Abstract

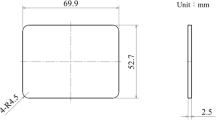

In this paper, creep age forming of aluminum 7075 tailor-machined blanks is experimentally studied. As there are two different thicknesses in a single tailor-machined blank, forming properties differ, e.g., spring-back in two sections with different thicknesses. Hence, creep age forming of this kind of blank is more difficult than monolithic plates. In the present work, the effect of two main creep forming process parameters, namely time and temperature, is investigated on spring-back of both thin and thick sections of a tailor-machined blank. First, a model was initiated and then a multi-objective optimization using response surface methodology was proposed considering time and temperature as input and spring-back as output parameters. Finally, a second-order linear regression for spring-back of thin and thick sections was introduced. Evaluation of the developed model and the role of considered parameters on spring-back were investigated using Sobol sensitivity analysis. The results showed that within the range of considered parameters with an increase in both time and temperature, spring-back for both thin and thick sections decreases. Based on the multi-objective optimization of the present work, the best time and temperature for creep age forming in a 7075 tailor-machined blank with minimum spring-back in both thin and thick sections are 19.6 h and 232 °C, respectively.

Similar content being viewed by others

References

Nguyen N T, Hariharan K, Chakraborti N, Barlat F, and Lee M G, Steel Res Int86 (2015) 1391.

Lyu F, Li Y, Huang X, Shi Z, Zeng Y, and Lin J, J Manuf Processes37 (2019) 232.

Liu C, Liu Y, Li S, Ma L, Zhao X, and Wang Q, Mater Sci Eng A725 (2018) 375.

Li Y, Shi Z, Lin J, Yang Y, Saillard P, and Said R, Int J Mach Tools Manuf132 (2018) 113.

Li Y, Shi Z, Lin J, Yang Y, Saillard P, and Said R, Int J Mach Tools Manuf140 (2018) 228.

Xu Y, Zhan L, Huang M, Shen R, Ma Z, Xu L, Wang K, and Wang X, J Mater Process Technol255 (2018) 26.

Yang Y, and Zhan L, Proc Manuf15 (2018) 1000.

Zimmermann F, Brosius A, Beyer R E, Standfuß J, Jahn A, and Banke D, Proc Manuf15 (2018) 1008.

Yang Y, Zhan L, Shen R, Yin X, Li X, Li W, Huang M, and He D, Mater Sci Eng A683 (2017) 227.

Ershadi Khamneh M, Askari-Paykani M, Shahverdi H, Hadavi S M M, and Emami M, Measurement88 (2016) 278.

Zhan L H, Tan S G, Yang Y L, Huang M H, Shen W Q, and Zhao X, Adv Mech Eng (2014) http://dx.doi.org/10.1155/2014/707628.

Zhan L H, Tan S G, Huang M H, and Xu H Y, Mater. Mech. Eng 01 (2013) 63.

Wang Y K, Wan M, Yang Z H, Huang X, and Zeng Y S, J Plast Eng20 (2013) 83.

Jia S F, Zhan L H, and Xu X L, J Plast Eng20 (2013) 80.

Zhan L H, Xu X L, Jiao S F, and Yang L, Chin J Nonferrous Met23 (2013) 2104.

Zhang J, Deng Y L, Li S Y, Chen Z Y, and Zhang X M, Trans Nonferrous Met Soc China23 (2013) 1922.

Zhan L H, Tan S G, Huang M H, and Niu J, Adv Mater Res457–458 (2012) 122.

Li J C, Zeng L F, Liu D H, and Zuo J, J Plast Eng19 (2012) 68.

Jeshvaghani R A, Zohdi H, Shahverdi H R, Bozorg M, and Hadavi S, Mater Charact73 (2012) 8.

Inforzato D J, Costa P R, Fernandez F F, Travessa D N, Mater Res15 (2012) 596.

Lv Y, and Gang Z, China Met Form Equip Manuf Technol01 (2011) 87.

Tahmasbi V, Ghoreishi M, and Zolfaghari M, J Eng Med231 (2017) 1012.

Funding

The authors hereby announce that no part of this study was funded by any institutions and/or organizations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors also acknowledge no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Safari, M., Hamidipour, S., Elahi, S.H. et al. Creep Age Forming of Aluminum 7075 Tailor-Machined Blanks: Statistical Modeling, Sensitivity Analysis and Multi-objective Optimization. Trans Indian Inst Met 73, 831–841 (2020). https://doi.org/10.1007/s12666-019-01836-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01836-4