Abstract

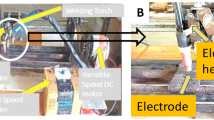

In this study, an experimental work was conducted to correlate the effect of gas metal arc welding (GMAW) process parameters such as wire feed speed, voltage, and contact tip to work piece distance along with interactive variables on bead-on-plate weld characteristics using multiple linear regression analysis and ANOVA (analysis of variance). The different responses such as convexity index, depth of penetration, reinforcement area, deposition rate, width of heat affected zone (HAZ), weld metal grain size and HAZ grain size were studied. The aim of the present investigation is to develop multiple linear regression equations to predict different responses (outputs) as a function of multiple input variables for ‘bead-on-plate’ type GMAW process. Multiple linear regression equations were first developed for weld bead geometry as a function of several individual and interactive variables. Then an effort was made to effectively predict the grain structure of the weldments as a function of multiple variables. Predicted responses are very close and sometime superimposed on the actual responses which clearly indicate the adequacy of the regression equations.

Similar content being viewed by others

References

Ganjigatti J P, Pratihar D K, and Roy Choudhury A, J Mater Process Technol 189 (2007) 352.

Shmoda T, and Doherty J, The Welding Institute Report 74 (1978).

Chandel R S, Seow H P, and Cheong F L, J Mater Process Technol 72 (1997) 124.

Jou M, J Manuf Sci Eng 125 (4) (2003) 801.

Gunaraj V, and Murugan N, J Mater Process Technol 95 (1999) 246.

Gunaraj V, and Murugan N, Weld J 10 (2000) 286s.

Gunaraj V, and Murugan N, Weld J 11 (2000) 331s.

Kim I S, Jeong Y J, Sona I J, Kim I J, Kimb J Y, Kim I K, and Yarlagadda P K D V, J Mater Process Technol 140 (2003) 676.

Kim I S, Son K J, Yang Y S, and Yarlagadda P K D V, Int J Mach Tools Manuf 43 (2003) 763.

Kim I S, Son J S, Kim I G, Kim J Y, and Kim O S, J Mater Process Technol 136 (2003) 139.

Lee J I, and Rhee S, Prediction of process parameters for gas metal arc welding by multiple regression analysis, in Proceedings of the Institution of Mechanical Engineers. Part B, 214 (2000) p 443.

Ganjigatti J P, Pratihar D K, and Roy Choudhury A, J Mater Process Technol 189 (2007) 352.

Gunaraj V, and Murugan N, Weld J 1 (2002) 94s.

Yang L J, Chandel R S, and Bibby M J, Weld J 1 (1993) 11s.

Rao P S, Gupta O P, Murty S S N, and Koteswara Rao A B, Int J Adv Manuf Technol 45 (2009) 496.

Francis R E, Jones J E and Olson D L, Weld J 11 (1990) 408s.

Zhang W, Elmer J W and DebRoy T, Sci Technol Weld Join 10 (2005) 574.

Yang Z, Sista S, Elmer J W and Debroy T, Acta Mater 48 (2000) 4813.

Mishra S and Debroy T, Acta Mater 52 (2004) 1183.

Acknowledgments

The authors would like to thank all the Research scholars of Welding Technology Centre, Metallurgical and Material Engineering Department, Jadavpur University and also to Dr. Dipak Kumar Mondal, H.O.D. Mechanical Engineering Department, college of Engineering & Management, Kolaghat; for their valuable support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adak, D.K., Mukherjee, M. & Pal, T.K. Development of a Direct Correlation of Bead Geometry, Grain Size and HAZ Width with the GMAW Process Parameters on Bead-on-plate Welds of Mild Steel. Trans Indian Inst Met 68, 839–849 (2015). https://doi.org/10.1007/s12666-015-0518-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0518-8