Abstract

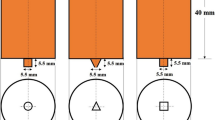

This work reports the characterization of AA6061/SiC/FA hybrid composites joined using friction stir welding (FSW). FSW was conducted by employing various tool pin profiles such as straight cylindrical (SC), tapered conical, straight square (SS) and cylindrical threaded. Microstructure and mechanical characteristics of joints were investigated using these tool pin profiles. Microstructure study of the weld joints was carried out through scanning electron microscopy and electron backscattered diffraction (EBSD) analysis. The results show equiaxed distribution of grains in the nugget zone. EBSD analysis indicates that the average grain size reduces to 3 µm after FSW with the presence of high-angle grain boundaries. Higher joint efficiency (85%) is obtained for joints obtained using SS tool pin compared to their counterparts, and SC tool yields minimum joint efficiency (77%). Overall 8% enhancement of the joint efficiency is achieved using SS tool pin profile.

Similar content being viewed by others

References

Xiu Z, Yang W, Chen G, Jiang L, Ma K, and Wu G, Mater Des 33 (2012) 350.

Ceschini L, Minak G, and Morri A, Compos Sci Technol 69 (2009) 1783.

Yigezu B S, Venkateswarlu D, Mahapatra M M, and Jha P K, Mater Des 54 (2014) 1019.

Sachinkumar, Narendranath S, and Chakradhar D, Silicon 11 (2019) 2557.

Sinclair P C, Longhurst W R, Cox C D, Lammlein D H, Strauss A M, and Cook G E, Mater Manuf Processes 25 (2010) 1283.

Schneider J, Beshears R, and Nunes Jr AC, Mater Sci Eng A 435 (2006) 297.

Buffa G, Hua J, Shivpuri R, and Fratini L, Mater Sci Eng A 419 (2006) 381.

Imam M, Biswas K, and Racherla V, Mater Des 52 (2013) 730.

Gopalakrishnan S, and Murugan N, Mater Des 32 (2011) 462.

Elangovan K, and Balasubramanian V, Mater Sci Eng A 459 (2011) 7.

Elangovan K, and Balasubramanian V, J Mater Process Technol 200 (2008) 163.

Khodaverdizadeh H, Heidarzadeh A, and Saeid T, Mater Des 45 (2013) 265.

Vijay S J, and Murugan N, Mater Des 31 (2010) 3585.

Salehi M, Saadatmand M, and Mohandesi J A, Trans Nonferrous Met Soc China 22 (2012) 1055.

Sundaram N S, and Murugan N, Mater Des 31 (2010) 4184.

Kalaiselvan K, and Murugan N, Trans Nonferrous Met Soc China 23 (2013) 616.

Garg A, and Bhattacharya A, J Manuf Processes 26 (2017) 203.

Marzbanrad J, Akbari M, Asadi P, and Safaee S, Metall Mater Trans B 45 (2014) 1887.

Chen Y, Liu H, and Feng J, Mater. Sci. Eng. A, 420 (2006) 21.

Sachinkumar, Narendranath S, and Chakradhar D, Emerging Mater Res 7 (2018) 192

Hamilton C, Dymek S, and Blicharski M, Mater Charact 59 (2008) 1206.

Hu Z L, Wang X S, and Yuan S J, Mater Charact 73 (2012) 114.

Thomas W M, and Nicholas E D, Mater Des 18 (1997) 269.

Padmanaban G, and Balasubramanian V, Mater Des 30 (2009) 2647.

Chaubey A, Konda Gokuldoss P, Wang Z, Scudino S, Mukhopadhyay N, and Eckert J, Technology 37 (2016) 1.

Kang S H, Bang W H, Cho J H, Han H N, Oh K H, Lee C G, and Kim S J, Mater Sci Forum 495 (2005) 901.

Rao C V, Reddy G M, and Rao K S, Def Technol 11 (2015) 197.

Feng A H, Xiao B L, and Ma Z Y, Compos Sci Technol 68 (2008) 2141.

Mishra R S, and Ma Z Y, Mater Sci Eng R 50 (2005) 1.

Liu H J, Hou J C, and Guo H, Mater Des 50 (2013) 872.

Ilangovan M, Boopathy S R, and Balasubramanian V, Def Technol 11 (2015) 174.

Liu H, Hu Y, Zhao Y, and Fujii H, Mater Des 65 (2015) 395.

Amirizad M, Kokabi A H, Gharacheh M A, Sarrafi R, Shalchi B, and Azizieh M, Mater Lett. 60 (2006) 565.

Vijayavel P, and Balasubramanian V, J Alloy Compd 729 (2017) 828.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sachinkumar, Narendranath, S. & Chakradhar, D. Characterization and Evaluation of Joint Properties of FSWed AA6061/SiC/FA Hybrid AMCs Using Different Tool Pin Profiles. Trans Indian Inst Met 73, 2269–2279 (2020). https://doi.org/10.1007/s12666-020-02035-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02035-2