Abstract

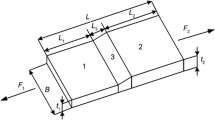

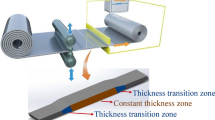

In the present work, tensile behavior of tailor rolled blanks (TRBs) made of DP590 was studied. The TRBs were produced by variable gauge rolling. The tensile specimens of TRB had thickness ratios (Tr) of 0.47, 0.52, 0.68, 0.78 and 0.89, whereas the lengths of thickness transition zone (TTZ) were 58, 75 and 110 mm. The results of tensile test along with SEM and EBSD observations revealed that the total elongation of TRBs is strongly dependent on the TTZ geometry. Accordingly, it was found out that the total elongation increases with increasing Tr. However, unprecedented results were obtained for variations of total percent elongation versus the length of TTZ. In case of tensile specimens with identical gauge length, the total elongation decreases with increasing the length of TTZ. To justify the results, a novel geometrical parameter called effective length ratio (ELR) was introduced. This new parameter showed a meaningful relation with the total elongation. Accordingly, the effects of TTZ position and geometry on the total elongation were studied utilizing ELR parameter. It was concluded that the total elongation increases with increasing the ELR parameter. Furthermore, a linear correlation between ELR and total elongation was established. This can be used to interpolate the tensile behavior of TRBs for any intermediate conditions which can be more applicable for prediction of tensile behavior without performing any tests. Finally, the influence of thickness ratio on the probability of fracture from a certain region was discussed.

Similar content being viewed by others

References

Cingara G A, Ososkov Y, Jain M K, and Wilkinson D S, Mater Sci Eng A, 516 (2009) 7.

Shafiei E, and Dehghani K, Vacuum 143 (2017) 71.

Merklein M, Johannes M, Lechner M, and Kuppert A, J Mater Proc Tech 214 (2014) 151.

Meyer A, Weitbrock B, and Hirt G, Int J Mach Tools Manuf 48 (2008) 522.

Kopp R, Weidner C, and Meyer A, Adv Mater Res 6–8 (2005) 81.

Hirt G, Abratis C, Ames J, and Meyer A, J Tech Plast 30 (2005) 1.

Zhang G, and Liu X, Adv Mater Res 418–420 (2012)1232.

Liu X, Wu Z, Zhi F, Zhang G, and Zhi Y, Mater Sci Forum 706–709 (2012) 1448.

Zhang H W, Liu X, Liu L Z, Hu P, and Wu J, Acta Metall Sin 28 (2015) 1198.

Zhang H W, Liu X, Liu L Z, Hu P, and Wu J, J Iron Steel Res Int 23 (2016) 185.

Ding C S, Cui X Y, and Li G Y, Struct Multidiscip Optim 54 (2016) 871.

ASTM E8/E8M, Standard Test Methods for Tension Testing of Metallic Materials, (2009), https://doi.org/10.1520/e0008_e0008m-09.

Shafiei E, and Dehghani K, Can Metall Q (in Press), https://doi.org/10.1080/00084433.2017.1399235.

Sharma A K, and Sharma C P, Mechanical Behavior and Testing of Materials (2011), PHI Limited, ISBN-978-81-203-4250-7.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shafiei, E., Dehghani, K. Effects of Thickness Ratio and Length of Thickness Transition Zone on the Tensile Behavior of Tailor Rolled Blanks. Trans Indian Inst Met 71, 1211–1222 (2018). https://doi.org/10.1007/s12666-017-1256-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1256-x