Abstract

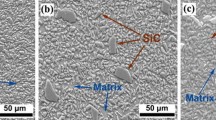

Damping characteristics of A356 alloy and its composites reinforced with 15 vol% SiC particles were investigated using a dynamic mechanical analyzer. Tests were done at three different temperatures 150 °C, 200 °C and 300 °C to study the influence of microstructural changes during recovery and recrystallization on the damping behaviour. Since recovery and recrystallization also depend on the heating rate, damping tests were done at slow (2 °C/min) and fast (10 °C/min) heating rates. The damping characteristics were explained with respect to the microstructure changes that took place during recovery and recrystallization.

Similar content being viewed by others

References

Stephens J J, Lucas J P, and Hosking F M, Scr Metall 22 (1988) 1307.

Bayoumi M A, Ribes R, and Suery M, Aging characteristics of Sic-particle reinforced Al-Si alloy, in Proceedings of 9th International Symposium in Metallurgy and Materials Science, Riso, Denmark, vol 8, p 291 (1988).

Kumai S, Hu J, Higo Y, and Nunomura S, Scr Metall Mater 27 (1992) 107.

Cottu J P, Couderc J J, Viguier B, and Bernard L, J Mater Sci 27 (1992) 3068.

Salvo L, L’Esprance G, Sury M, and Legoux J G, Mater Sci Eng A 177 (1994) 173.

Samuel A M and Samuel F H, Metall Trans A 24 (1993) 1857.

Wang Z and Zhang R J, Metall Trans A 22 (1991) 1585.

Rozak G A, Lewandowski J J, Wallace J F, and Altmisoglu A, J Compos Mater 26 (1993) 2076.

Alpas A T and Zhang J, Scr Metall Mater 26 (1992) 505.

Alpas A T and Zhang J, Wear 155 (1992) 83.

Wood J V, Davies P, and Kellie J L F, Mater Sci Technol 9 (1993) 833.

Garca-Cordovilla C, Louis E, Narciso J, and Pamies A, Mater Sci Eng A 189 (1994) 219.

Zhang J, Perez R J, Wong C R, and Lavernia E J, Mater Sci Eng R Rep 13 (1994) 325.

Zhang Y, Ma N, Li X, and Wang H, Mater Des 29 (2008) 1057.

Zhang X, Liao L, Ma N, and Wang H, Compos Part A Appl Sci Manuf 37 (2006) 2011.

Lu Y X, Lee C S, Li R K Y, and Lai J K L, J Mater Process Technol 91 (1999) 215.

Xiuqing Z, Haowei W, Lihua L, and Naiheng M, Compos Sci Technol 67 (2007) 720.

Sastry S, Krishna M, and Uchil J, J Alloys Compd 314 (2001) 268.

Groma I and Szekely F, J Appl Crystallogr 33 (2000) 1329.

Lavernia E J, Perez R J, and Zhang J, Metallur Mater Trans A 26 (1995) 2803.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhaskar, M.S., Surappa, M.K. Effect of Recovery and Recrystallization on the Damping Behaviour of A356/SiCp Composites. Trans Indian Inst Met 72, 849–857 (2019). https://doi.org/10.1007/s12666-018-1541-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1541-3