Abstract

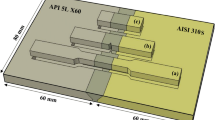

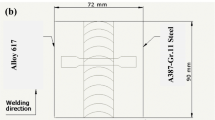

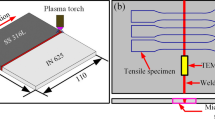

The dissimilar lap joint was investigated among Inconel 718 and high-strength steel using tungsten inert gas welding. The weld zone has an austenitic microstructure with the existence of secondary phases. The distribution of secondary phases is observed in the weld zone and the fusion line of the Inconel 718. The elemental mapping from the electron probe microanalyzer has analyzed the development of secondary phases along the grain boundaries and interdendritic regions. The hardness of the weld zone varies due to the presence of secondary phases. The hardness mapping-confirms secondary phases causing the higher hardness in the weld zone. The selected filler metal has good compatibility with the Inconel 718 and the high-strength steel base metal to obtain a high-quality weld. The X-ray diffraction analysis confirms the presence of secondary phases in the weld zone.

Similar content being viewed by others

References

Jun J H, Park J H, Cheepu M, and Cho S M, Sci Technol Weld Join25 (2020) 106.

Hori K, Watanabe H, Myoga T, and Kusano K, Weld Int18 (2004) 456.

Cheepu M, Venkateswarlu D, Rao P N, Kumaran S S, and Srinivasan N, Mater Sci Forum969 (2019) 895.

Anuradha M, Das V C, Venkateswarlu D, and Cheepu M, Mater Sci Forum969 (2019) 496.

Hejripour F, and Aidun D K, J Mater Process Technol245 (2017) 287.

Venukumar S, Cheepu M, Babu T V, and Venkateswarlu, D., Mater Sci Forum969 (2019) 768.

Cheepu M, Srinivas B, Abhishek N, Ramachandraiah T, Karna S, Venkateswarlu D, Alapati S, and Che W S, IOP Conf Ser Mater Sci Eng330 (2018) 012048.

Song J L, Lin S B, Yang C L, Ma G C and Liu H, Mater Sci Eng A509 (2009) 31.

Devireddy K, Devuri V, Cheepu M, and Kumar B K, Int J Mech Prod Eng Res Dev8 (2018) 243.

Lin S B, Song J L, Ma G C, and Yang C L, Front Mater Sci3 (2009) 78.

Rowe M D, Nelson T W, and Lippold J C, Weld J Suppl 78 (1999) 31.

Sireesha M, Albert S K, Shankar V, and Sundaresan S, Mater Sci Eng A292 (2000) 74.

Naffakh H, Shamanian M, and Ashrafizadeh F, J Mater Process Technol209 (2009) 3628.

Dev S, Ramkumar K D, Arivazhagan N, and Rajendran R. Trans Indian Inst Met, 70 (2017) 729.

Devendranath Ramkumar D K, Sai R J, Reddy V S, Gundla S, Mohan T H, Saxena V, and Arivazhagan N, J Manuf Process18 (2015) 23.

Thompson G R, Genculu S, Weld Res Suppl 62 (1983) 337.

Anuradha M, Das V C, Venkateswarlu D, and Cheepu M, Mater Sci Forum969 (2019) 558.

Cheepu M, and Che W S, Trans Indian Inst Met (2020). https://doi.org/10.1007/s12666-020-01908-w.

Kong Y, Cheepu M, and Kim D, Trans Indian Inst Met (2020). https://doi.org/10.1007/s12666-020-01911-1.

Sivaprasad K, and Raman S G S, Metall Mater Trans A39 (2008) 2115.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

P. Susila: On-deputation to BIT Campus, Anna University, Trichy.

Rights and permissions

About this article

Cite this article

Anuradha, M., Das, V.C., Susila, P. et al. Microstructure and Mechanical Properties for the Dissimilar Joining of Inconel 718 Alloy to High-Strength Steel by TIG Welding. Trans Indian Inst Met 73, 1521–1525 (2020). https://doi.org/10.1007/s12666-020-01925-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01925-9