Abstract

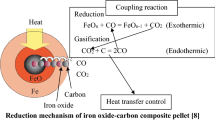

In order to explore the efficacy of iron ore–coal composite pellets over ordinary green pellets, indurated pellets, briquettes as well as standard charging of material in the form of concentric layers of iron ore and coal fines, or their mixture, these pellets were tested at 1,150 °C in a 7 tons per day (7 tpd) pilot tunnel kiln. Reduction of iron ore coal composite pellets in tunnel kiln emerges with an edge over all other systems studied. Performance parameters like percentage metallic iron formed, percentage metallization, reduction efficiency, carbon utilization efficiency, energy efficiency have been calculated and found to be significantly higher for composite pellets than the other systems studied. The materials of the container are found to have significant effect on the reduction kinetics. Energy and carbon efficiency have also been observed to be higher for higher capacity kiln. Significant amount of energy (25 % of total loss) is found to escape through exit gas.

Similar content being viewed by others

References

Kokunov A I, Naidis M G, Berenshtein P I, and Kochin G I, Stekloi Keramika 11 (1977), 36.

Shvartsman M Z, Ketslakh G A, Gubko I T, Orlov G V, Naginskii M Z, Shubin G A, Tsibin I P, Bryzgalov A B, Grachev A K, and Kolkin S M, Ogneupory 9 (1980), 16.

Upadhyay G S, Powder Metallurgy Technology, Cambridge International Science Publishing, England (2002).

van Vuuren D S, and Tshilombo G T, S Afr Inst Min Metall 111 (2011), 173.

Donskoi E, McElwain D L S, and Wibberley L J, Metall Mater Trans B 34B (2003), 255.

Chatterjee A, Sponge Iron Production by Direct Reduction of Iron Oxide, Prentice Hall of India Pvt. Ltd., New Delhi (2010), p 376

Agrawal B B, Prasad K K., Sarkar B, and Ray H S, Iron Making Steel Making 27(2000), 421.

Kubaschewski O, and Alcock C B, Materials Thermochemistry, 6th ed., Elsevier, New Delhi (2014), p 363

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khattoi, S.C., Roy, G.G. Reduction Efficiency of Iron Ore–Coal Composite Pellets in Tunnel Kiln For Sponge Iron Production. Trans Indian Inst Met 68, 683–692 (2015). https://doi.org/10.1007/s12666-014-0498-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-014-0498-0