Abstract

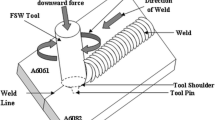

This paper presents the efforts of joining dissimilar aluminum alloys (AA6351-T6 and AA6061-T6) by friction stir welding (FSW) process. FSW experiments are conducted according to the three factors five level central composite rotatable design method, and the response surface methodology was used to establish the empirical relationship between FSW process parameters such as tool rotational speed (N), tool traverse speed (S) and axial force (F), and the response variables such as ultimate tensile strength, yield strength, and percentage of elongation. The developed empirical models’ adequacies are estimated using the analysis of variance technique. This paper also presents the application of the artificial bee colony algorithm to estimate the optimal process parameters to achieve good mechanical properties of FS weld joints. Results suggest that the estimations of the algorithm are in good agreement with the experimental findings.

Similar content being viewed by others

References

Mahoney M W, Rhodes C G, Flintoff J G, Spurling R A, and Bingel W H, Metall Mater Trans A (1998) 1955.

Colligan K, Weld J (1999) 229.

Hamilton C, Dymek S, and Blicharski M, Arch Metall Mater (2007) 67.

Mishra R S, Ma Z Y, Mater Sci Eng (2005) 1.

Bitondo C, Priscso U, Squilace A, Buonadonna P, and Dionoro G, Int J Adv Manuf Technol (2011) 505.

Karthikeyan R, and Balasubramanian V, Int J Adv Manuf Technol (2010) 73.

Elatharasan G, and Senthil Kumar V S, Procedia Eng (2013) 1227.

Palanivel R, and Koshymathews P, J Cent South Univ (2012) 1.

Lakshminarayanan A K, Balasubramanian V, and Elangovan K, Int J Adv Manuf Technol (2009) 286.

Palanivel R, Mathews K, and Murugan N, J Eng Sci Technol Rev (2011) 25.

Patil H S, and Soman S N, Frat Integrità Strutt (2013) 151.

Morisada Y, Imaizumi T, and Fujii H, Sci Technol Weld Join (2015) 130.

Chien C –H, Lin W –B, and Chen T, J Chin Inst Eng (2011) 99.

Parida B, and Pal S, Sci Technol Weld Join (2015) 35.

Karaboga D, and Akay B A, Appl Math Comput (2009) 108.

Montgomery D C, Design and Analysis of Experiments, Wiley (1991) p 547.

Rajkumar S, Muralidharan C, and Balasubramnian V, Trans Nonferrous Met Soc China 20 (2010) 1863.

Singh G, Singh K, and Singh J, Exp Tech (2012) 1.

Reddy T A, Applied Data Analysis and Modeling for Energy Engineers and Scientists, Springer, US (2011). DOI 10.1007/978-1-4419-9613-8

Cochran W G, and Cox G M, Experimental Design, 2nd edition, Wiley, New York (1957), p 350.

Chambers J, Cleveland W, Kleiner B and Tukey P, (1983), Graphical Methods for Data Analysis, Wadsworth. In http://www.itl.nist.gov/div898/handbook/eda/section3/normprpl.html

http://www.itl.nist.gov/div898/handbook/prc/section1/prc16.html

Kim I S, Son K J, Yang Y S, Yaragada P K D V, Int J Mach Tools Manuf 43 (2003) 776.

Elangovan K, Balasubramanian V, Babu S, Mater Des 30 (2009) 193.

Lomolino S, Tovo R, Dos Santos J, Int J Fatigue 27 (2005) 316.

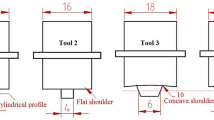

Elangovan K, Balasubramanian V, Mater Sci Eng A 459 (2007) 18.

Colligan J, Paul J, Konkol, James J, Fisher Pickens Joseph R, Weld J 82 (2003) 40.

Elangovan K, Balasubramanian V, Vallliappan M, Int J Adv Manuf Technol 38 (2008) 295.

Prasanth R S S, and Hans Raj K, Adv Intell Syst Comput (2012) 323.

Acknowledgement

Authors gratefully acknowledge the inspiration and guidance of Revered Prof. P.S. Satsangi, the Chairman of the Advisory Committee on Education, Dayalbagh, Agra, India.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The pseudo code of ABC algorithm [26] is presented below:

-

1.

Initialize the Colony Size (CS), Number of Food Sources/Solutions (SN), Number of dimensions to each solution (D), Modification Rate (MR), SPP (Scout Production Period-limit).

-

2.

Initialize the population of solutions x i,j where i = 1… SN and j = 1…D.

-

3.

Evaluate the population.

-

4.

cycle = 1.

-

5.

REPEAT

-

6.

Produce a new solution v i for each employee bee by using (6) and evaluate it as

$$v_{ij} = x_{ij} + \emptyset_{ij} \left( {x_{ij} {-} x_{kj} } \right) {\text{if}}\,R_{j} < {\text{MR}},{\text{ otherwise}}\,\,x_{ij} \ldots$$(9)[\(\emptyset_{ij}\)—is a random number in the range [−1, 1]. k ∈ {1, 2…SN} (SN: Number of solutions in a colony) is randomly chosen index. Although k is determined randomly, it has to be different from i. R j is a randomly chosen real number in the range [0, 1] and j ∈ {1, 2,…D} (D: Number of dimensions in a problem). MR, modification rate, is a control parameter.]

-

7.

Apply greedy selection process for the employee bees between the v i and x i.

-

8.

Calculate the probability values P i using (7) for the solutions x i

$$P_{i} = \frac{{Fitness_{i} }}{{\mathop \sum \nolimits_{N = 1}^{SN} \left( {Fitness_{N} } \right)}} \ldots.$$(10) -

9.

For each onlooker bee, produce a new solution v i by using (6) in the neighborhood of the solution selected depending on P i and evaluate it.

-

10.

Apply greedy selection process for the onlooker bees between the v i and x i.

-

11.

If Scout Production Period (SPP) is completed, determine the abandoned solutions by using “limit” parameter for the scout, if it exists, replace it with a new randomly produced solution using (8).

-

12.

$$x_{j}^{i } = x_{min}^{ji} + rand\left( {0,1} \right)\left( {x_{jmax}^{j } - x_{jmin}^{j } } \right) \ldots$$(11)

-

13.

Memorize the best solution achieved so far.

-

14.

cycle = cycle +1.

-

15.

UNTIL (Max Cycle Number or Max CPU time).

Rights and permissions

About this article

Cite this article

Prasanth, R.S.S., Hans Raj, K. Determination of Optimal Process Parameters of Friction Stir Welding to Join Dissimilar Aluminum Alloys Using Artificial Bee Colony Algorithm. Trans Indian Inst Met 71, 453–462 (2018). https://doi.org/10.1007/s12666-017-1176-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1176-9