Abstract

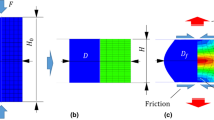

Temperature dependence of constraint factor i.e. the ratio of static indentation hardness to uniaxial flow stress was studied for Ti–6Al–4V from RT to 673 K using FEA. Surface-to-surface contact with finite sliding, which was used to model the interaction between spherical indenter/test specimen and the constitutive equations were then applied in axi-symmetric FE model. The results obtained from numerical analysis were in good agreement with the modified Expanding Cavity Model. Meyer’s hardness increased with average strain and strain hardening index increased from 0.19 to 0.21 with rise in temperature.

Similar content being viewed by others

References

Haggag F M, Byun T S, Hong J H, Miraglia P Q, and Murty K L, Script Mater (1998) 645.

Mathew M D, Murty K L, Rao K B S, and Mannan S L, Mater Sci Eng (1999) 159.

Taljat B, and Pharr G M, Int J Solids Struct 41 (2004).

Kim J Y, Lee K W, Lee J S, and Kwon D, Surf Coat Technol 201 (2006) 4278.

Field J S, and Swain M V, J Mater Res (1995) 101.

Pirondi A, and Bonora N, Comput Mater Sci (2006) 129.

Bonora N, Eng Frac Mech (1997) 11.

Meyers D E, Chen F C, Zhang J, and Ardell A J, J Test Eval (1993) 263.

Tabor D, The hardness of Metals, Clarendon Press, Oxford (1951), p 15.

Mok C H, and Duffy J, Int J Mech Sci (1965) 355.

Haggag F M, Wang J A, and Theiss T J, SPIE (1996) 217.

Haggag F M, and Lucas G E, Metall Trans A (1983) 1607.

Haggag F M, US Patent No. 4852397 (1989).

Byun T S, Hong J H, Haggag F M, Farrell K, and Lee E H, Int J Pres Ves Piping (1997) 231.

Murty K L, Mathew M D, Wang Y, Shah V N, and Haggag F M, Int J Pres Ves Piping (1998) 831.

Tirupataiah Y, and Sundararajan G, J Mater Sci Eng (1987) 169.

Tirupataiah Y, and Sundararajan G, Metall Trans A (1991) 2375.

Moteff J, Bhargava R K, and McCullough W L, Metall Trans A (1975) 1101.

Patnaik M N M, Narasimhan R, and Ramamurty U, Acta Mater (2004) 3335.

Kumaraswamy A, and Venkataraman B, Scr Mater (2006) 493.

Johnson K L, Cambridge University Press (1987), p 176.

Gao X L, Jing X N, and Subhash G, Int J Solids Struct (2006) 2193.

Ai K, and Dai L H, Scr Mater (2007) 761.

Fischer-Cripps A C, and Mustafaev I, Introduction to contact mechanics, Springer, New York (2000), p 87

Boyer R, Welsch G, and Collings E W, Materials properties handbook-Ti alloys, ASM International, Materials Park, OH (1994).

Acknowledgments

The authors are grateful to Vice Chancellor, DIAT (DU), Pune for according permission to publish this paper in the journal. Acknowledgements are due to fellow M. Tech students for providing necessary inputs during the simulations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saxena, A., Rai, A. & Kumaraswamy, A. A Numerical Approach to Investigate the Effect of Temperature on Constraint Factor of Ti Alloy Under Static Indentation Conditions. Trans Indian Inst Met 70, 1549–1553 (2017). https://doi.org/10.1007/s12666-016-0952-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0952-2