Abstract

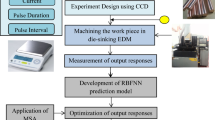

An innovative hybrid machining called as slotted-electrical discharge diamond face grinding (S-EDDFG) has been developed by comprising the electrical discharge face grinding and diamond face grinding. Due to complexity in S-EDDFG process, the selection of suitable combinations of input parameters is a challenging task for manufacturers. In recent, soft computing techniques are gaining more attention of researchers for modeling and optimization for the process parameters of complex manufacturing processes. In the present paper, two soft computing techniques known as artificial neural network (ANN) and non-dominated sorting genetic algorithm-II (NSGA-II) have been applied for modeling and optimization of process parameters (pulse current, pulse on-time, pulse off-time, wheel RPM and grit number) during machining of Aluminium–Silicon Carbide–Graphite (Al/SiC/Gr) composite. The results shown that two hidden layer ANN architecture was more appropriate to predict the material removal rate and average surface roughness during S-EDDFG of Al/SiC/Gr workpiece. The optimal results obtained by combined approach of ANN–NSGA-II are experimentally validated and found that optimal data are under acceptable limits.

Similar content being viewed by others

References

Kozak J, and Oczos K E, J Mater Process Technol 109 (2001) 360.

Koshy P, Jain V K, and Lal G K, Int J Mach Tools Manuf 36 (1996) 1173.

Kozak J, Arch Civ Mech Eng 2 (2002) 83.

Kopac J, and Krajnik P, J Mater Process Technol 175 (2006) 278.

Ghosh A, and Mallik A K, Manufacturing Science, East-West Press, New Delhi (1999).

Wei B, and Rajurkar K P, Abrasive electro discharge grinding of super alloys and ceramics. In: Proceedings of 1st International Machining Grinding Conference Dearborn, Michigan (1995) p 188.

Choudhury S K, Jain V K, and Gupta M, Mach Sci Technol 3 (1999) 91.

Yadav S K S, Yadava V, and Narayana V L, Int J Adv Manuf Technol 36 (2008) 34.

Singh G K, Yadava V, and Kumar R, Mater Manuf Process 25 (2010) 851.

Ji R, Liu Y, Zhang Y, Wang F, Cai B, and Dong X, Mater Manuf Process 27 (2012) 221.

Yadav R N, and Yadava V, Mater Manuf Process 28 (2013) 1361.

Yadav R N, and Yadava V, J Mech Sci Technol 28 (2014) 309.

Yadav R N, and Yadava V, Int J Manuf Technol Manag 28 (2014) 132.

Yadav R N, and Yadava V, Modeling of slotted-electrical discharge diamond face grinding of using artificial neural network. Int Conf Smart Technol Mech Eng (STME-2013), Delhi Technological University, Delhi 2013, p 669.

Mandal D, Pal S K, and Saha P, J Mater Process Technol 186 (2007) 154.

Momani E S A, Mayyas A T, Rawabdeh I, and Alqudah R, J Mater Eng Perform 1 (2012) 1611.

Kumar S, and Choudhury S K, J Mater Process Technol 191 (2007) 206.

Yadav S K S, and Yadava V, Int J Abras Technol 4 (2011) 346.

Yadav R N, and Yadava V, Int J Abras Technol 6 (2013) 93.

Agrawal S S, and Yadava V, Mater Manuf Process 28 (2013) 381.

Deb K, Pratap A, Agarwal S, and Meyarivan T, IEEE Trans Evol Comput 6 (2002) 182.

Saha P, Singha A, Pal SK, and Saha P, Int J Adv Manuf Technol 39 (2008) 74.

Kanagarajan D, Karthikeyan R, Palanikumar K, and Davim J P, Int J Adv Manuf Technol 36 (2008) 1124.

Maji K, and Pratihar D K, J Mater Eng Perform 20 (2010) 1121.

Zhang L, Li L, Wang S, and Zhu B, J Mater Eng Perform 21 (2012) 492.

Jain N K, Jain V K, and Deb K, Int J Mach Tools Manuf 47 (2007) 900.

Kumar K, and Agarwal S, Int J Adv Manuf Technol 62 (2012) 617.

Yadav R N, Yadava V, and Singh G K, Front Mech Eng 8 (2013) 319.

Yadav R N, and Yadava V, Proc IMechE Part B: J Eng Manuf 227 (2013) 1442.

Periyasamy P, Mohan B, and Balasubramanian V, J Mater Eng Perform 21 (2012) 2417.

Basavarajappa S, Chandramohan G, and Paulo D J, J Mater Process Technol 196 (2008) 332.

Montgomery D C, Design and analysis of experiments Wiley, New York (1997).

Song L, NGPM–A NSGA-II program in MATLAB, version 1.4, file exchange, Mathworks (2011). http://www.mathworks.com/matlabcentral/fileexchange.

Acknowledgments

Authors would like to thank the Aeronautics R&D Board, Government of India, New Delhi for providing the financial support for this work of the project entitled “Electro-Discharge Diamond Grinding: Development and Optimization” [Project no.: DARO/08/2031574/M/I].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yadav, R.N., Yadava, V. Application of Soft Computing Techniques for Modeling and Optimization of Slotted-Electrical Discharge Diamond Face Grinding Process. Trans Indian Inst Met 68, 981–990 (2015). https://doi.org/10.1007/s12666-015-0536-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0536-6