-Mg2Si, and T6 heat treatment promoted the precipitation of fine particles (β”-Mg2Si). The introduced Cu-Zn-Al particles in the FSPed composites still exhibited reversible phase transformation between martensite and austenite. The tensile strength of the FSPed composites was inferior to that of base metal, while the elongation of composites was obviously enhanced. The tensile strengths of composites after T6 heat treatment increased greatly. The results indicated that FSP is an effective way to produce Cu-Zn-Al particles/Al composites with good mechanical properties.

Similar content being viewed by others

References

Song Y, Yang X, and Lei C, Mater Des 55 (2014) 9.

Yo S H K, Han G, and Nobu H, Mater Sci Eng A 613 (2014) 163.

Ma Z Y, Metall Mater Trans A 39 (2008) 642.

Mishra R S and Ma Z Y, Mat Sci Eng R 50 (2010) 1.

Moharami A, Razaghian A, and Paidar M, Mater Chem Phys 250 (2020) 1230.

Prasad R, Tewari S P, and Singh J K, Mater Res Express 6 (2019) 9.

Liu F, Ji Y, and Sun Z, J Alloy Compd 829 (2020) 154452.

Ammouri A H, Kridli G, and Ayoub G, J Mater Process Tech 222 (2015) 301.

Xu N and Bao Y F, Mater Sci Eng A 655 (2016) 292.

Wen W, Kuaishe W, and Qiang G, Rare Metal Mat Eng 41 (2012) 1522.

Xu W, Liu J, and Zhu H, Mater Design 47 (2013) 599.

Sahraeinejad S, Izadi H, and Haghshenas M, Mater Sci Eng A 626 (2015) 505.

Morisada Y, Fujii H, and Nagaoka T, Scripta Mater 55 (2006) 1067.

Essam and Moustaf, Materials 10 (2017) 9.

Ke L, Huang C, and Xing L, J Alloy Compd 503 (2010) 494.

Lee I, Kao P, and Ho N, Intermetallics 16 (2008) 1104.

Aruri D, Adepu K, and Bazavada K, J Mater Res Technol 2 (2013) 362.

Hosseini S, Ranjbar K, Dehmolaeia R, and Amirani A, J Alloy Compd 622 (2015) 725.

Huang G Q, Yan Y F, and Wu J, J Alloy Compd 786 (2019) 257.

Zarinejad M and Yong L, Adv Funct Mater 82 (2008) 2789.

Wei Z G, Tang C Y, and Lee W B, J Mater Process Technol 69 (1997) 68.

Ni D, Wang J, and Ma Z Y, J Mater Sci Technol 162 (2016) 2.

Ni D R, Wang J J, Zhou Z N, and Ma Z Y, J Alloy Compd 586 (2014) 368.

Jani M, Leary M, and Subic A, Mater Design 1078 (2014) 56.

Asa V, Del K, and Ja N, Acta Mater 599 (2008) 58.

Agnihotri R and Bhardwaj S, Int J Comput Mat Sci 229 (2016) 4.

Porter G A, Liaw P K, and Tiegs T N, JOM 52 (2000) 52.

Thorat R R, Risanti D D, and Martín D S, J Alloy Compd 477 (2009) 307.

Sato Y S, Urata M, and Kokawa H, Metall Mater Trans A 33 (2002) 625.

Dixit M, Newkirk J W, and Mishra R S, Scripta Mater 56 (2007) 541.

Zina N, Zahaf S, and Bouaziz S A, J Fail Anal Prev 19 (2019) 1698.

Sato Y S, Kokawa H, and Enomoto M, Metall Mater Trans A 30 (1999) 2429.

Edwards G A, Stiller K, Dunlop G L, and Couper M J, Acta Mater 46 (1998) 3893.

Kim J, Lee Y, and Paik, Ieee T Compon Pack T 367 (2003) 26.

Bra M and Alexandrov, Ieee T Comp Pack Man 78 (1994) 17.

Sato S, Urata M, and Kokawa H, Metall Mater Trans A 625 (2002) 33.

Wei Z G, Tang C Y, and Lee W B, J Mater Process Tech 69 (1997) 68.

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant nos. 51865006 and 52165068), Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant nos. 19KJA430001 and 18KJA460001), Guangxi Natural Science Foundation Project (Grant No. 2020GXNSFAA297004) and Middle-aged and Young Teachers' Basic Ability Promotion Project of Guangxi (Grant No. 2021KY0787).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, L., Lu, K.J., Liu, Z. et al. Microstructural and Mechanical Properties of Aluminum Matrix Composite Reinforced with Cu-Zn-Al Particles Fabricated by Friction Stir Processing. Trans Indian Inst Met 75, 1471–1479 (2022). https://doi.org/10.1007/s12666-021-02495-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02495-0