Abstract

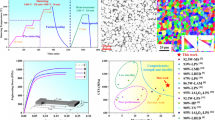

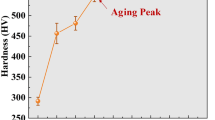

Nanostructured alloys exhibit high strength and large elastic strain limit. Unfortunately, the plasticity of these alloys is disappointingly low at room temperature than that of the coarse grain counterparts. In this work, a series of nanoeutectic composites have been developed in Ti–Fe and Ni–Zr based alloys, which exhibit very high strength, like bulk metallic glasses and large plasticity at room temperature. Systematic investigations have been performed to reveal the effect of alloy addition on the alteration of the microstructure and the properties of nano-lamellar phases. Even though, in some cases, alloy addition stabilizes micrometer-sized proeutectic bcc/fcc solid solution phase(s) with dendritic morphology, but the residual melt solidifies into a binary nanoeutectic comprised of alternating soft bcc/fcc phase together with hard intermetallic phase. Furthermore, electron microscopic studies of differently deformed specimens and strain rate jump test have been performed to reveal the role of eutectic lamellae on the strain rate sensitivity and to explore the origin of plasticity in nanoeutectic composites.

Similar content being viewed by others

References

Woodcock T G, Kushy M, Mato S, Alcala G, Thomas J, Loser W, Gebert A, Eckert J, and Schultz L, Acta Mater 53 (2005) 5141.

Sun B B, Sui M L, Wang Y M, Li Y, He G, Eckert J, and Ma E, Acta Mater 54 (2006) 1349.

Barbier D, Huang M X, and Bouaziz O, Intermetallics 35 (2013) 41.

Das J, Kim K B, Baier F, Löser W, and Eckert J, Appl Phys Lett 87 (2005) 161907.

Park J M, Sohn S W, Kim T E, Kim D H, Kim K B, and Kim W T, Scr Mater 57 (2007) 1153.

Das J, Theissmann R, Löser W, and Eckert J, J Mater Res 25 (2010) 943.

Kim J Y, Lee B W, Read D T, and Kwon D, Scr Mater 52 (2005) 353.

Zhang L C, Lu H B, Mickel C, and Eckert J, Appl Phys Lett 91 (2007) 051906.

Park J M, Kim T E, Sohn S W, Kim D H, Kim K B, Kim WT, and Eckert J, Appl Phys Lett 93 (2008) 031913.

Maity T, and Das J, AIP Adv 2 (2012) 032175.

Maity T, and Das J, Intermetallics 63 (2015) 51.

Standard ASTM G129-00, Standard practice for slow strain rate testing to evaluate the susceptibility of metallic materials to environmentally assisted cracking, ASTM International, Conshohocken (2013).

Wei Q, Cheng S, Ramesh K T, and Ma E, Mater Sci Eng A 381 (2004) 71.

Young R A, Introduction to Rietveld Method, Oxford University Press, Oxford, UK (1993).

Maity T, and Das J, J Alloys Compd 585 (2014) 54.

Taylor G, Prog Mater Sci 36 (1992) 29.

Elmustafa A A, and Stone D S, J Mech Phys Solids 51 (2003) 357.

Maity T, Roy B, and Das J, Acta Mater 97 (2015) 170.

Juhasz A, Tasnadi P, Szaszvari P, and Kovacs I, J Mater Sci 21 (1986) 3287.

Stroh A N, Adv Phys 6 (1957) 418.

Acknowledgments

The authors thank P. Das, R. Kundu, S. Maity, and K. Sahoo for technical assistance. Financial support provided by SRIC, IIT Kharagpur (SGIRG Grant), and Naval Research Board, Govt. of India (Grant No. NRB/4003/PG/357), are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, J., Maity, T. & Singh, A. Nanoeutectic Composites: Processing, Microstructure and Properties. Trans Indian Inst Met 68, 1199–1205 (2015). https://doi.org/10.1007/s12666-015-0704-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0704-8